Distribution auger vehicle of fermentation tank

A fermenter and cloth technology, applied in the field of fermenter cloth auger, can solve the problems of time-consuming, labor-saving and labor-intensive, and achieve the effects of convenient use, low energy consumption and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

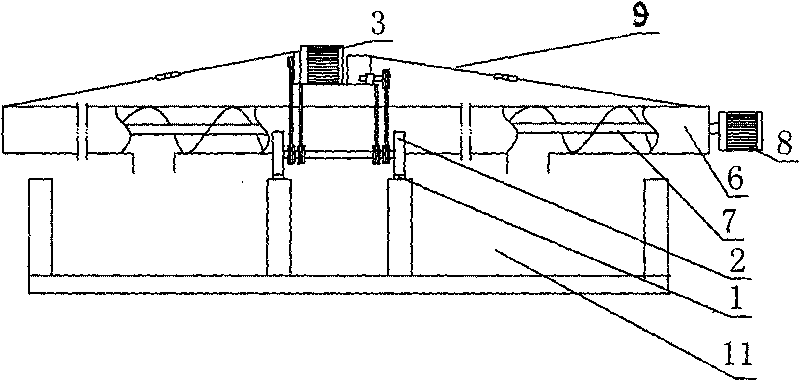

[0009] Such as figure 1 , figure 2 As shown, the traveling wheel 2 is installed on the large frame 10, and the power shaft of the traveling wheel 2 and the motor 3 is connected through the reducer transmission, and the traveling wheel 2 is located on the track 1; the feeding mechanism is fed by the bin body 4, the rake wheel 5 and the conveyor belt The device (commercially available standard parts, mainly composed of a transmission belt, a transmission wheel and a transmission wheel drive mechanism), the warehouse body 4 is installed on the large frame 10, the warehouse body 4 is provided with a material inlet and a material outlet, and the rake wheel 5 Installed in the bin body 4 through bearings, the rake wheel 5 is connected to the power shaft of the rake wheel motor, and the conveyor belt feeding device is located at the feeding port of the bin body 4; Composition, the distributing cylinder 6 is installed on the large frame 10, and the distributing cylinder 6 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com