Process for weaving wool knitted linings

A technology of wool knitted fabrics and crafts, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of different densities and styles, low work efficiency, high labor intensity, etc., and achieve high production efficiency, low cost, and ready-made garments high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0012] A weaving process for pure wool knitted fabric, the specific method comprising:

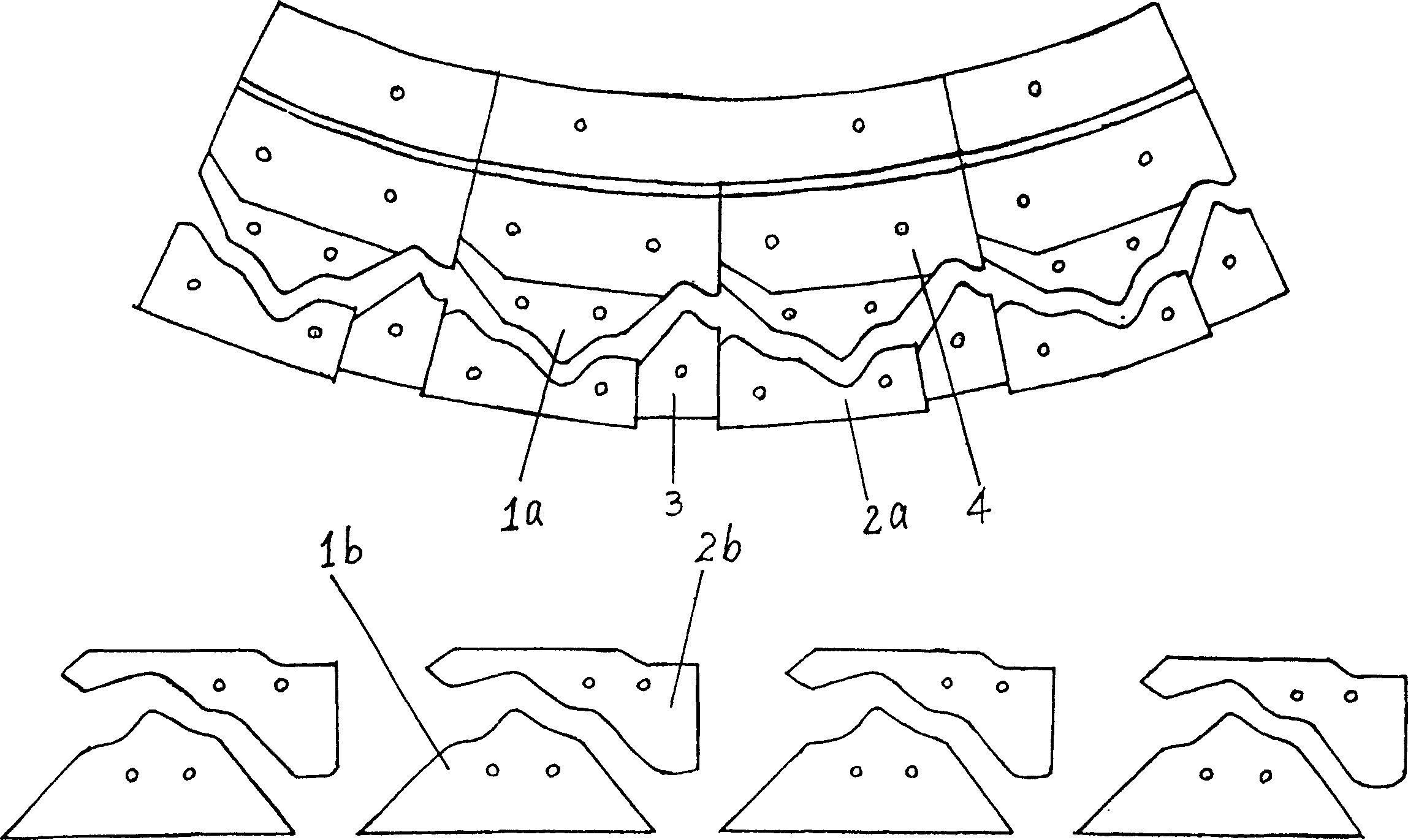

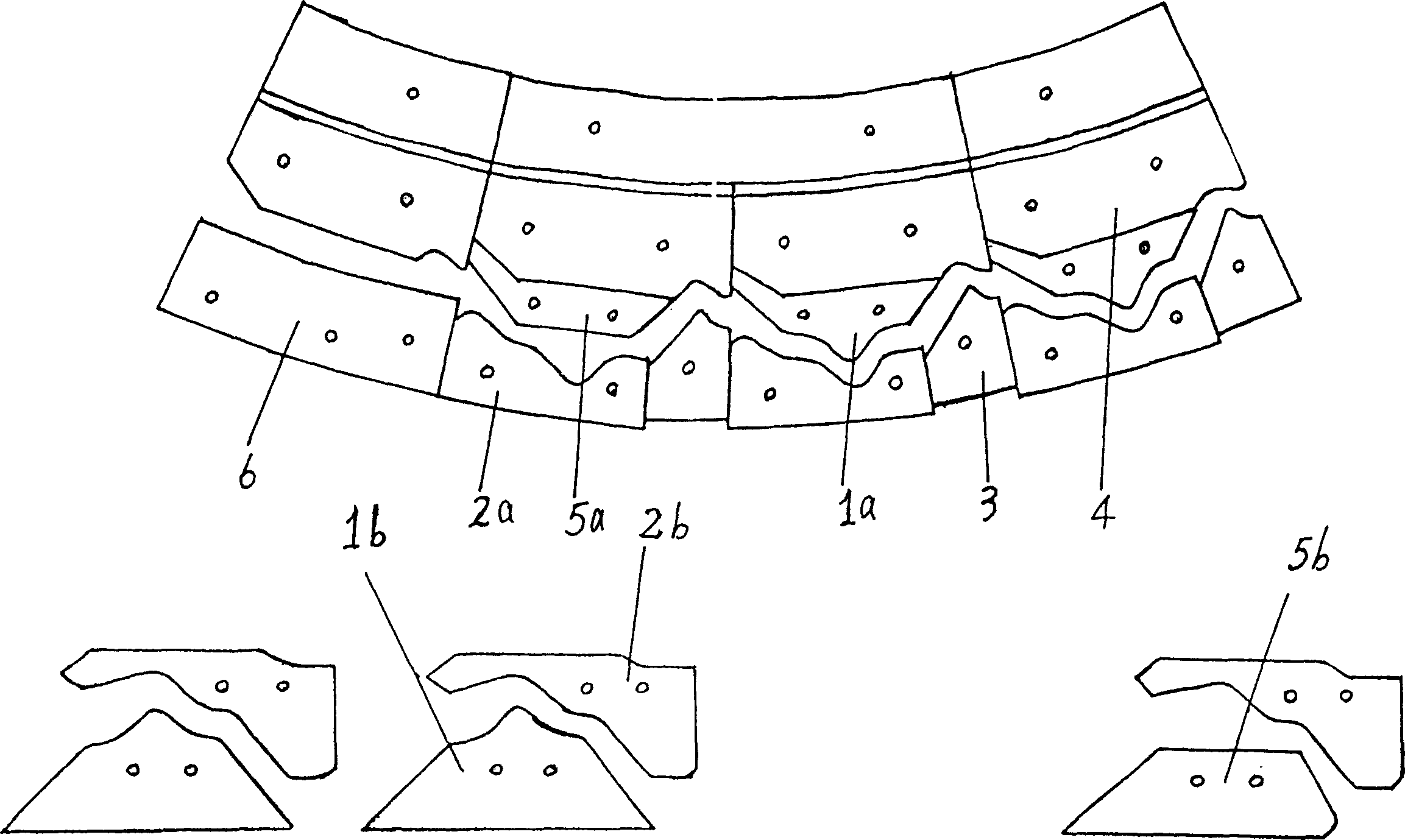

[0013] (1) Equipment: ① Using domestic YRNK-340 type 7-needle circular weft machine or SDZ-V type 11-needle circular weft machine, the upper and lower triangles of the original machine correspond to one complete knitting for each channel, and the current upper and lower triangles are changed. Corresponding to one complete knitting (cycle) for every four passes, in the first pass of each cycle, remove the upper needle starter triangle (1a), keep the upper needle auxiliary triangle (4), and put the upper needle auxiliary triangle (2a) and the upper needle Remove the needle pressing triangle (3) and replace it with the upper needle auxiliary triangle (6), and the lower needle triangle remains unchanged, then the needle on this route will go to the plain stitch (no needle), and the lower needle will knit single-sided; the second route of each cycle , remove the upper needle tuck triangle (1a) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com