Material distribution technology of one-time forming brazing super-hard material grinding tool

A super-hard abrasive and process technology, applied in abrasives, manufacturing tools, grinding devices, etc., can solve the problems of too little solder, difficult to brush evenly, uneven thickness, etc., to achieve improved cloth efficiency, good production consistency, Aesthetically pleasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The present invention is a one-time forming brazing superabrasive material distribution process. In this embodiment, a conventional brazing diamond saw blade with an outer diameter of 105mm is prepared. The particle size of the abrasive grains is required to be 50 / 60 mesh, and the distance between the abrasive grains is 1.2mm, which specifically includes the following steps:

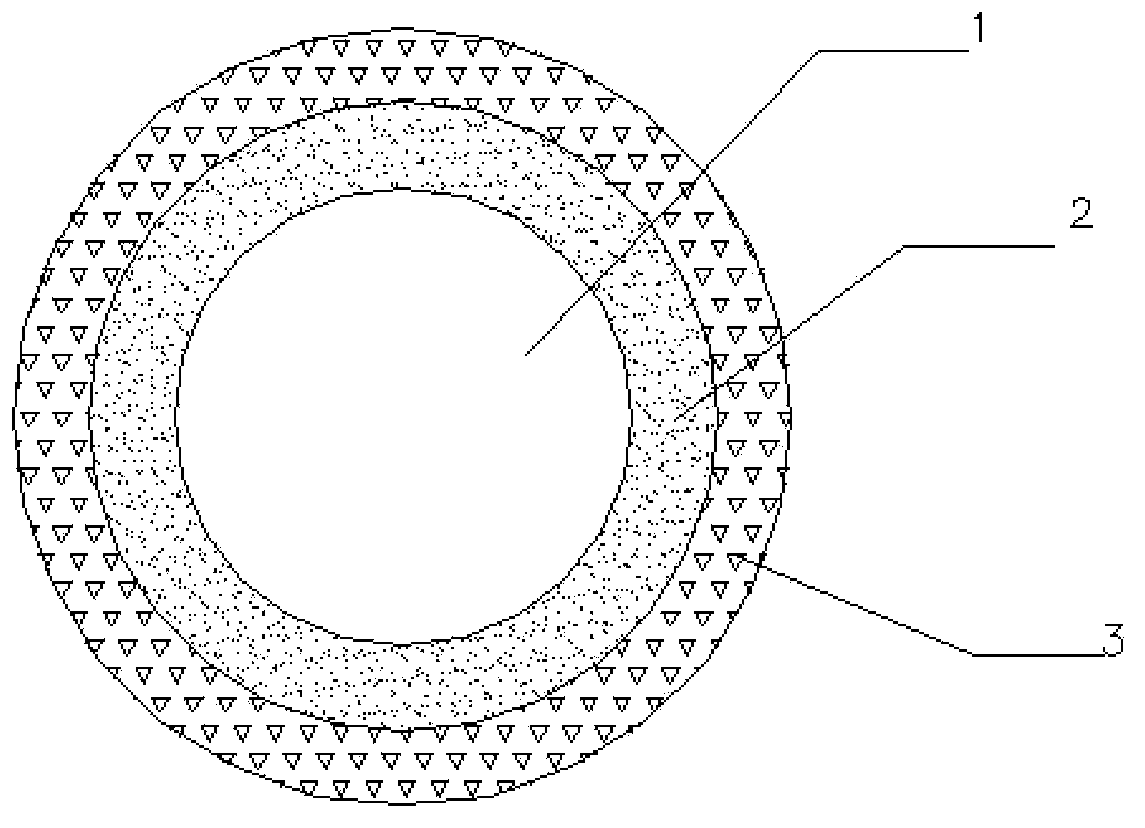

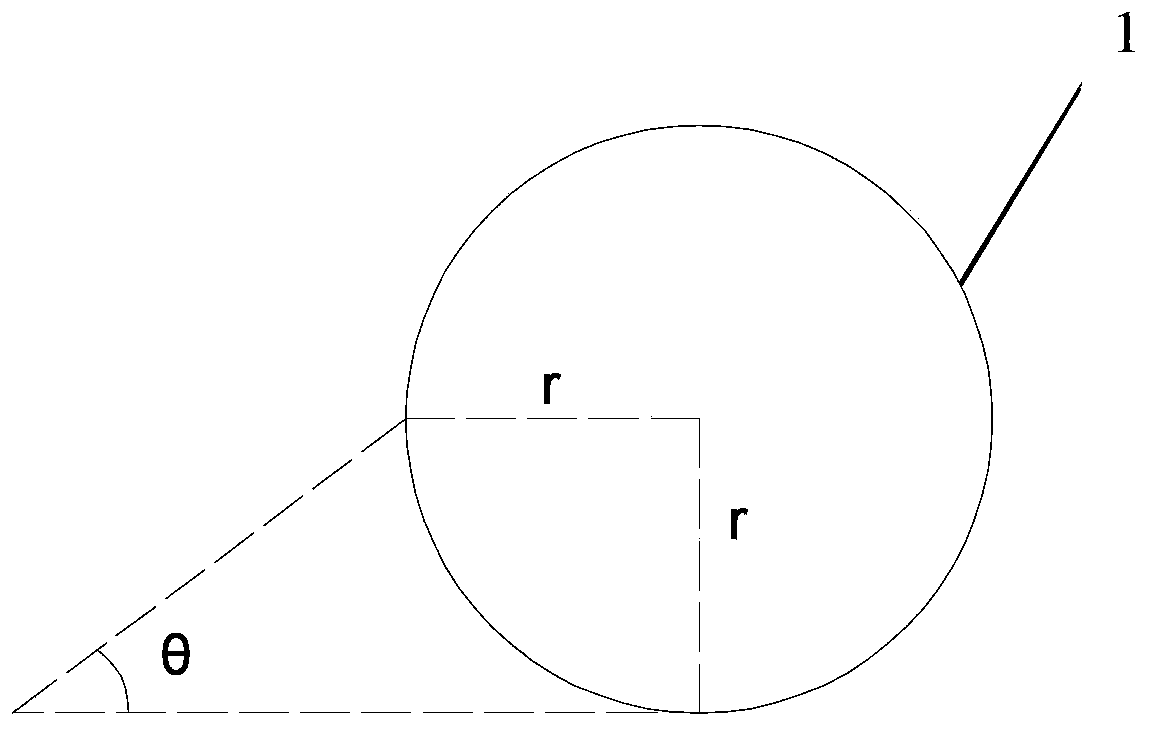

[0051] (1) Preparation of composite pellets for use: after the abrasive grain 1 is wrapped with the solder layer 2 to form a composite, then the paraffin layer 3 is wrapped around the composite to form a spherical or similar composite pellet, such as figure 1 shown;

[0052] Composite pellets are prepared by granulation process, including the following steps:

[0053] ① Place the abrasive grains in an empty shell that rotates along a complex curve;

[0054] ②Blow air into the empty shell to blow up the abrasive grains, and at the same time spray and mix solder containing granulating agent on one...

Embodiment 2

[0079] The difference between this example and Example 1 lies in: preparation of copper-based solder brazed special-shaped curved surface hand grinding wheel F20.

[0080] The specific fabric process is as follows:

[0081] ⑴Process the F20 substrate of the special-shaped curved surface hand grinding wheel according to the requirements.

[0082] ⑵Clean the surface of the grinding wheel to ensure that there is no grease and impurities.

[0083] (3) Apply a layer of pressure-sensitive adhesive evenly on the outer surface of the grinding wheel (volume concentration is 80%).

[0084] (4) Sprinkle composite pellets on the outer surface of the grinding wheel obtained in step (3), and the composite pellets are closely arranged and bonded on the outer surface of the grinding wheel to obtain a semi-finished product; the diamond particle size in the composite pellets is 30 / 35 mesh, copper-based solder The particle size is 200 mesh, its composition is copper-tin-titanium, and the conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com