Production systems for concrete elements

A production system and concrete technology, applied in ceramic molding workshops, auxiliary molding equipment, supply devices, etc., can solve the problems of incapable of continuous production, time-consuming and laborious, low work efficiency, etc., achieve simple and fast demoulding, improve product quality, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

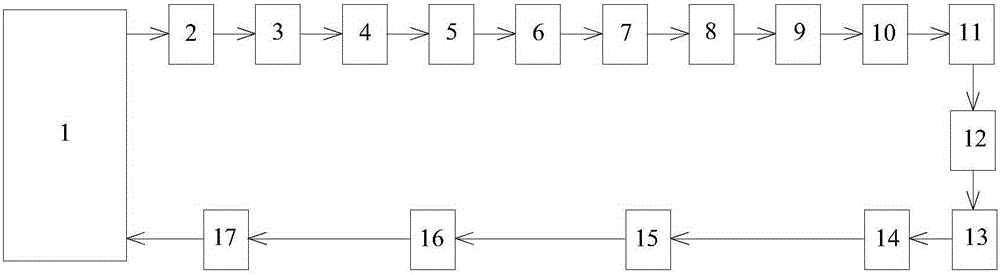

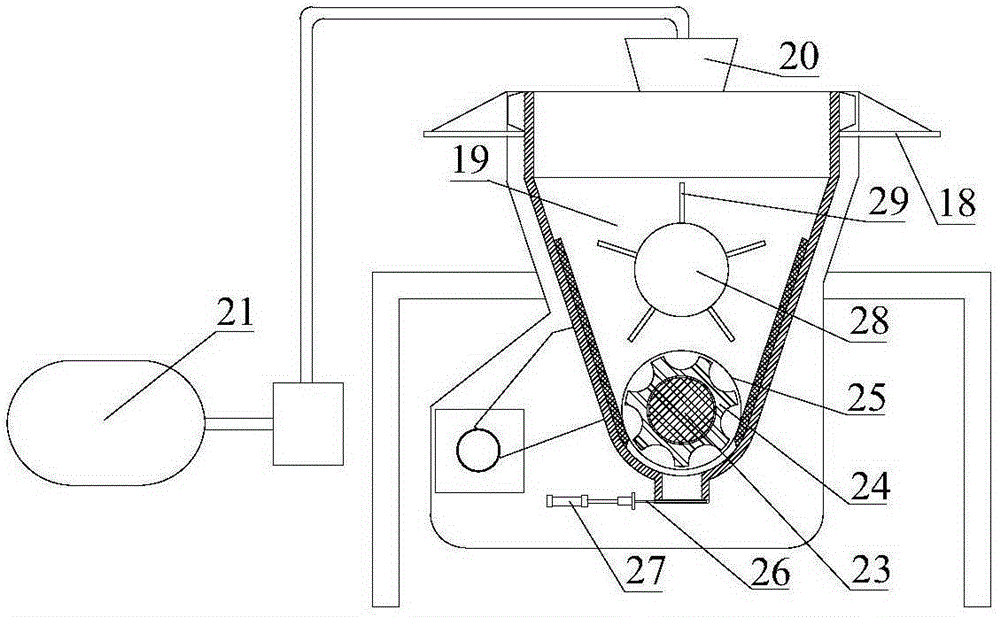

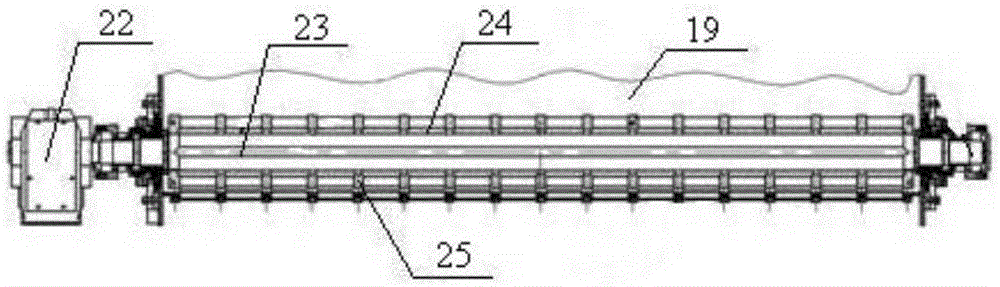

[0027] The production system of concrete components, the key is: the production system includes the mold platform conveying device, the mold platform pretreatment equipment, the first distributing machine, the second distributing machine, post-distributing equipment, maintenance warehouse 1, side stand removal bottom The maintenance warehouse 1 is equipped with an entrance and an exit, and a set of mold table conveying device is installed at the entrance of the maintenance warehouse 1, and a set of mold table conveying device is also installed at the exit of the maintenance warehouse 1. The ends of the two sets of mold table conveying devices Connected by means of a ferry conveying device 12, the mold table conveying device at the exit of the maintenance warehouse 1 is sequentially provided with a demoulding station, a mold table pretreatment station, a first fabric distributing station 10, a vibrating and compacting station 11, and a maintenance warehouse 1 The mold platform c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com