Concrete spreader

A distributing machine and distributing technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of time-consuming and labor-intensive, difficult to guarantee pouring quality, and low efficiency, and achieve flexible control, simple structure and high distributing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

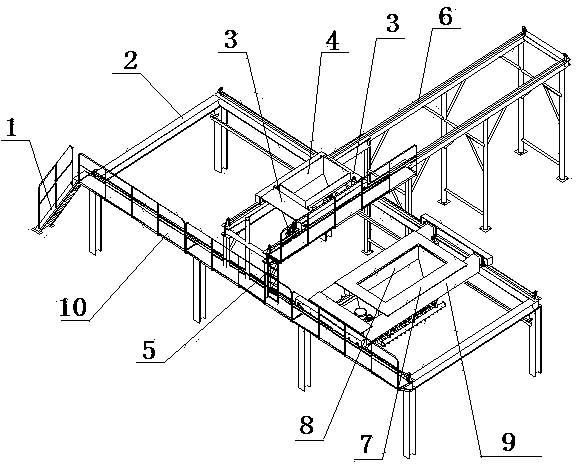

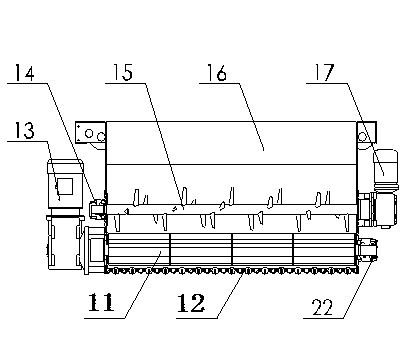

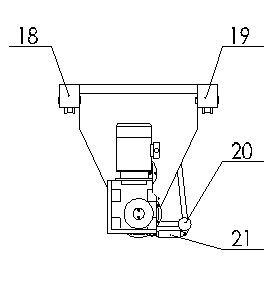

[0021] see figure 1 — Figure 8 , The concrete distribution machine of the present invention adopts a distribution hopper assembly, a feeding hopper assembly, a cart beam assembly, and two frames to form a complete distribution machine. The two frames are respectively a cloth frame and a feed frame, the feed frame is supported on the cloth frame, and two parallel and straight light rail tracks are respectively installed on the cloth frame and the feed frame. The distribution bucket assembly is installed on two straight and parallel light rails of the cart beam assembly, and can realize walking in the Y-axis direction. The trolley beam assembly is installed on the track of the distribution frame again, which can realize the walking in the X-axis direction, so that the distribution bucket can realize the cloth demand for walking in the X and Y-axis directions. The distribution hopper assembly consists of two distribution hopper walking beams, a distribution hopper shell steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com