Concrete spreading experimental platform with functions of precise positioning and fine spreading

A precise positioning and experimental platform technology, applied in the processing of building materials, construction, building construction, etc., can solve the problems of inability to achieve precise control, digital intelligent production, large size deviation of cloth, and difficulty in controlling the accuracy of cloth. Achieve the effect of improving cloth accuracy, avoiding waste, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

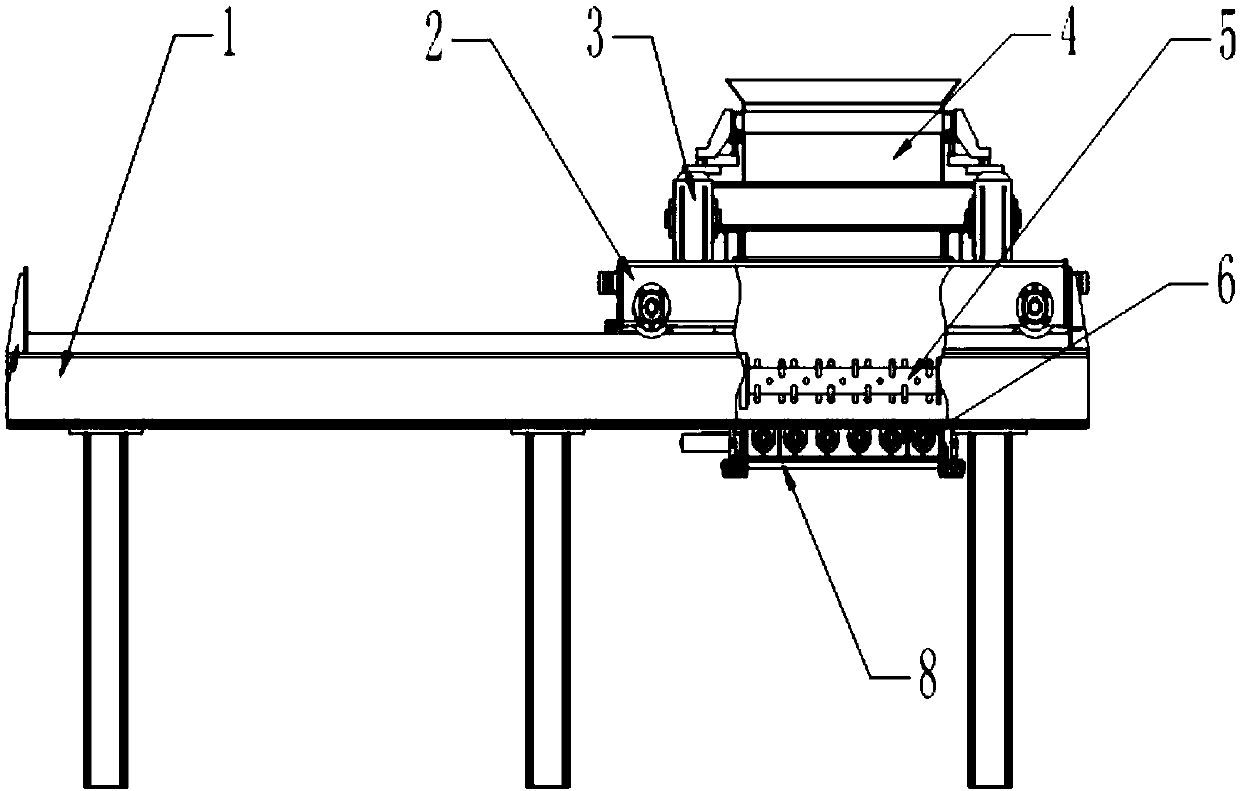

[0025] Such as Figure 1-6 As shown, a concrete distribution experimental platform for precise positioning and fine distribution includes a distribution system and a walking system. The distribution system includes a hopper 4, a breaking device 5, a screw conveyor 6, a gate assembly 7 and a floor assembly 8; The walking system includes a steel structure support 1, a trolley micro-moving device 2 and a trolley micro-traveling device 3; On the trolley micro-movement running device 2, the cloth system is installed on the trolley micro-moving running device 3;

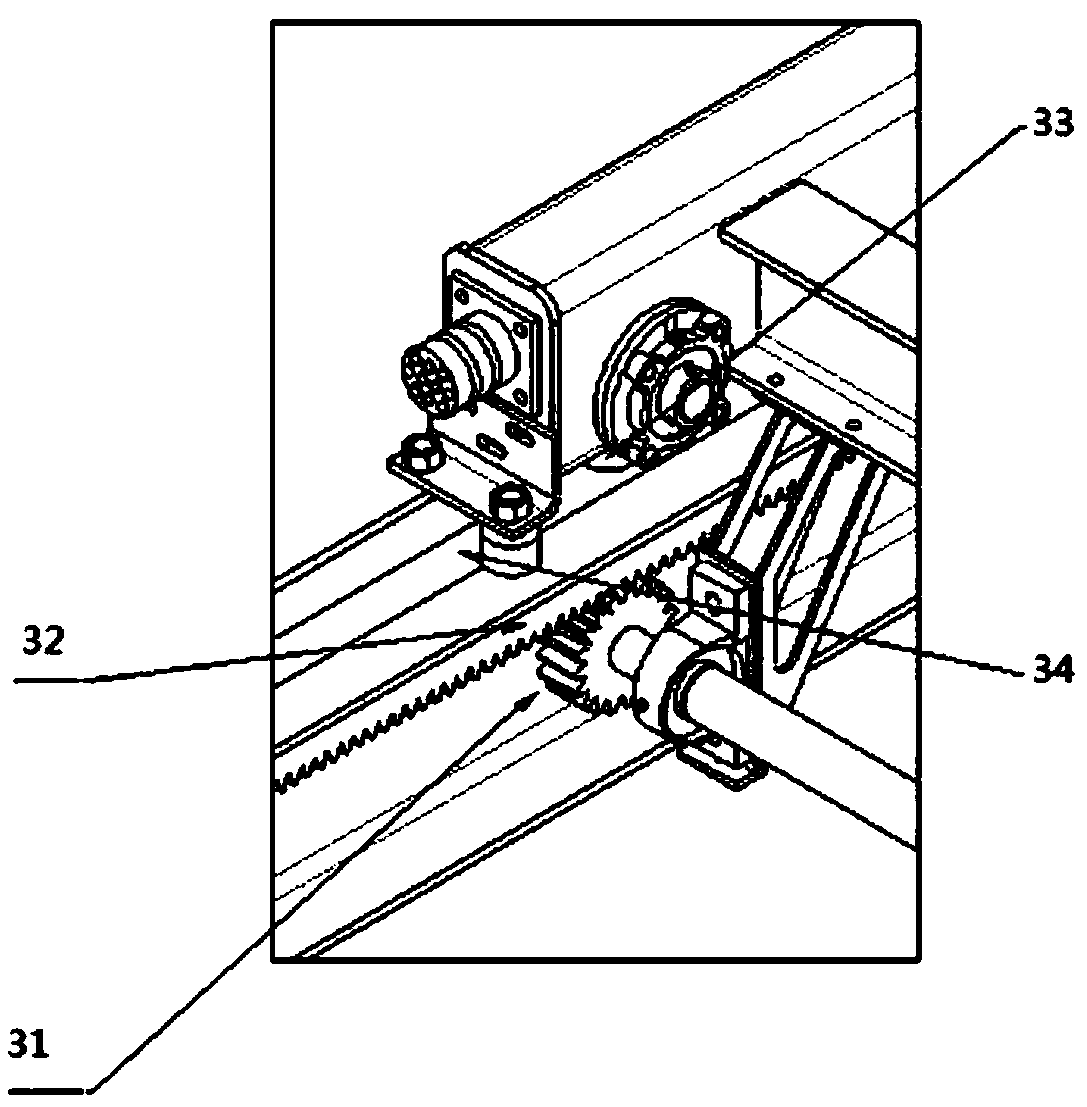

[0026]Wherein said steel structure support 1 is provided with a pair of crossbeams, and above said crossbeams is provided with track one, and below said crossbeams is provided with rack one; Motor 1 and reducer 1, four wheels 1 are installed under the frame 1, wheels 1 is placed on track 1, gear 1 is installed in the lower part of the frame to engage with rack 1, servo motor 1 and reducer 1 are installed on the vehicle O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com