Method for constructing combined steel and concrete column of large metallurgy industrial factory building

A technology of steel reinforced concrete and metallurgical industry, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of difficult construction, reducing the overall quality of steel reinforced concrete, and complex forms of the connection between steel reinforced beams and steel reinforced columns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

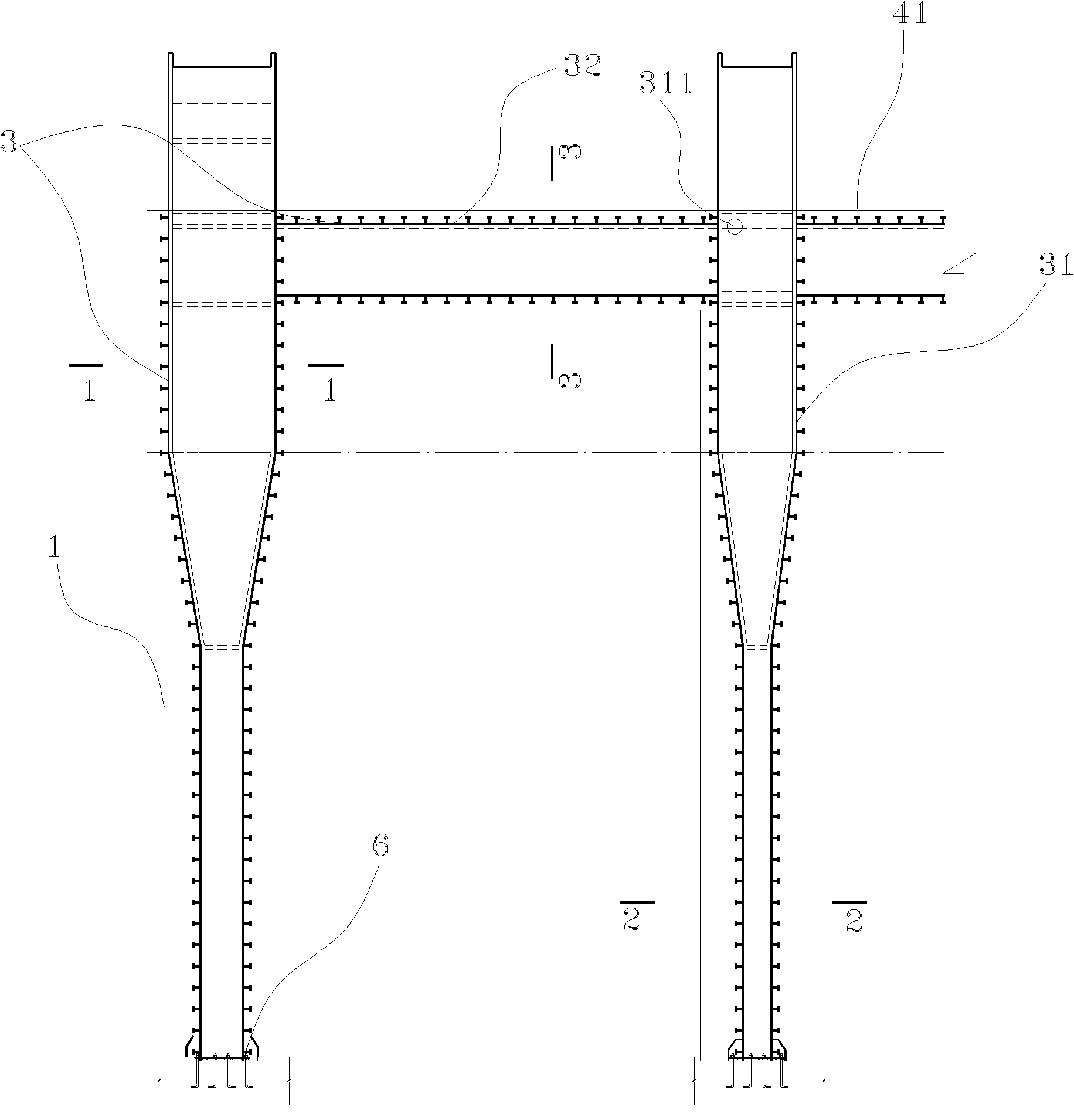

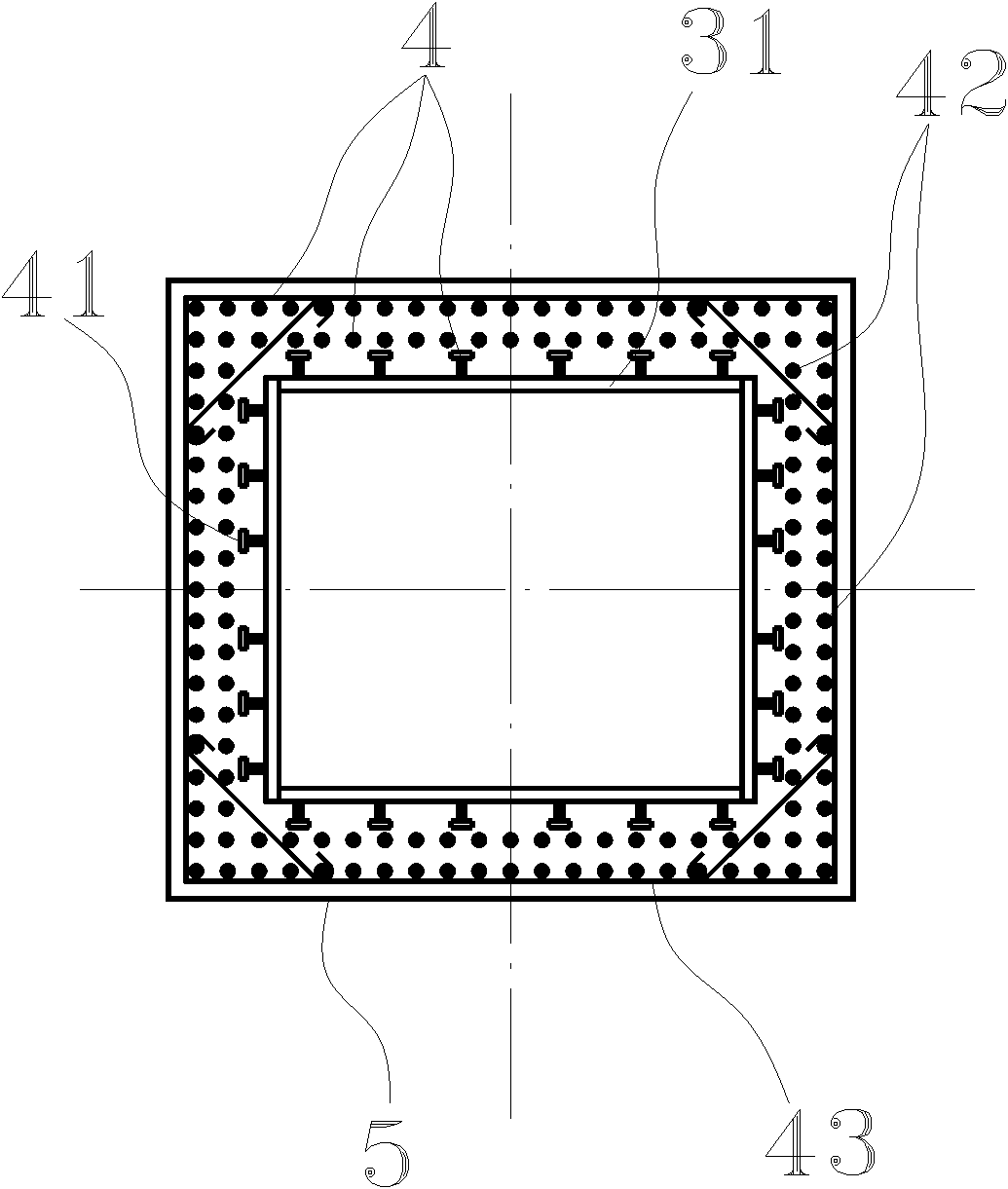

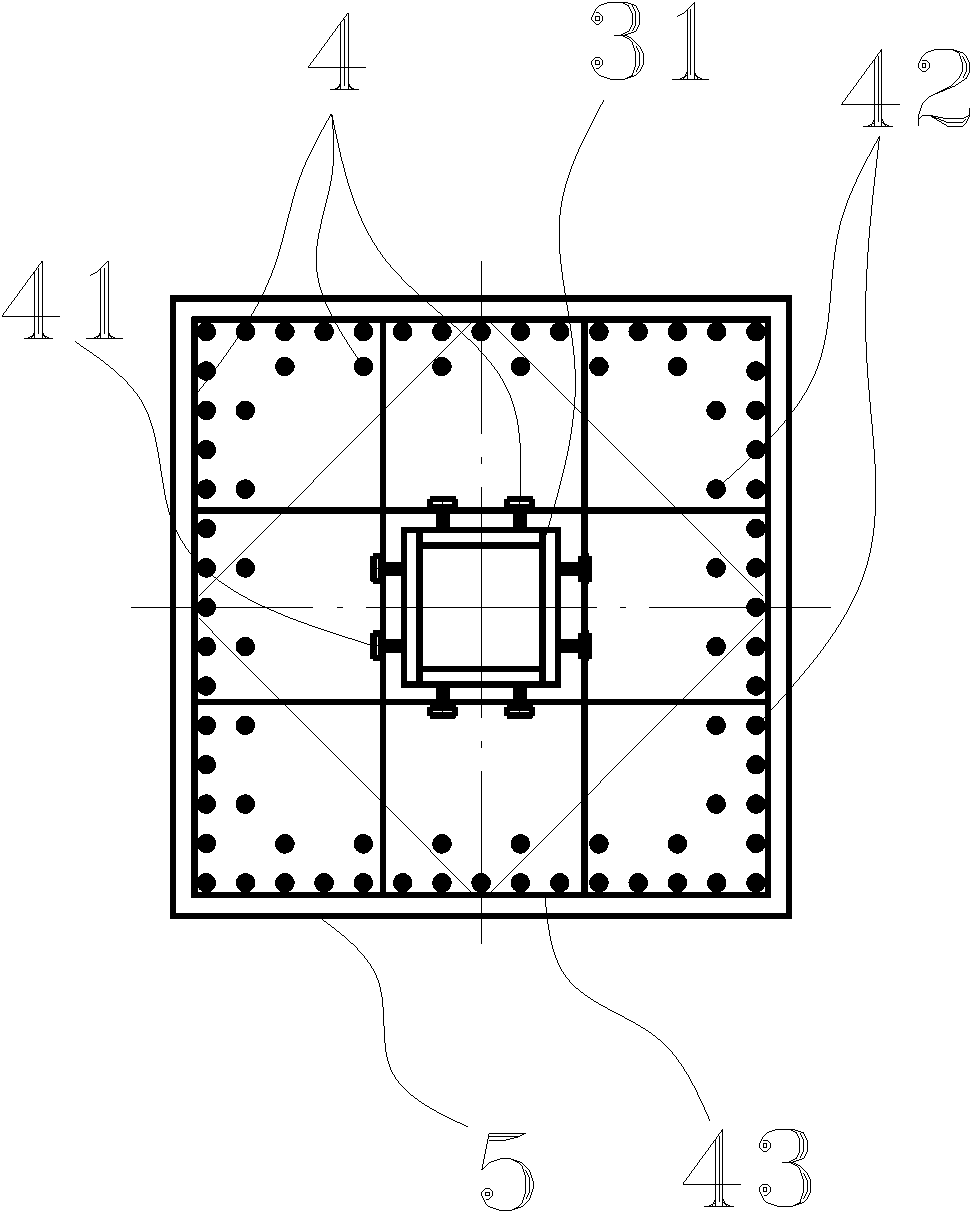

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 as well as Image 6 Shown are the schematic diagram of the structure of the steel-reinforced concrete frame of the factory building involved in the construction method of the steel-reinforced concrete column of the large-scale metallurgical industrial plant of the present invention, the installation layout diagram of the steel skeleton, the concrete reinforcement, and the connection schematic diagram of the steel-reinforced concrete column and the steel-reinforced concrete beam . The following is a construction method for a steel-reinforced concrete column in a large metallurgical industrial plant that can ensure the production quality of the steel-reinforced concrete column provided by the present invention in conjunction with the drawings. The construction method of the present invention includes the following steps,

[0028] a. Install the steel skeleton 3. First install the pre-prepared box-shaped steel c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com