Tunnel concrete lining formwork apparatus

A technology of concrete and formwork, which is applied in the direction of tunnel lining, shaft lining, tunnel, etc., can solve the problems of increasing tunnel roughness, poor safety performance, and limited operating space, so as to eliminate hidden dangers in construction safety, increase operating space, and pouring The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

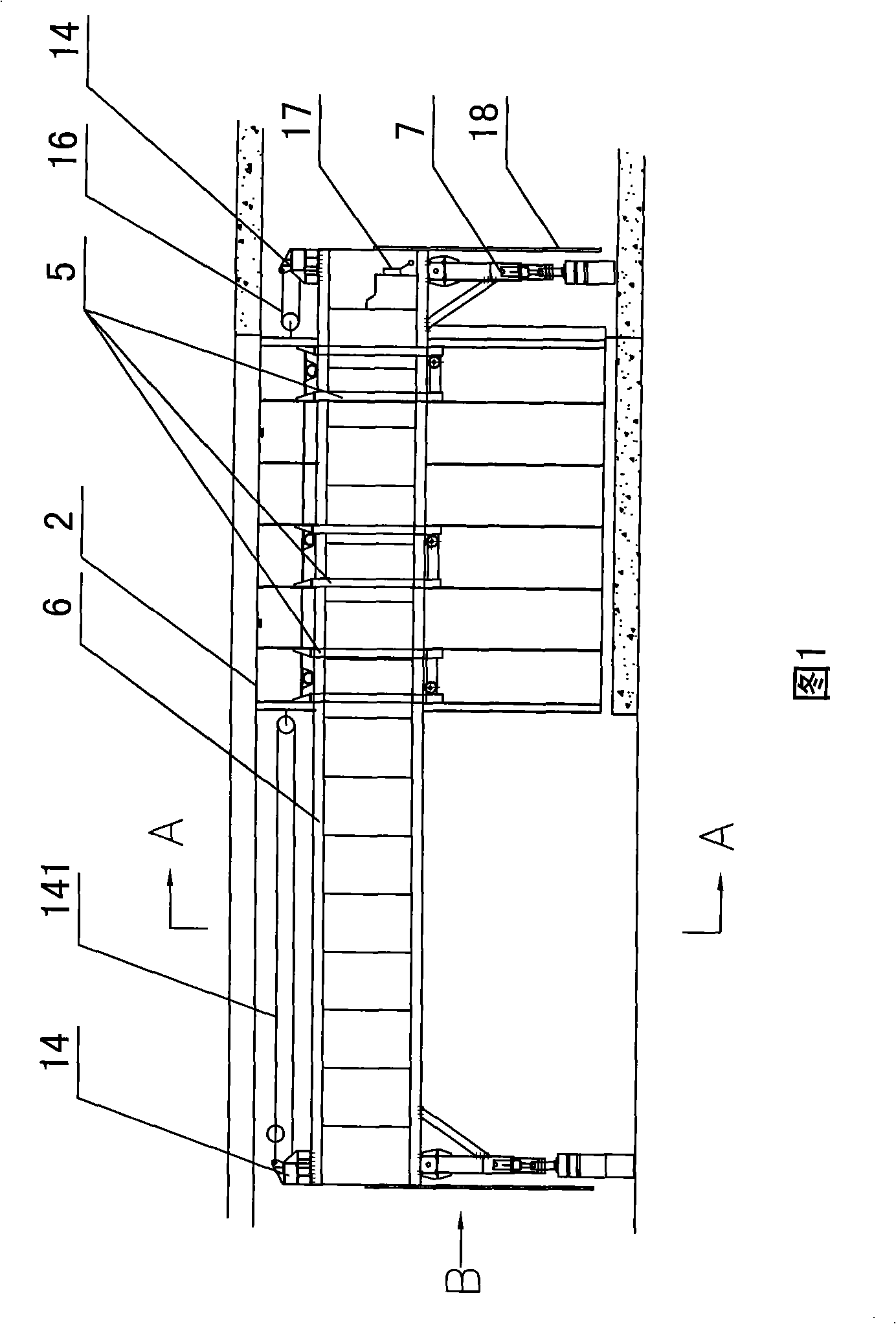

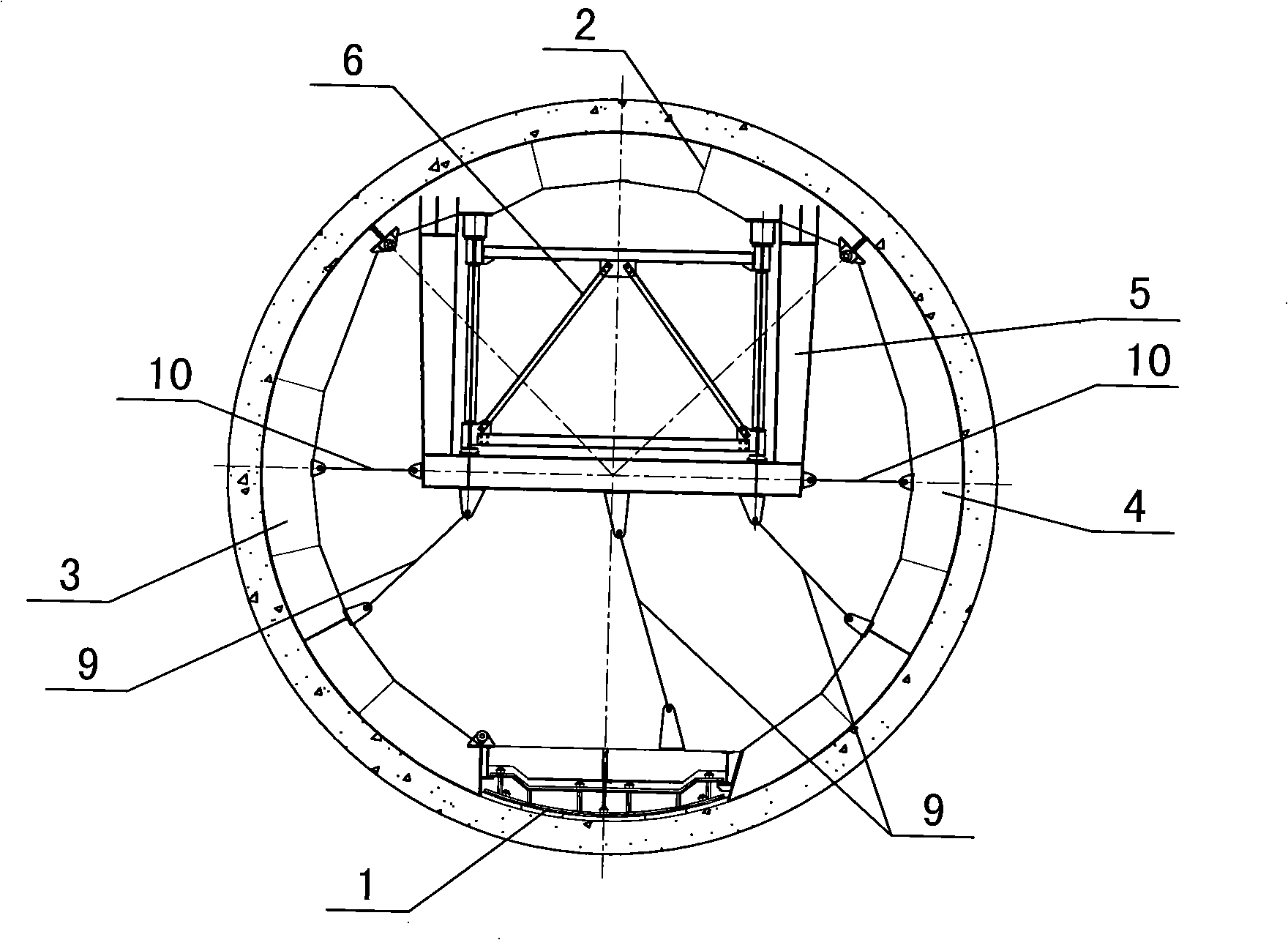

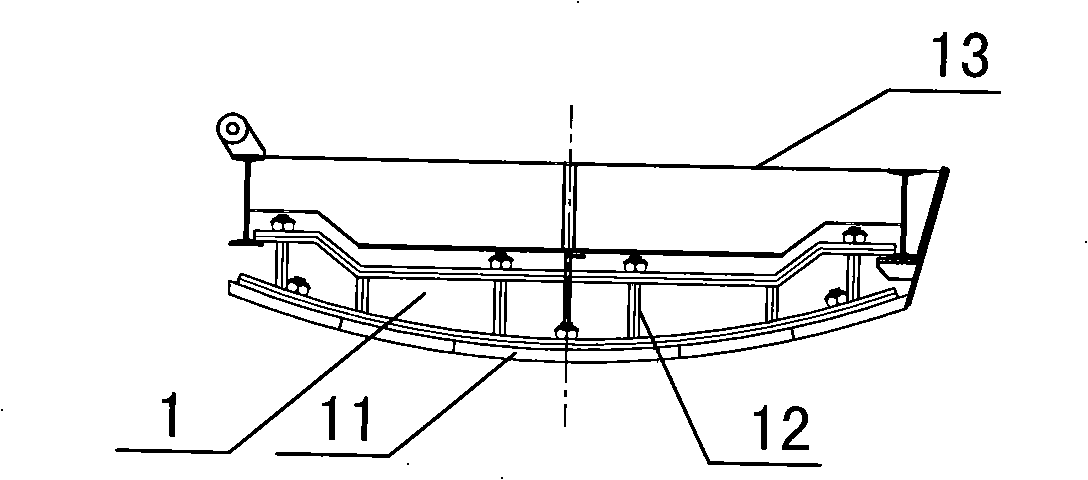

[0045]Figure 1~ Figure 6 As shown, a tunnel concrete lining formwork device according to the present invention includes a formwork system and a load-bearing needle beam system. The formwork system includes a formwork assembly and a formwork hanger 5. The formwork assembly includes an arc-shaped left formwork 3 , right side mold 4, top mold 2 and bottom mold 1, the left side mold 3, right side mold 4, top mold 2 and bottom mold 1 are correspondingly hinged to form a circular formwork assembly in section; Located on the top mold 2, and the bottom of the formwork hanger 5 is correspondingly provided with a telescopic vertical mold demoulding device connected with the left mold 3, the right mold 4 and the bottom mold 1; Figure 10 As shown in ~14, the needle beam system includes a load-bearing needle beam placed in the upper part of the tunnel and a front and rear support leg device 7 for supporting the load-bearing needle beam 6 and can be adjusted in height; the upper end surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com