Device for testing cooling performance of liquid controlled stepless speed changer and its testing method

A continuously variable transmission and cooling performance technology, applied in the direction of measuring devices, machine/structural component testing, mechanical component testing, etc., can solve problems that can only be qualitative, trouble CVT research and development, verification and testing, and cannot be quantitatively verified and tested, etc. problems, to achieve rapid analysis and processing, scientific and feasible detection methods, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

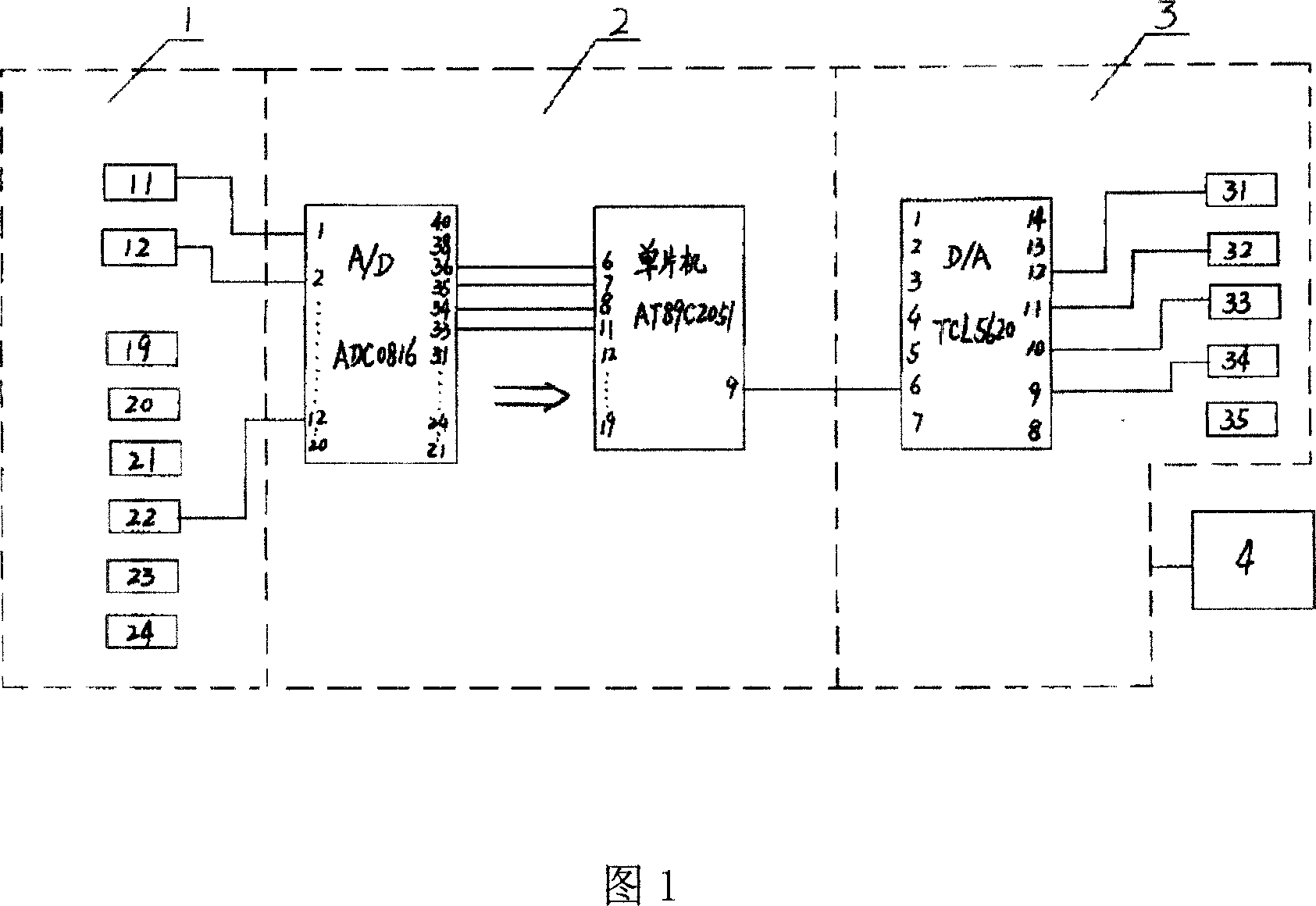

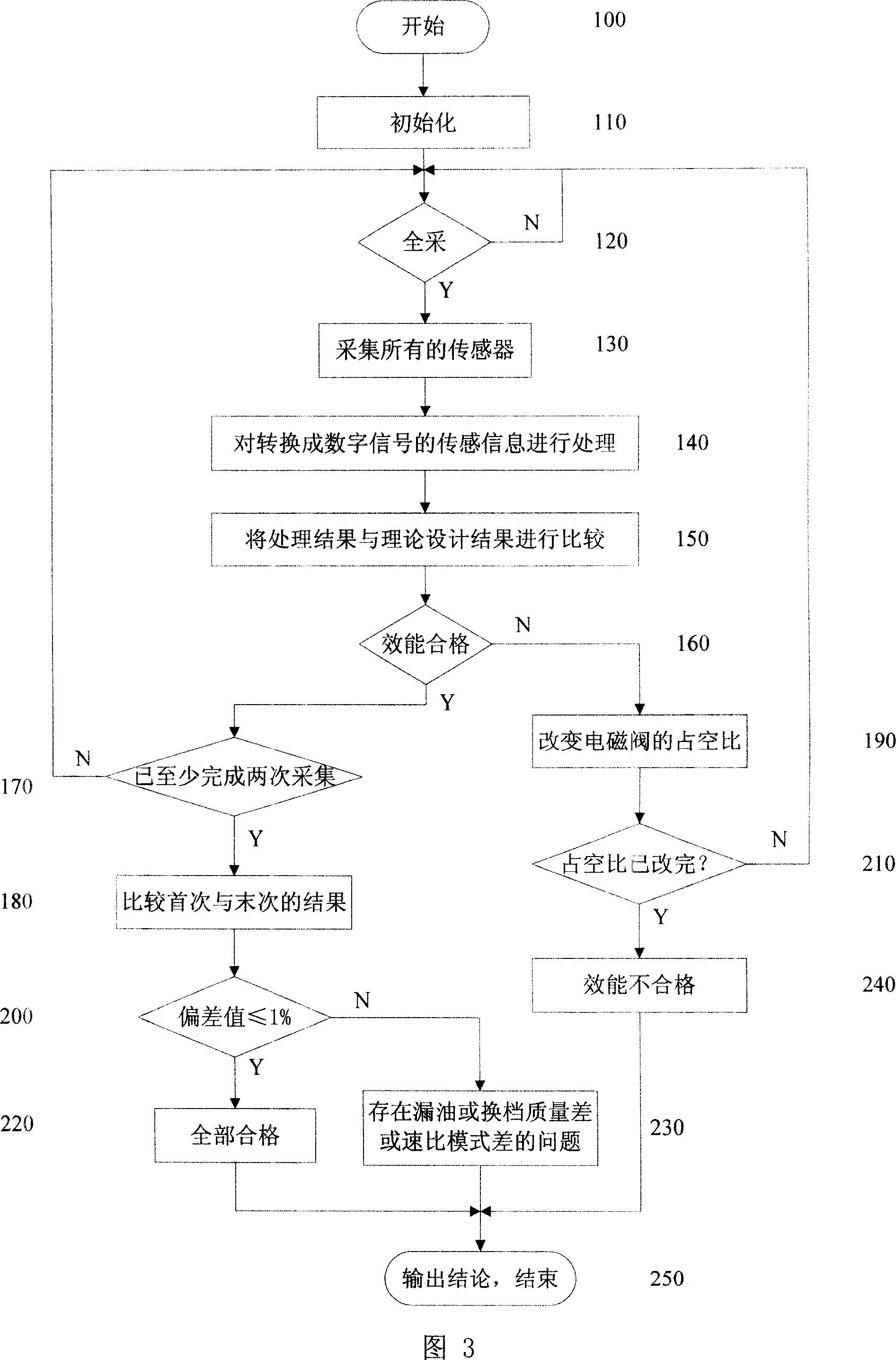

[0014] Referring to Figures 1 and 2, the detection device for the cooling performance of the hydraulically controlled continuously variable transmission includes a speed sensor 11 of the output shaft of the gearbox, a clutch oil pressure sensor 12, a transmission speed sensor 11 and a transmission speed sensor 12, which are respectively placed on the engine C, the gearbox B and the air cooler A. Case input shaft speed sensor 13, engine output shaft speed sensor 14, transmission oil drain temperature sensor 15, transmission main oil pressure sensor 16, transmission oil temperature sensor 17, transmission one shaft oil pressure sensor 18, cooler inlet The oil temperature sensor 19, the cooler outlet oil temperature sensor 20, the torque converter lock oil pressure sensor 21, the ambient temperature sensor 22, the gradient sensor 23 and the accelerator opening sensor 24 are the sensing components 1, which are used to connect each point to be measured. The physical quantity of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com