Tunnel lining self waterproof drainage system

A waterproof and drainage technology for tunnels, applied in tunnel lining, drainage, tunnels, etc., can solve unsolved tunnel leakage problems, affect lining and driving safety, reduce equipment service life, etc., achieve durable and reliable drainage characteristics, easy to clean The effect of silting and speeding up the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

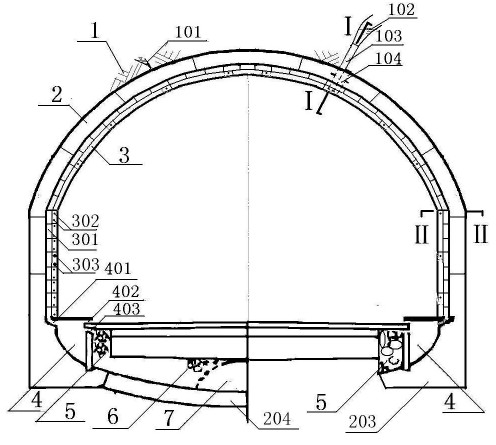

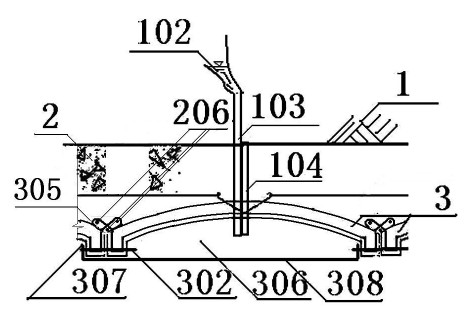

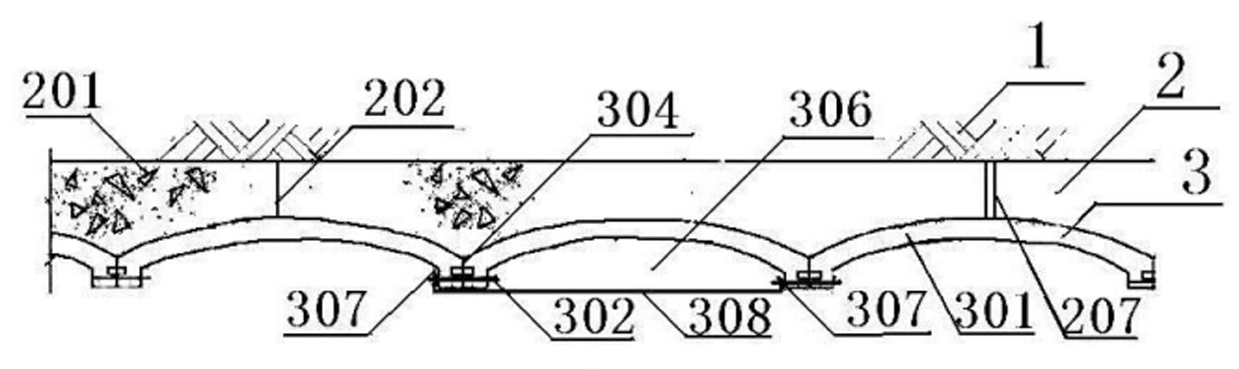

[0052] Such as Figure 1 to Figure 3 Shown: a tunnel lining self-proof drainage system, including surrounding rock bearing arch 1, cast-in-situ concrete main waterproof layer 2, precast concrete arch layer 3, longitudinal drainage ditch 4, arch layer construction joints and cast-in-situ concrete main waterproofing Staggered construction joints in each layer; it is characterized in that: at the position 102 of the concentrated water inflow and leakage point 102 in the soft surrounding rock, a movable drainage groove 308 is fixed under the prefabricated concrete arch layer 3, and the movable drainage groove 308 is connected with the inner surface of the prefabricated reinforced concrete arch 301. The concave surface forms a drainage space 306, and the side-by-side drainage spaces 306 arranged along the section of the tunnel form an active drainage ditch. The active drainage ditch is connected with the vertical drainage ditch 4 on both sides of the tunnel road surface, and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com