Construction method of jet-grouting pile and composite soil-nailed wall support for deep foundation pit construction

A composite soil nailing and construction method technology, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve problems such as safety hazards, subsidence, and broken walls of deep foundation pits, and achieve strong overload capacity, reduce impacts, and shorten the total construction period short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

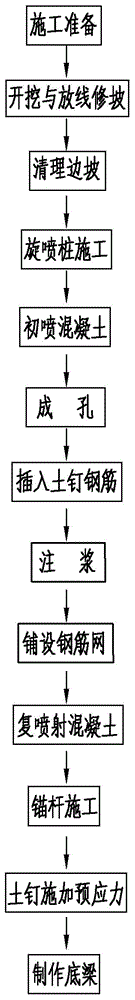

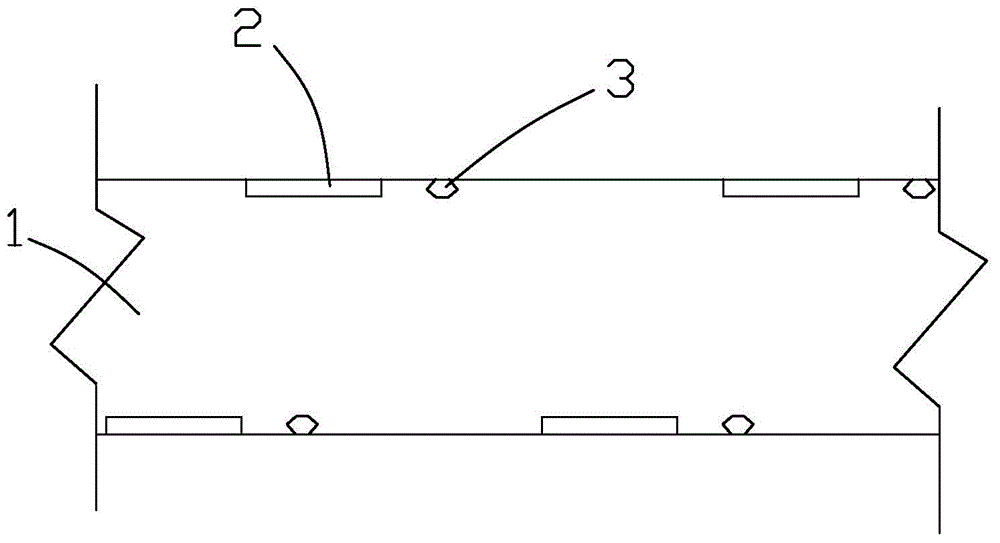

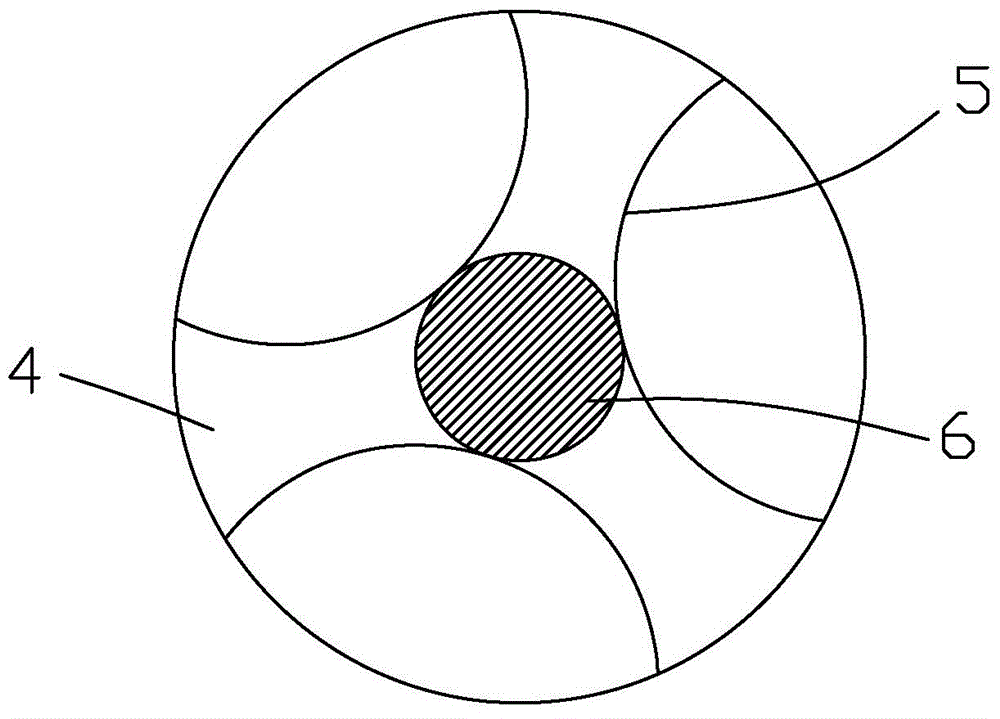

[0063] The invention discloses a construction method for the support of a deep foundation pit construction rotary grouting pile composite soil nailing wall, and its technological principle is to uniformly nail several rows of slender bar soil nails to the natural soil on the side of the foundation pit during the excavation process of the deep foundation pit. , and lay a reinforced concrete surface layer on the wall of the foundation pit, and form a gravity retaining wall through the joint action of natural soil, soil nails and reinforced concrete surface layer.

[0064] This construction method requires the following materials:

[0065] 1. Class II steel bar, ordinary Portland cement, sand, gravel, early strength agent, expansion agent, accelerator, antifreeze agent.

[0066] 2. Machinery and equipment: shotcrete machine, concrete mixer, mixing tank, storage tank, DC welding machine, straightening machine, air compressor, grouting machine, cutting machine, Luoyang shovel.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com