Steel plate with low density and high marine environment resistance and production technology thereof

A marine environment, low-density technology, applied in the field of low-alloy corrosion-resistant steel medium and thick plates (60mm), can solve the problems of insignificant corrosion resistance in marine environments, low strength levels, and reduced corrosion rates to achieve corrosion resistance Remarkable performance, low production cost, and improved corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

[0050] Embodiment 1.1: 20mm thick steel plate and its production process:

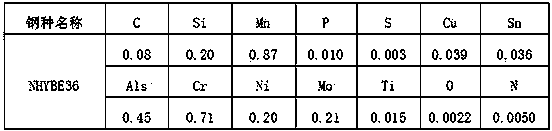

[0051] According to the chemical composition requirements of steel in the present invention, the chemical composition (wt%) obtained is shown in the following table 1:

[0052] .

[0053] The molten steel is cast into 250mm thick slabs, cut to length and then stacked and cooled slowly to room temperature, and the slabs are heated to 1200°C for 4.5 hours in the furnace.

[0054] The process of controlled rolling and controlled cooling is:

[0055] The starting temperature of rough rolling is 1000~1010℃, three times the thickness of the intermediate billet is adopted, 250mm→60mm, and the pressure rate of the last two passes of rough rolling is guaranteed to be greater than 20%. When the starting temperature is 940~950℃, the finishing temperature is 910~920℃, rolled into 20mm thick steel plate, the starting cooling temperature after rolling is 880~890℃, the final cooling temperature is 730~740℃, after...

Embodiment 12

[0056] Embodiment 1.2: 16mm thick steel plate and its production process

[0057] Adopt chemical composition and slab casting process identical with embodiment 1.1, its technology of controlled rolling and controlled cooling is:

[0058] The starting temperature of the rough rolling is 1000~1010℃, and the thickness of the intermediate billet is three times, 250mm→48mm, to ensure that the pressure rate of the last two passes of the rough rolling is greater than 20%. When the rolling start temperature is 940~950°C, the finish rolling end temperature is 910~920°C, rolled into a 16mm thick steel plate, the starting and cooling temperature after rolling is 880~890°C, and the final cooling temperature is 730~740°C. Stacking slow cooling, its mechanical properties are shown in Table 2.

[0059] Table 2 Mechanical properties of the steel plates of Example 1.1 and Example 1.2

[0060] .

Embodiment 21

[0061] Embodiment 2.1: 24mm thick steel plate and its production process:

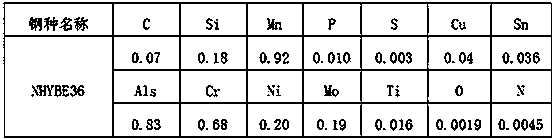

[0062] According to the chemical composition requirements of steel in the present invention, the obtained chemical composition (wt%) is shown in the following table 3:

[0063] .

[0064] The molten steel is cast into 250mm thick slabs, cut to length and then stacked and cooled slowly to room temperature, and the slabs are heated to 1200°C for 4.5 hours in the furnace.

[0065] The controlled rolling and controlled cooling process adopted is:

[0066] The starting temperature of the rough rolling is 1010~1030℃, and the thickness of the intermediate billet is three times that of 250mm→72mm to ensure that the pressure rate of the last two passes of the rough rolling is greater than 20%. When the starting temperature is 930~940℃, the finishing temperature is 900~910℃, rolled into 24mm thick steel plate, the starting cooling temperature after rolling is 870~880℃, the final cooling temperature is 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com