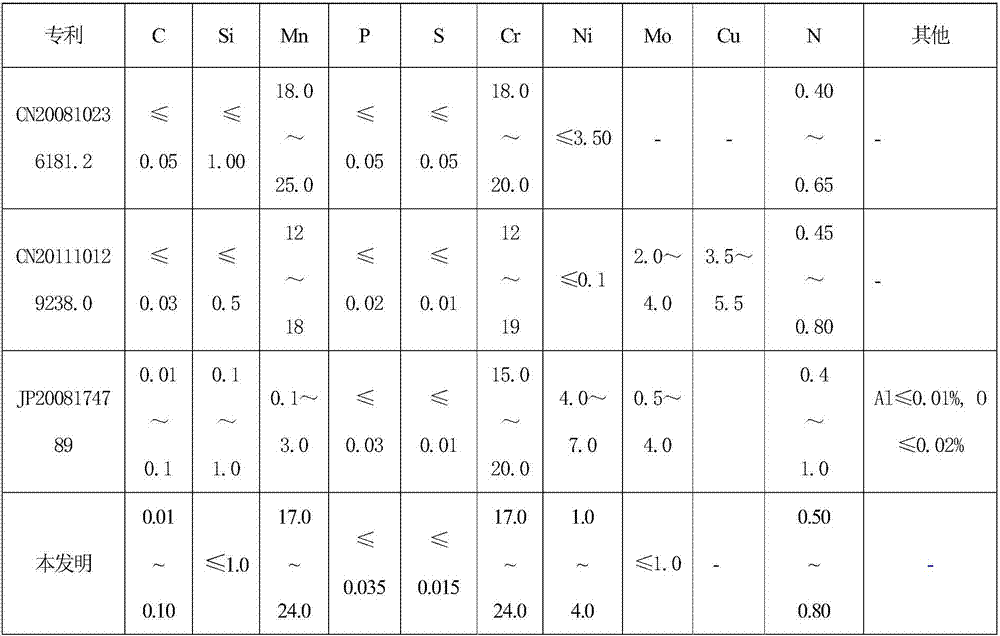

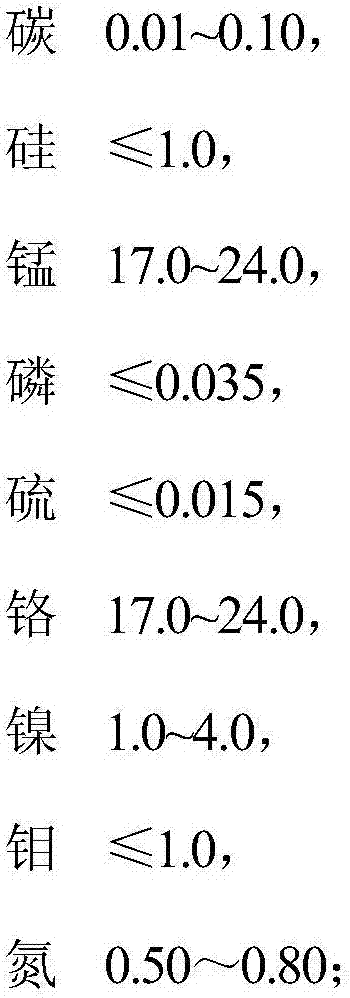

High-nitrogen non-magnetic austenitic stainless steel and manufacturing method thereof

A high-nitrogen austenitic and magnetic austenitic technology, applied in high-nitrogen non-magnetic austenitic stainless steel hot-rolled sheet and its manufacture, and high-nitrogen non-magnetic austenitic stainless steel field, can solve the problem of low strength and difficult to achieve high Yield strength and toughness, non-magnetic, good matching of corrosion resistance, etc., to achieve the effect of good plastic toughness and corrosion resistance, good plastic toughness, high yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] EAF (electric furnace) + AOD (argon oxygen decarburization furnace) + LF (ladle refining furnace) is used for smelting, casting 200mm continuous casting slabs, and the continuous casting control superheat is less than 50 ° C. The chemical composition is shown in Table 2. The continuous casting The billet is heated in a walking heating furnace, controlled rolling on the rolling mill to form a hot-rolled plate with a thickness of 20mm, the final rolling temperature is controlled at 870°C, air-cooled to room temperature, and the hot-rolled plate is then pickled to obtain a high-nitrogen Austrian It is a hot-rolled stainless steel plate with high yield strength, good ductility, non-magnetism and corrosion resistance. All properties are listed in Table 3.

Embodiment 2

[0042] EAF (electric furnace) + AOD (argon-oxygen decarburization furnace) + LF (ladle refining furnace) is used for smelting, casting 150mm continuous casting slabs, and the continuous casting control superheat is less than 50 ° C. The chemical composition is shown in Table 2. The continuous casting The billet is heated in a walking heating furnace, controlled rolling on a rolling mill to form a hot-rolled plate with a thickness of 10mm, the final rolling temperature is controlled at 820°C, air-cooled to room temperature, and the hot-rolled plate is then pickled to obtain a high-nitrogen Austrian It is a hot-rolled stainless steel plate with high yield strength, good ductility, non-magnetism and corrosion resistance. All properties are listed in Table 3.

Embodiment 3

[0044] EAF (electric furnace) + AOD (argon oxygen decarburization furnace) + LF (ladle refining furnace) is used for smelting, casting 350mm molded ingots, the chemical composition is shown in Table 2, and the molded ingots are put into the walking heating furnace Heating, controlled rolling on the rolling mill to form a hot-rolled plate with a thickness of 40mm, the final rolling temperature is controlled at 940°C, air-cooled to room temperature, and the hot-rolled plate is then pickled to obtain a finished high-nitrogen austenitic stainless steel hot-rolled plate. The product also has high yield strength, good ductility, non-magnetic properties and corrosion resistance. All properties are listed in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com