Double-layer telescopic welding robot system

A welding robot and telescopic technology, used in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of slow welding speed, high welding requirements, and unstable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

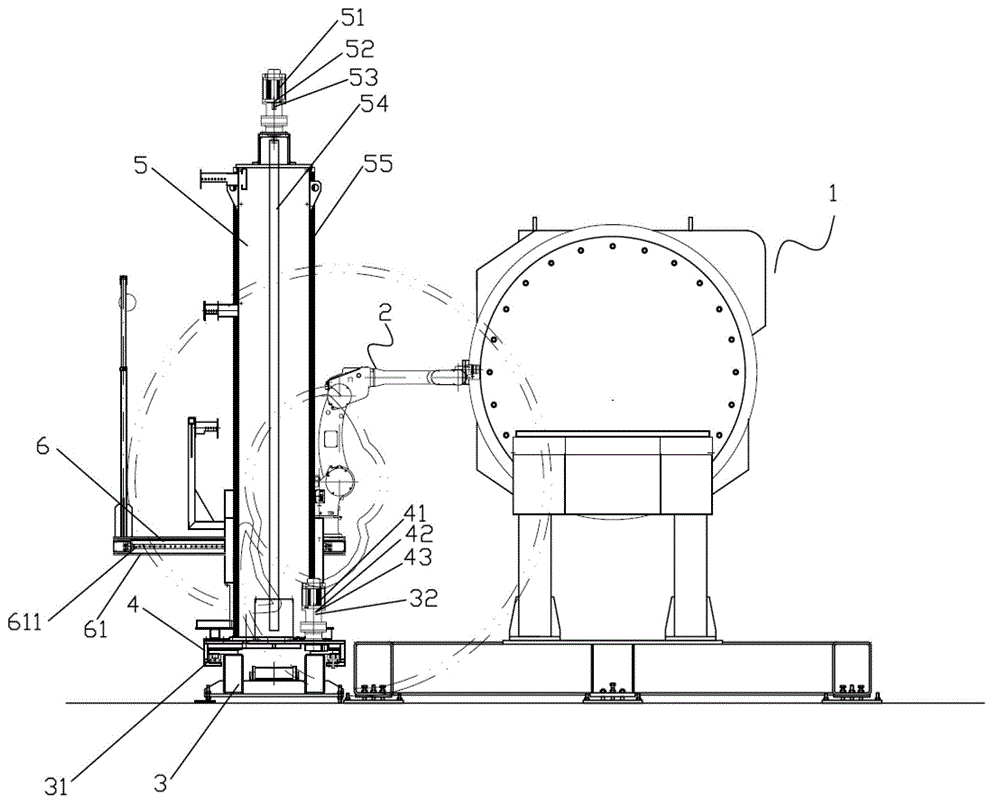

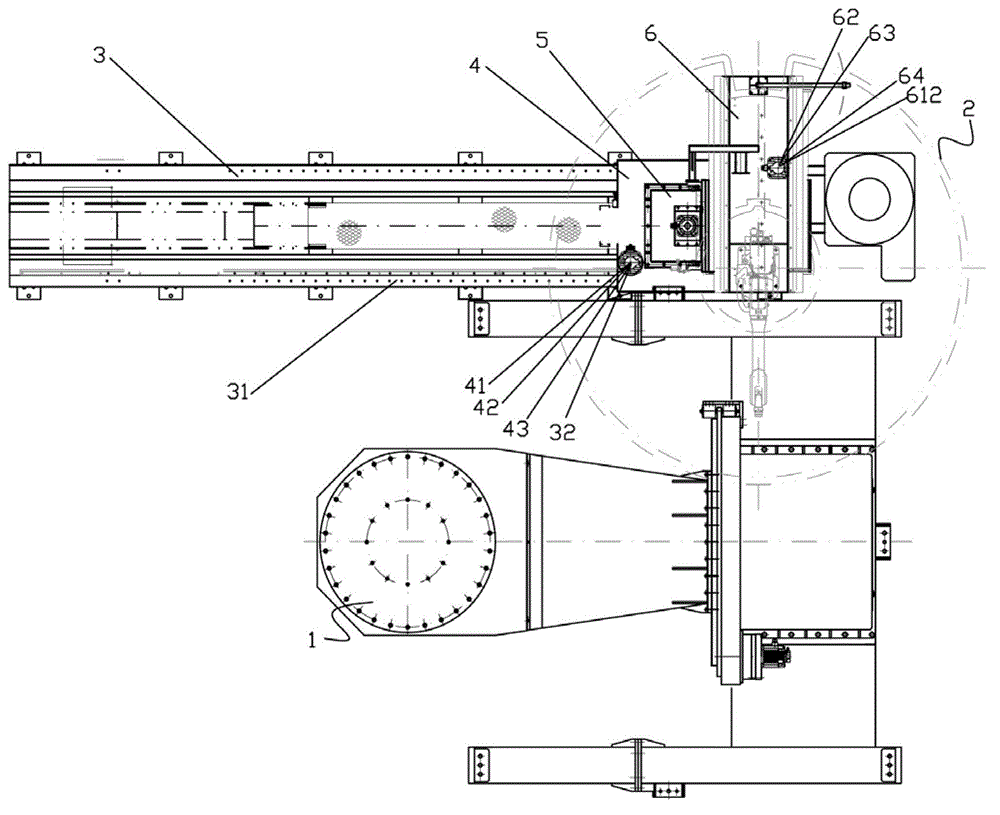

[0034] see figure 1 and 2 , a double-layer telescopic welding robot system, including a positioner 1 for flipping and / or rotating workpieces to be processed, a trolley body 3, a walking mechanism 4, a lifting mechanism 5, a double-layer telescopic mechanism 6, and a welding robot 2 and an automatic control circuit (not shown) for controlling the welding robot system to perform welding, wherein: the positioner 1 is arranged on one side of the traveling mechanism 4, and is arranged within the operating range of the welding robot; the traveling mechanism 4 is installed On the trolley body 3, the traveling mechanism 4 is set to move according to the needs of the welding position on the trolley body 3; The other end is connected to the welding robot 2, and the lifting mechanism 5 is set to make the double-layer telescopic mechanism 6 move up and down according to the needs of the welding position; the double-layer telescopic mechanism 6 is set to make the welding robot 2 stretch a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com