Steel pipe welding device for hardware machining and using method of steel pipe welding device

A technology for welding devices and steel pipes, applied in metal processing equipment, auxiliary devices, welding equipment, etc., can solve problems affecting efficiency, manual removal, and inconvenient processing of steel pipes, and achieve the effects of improving processing efficiency, processing convenience, and reducing limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

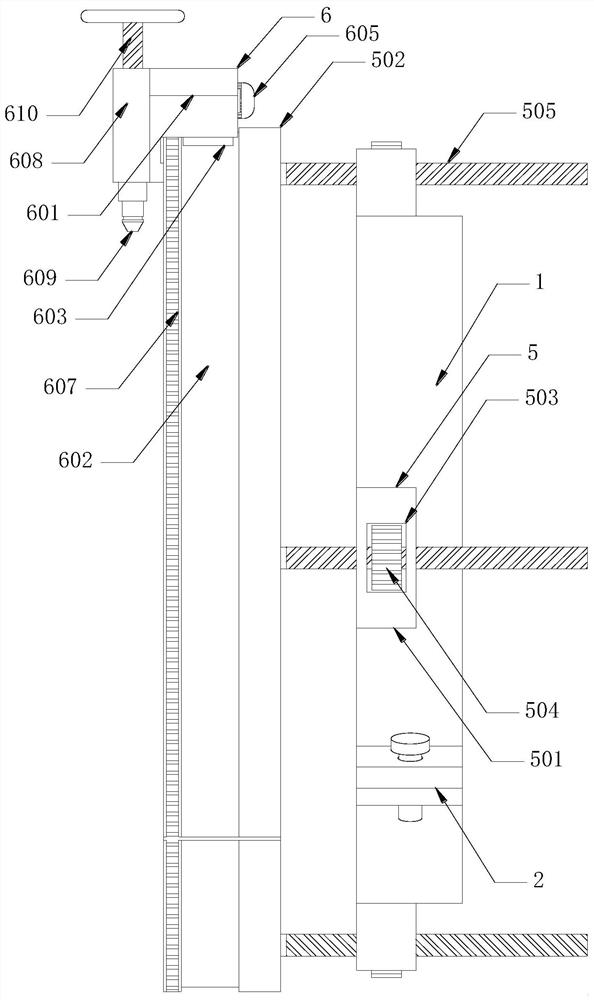

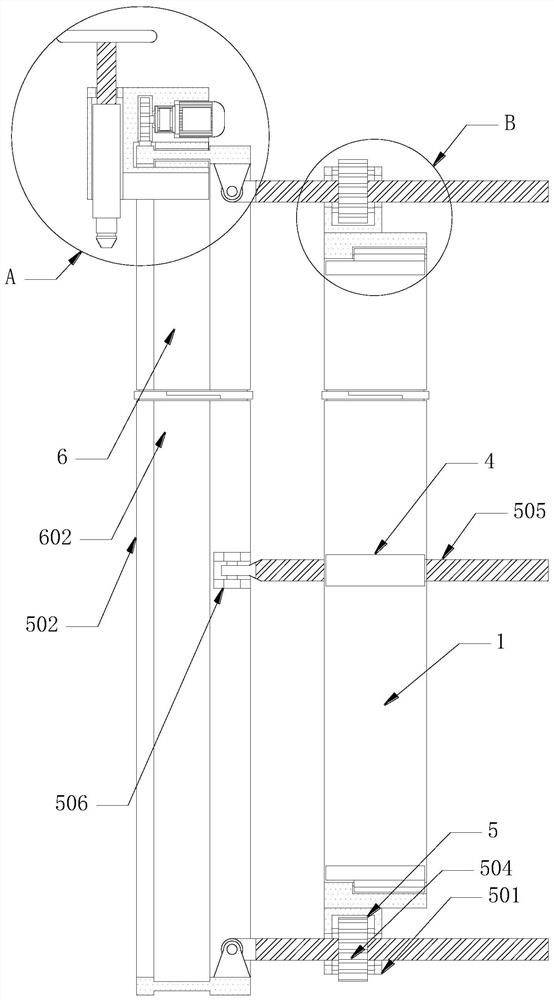

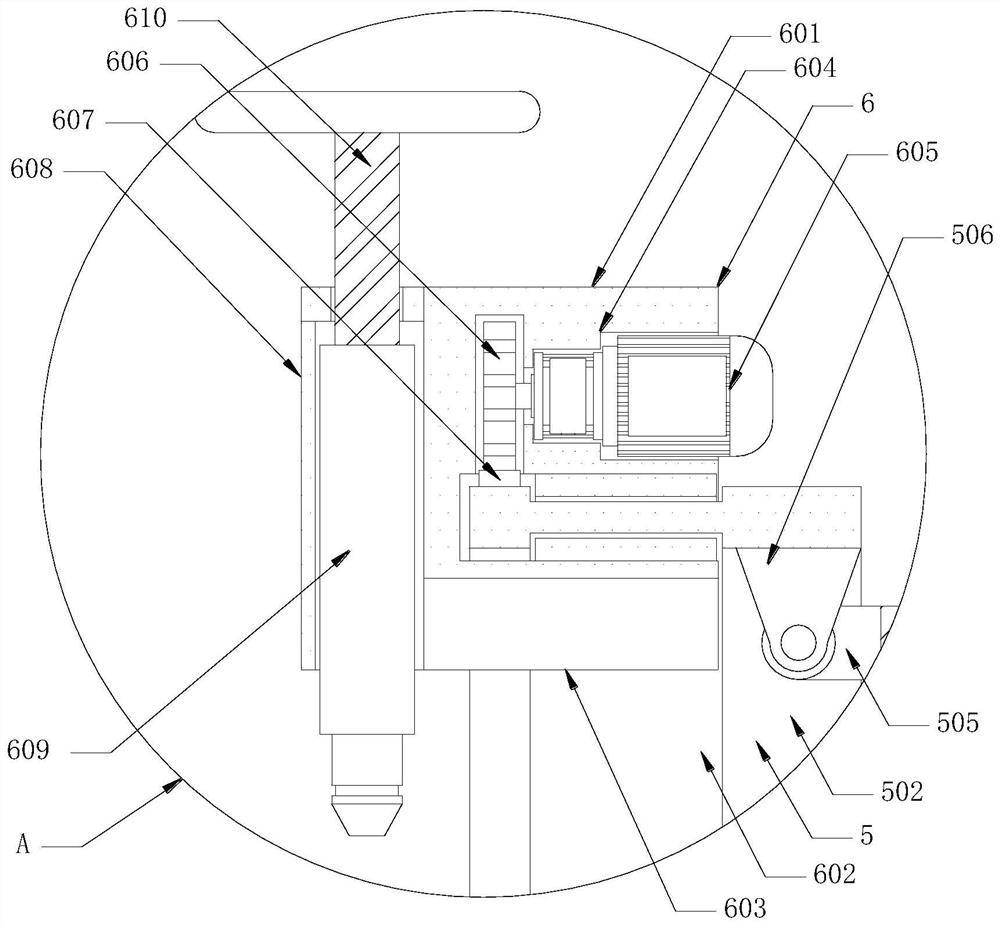

[0029] See Figure 1-5 However, a hardware-proof steel pipe welding device includes a semi-junan ring 1, two of the half-junan ring 1, and hinges each other with each other, and it is circularly constructed by hinge hinges. The front end of the two half-junan ring 1 is fixedly connected to the bolt buckle 2, and the inner side of the surface of the half-junction ring 1 is opened, and the inner card of the T-shaped groove 3 is connected to the working block 4, according to the diameter of the different steel pipes. The thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com