System and method for tracking weaving arc space weld based on MEMS (micro-electromechanical systems) sensor

A tracking system and sensor technology, used in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problem of space welding being difficult to achieve automation, and achieve the effect of expanding the welding range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

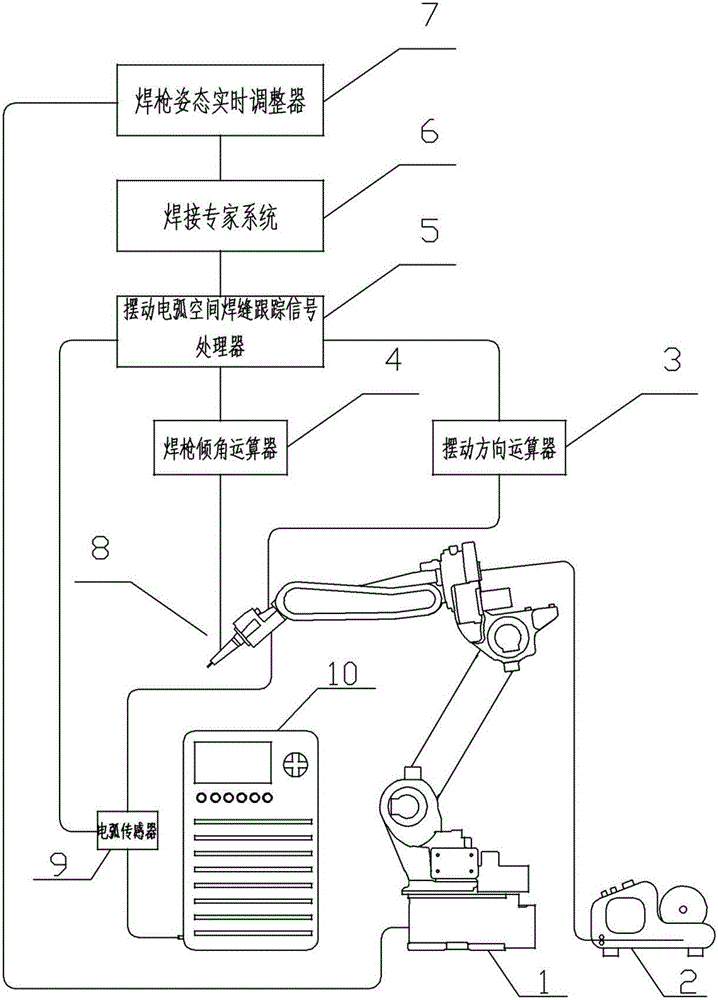

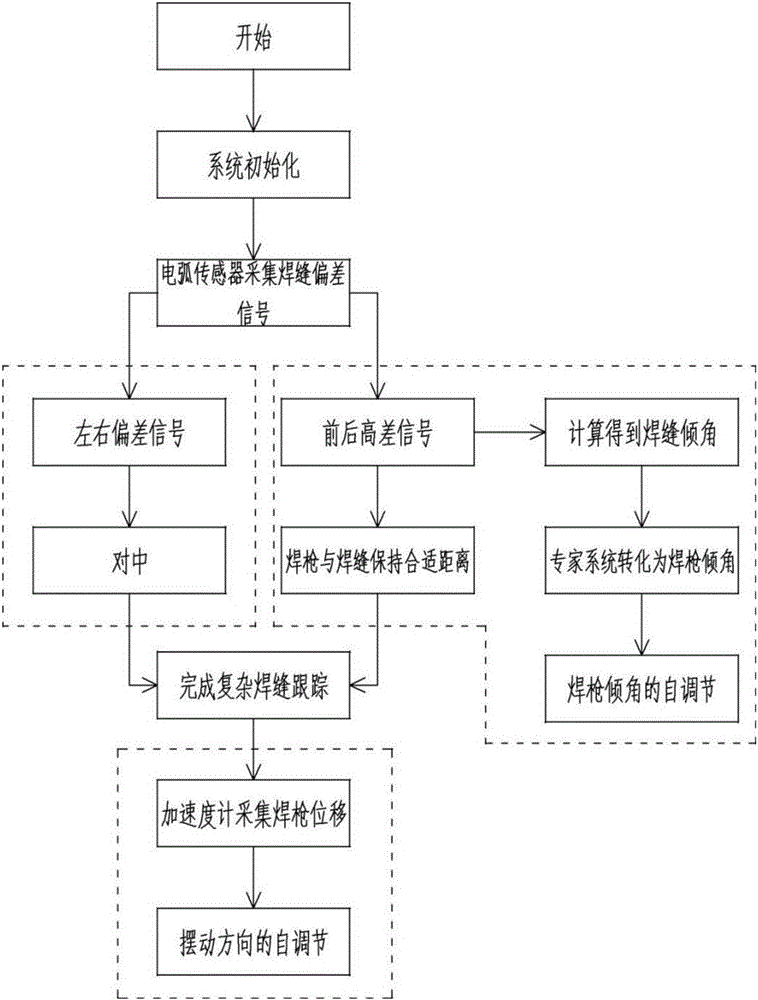

[0018] attached figure 1 Shown is the system hardware link diagram of the embodiment of the present invention, equipped with a manipulator 1, a wire feeder 2, a swing calculator 3, a welding torch inclination calculator 4, a swing arc space seam tracking signal processor 5, a welding expert system 6, Welding torch posture real-time adjuster 7, built-in MEMS sensor welding torch 8, arc sensor 9, welding power supply 10.

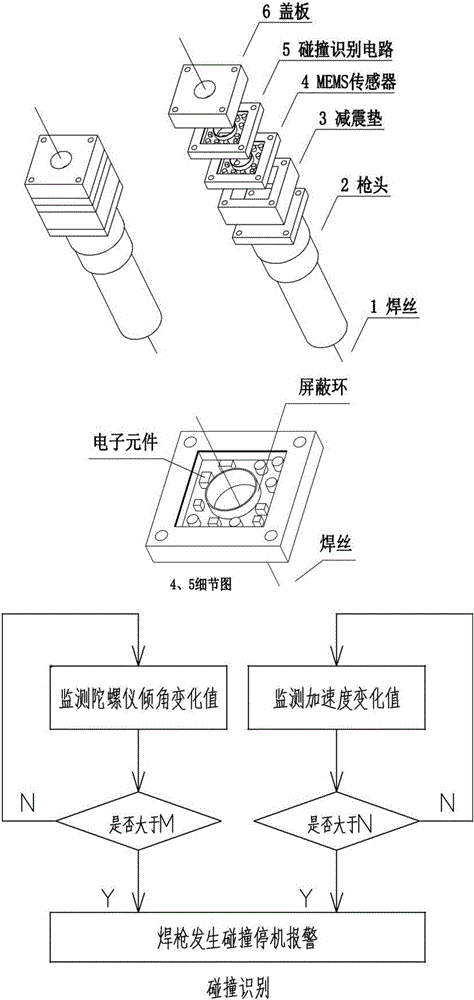

[0019] The built-in MEMS sensor welding torch 8 is a welding torch specially designed for this system, see attached figure 2 In addition to the torch head 2 and the cover plate 6, the welding torch also integrates a MEMS sensor 4 (gyroscope, accelerometer), a collision recognition circuit 5, and necessary shock-absorbing pads 3. For the welding robot, there is a defect that its body has anti-collision but the welding torch does not. The function of the collision identification circuit 5 is to identify abnormal collisions in the welding work and control the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com