Prediction method for quantitative deviation of additive manufacturing cladding layer

An additive manufacturing and prediction method technology, applied in prediction, neural learning method, biological neural network model, etc., can solve the problems of passive welding seam offset monitoring rarely reported, welding seam tracking rarely reported, etc., to solve the problem. Weld seam tracking problems, improved welding quality, and the effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

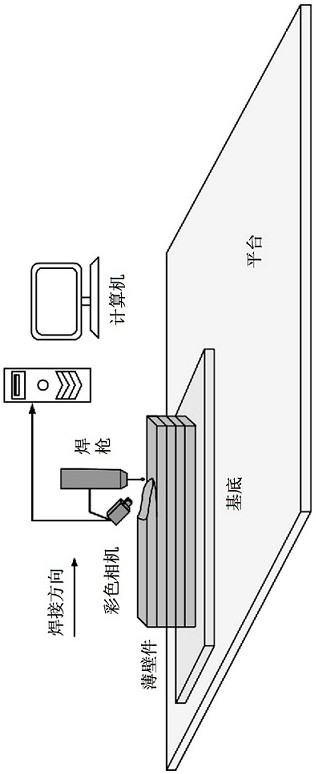

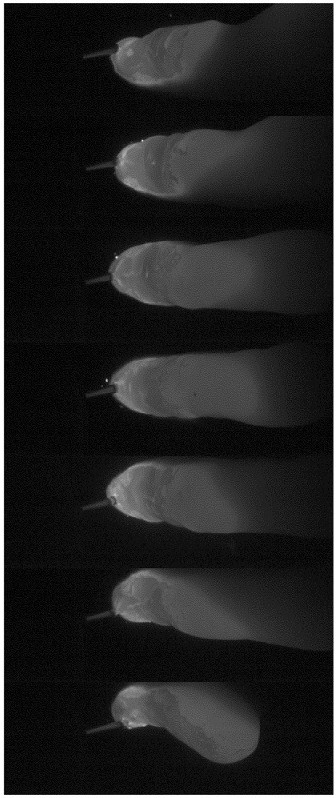

[0036] Such as figure 1 As shown, the equipment for monitoring the offset of the cladding layer during the arc additive manufacturing process consists of two parts: the welding system and the molten pool vision sensor system. The welding system consists of welding power supply, wire feeder and cooling system. The vision sensor system consists of a color CCD camera (Basler acA640-750uc) fixed on the robot at a 40° angle to the welding torch. The computer is at the heart of the molten pool visual sensing and prediction of cladding offset.

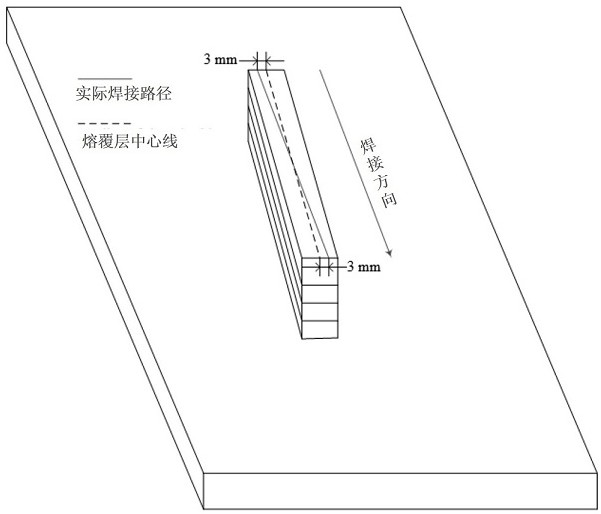

[0037] The method for quantitatively predicting the deviation of the additive manufacturing cladding layer of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com