Automatic assembling and welding device for heat pipe radiator machining

A heat pipe radiator and automatic assembly technology, which is applied in auxiliary devices, metal processing, welding equipment, etc., can solve problems such as time-consuming, laborious, troublesome, and affect welding work efficiency, and achieve the effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

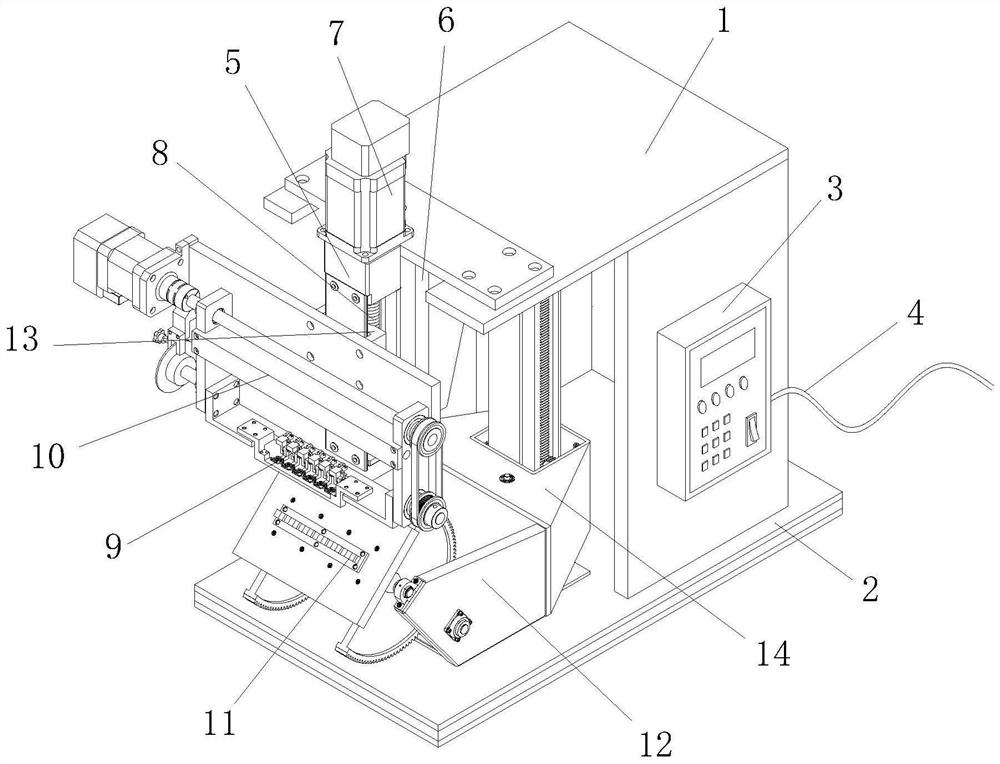

[0034] see figure 1 As shown, the present invention provides an automatic assembly and welding device for heat pipe radiator processing through improvement, including a cabinet 1, a support base 2, a control panel 3, a power cord 4, a frame 5, a fixed rear frame 6, a first Motor 7, screw mandrel 8, welding head 9, direction reversing device 10, welding base 11, angle adjustment mechanism 12, sliding block 13 and position adjustment mechanism 14, the supporting base 2 is installed on the bottom of cabinet 1, is used for supporting, and the right side The middle part is equipped with a control panel 3, which can be used to control the energized components of the device to work. The control panel 3 is connected with a power cord 4, which can be connected to an external power supply to provide power for the device. The rear side of the frame 5 is installed on the The front end of the chassis 1 and the top are equipped with a first motor 7, and a screw 8 is installed on the inside. T...

Embodiment 2

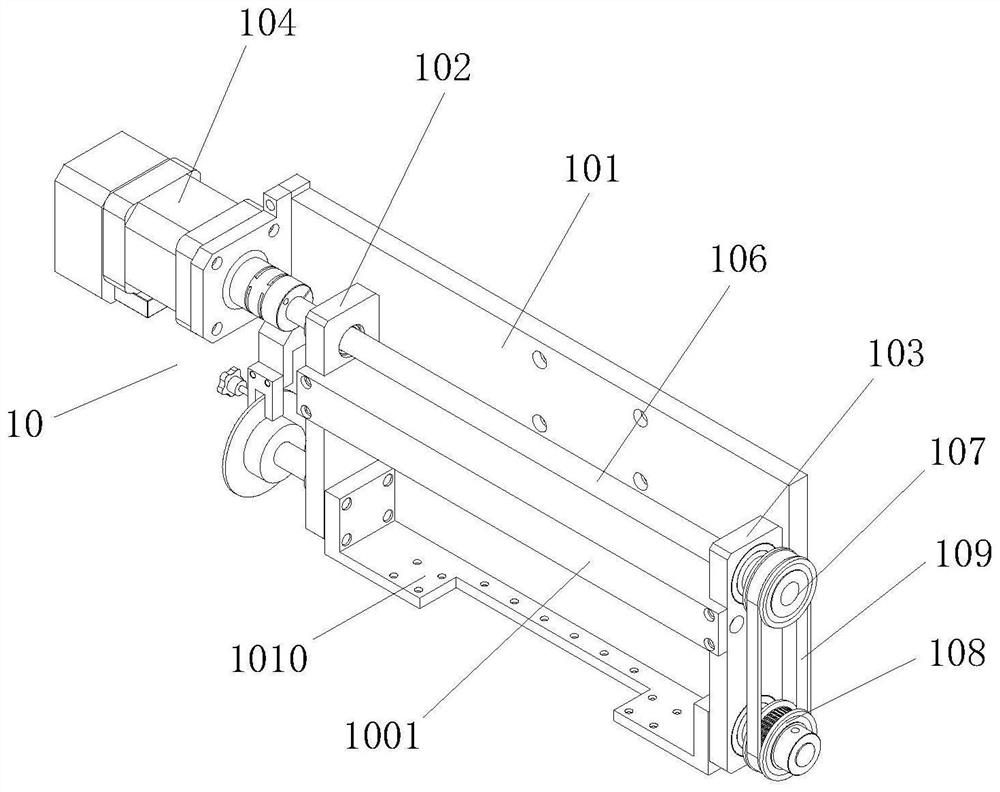

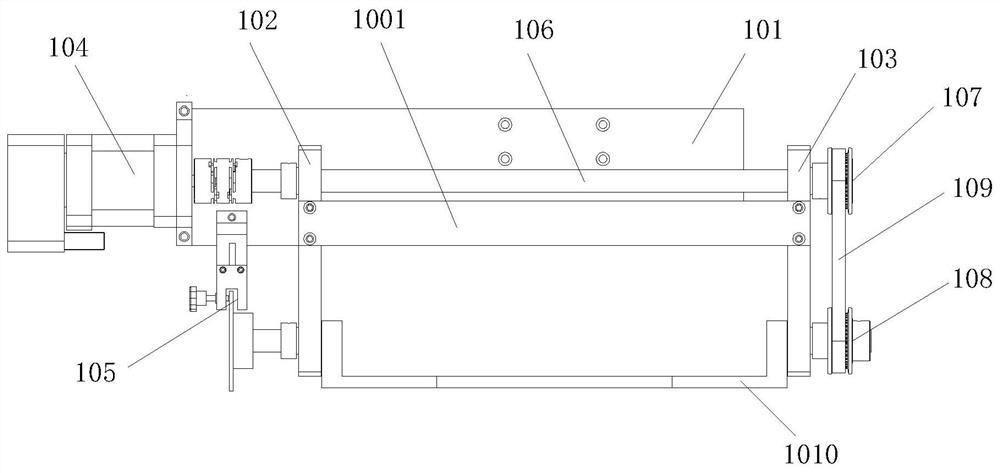

[0041] The present invention provides an automatic assembly and welding device for heat pipe radiator processing through improvement. The rear end of the stop mechanism 105 is fixed to the mounting plate 101, and the stop mechanism 105 can be fixed through the mounting plate 101 to ensure its stability. , the output shaft of the second motor 104 is connected to one end of the first rotating shaft 106 through a shaft coupling, so that after the second motor 104 works, the rotation of the output shaft can drive the first rotating shaft 106 to rotate through the transmission of the shaft coupling, The first runner 107 and the second runner 108 are arranged on the right side of the right vertical plate 103, which facilitates the transmission work of the first runner 107 and the second runner 108. The longitudinal bevel gear 148 and the transverse bevel gear 146 are perpendicular to each other. Mesh, make the 4th electric motor 143 work and drive the 2nd rotation shaft 145 to rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com