Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

160results about How to "Increase feeding rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cutting device for mechanical automatic production of spare and accessory parts

ActiveCN109227663APlay a limiting roleSwipe up and down smoothlyMetal working apparatusEngineeringOperation safety

The invention discloses a cutting device for mechanical automatic production of spare and accessory parts, which includes a feeding mechanism, a cutting mechanism and an unloading mechanism, wherein the feeding mechanism includes a feeding table and a pushing mechanism and the cutting mechanism includes a cutting table and a cutting head group. Gate components are arranged on both sides of the cutting table, a supporting plate is arranged under the cutting table, and lifter columns are evenly arranged between the supporting plate and the cutting table. The cutting table comprises a supportingbracket and a lifting table. A longitudinal chute and a transverse chute are arranged on the top face of lifting table. The longitudinal chute includes a left longitudinal chute and a right longitudinal chute, wherein a left spacing splint is arranged in the longitudinal chute and a right spacing splint is arranged in the right longitudinal chute, and the transverse chute is communicated with theleft longitudinal chute. The overall structure of the cutting device for mechanical automatic production of spare and accessory parts is ingenious and reasonable. The automatic operation is achieved by the design of the feeding mechanism and the unloading mechanism which can feed and unload workpieces automatically, thereby reducing the labor intensity and hidden safety hazard, improving the operation safety performance and the cutting speed.

Owner:柳州蒸达机械配件有限公司

High-speed cold rolled steel strip uncoiling automatic guiding and feeding device

ActiveCN110026434ASmooth transmissionQuick changeMetal working apparatusMetal rolling arrangementsEngineeringMechanical engineering

The invention discloses a high-speed cold rolled steel strip uncoiling automatic guiding and feeding device, and particularly relates to the technical field of cold rolling equipment. The high-speed cold rolled steel strip uncoiling automatic guiding and feeding device comprises a base, the two sides of the top of the base are provided with adjusting plates, a conveying belt is arranged between the two adjusting plates, first electric push rods are fixedly arranged on the surface of the conveying belt, the end portions of the first electric push rods are fixedly connected with vacuum chucks, one sides of the first electric push rods are fixedly provided with vacuumizing pumps, the vacuum chucks and the vacuumizing pumps communicate with each other through connecting pipes, and an infrareddetector is fixedly arranged on the inner side of one of adjusting plates. According to the high-speed cold rolled steel strip uncoiling automatic guiding and feeding device, the first electric push rods connected with the vacuum chucks are arranged on the surface of the conveying belt, and the position change of the first electric push rods is monitored in real time through the infrared detector,so that the working states of the vacuumizing pumps on one sides of the two adjacent first electric push rods are controlled so as to ensure stable conveying of a steel strip.

Owner:广东宝盛兴实业有限公司

Exopalaemon carinicauda feed

InactiveCN102511674AImprove palatabilityIncrease feeding rateAnimal feeding stuffPeanut mealPollution

The invention discloses an exopalaemon carinicauda feed, which comprises 32 to 36 percent of crude protein, 4 to 6 percent of crude fat, 1 percent of total phosphorus of which total energy content is 3.0 to 3.3MJ / kg, and 1.5 percent of lysine. The feed comprises the following accessories in part by weight: 50 to 300 parts of fish meal, 100 to 300 parts of bean pulp of which content is more than 46 percent, 50 to 150 parts of peanut meal, 50 to 100 parts of rapeseed meal, 50 to 100 parts of cotton seed meal, 20 to 40 parts of cuttlefish paste, 20 to 40 parts of shrimp shell meal, 200 to 250 parts of high protein flour, 10 to 25 parts of fish oil, 10 to 25 parts of phospholipid oil, 10 to 25 parts of bentonite, 1 part of shell removing element, 5 parts of vitamin premix, and 10 parts of mineral premix. The exopalaemon carinicauda feed changes the conventional breeding mode using wheat and fresh iced fish, can remarkably improve the breeding benefits, and has low labor intensity and low pollution to water.

Owner:SUZHOU TONGWEI SPECIAL FEED

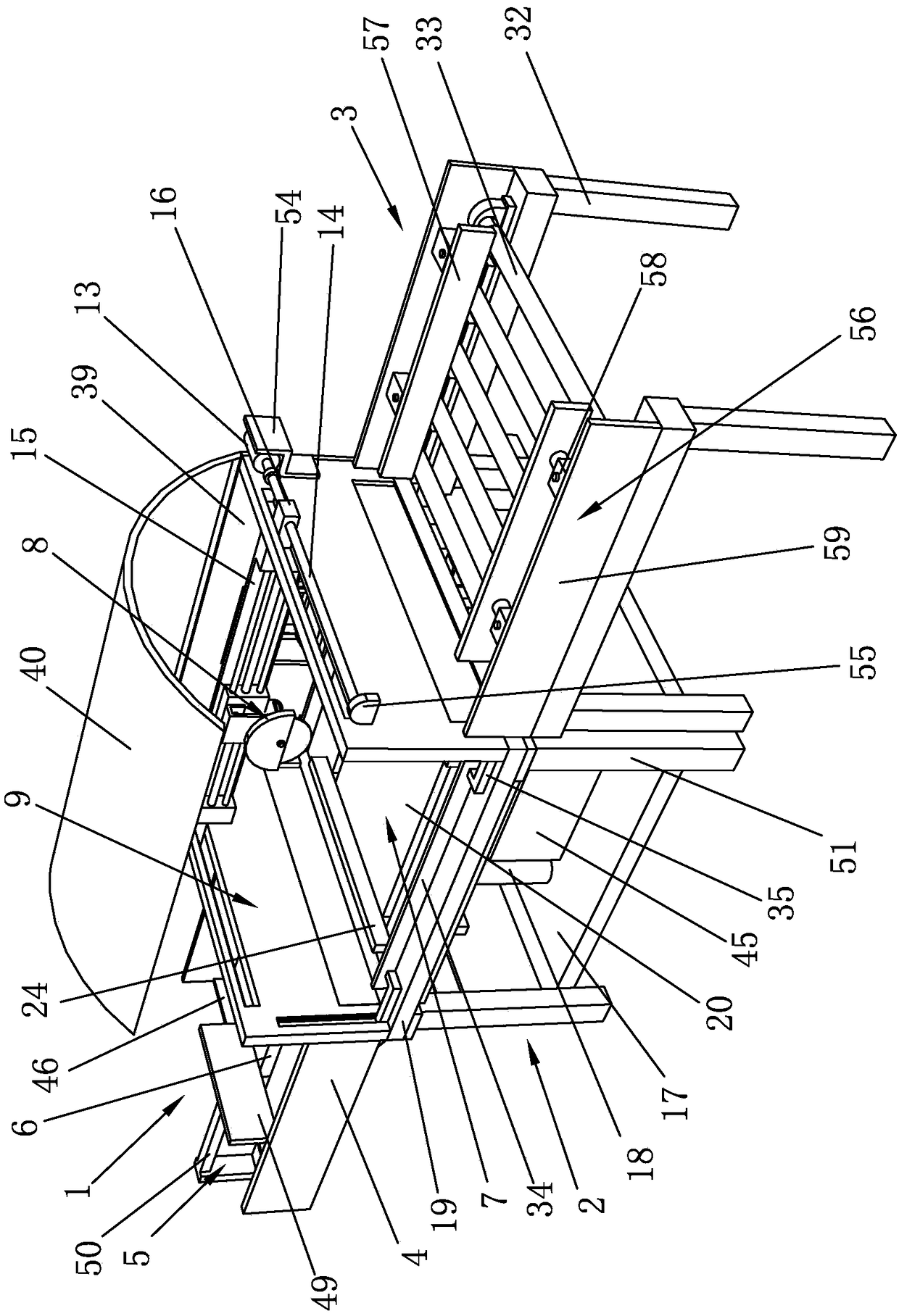

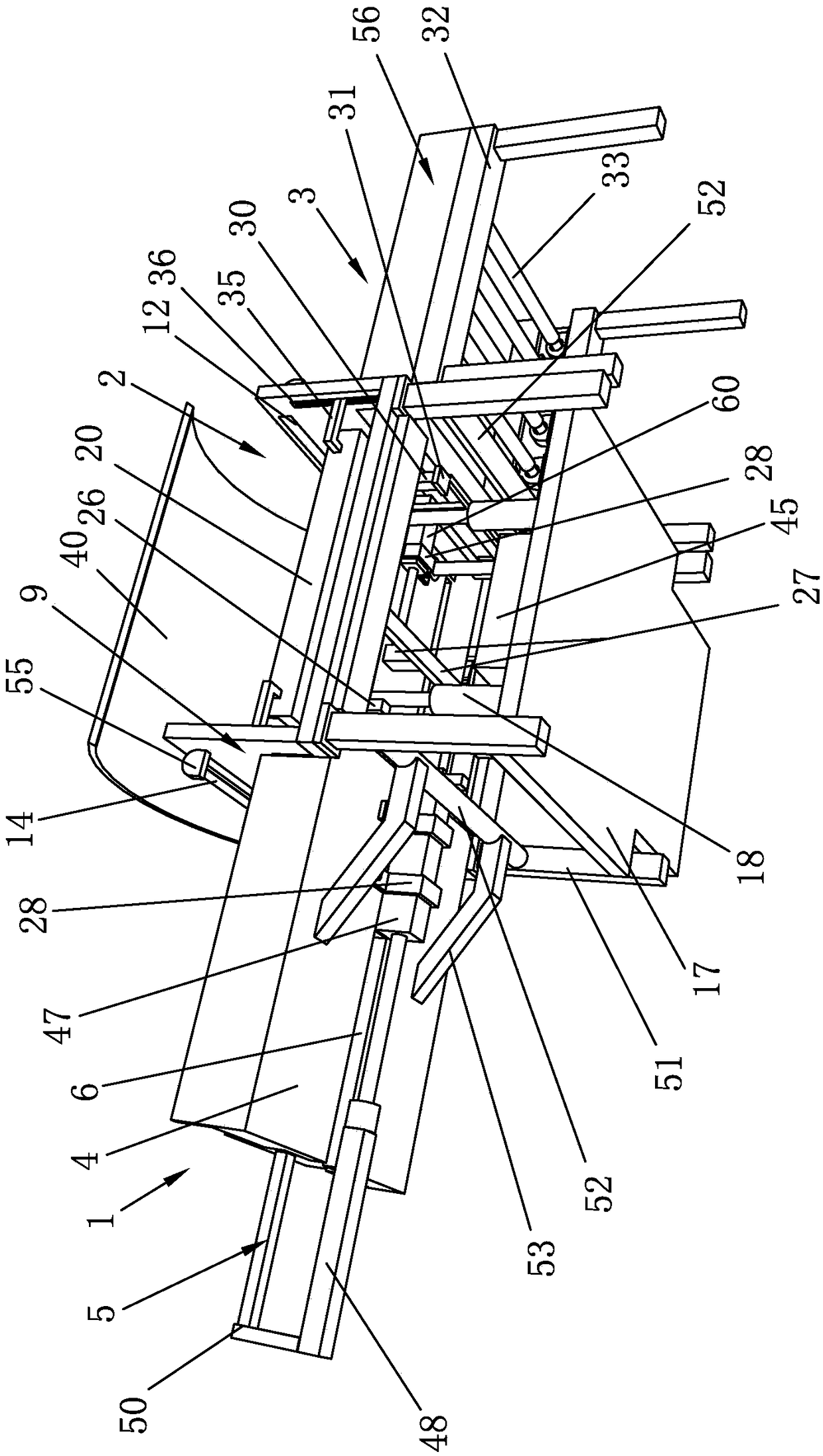

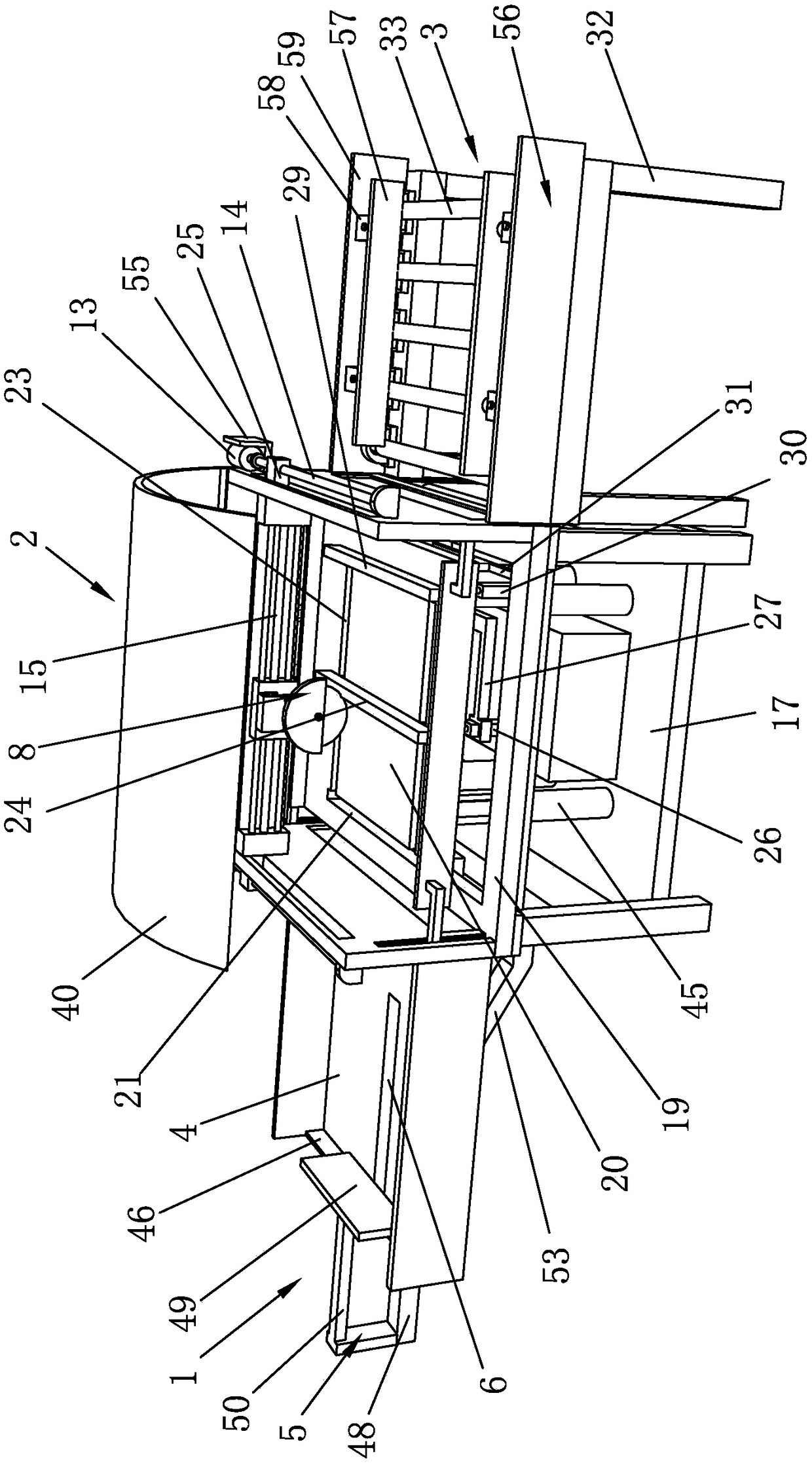

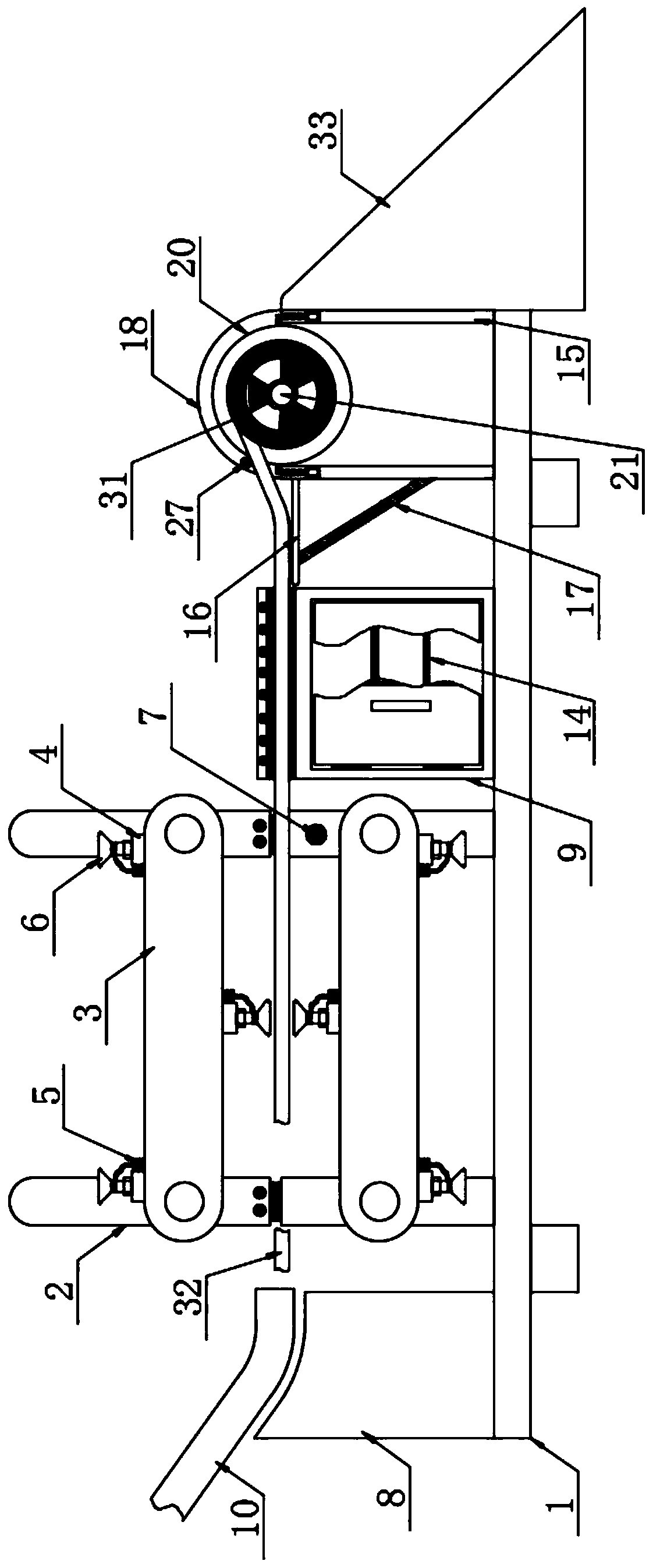

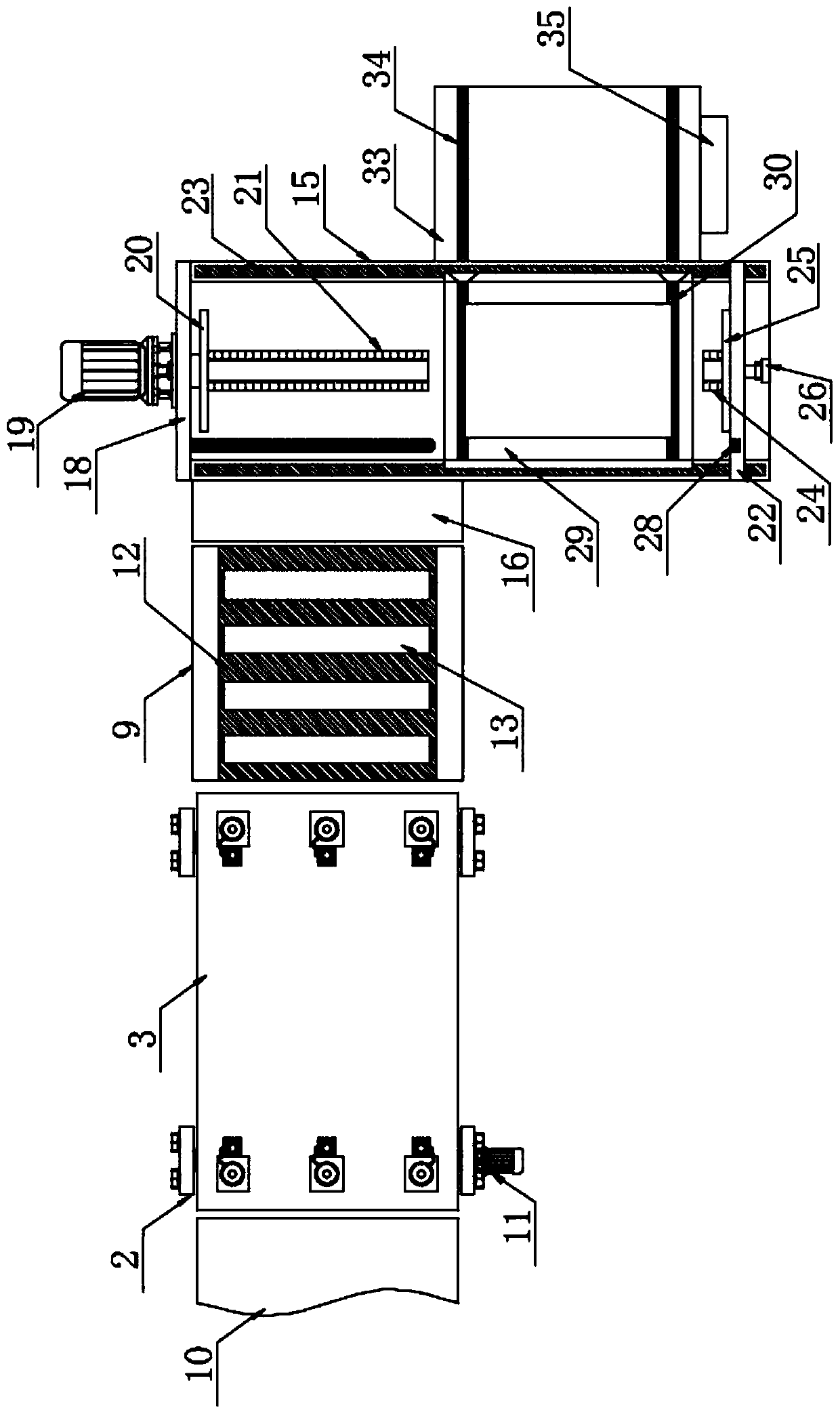

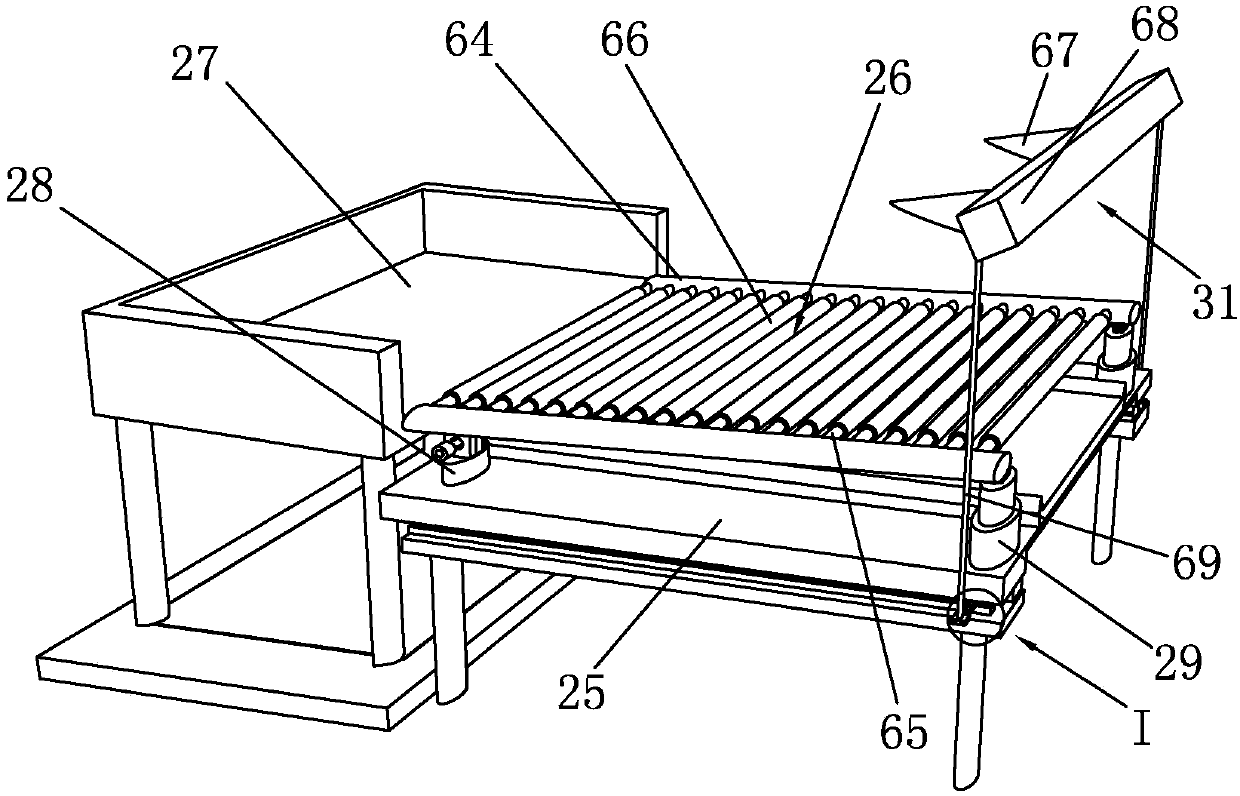

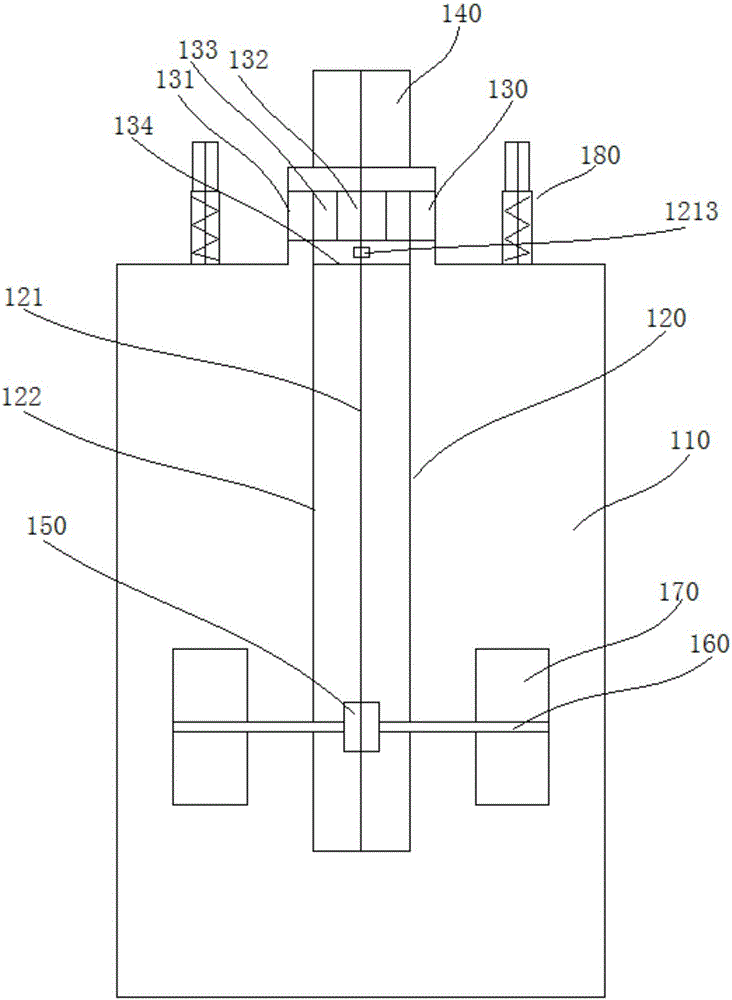

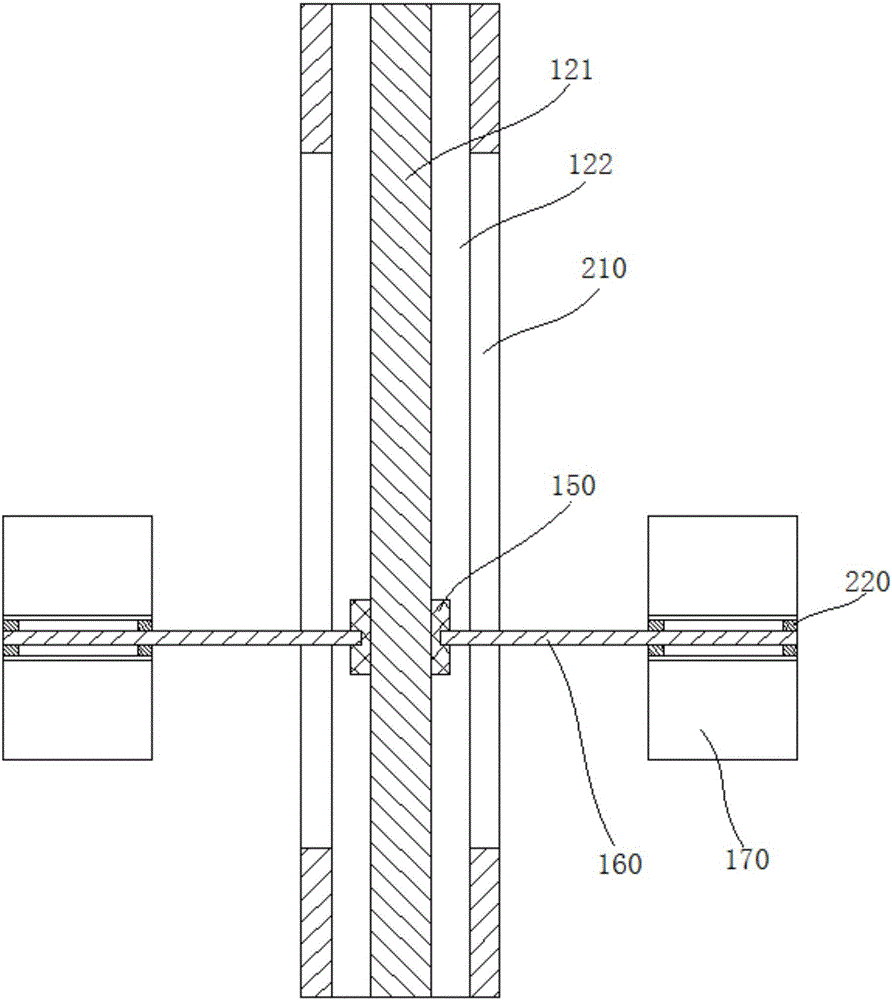

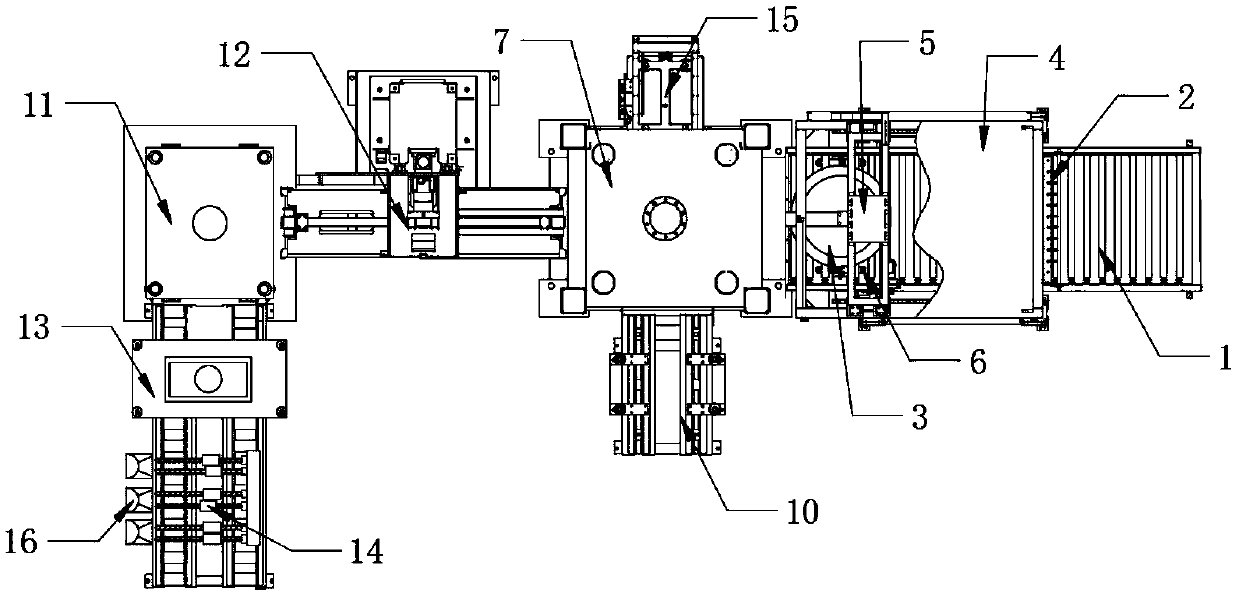

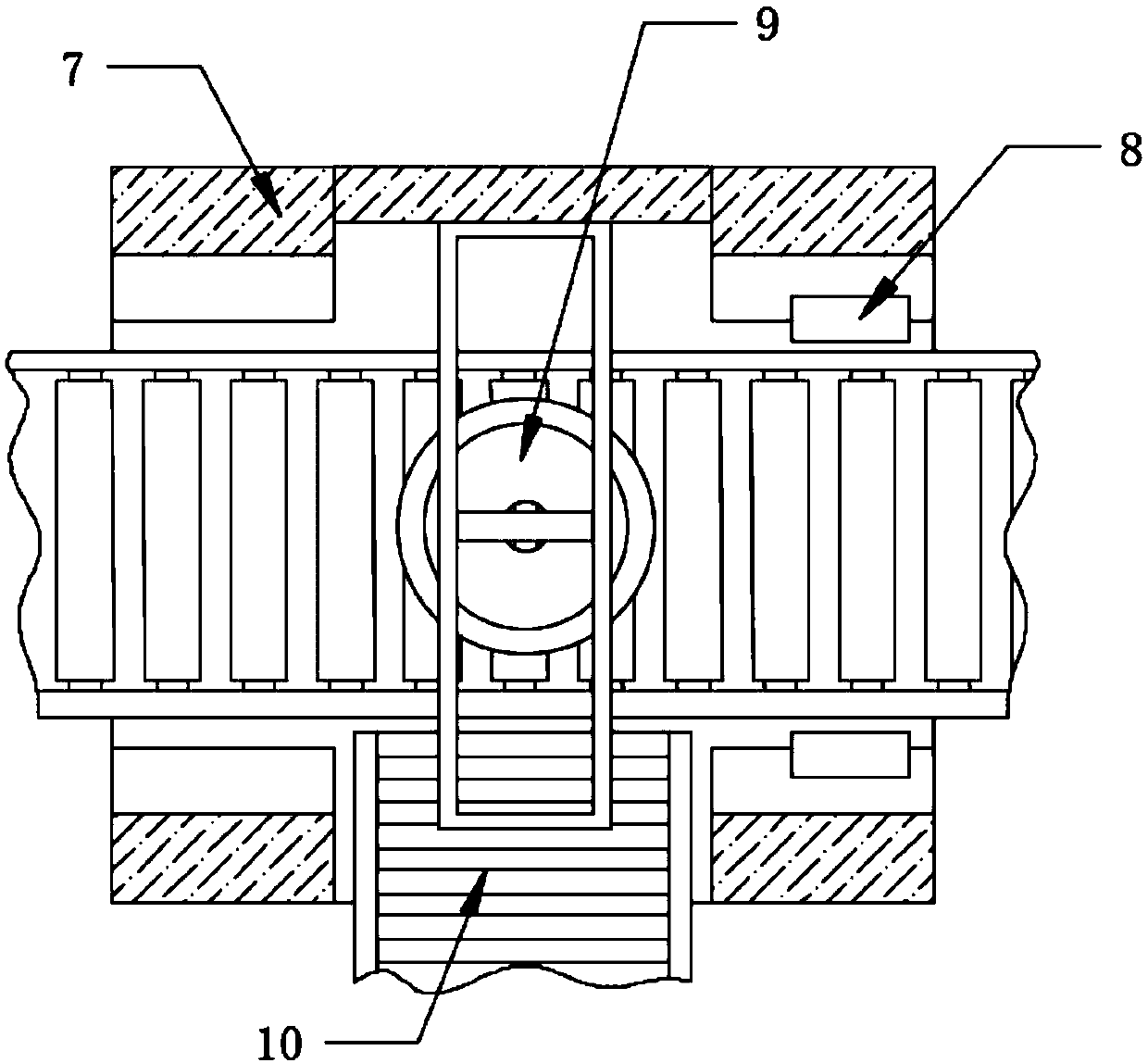

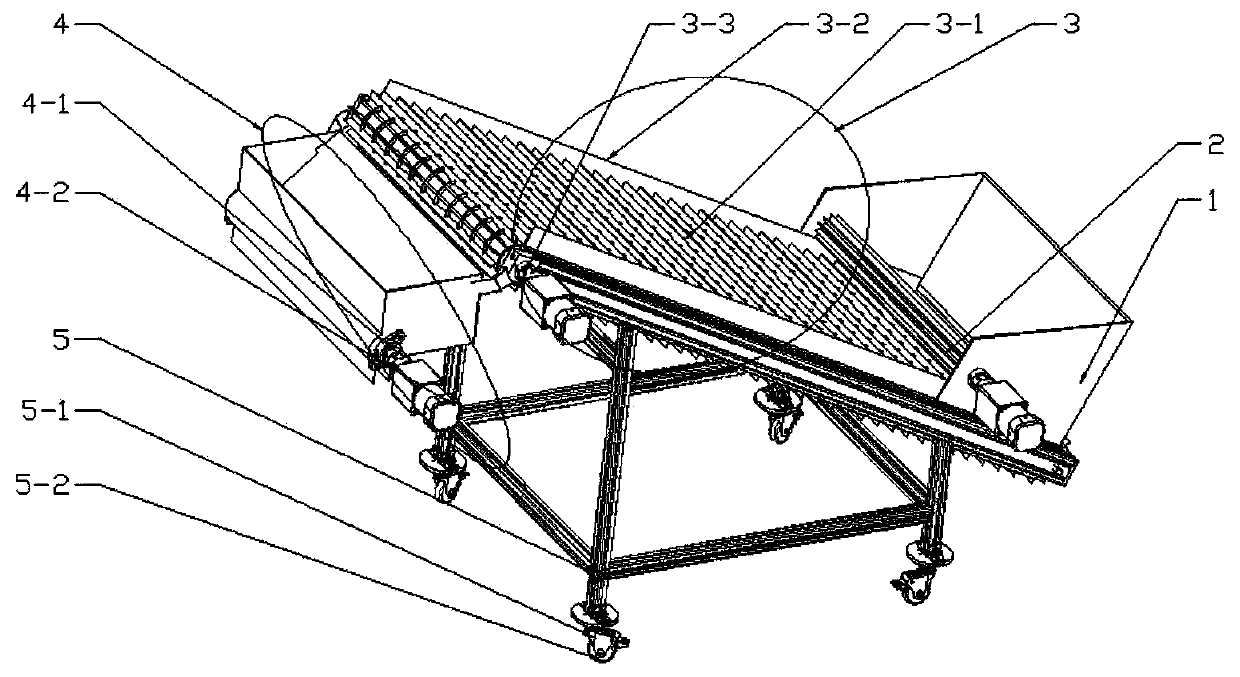

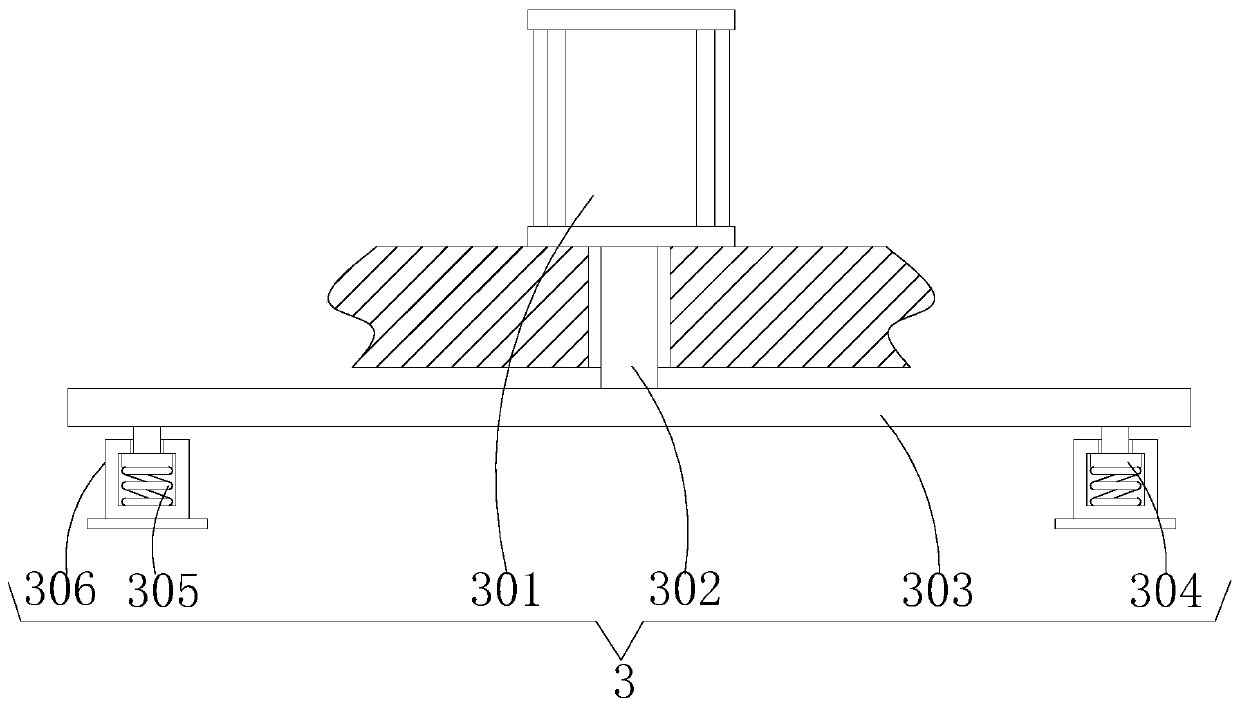

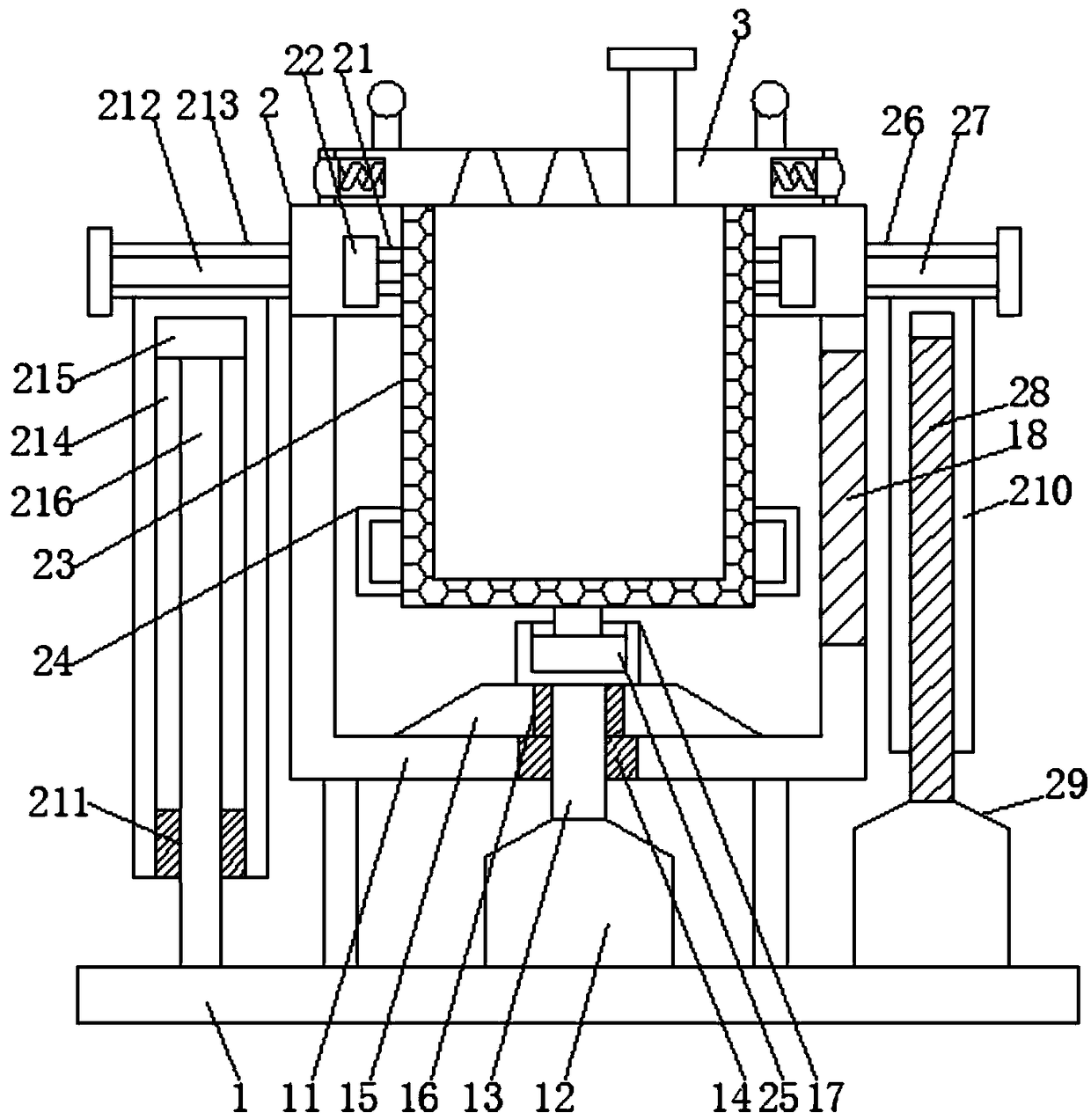

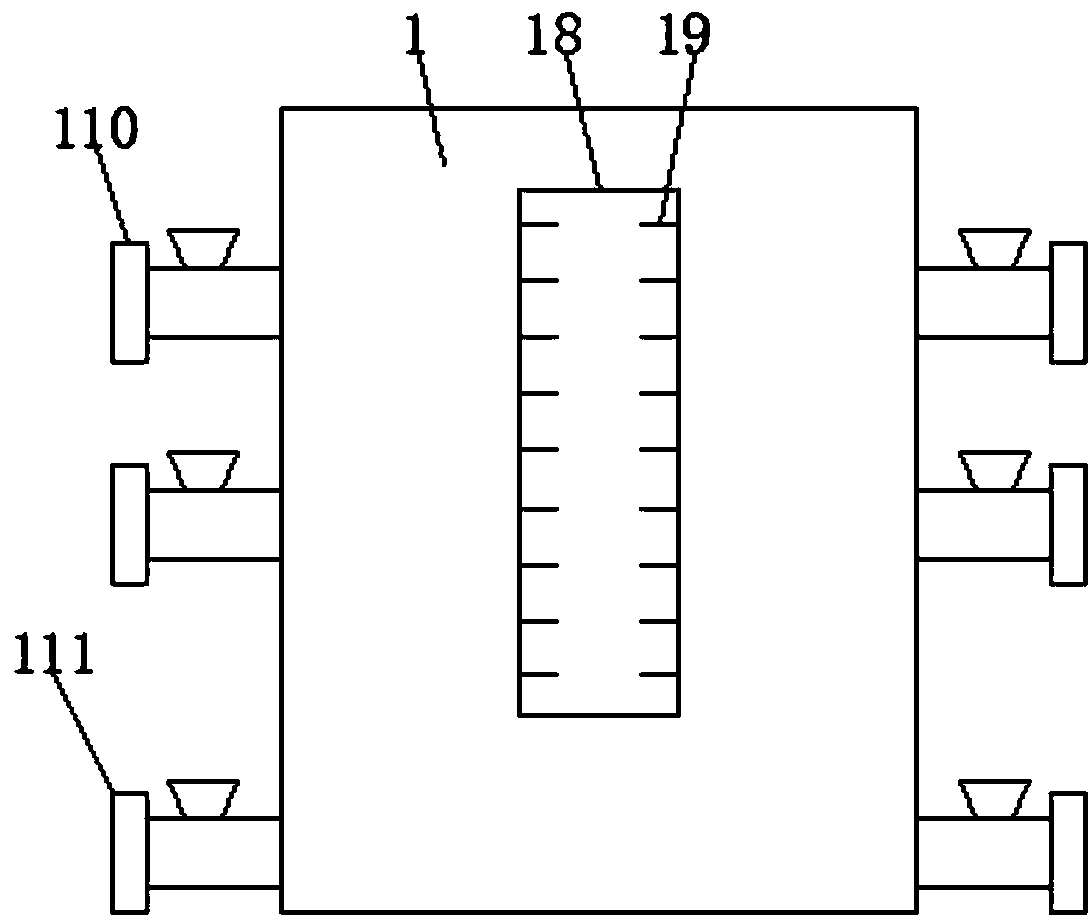

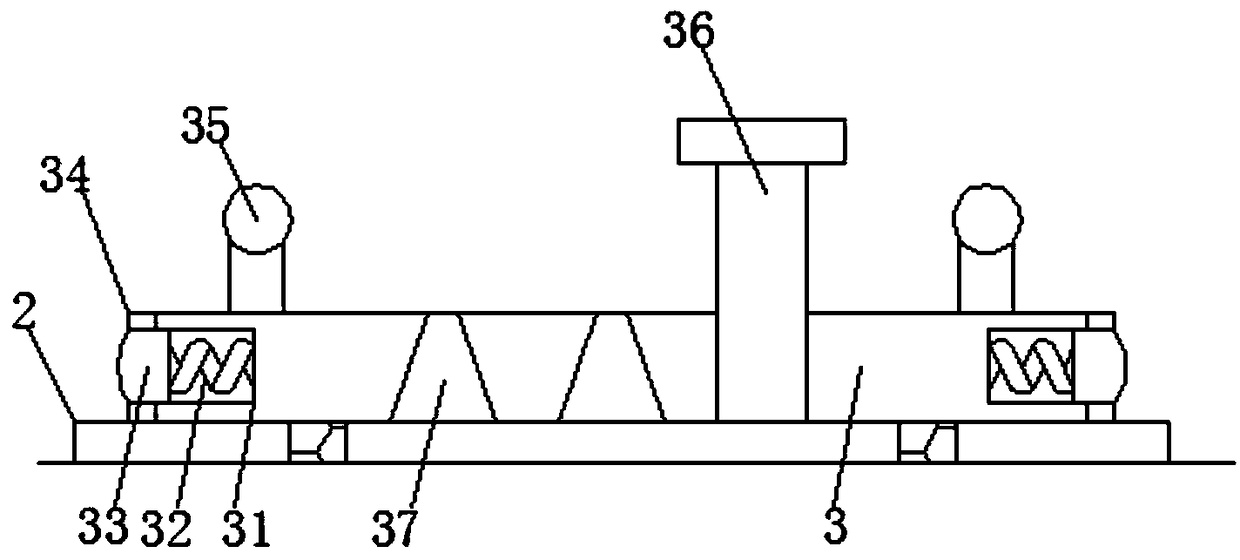

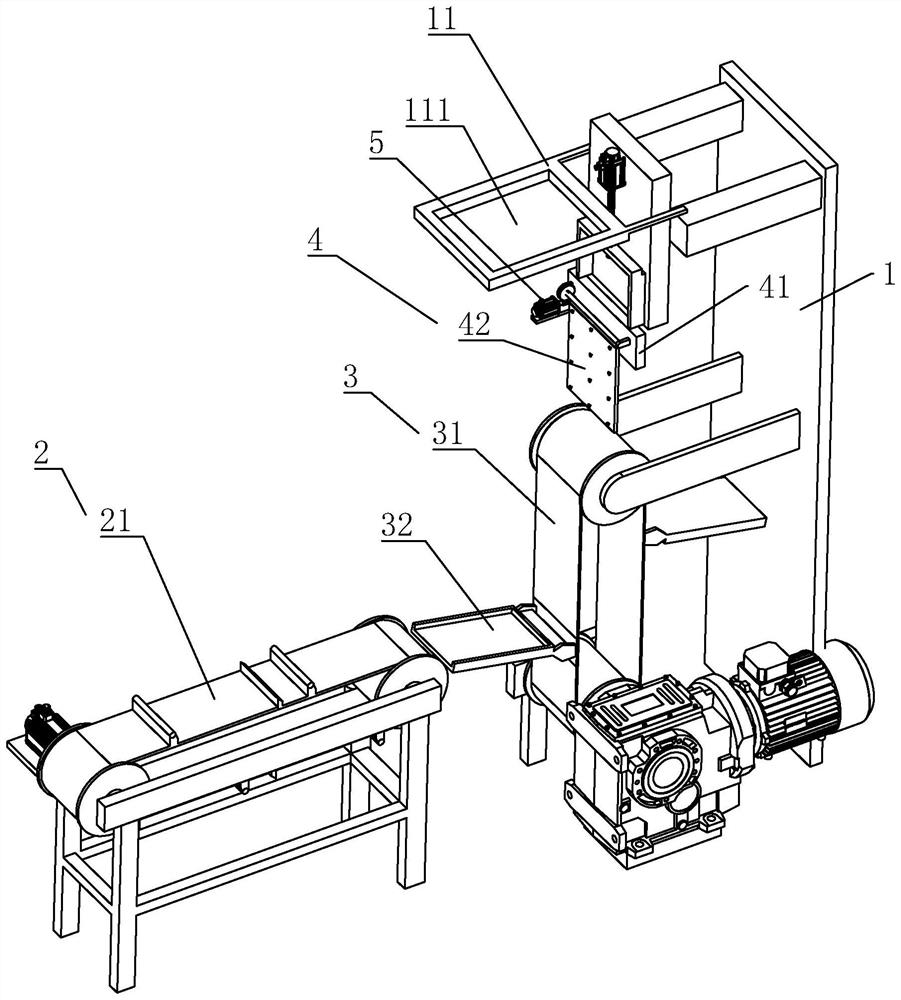

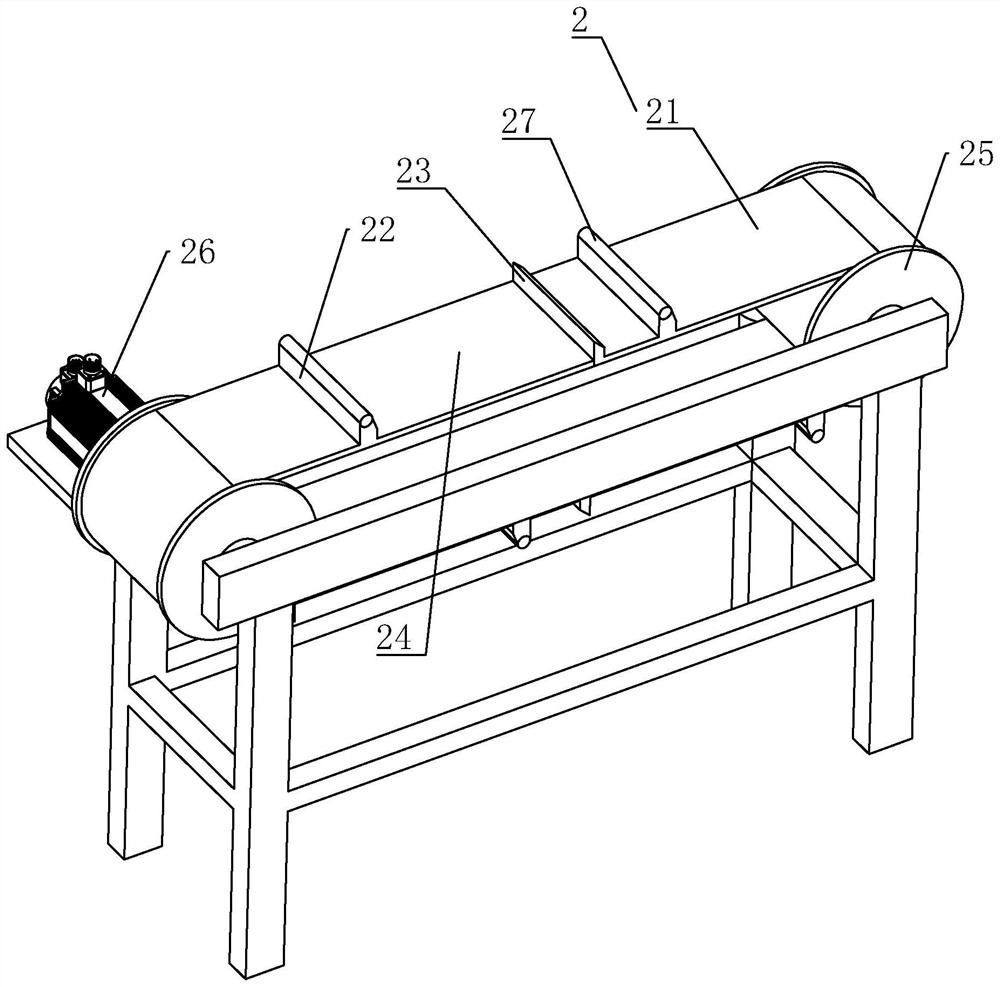

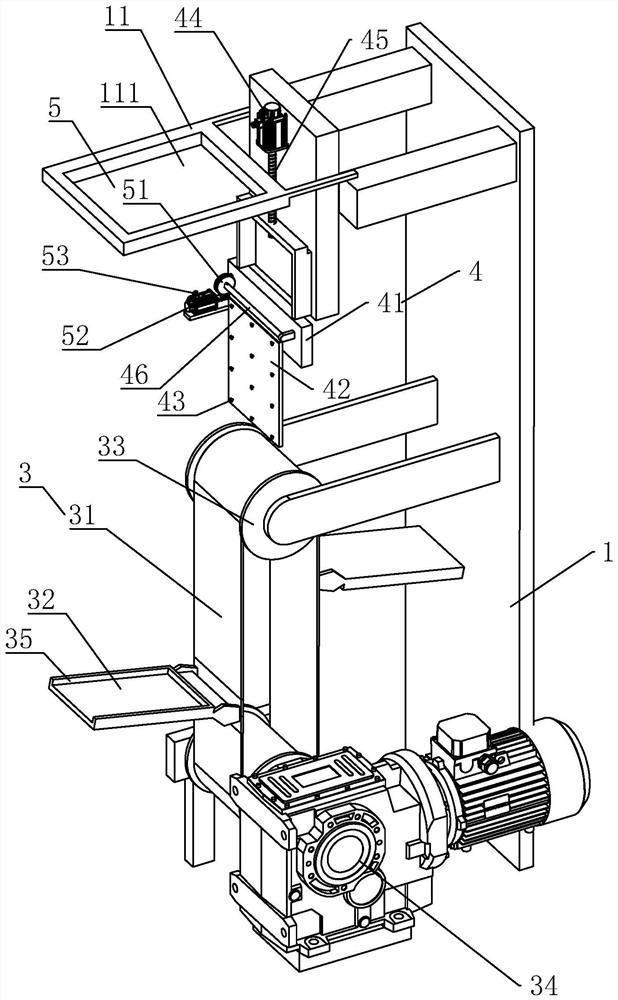

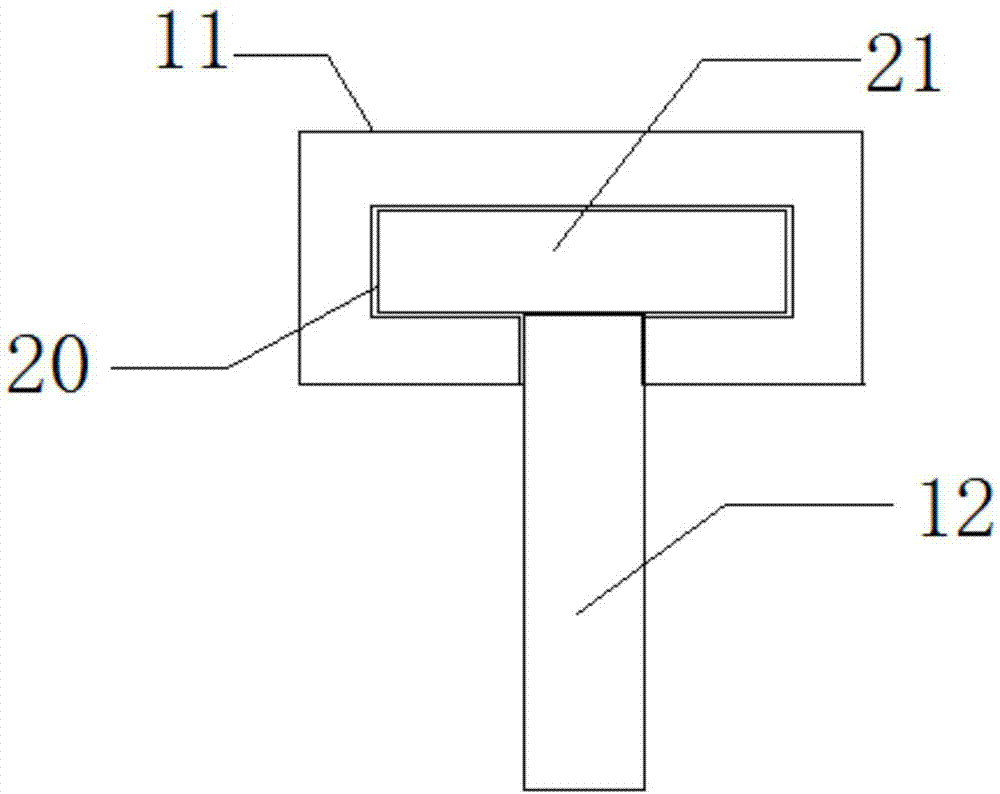

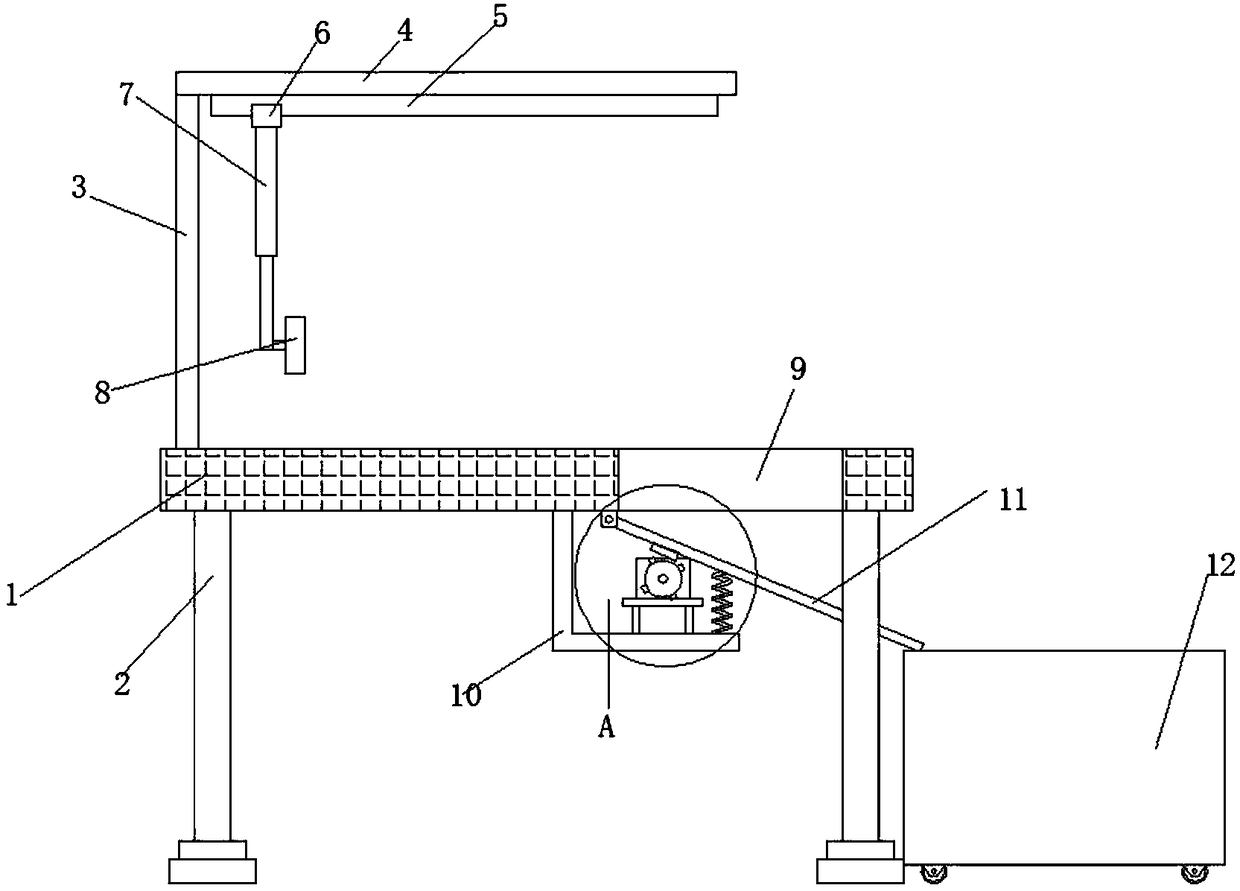

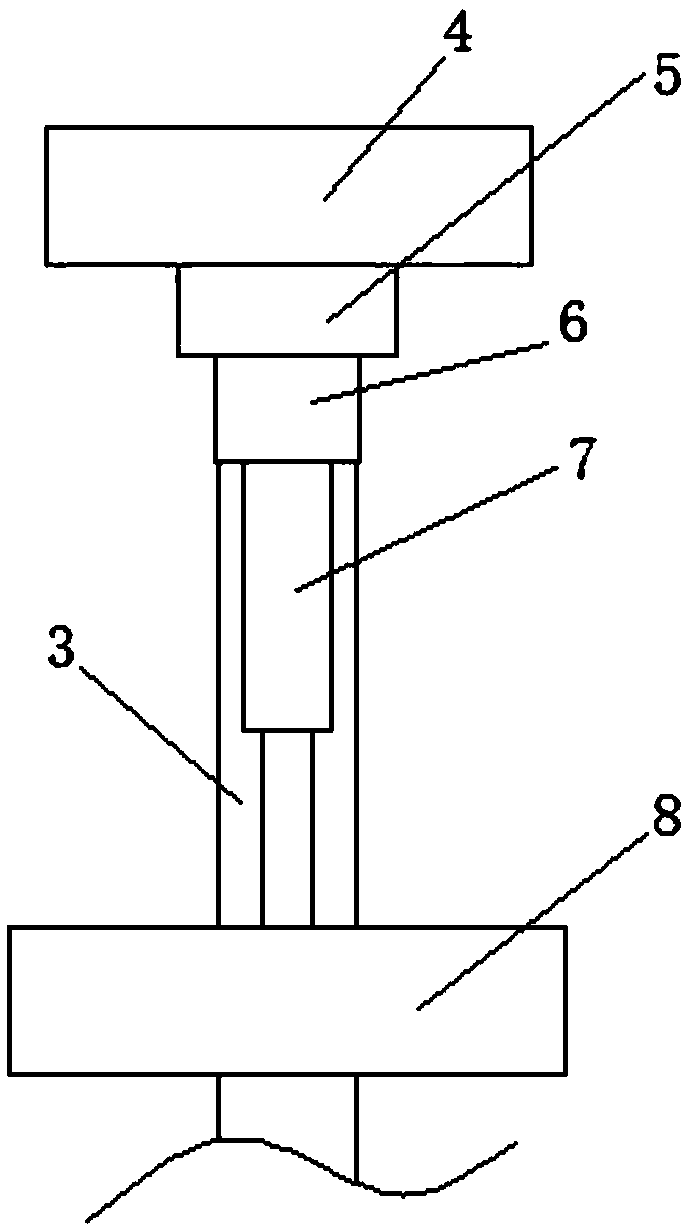

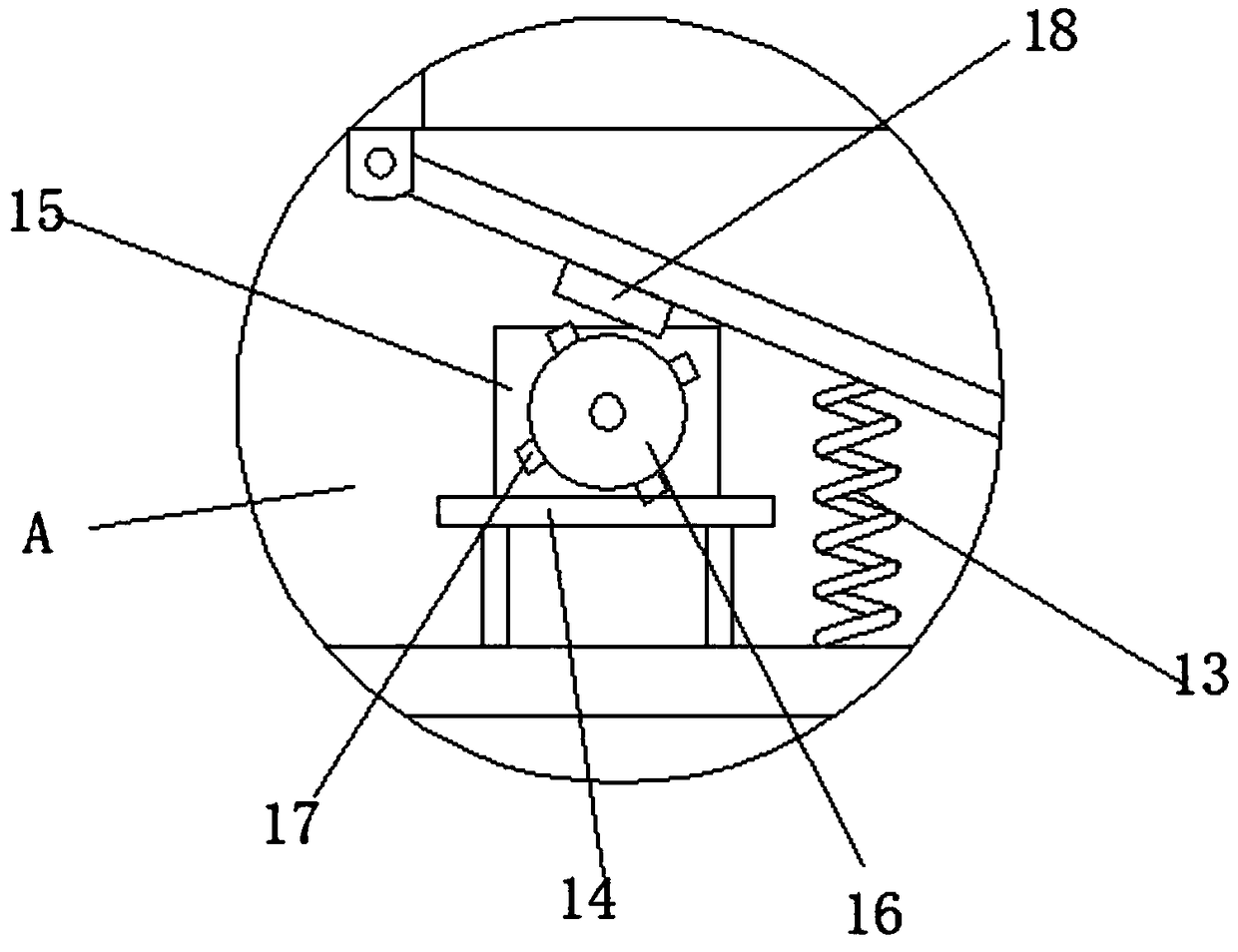

Linear flame welding machine and welding method thereof

ActiveCN107717171AEasy to handleIncrease feeding rateGas flame welding apparatusOperation safetyOperations security

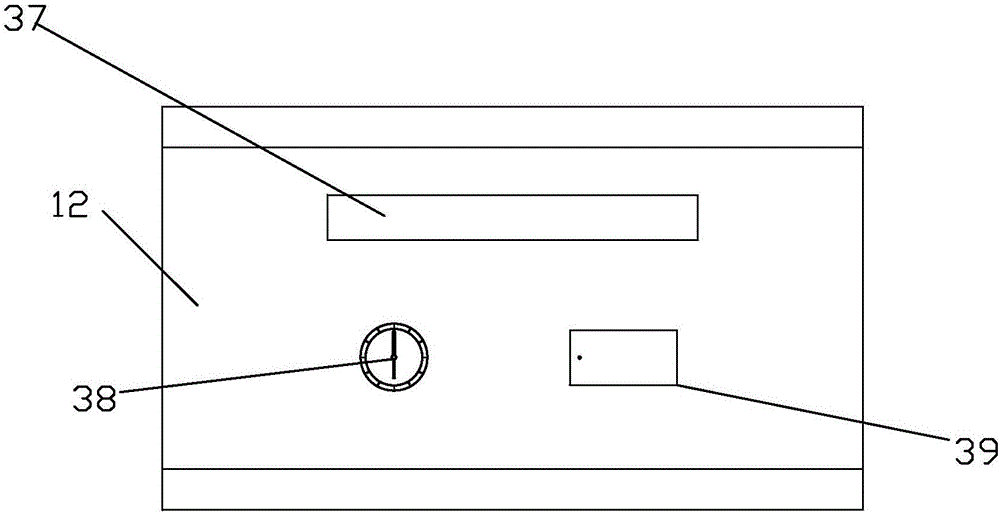

The invention discloses a linear flame welding machine. The linear flame welding machine comprises a feeding mechanism, a welding mechanism and a discharging mechanism; the feeding mechanism comprisesa feeding table, a storing table and a pushing device; the welding mechanism comprises a welding room supporting frame and welding assemblies; each welding assembly comprises a welding head set, a longitudinal adjusting assembly and a transverse adjusting assembly; and the discharging mechanism comprises a discharging table, a material conveying device and a material table. A welding method comprises the following steps of (1) feeding of welded workpieces; (2) adjustment of the height of the welding assemblies; (3) adjustment of the position of the welding head sets; (4) welding; and (5) discharging of the welded workpieces. The linear flame welding machine is ingenious and reasonable in structural design, and convenient and rapid to use and operate, achieves automatic treatment operationof workpiece feeding and discharging through the feeding mechanism and the discharging mechanism, relieves labor intensity, improves operation safety performance, can conduct welding on the workpieces at the same time through design of the multiple welding assemblies, effectively increases the welding rate, and improves the work efficiency.

Owner:XINCHANG KECHUANG AUTOMATION EQUIP

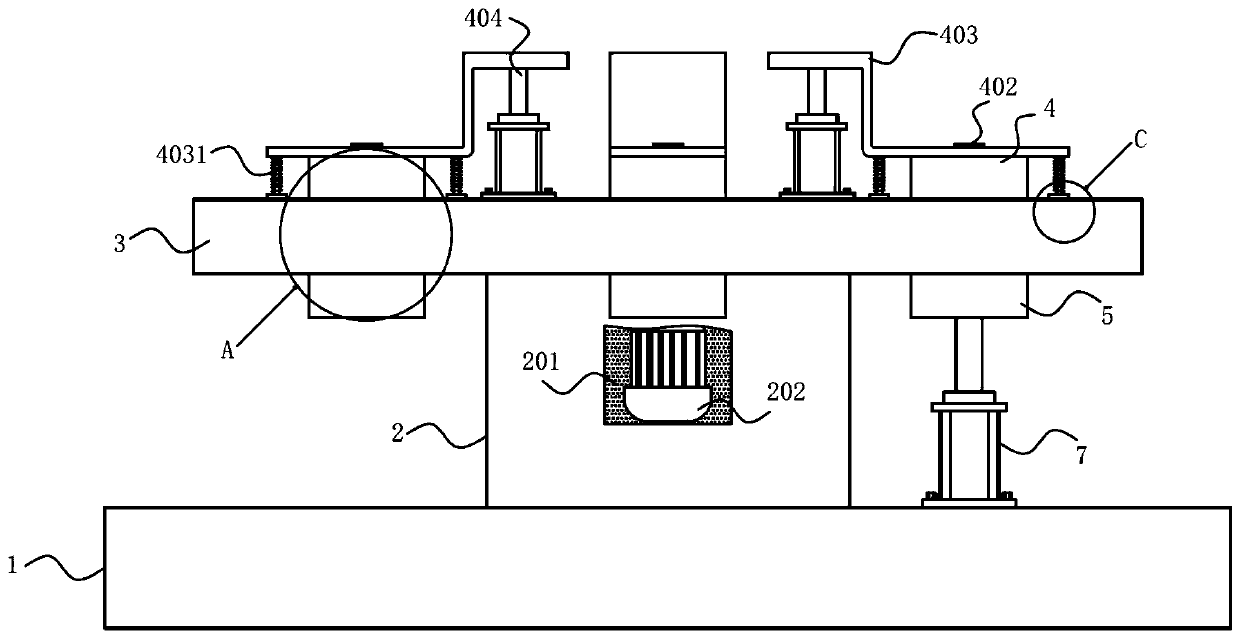

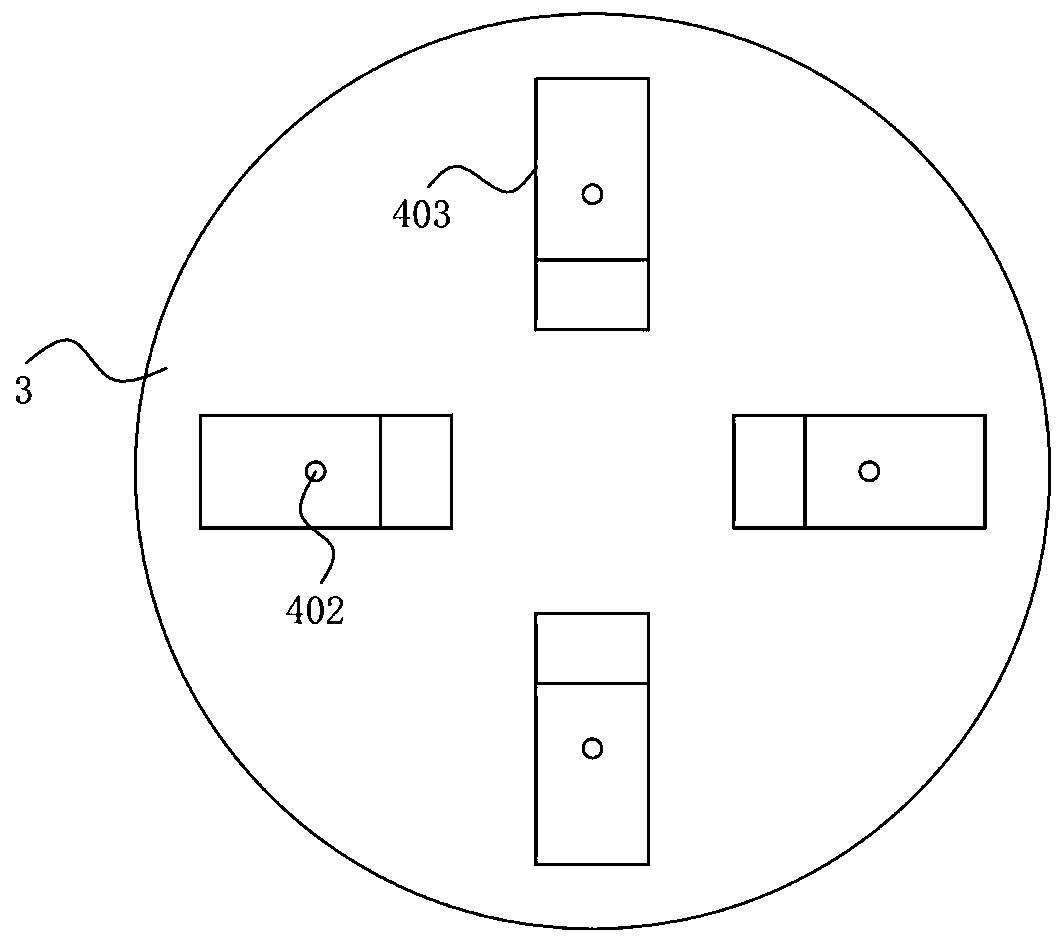

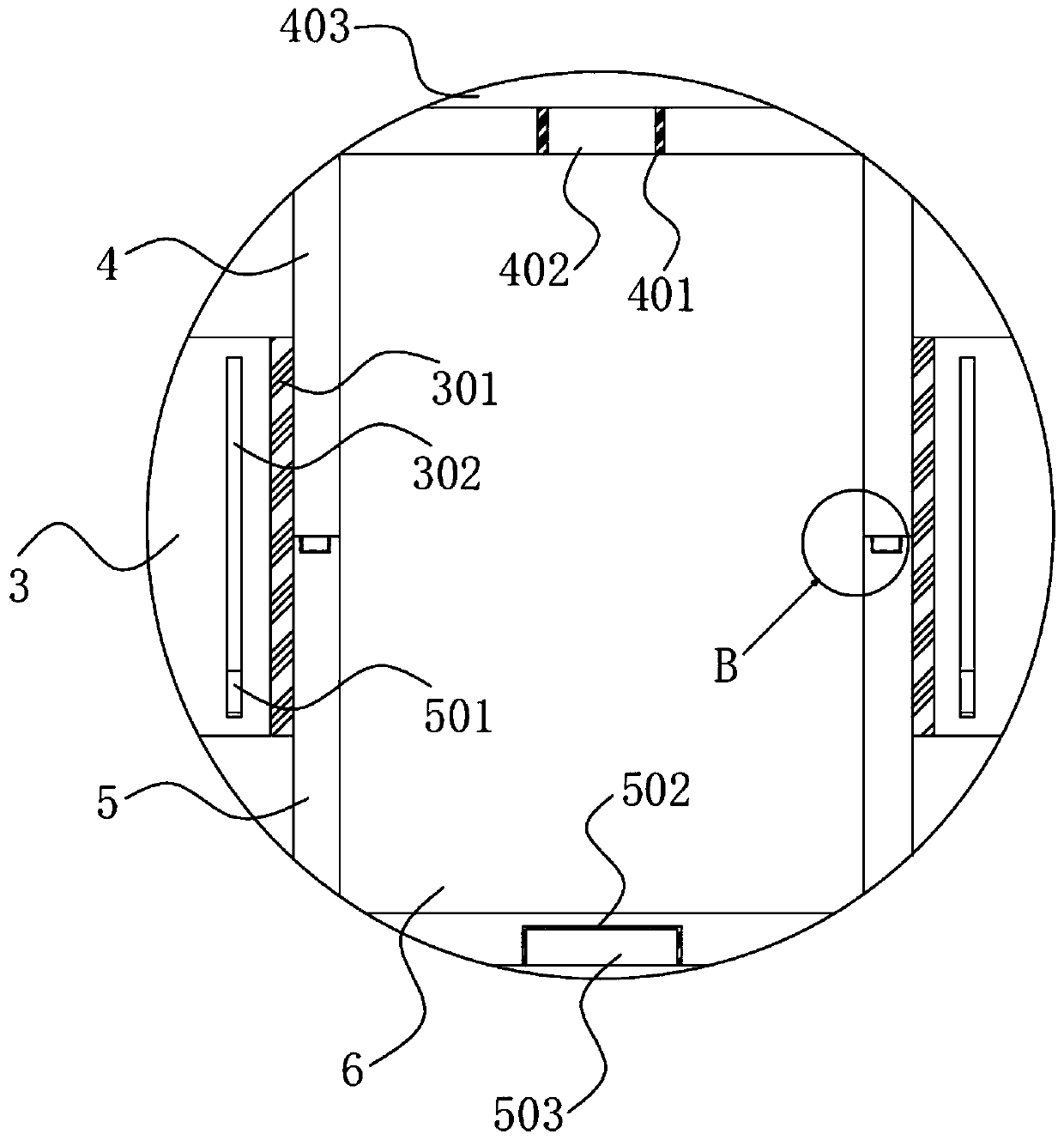

Rotary plastic handicraft injection mold and injection molding method thereof

InactiveCN110435072AImprove continuityFacilitate continuous injection moldingEngineeringInjection molding machine

The invention discloses a rotary plastic handicraft injection mold and an injection molding method thereof. The rotary plastic handicraft injection mold comprises a base; the top of the base is fixedly connected with a support through bolts; the upper end of the support is connected with a workbench through a bearing; the lower end of the middle of the workbench is fixedly connected with the output end of a stepping motor; one end of the base is fixedly provided with a second telescopic air cylinder through bolts; and the output end of the second telescopic air cylinder is inserted into the lower end of one lower mould base According to the rotary plastic handicraft injection mold and the injection molding method thereof, through the cooperation of the stepping motor, the workbench, fixedgrooves, limiting blocks, limiting grooves, adjusting support plates and first telescopic air cylinders, the continuous injection molding of the injection mold is facilitated, the mold closing efficiency is high, the sealing performance is good, the injection molding effect is good, through the cooperation of guiding grooves, rubber pads, the limiting grooves, the limiting blocks and the second telescopic air cylinder, the continuous ejection blanking of the lower mold base is convenient, the blanking rate is effectively improved, therefore, the continuity of injection molding work is effectively improved, and the working efficiency is greatly improved.

Owner:义乌市拓一斯玩具有限公司

Positive-pressure conveying system device

The invention discloses a positive-pressure conveying system device which comprises a sending tank and a storehouse. The sending tank and the storehouse are connected through a pipeline. Butterfly valves are arranged at the position of a feeding port of the sending tank and the connecting position of the bottom of the sending tank and a discharging pipe. The positive-pressure conveying system device further comprises a tonnage and standard dual-purpose unpacking and material collecting device, an exhaust noise-reduction device, a negative-pressure accelerated feeding device, a material plug forming device, a pipeline cleaning device, a pipeline blocking removing device, and a mixing device with the ratio of fed materials and inlet gas capable of being adjusted. By means of the positive-pressure conveying system device, material conveying can be completed with high efficiency, pollution is reduced, energy consumption is reduced, time and labor are saved, and the production cost is reduced.

Owner:CHANGZHOU CHANGHENG DEYU POWDER INTEGRATIVE SYST

Slicing device for angelica sinensis processing

ActiveCN113370278AImprove product qualityEasy for slicing workSievingScreeningAngelica Sinensis RootKnife blades

The invention provides a slicing device for angelica sinensis processing, and relates to the field of traditional Chinese medicinal material processing. The slicing device for angelica sinensis processing comprises a carrying table, a slicing mechanism, a cleaning mechanism, a material guiding mechanism and supporting legs; the bottom of the right end of the slicing mechanism is fixedly connected with the top face of the right end of the carrying table; the left end of the cleaning mechanism is fixedly connected with the right side face of the left end of the slicing mechanism; the bottom of the material guiding mechanism is fixedly connected with the top face of the left end of the carrying table; and the top ends of the supporting legs are connected with the four corners of the bottom face of the carrying table respectively. According to the slicing device for angelica sinensis processing, through an arranged cleaning piece, firstly, the shape of the cleaning piece can prevent a blade from damaging the cleaning piece; then, cutter teeth on the cleaning piece can prevent sliced angelica sinensis pieces from adhering to the surface of the cleaning piece; impurities on the blade can be effectively scraped, and juice in angelica sinensis is prevented from adhering to the surface of the blade; and therefore, the service life of the blade is prolonged to a great extent.

Owner:JILIN AODONG SHIHANG PHARMA

Pure natural botanical insecticide and preparation method thereof

ActiveCN113180067AEvenly distributedImprove grinding qualityBiocideAnimal repellantsStrychnos nux-vomicaToxicology

The invention belongs to the technical field of pesticides, and relates to a pure natural botanical insecticide and a preparation method thereof. The preparation method includes the steps that: S1, fructus cnidii, camphor, tobacco leaves, herba lysimachiae, radix sophorae flavescentis, liquorice and semen strychni are weighed according to the weight part ratio and sequentially put into a grinding machine to be ground into powder; S2, the mixed powder obtained in the step S1 is added into a leaching kettle, water, an emulsifying agent and a dispersing agent are added according to a ratio, heating, and uniform stirring are performed; and S3, after the mixture obtained in the step S2 is cooled, the mixture is put into a centrifugal machine to be subjected to high-speed centrifugal separation, a finished product is collected and put into a chemical agent tank, and the chemical agent tank is closed. When materials are put into a grinding box, the materials cannot be uniformly laid in a grinding seat, as a result, the grinding efficiency is reduced, and the grinding quality of grinding balls on the materials is influenced. With the pure natural botanical insecticide and the preparation method thereof adopted, the above problems can be solved.

Owner:HENAN DECI YANGNONG BIOTECH CO LTD

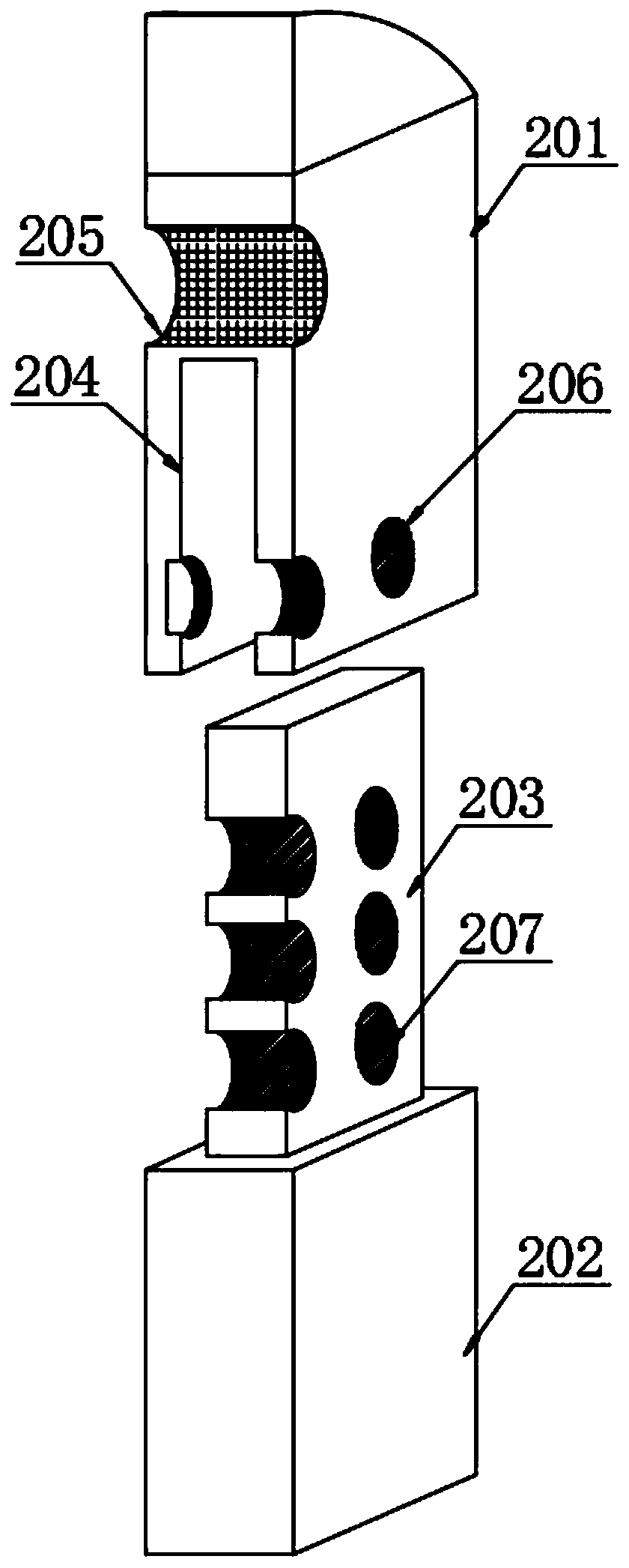

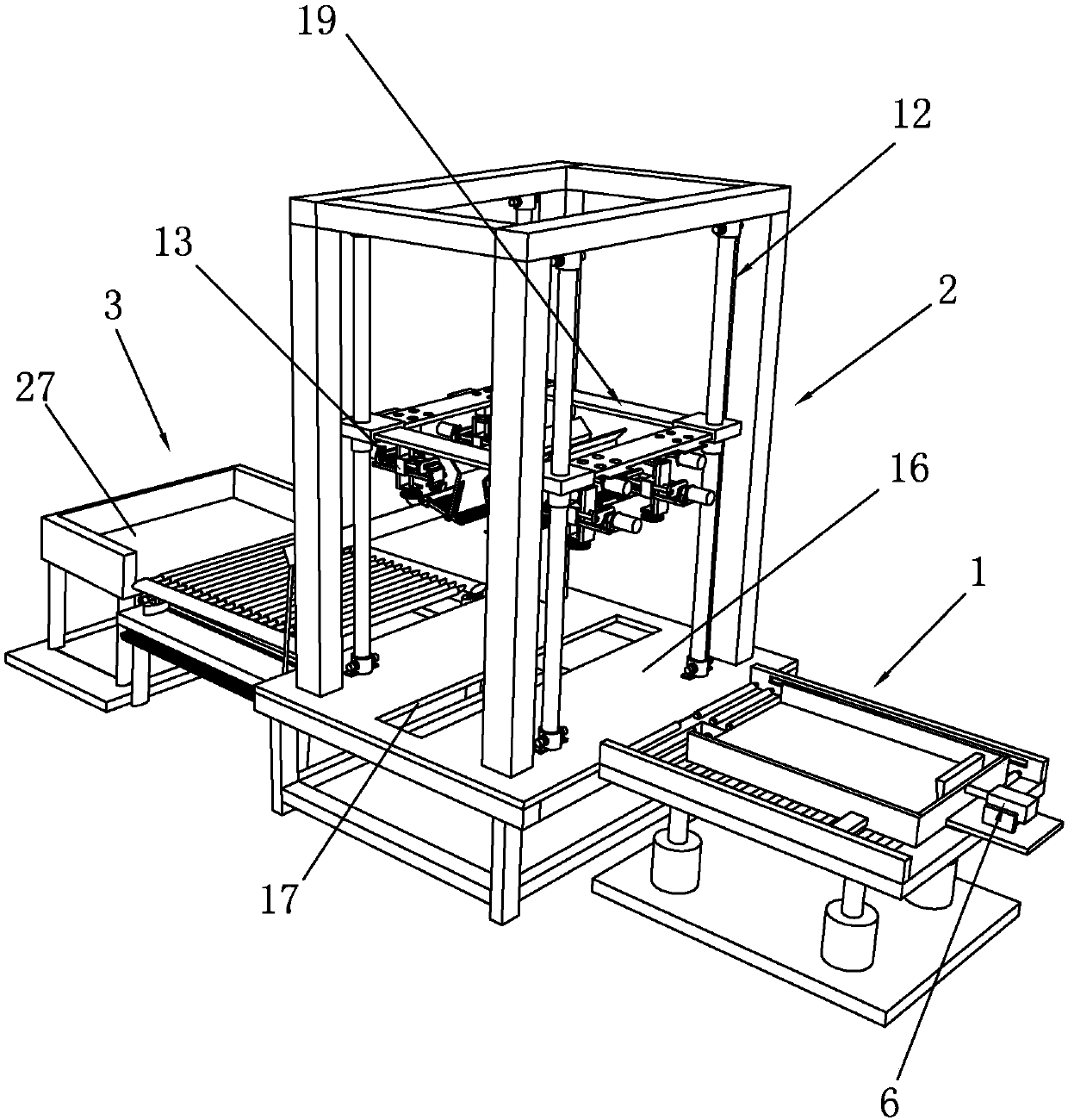

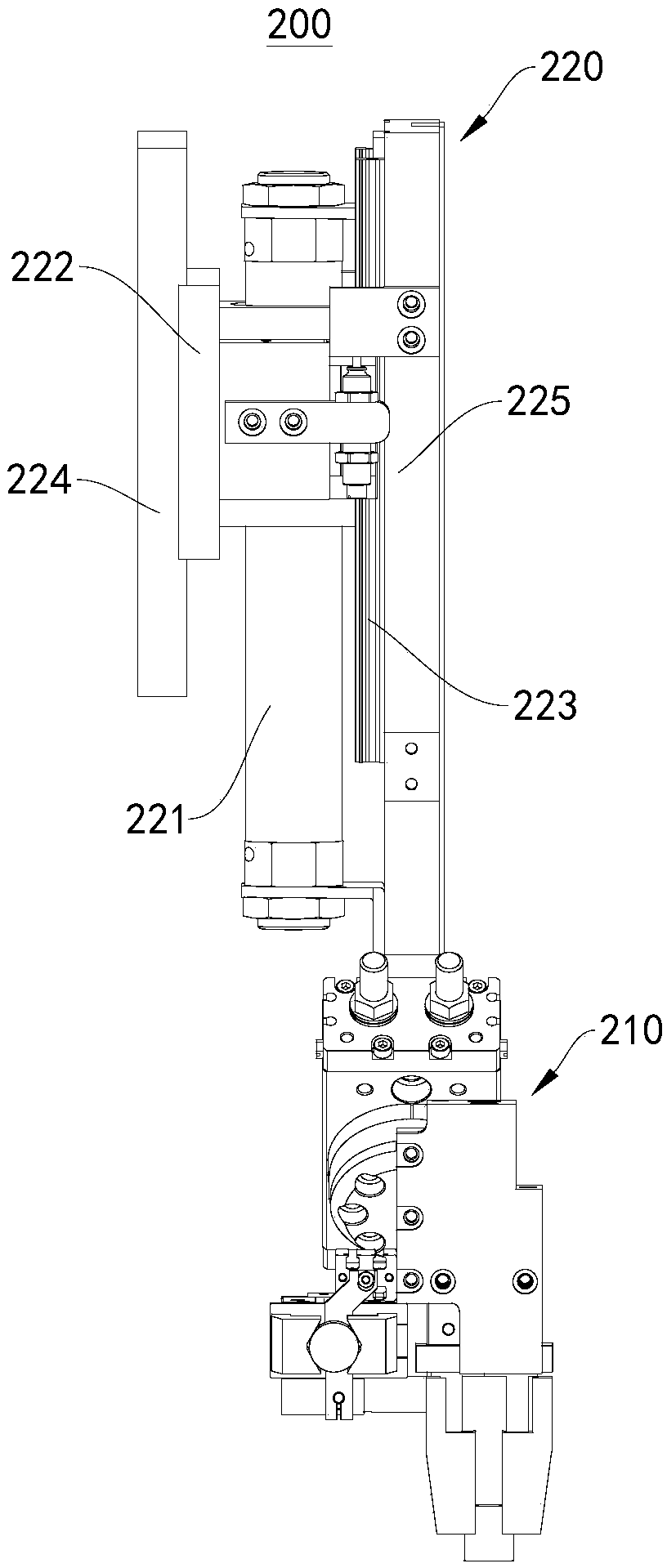

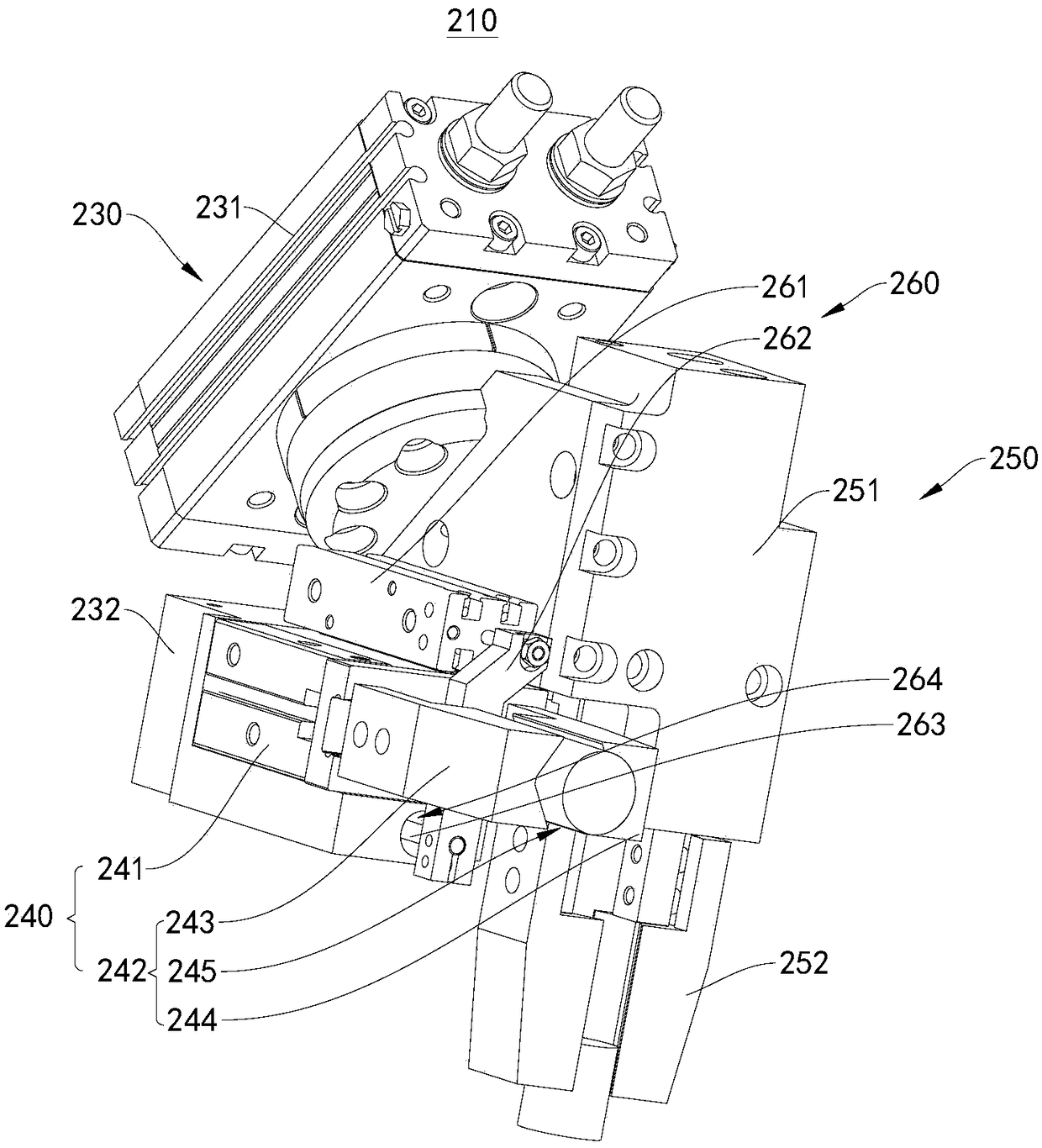

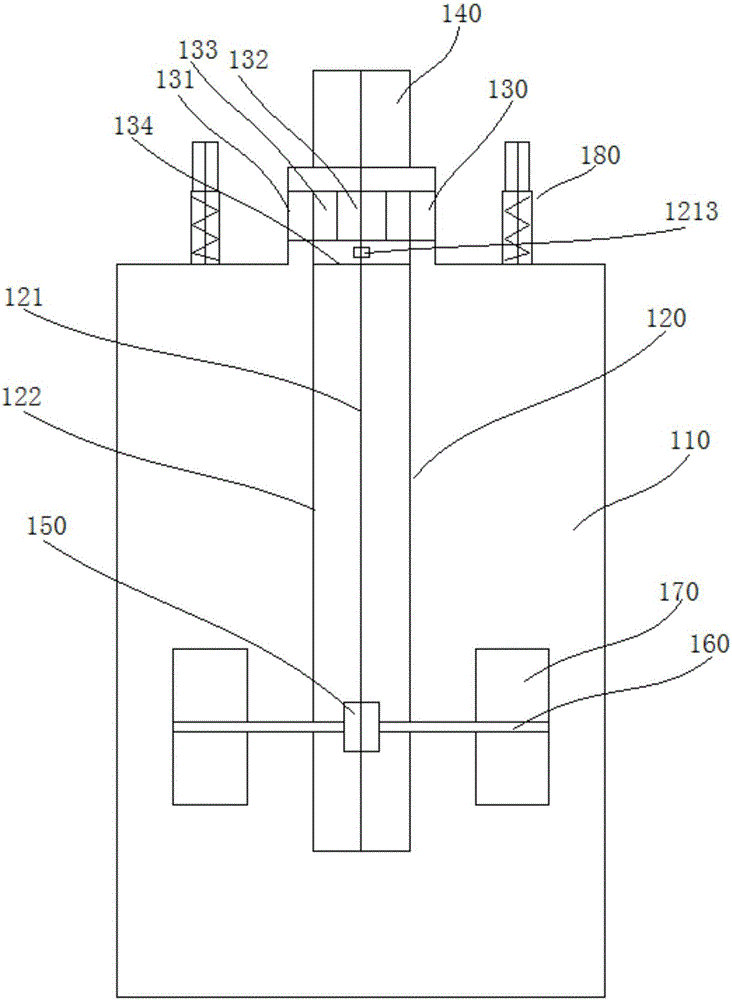

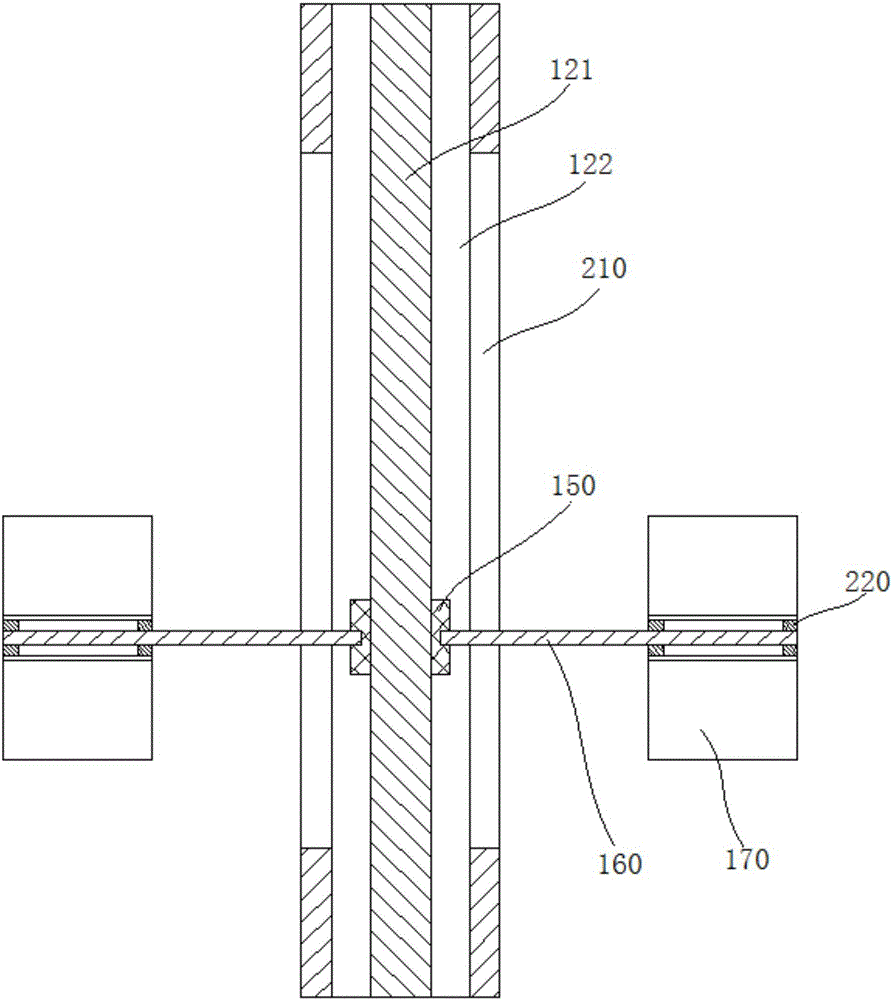

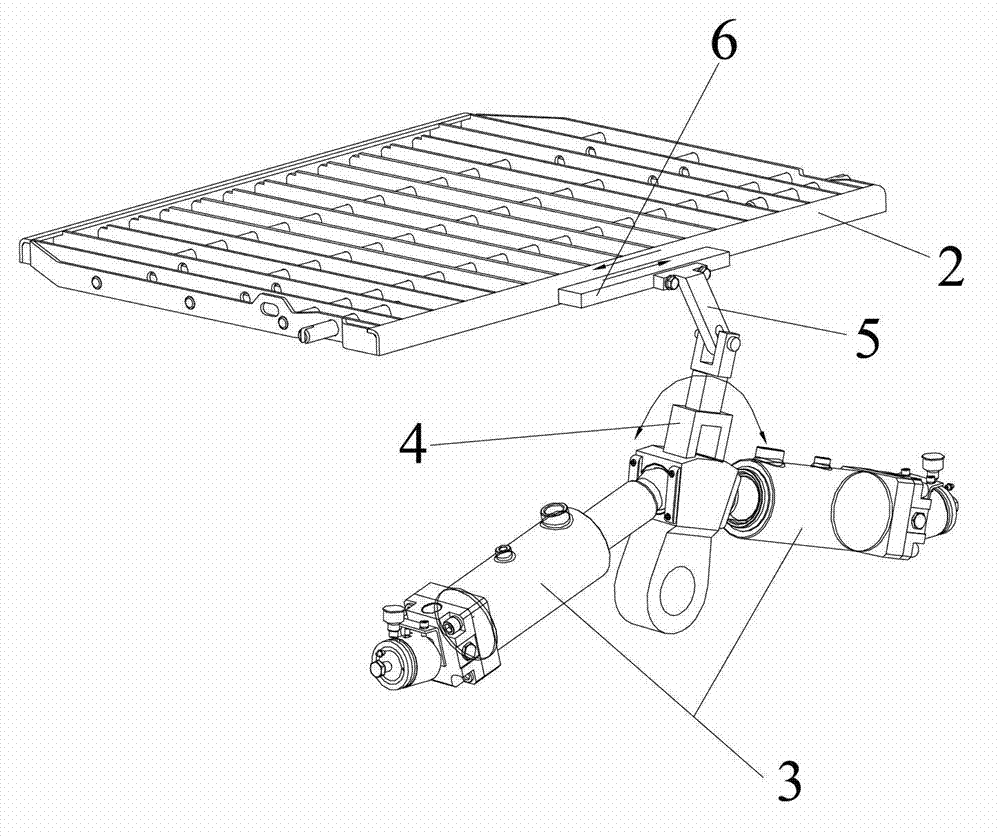

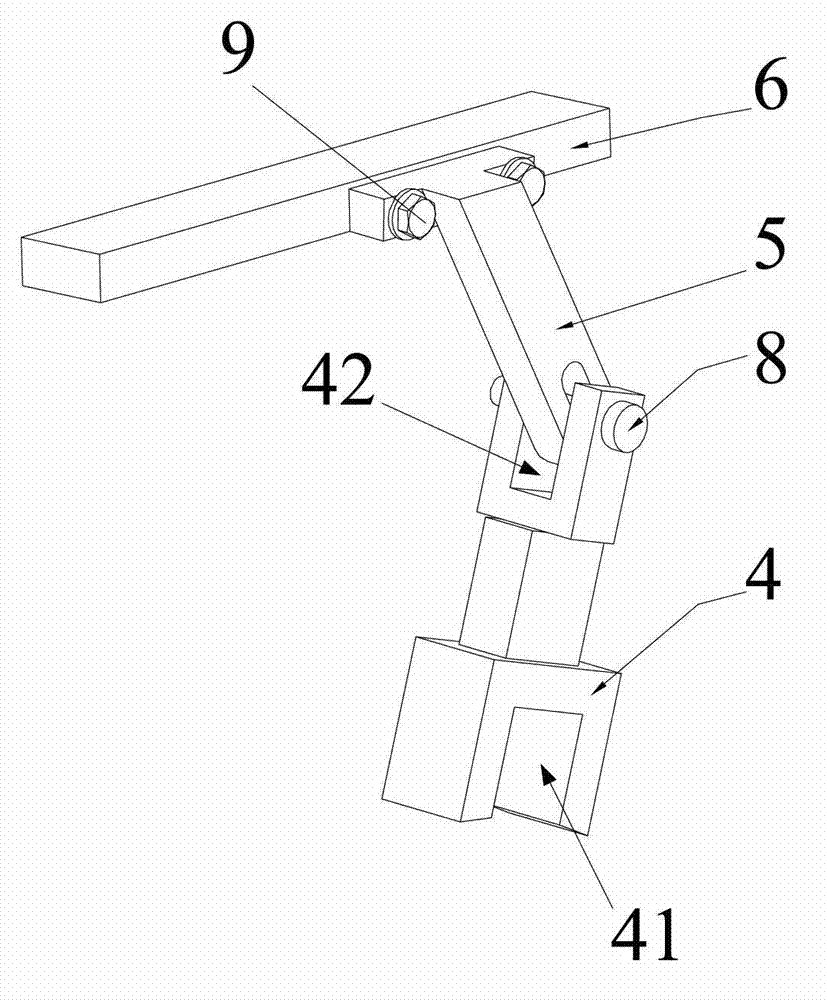

Loading and unloading device for lathe

ActiveCN109249040ARealize automatic feeding processRealize blankingMetal working apparatusEngineeringManipulator

The invention relates to the technical field of automatic equipment, in particular to a loading and unloading device for a lathe. The loading and unloading device comprises a lathe body, a first horizontal movement module, a second horizontal movement module, a manipulator mechanism and a tray. The first horizontal movement module and the second horizontal movement module are fixedly arranged on the lathe body, included angles are formed between the first horizontal movement module and the second horizontal movement module, and the second horizontal movement module is arranged below the firsthorizontal movement module at intervals along the vertical direction; the manipulator mechanism is in transmission connection with the first horizontal movement module, and the first horizontal movement module is configured in such a manner that the manipulator mechanism can be driven by the first horizontal movement module to move along first directions; the tray is in transmission connection with the second horizontal movement module, and the second horizontal movement module is configured in such a manner that the tray can be driven by the second horizontal movement module to move along second directions. The loading and unloading device has the advantages that the amounts of labor of operators can be reduced, and the workpiece feeding and discharging speeds can be increased.

Owner:HUBEI UNIV OF ARTS & SCI +2

Method for recycling cold pressing navel orange essential oil by using three-level disc separation system

The invention relates to a process for industrially recycling cold pressing navel orange essential oil, and particularly relates to a method for recycling cold pressing navel orange essential oil by using a three-level disc separation system. Aiming at the characteristic that the orange essential oil is unsmooth in separation during the recycling process because of the yellow ropiness substances such as pectin in the navel orange pericarp, an essential oil extraction process including the deslagging, the pretreatment, the first disc separation, the second disc separation and the third disc separation is designed creatively; and the technical difficulties that a traditional extraction process requires highly on eccentric equipment and the separation process is hard to master are overcome. Furthermore by adjusting the pressure of the light phase and the heavy phase of the outlet of a disc separation machine and by controlling the water temperature and the pH value, the essential oil content of the product exceeds 99%; and the process requirements on industrially recycling the high quality navel orange essential oil in large scale are met.

Owner:赣州中橙果业科技开发股份有限公司

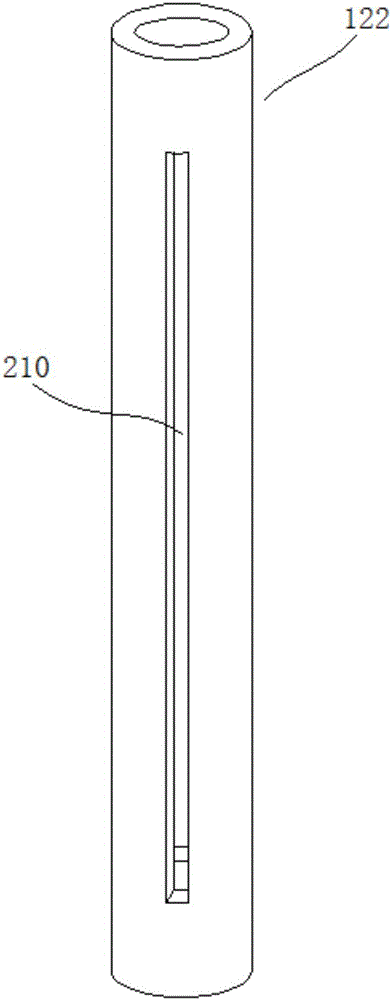

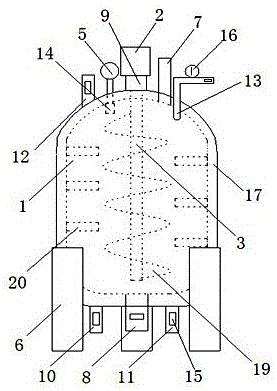

Stereoscopic stirring device for mixing plastic raw materials

The invention relates to the technical field of plastic production equipment, in particular to a stereoscopic stirring device for mixing plastic raw materials. The stereoscopic stirring device for mixing plastic raw materials comprises a barrel, a stirring shaft is arranged in the barrel, and the stirring shaft is connected with a stirring motor through a planetary gear. The planetary gear comprises a gear ring, a sun wheel, a planet wheel and a planet support, the gear ring is fixedly connected with the barrel, the stirring motor is used for driving the sun wheel, and the sun wheel drives the planet support through the planet wheel. The stirring shaft comprises a screw shaft and a sleeve shaft, the screw shaft is coaxial with the sun wheel and is arranged at the sun wheel, the sleeve shaft is coaxial with the screw shaft and is arranged on the outer side of the screw shaft in a sleeving mode, and the sleeve shaft is connected with the planet support. The lateral wall of the sleeve shaft is provided with long guide holes in the axial direction, the screw shaft is in threaded connection with a blade base, blade mounting rods stretching out from the long guide holes are arranged on the lateral wall of the blade base, blades are arranged on the blade mounting rods, and each blade is connected with the corresponding blade mounting rod through a first bearing. The stereoscopic stirring device can be used for well stirring and mixing plastic production raw materials.

Owner:HEBEI CHENSHENG PLASTIC PROD CO LTD

Raw material premixing device for plastic production process

ActiveCN106076183AStir wellEasy to controlRotary stirring mixersTransportation and packagingMechanical engineeringMixing chamber

The invention relates to the technical field of plastic production equipment, and specifically relates to a raw material premixing device for a plastic production process. The device comprises premixing device bodies disposed at a cylinder, each premixing device body includes a mixing cylinder, the mixing cylinder is internally provided with a mixing chamber, the mixing chamber consists of a charging cavity and a feeding cavity, the charging cavity is equipped with a plurality of charging ports, and the charging cavity is communicated with the cylinder cavity through the feeding cavity. The mixing chamber is internally provided with a mixing rotating shaft, which is driven by a mixing motor, and the mixing rotating shaft consists of a first mixing section at the charging cavity and a second mixing section at the feeding cavity, the first mixing section is provided with mixing blades, and the second mixing section is provided with spiral grooves. The raw material premixing device for a plastic production process provided by the invention can well perform premixing on plastic production raw materials.

Owner:沧州盛丰塑胶制品有限公司

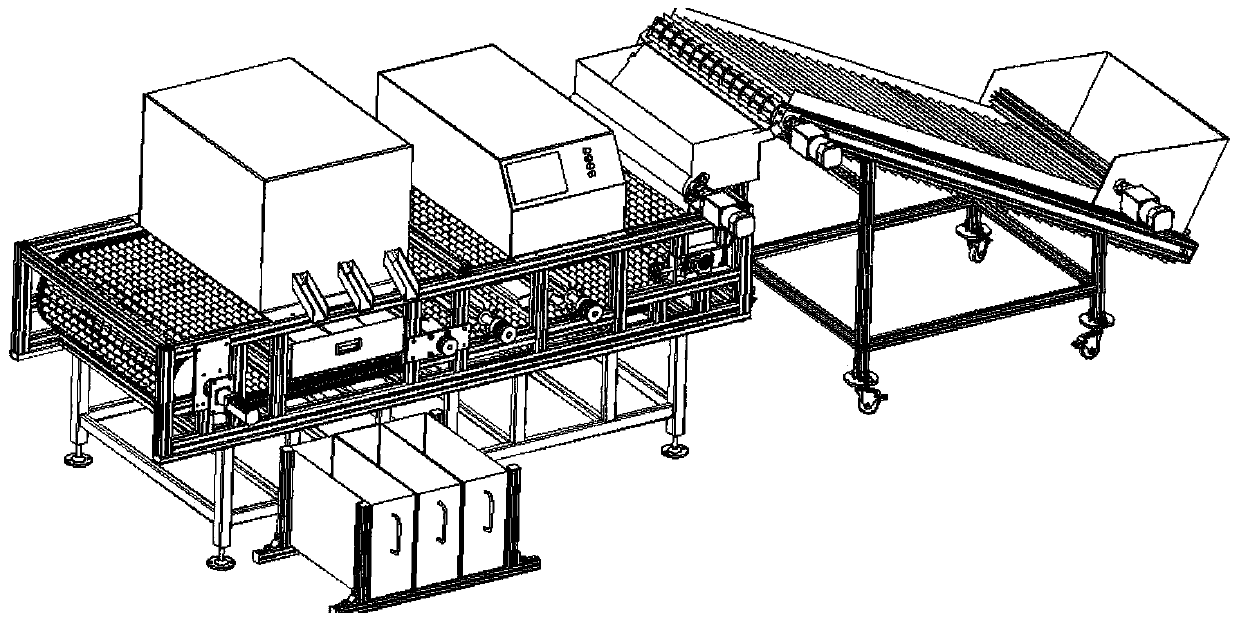

Automatic sorting and distributing system for automobile parts

The invention discloses an automatic sorting and distributing system for automobile parts. The automatic sorting and distributing system comprises a feeding mechanism, a detection and sorting mechanism and a distributing mechanism. The feeding mechanism comprises a conveying frame, a proximity sensor and a feeding manipulator. The detection and sorting mechanism comprises a laser ranging sensor, ascreening robot and a discharging frame. The distributing mechanism comprises an adjusting robot, a scanner and a sorting and guiding vehicle. According to the automatic sorting and distributing system for the automobile parts, a position sensor can accurately sense the positions of the parts and adjust the feeding manipulator for stable clamping and transferring, a detector on the side of a detection box can evaluate the performance of the parts and withdraw unqualified products from a distribution line under the action of the screening robot and the discharging frame, and the scanner can quickly read the product information after the product information position is adjusted by the adjusting robot and transmit the product information to the sorting and guiding vehicle through a controller and a counter so as to convey the scanned products into specific discharging chutes according to the sorting requirement, so that the automation degree is high, and the use effect is good.

Owner:广州市阿思柯物流系统有限公司

Stirring device for plastic production

The invention relates to the technical field of plastic production equipment, in particular to a stirring device for plastic production. The stirring device comprises a cylindrical body, wherein a stirring shaft is arranged in the cylindrical body, and connected with a stirring motor through a planet gear; the planet gear comprises a gear ring, a sun gear, a planet gear body and a planet support; the gear ring is fixedly connected with the cylindrical body; the stirring motor is used for driving the sun gear; the sun gear drives the planet support through the planet gear body; the stirring shaft comprises a screw shaft and a sleeve shaft; the screw shaft is coaxially arranged at the sun gear; the sleeve shaft coaxially sleeves the screw shaft, and is connected with the planet support; a guiding long hole is axially formed in the side wall of the sleeve shaft; a blade seat is in threaded connection with the screw shaft; a blade mounting rod which extends out of the guiding long hole is arranged on the side wall of the blade seat; and blades are arranged on the blade mounting rod. By adoption of the stirring device provided by the invention, raw materials for plastic production can be mixed and stirred relatively well.

Owner:南京利佳塑料发展有限公司

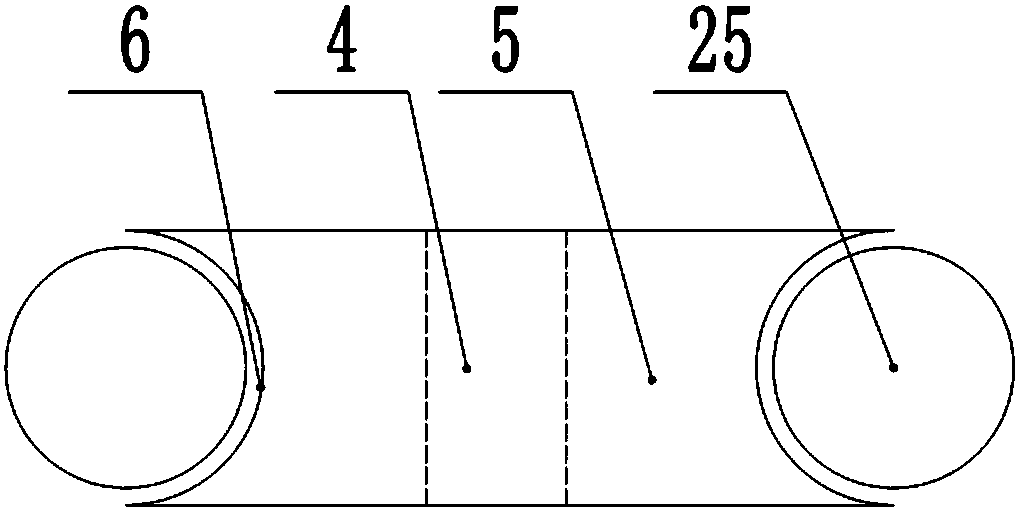

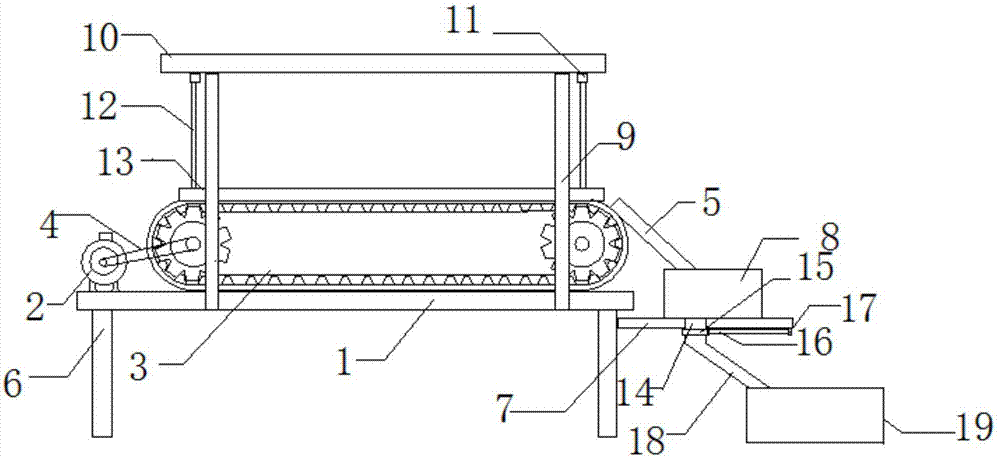

Feeding and conveying mechanism of fruit optimization equipment

PendingCN111299172AArranged in orderImprove feeding efficiencySortingElectric machineAgricultural engineering

The invention provides a feeding and conveying mechanism of fruit optimization equipment. The feeding and conveying mechanism mainly comprises a conveying belt, partition plates, baffle plates, a height limiting brush, surrounding edges, a transmission rotating shaft, a discharging box, a flow limiting rolling shaft, a transmission motor, a rotating motor, a feeding support, pressure sensors and caster wheels. The conveying belt is arranged on the feeding support, the conveying belt is driven to rotate through the transmission rotating shaft, the conveying belt adopts an inclined placing mode,the partition plates are arranged on the conveying belt and used for separating materials, the baffle plates are arranged below the conveying belt and used for preventing the materials from rolling off, the two sides are provided with the surrounding edges to ensure that fruits do not fall off from the side surfaces, the tail end of the conveying belt is connected with the discharging box, the flow limiting rolling shaft is arranged in a storage hopper, and the pressure sensors and the caster wheels are arranged at the bottom of the feeding support. According to the feeding and conveying mechanism, the feeding and conveying process is stable and reliable, the feeding efficiency is high, the fruits are orderly arranged in the feeding process, the subsequent screening work is facilitated, and the labor intensity of workers is greatly reduced.

Owner:ZHENGZHOU UNIV

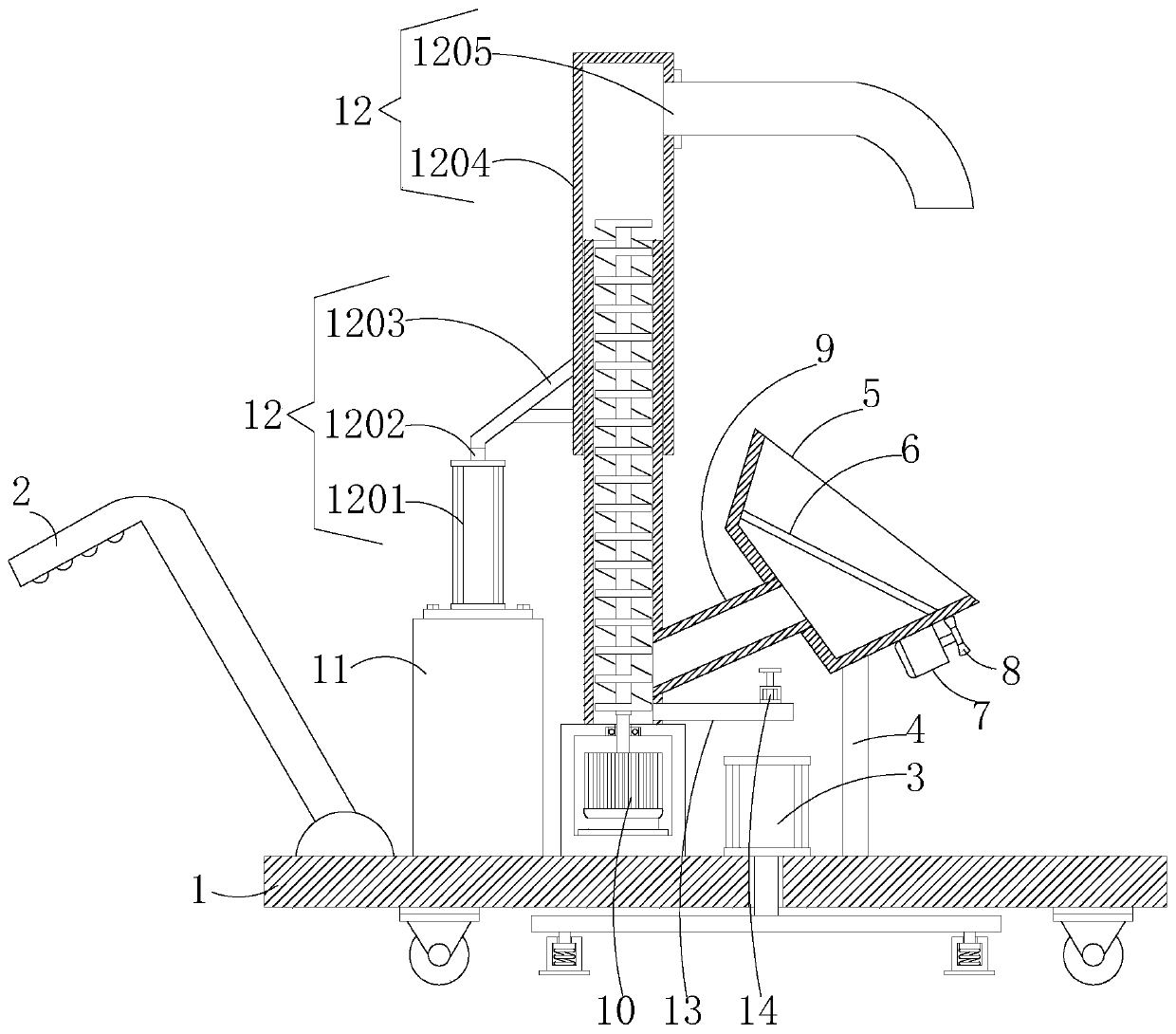

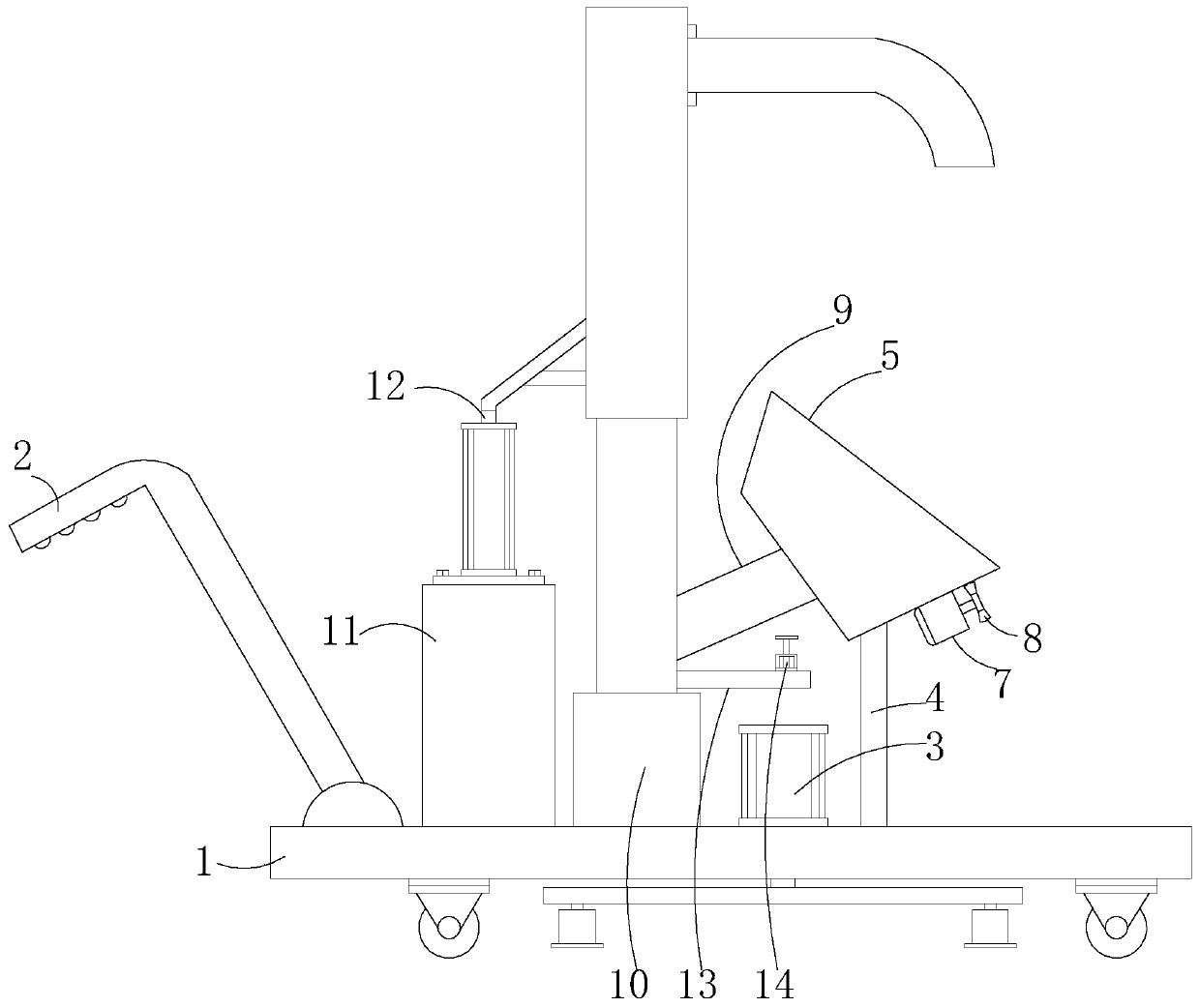

Constructional column pouring device for buildings

InactiveCN109779265AReduce shakingImprove stabilityBuilding material handlingMaterial transportArchitectural engineering

The invention discloses a constructional column pouring device for buildings, and relates to the technical field of building construction tools. The constructional column pouring device for buildingscomprises a cart body, a pushing handle, a stabilizing mechanism, a supporting rod, a feeding hopper, a screen, a first gear motor, a vibration rod, a material transport pipe, a feed mechanism, a control box and an expansion mechanism. The bottom end of the pushing handle is fixedly connected with the top surface of the left end of the vehicle body; the top end of the stabilizing mechanism is fixedly installed at the center of the top surface of the vehicle body; and the bottom end of the supporting rod is fixedly connected with the top surface of the right end of the vehicle body. The constructional column pouring device for buildings can quickly position the vehicle body; in this way, the stability of the whole pouring device can be fully improved; the pouring device is simple in structure and convenient to use, concrete can be rapidly fed, the material conveying speed of the pouring device can be increased, the height of a material conveying pipeline can be rapidly adjusted finally,the labor intensity of workers can be reduced, and therefore the working efficiency of the pouring device is further improved.

Owner:王琪

Full-automatic vegetable washing equipment applied to food pairings

PendingCN109198688AIncrease feeding rateHas a centrifugal effectFood treatmentDrive shaftEngineering

Owner:GUANGZHOU RESTAURANT GRP LIKOUFU FOOD +1

Raw material mixing device in plastic production process

The invention relates to the technical field of plastic production equipment and relates to a raw material mixing device in a plastic production process. A stirring shaft is arranged in a cylinder body of the raw material mixing device and is connected with a stirring motor through a planetary gear; the stirring shaft comprises a screw shaft and a sleeve shaft; the screw shaft and a sun wheel are coaxially arranged at the sun wheel; the sleeve shaft is connected with a planetary carrier; guiding long holes are formed in the side wall of the sleeve shaft along the axial direction; a paddle holder is in threaded connection with the screw shaft; paddle mounting rods extending from the corresponding guiding long holes are arranged on the side wall of the paddle holder; a paddle is arranged at each paddle mounting rod; each paddle is connected with the corresponding paddle mounting rod through a first bearing; premixing device bodies are arranged at the cylinder body and comprise material mixing barrels; a material mixing cavity is arranged in each material mixing barrel; and a material mixing rotary shaft is arranged in each material mixing cavity and is driven by a material mixing motor. According to the raw material mixing device disclosed by the invention, plastic production raw materials can be better stirred and mixed at multiple stages.

Owner:GUANGDONG SHUNDE JIANGSUN MAGNETIC CO LTD

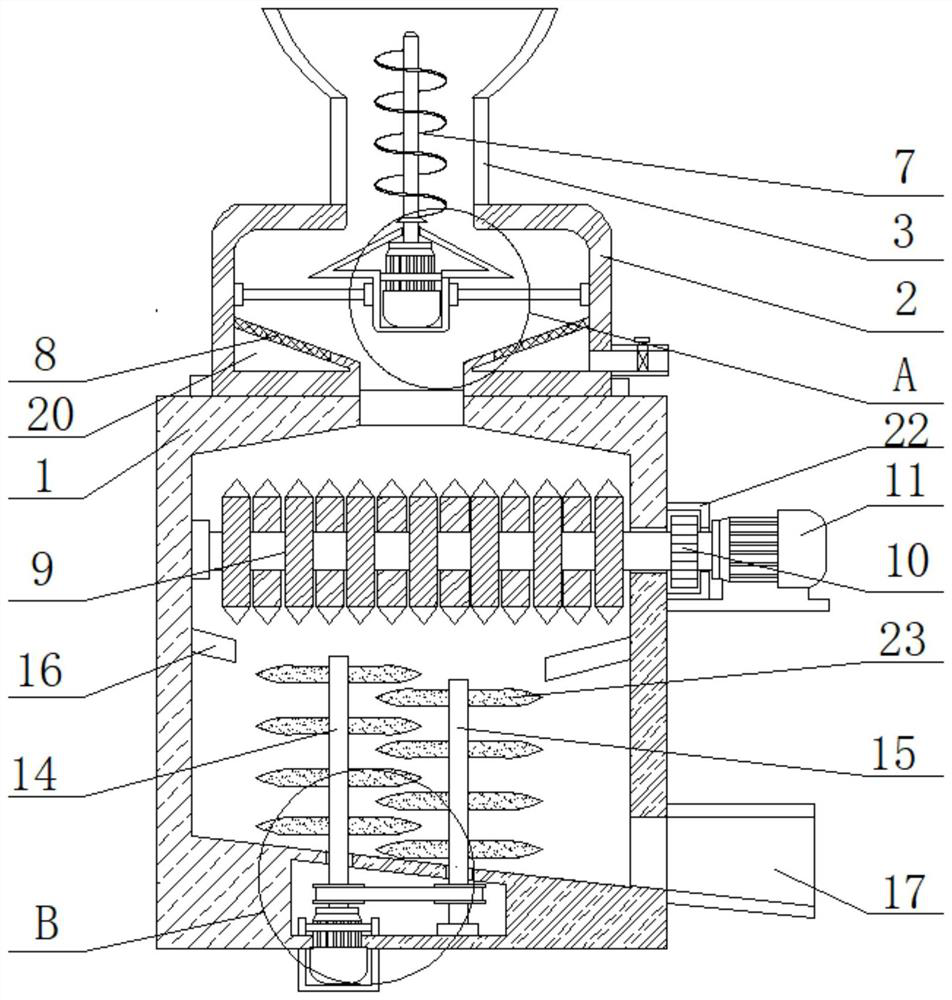

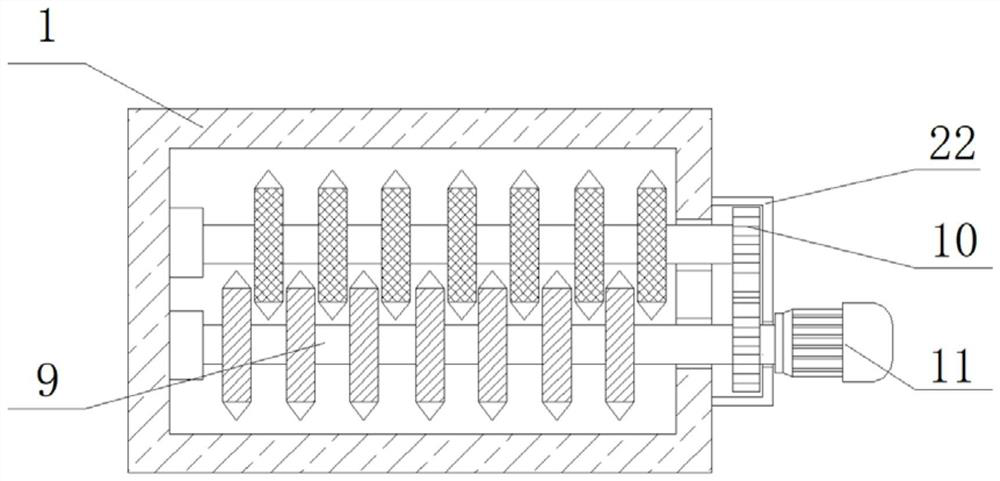

Pollution-free laying hen feed and processing equipment thereof

InactiveCN111887359AIncrease feeding rateImprove work efficiencySievingFeeding-stuffAgricultural scienceAgricultural engineering

The invention discloses pollution-free laying hen feed and processing equipment thereof. The laying hen feed is prepared from raw materials in parts by weight as follows: 20-40 parts of corn flour, 15-25 parts of wheat bran, 10-15 parts of millet flour, 6-12 parts of soybean meal, 2-8 parts of sweet potato flour, 1-6 parts of locust powder, 1-6 parts of fishbone meal, 2-4 parts of vitamins, 2-4 parts of trace elements and 2-4 parts of amino acid. According to the pollution-free laying hen feed and the processing equipment thereof, blockage during feeding is avoided, feeding rate of the feed isincreased, working efficiency of feed processing is increased, besides, the feed raw materials are prevented from sticking on the inner wall of a mixing box, the preparation quantity of pellet feed is guaranteed, quality of the feed can be improved, and the feed raw materials are saved.

Owner:安徽亳诚农牧科技股份有限公司

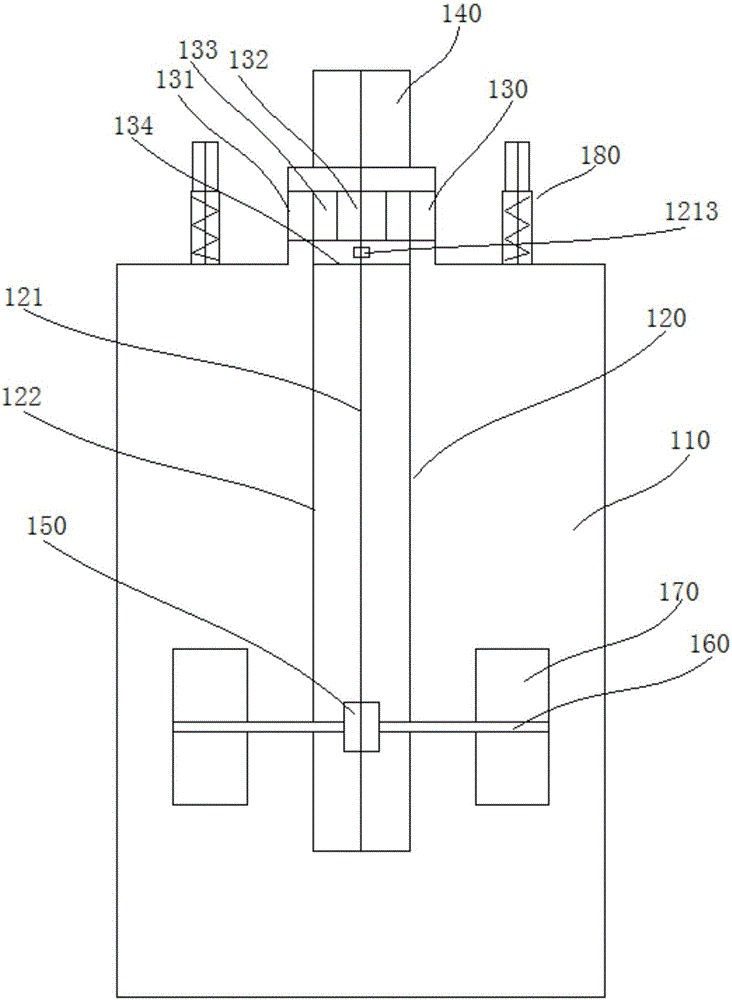

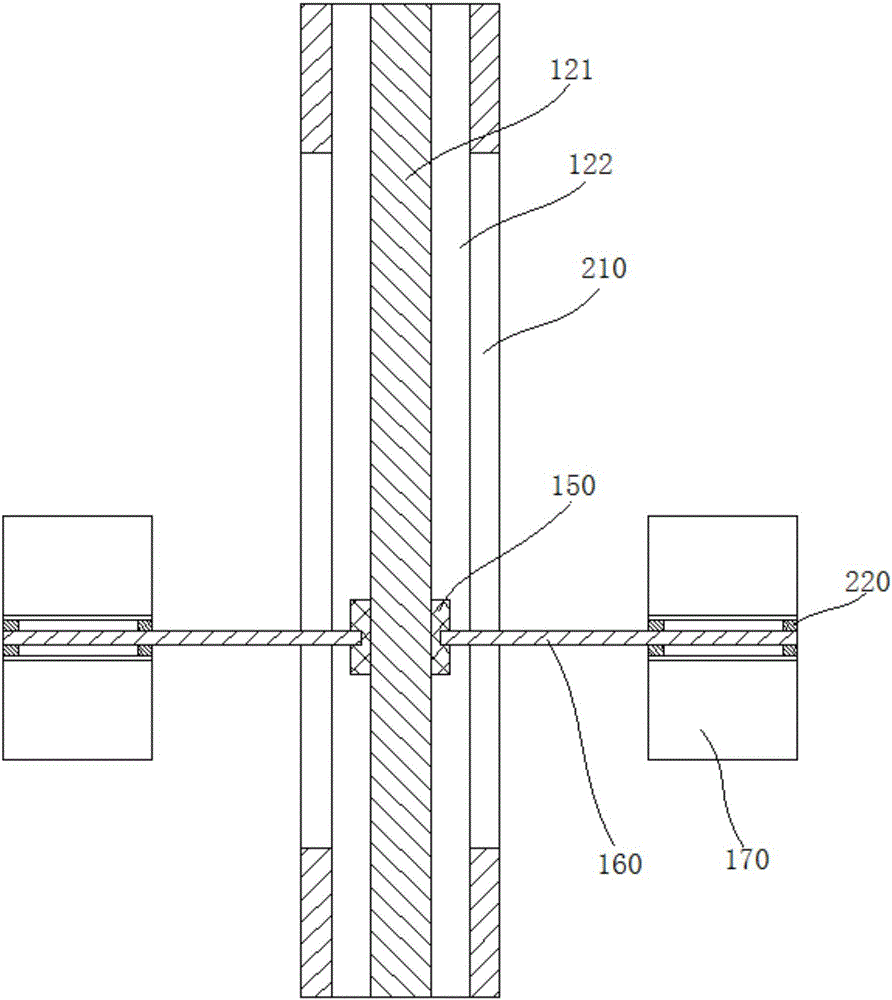

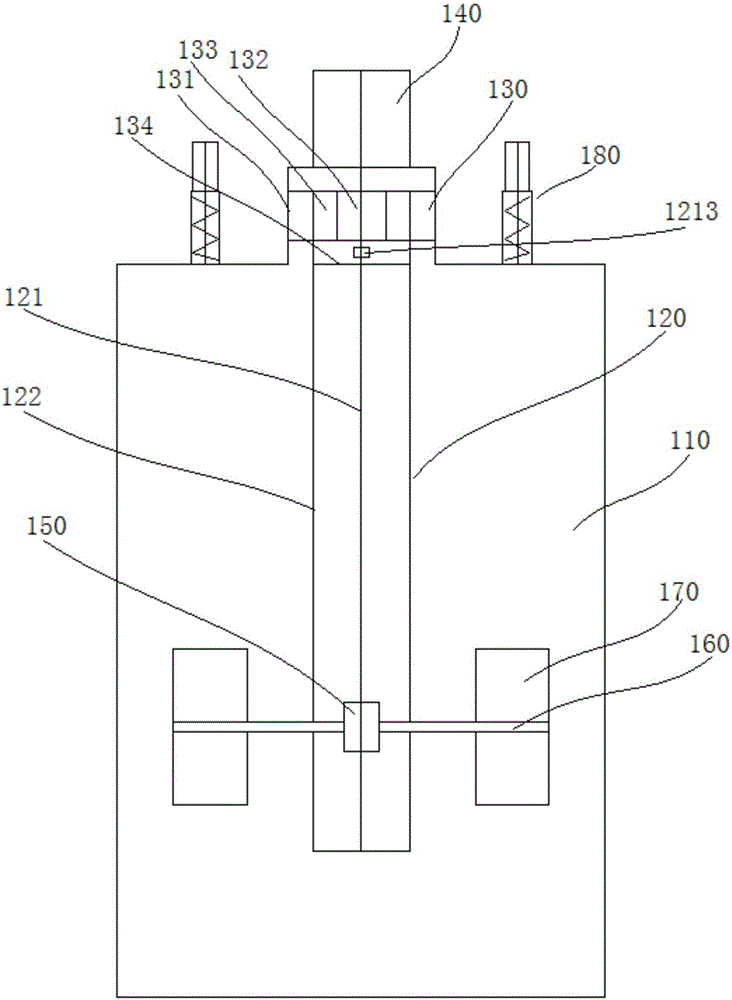

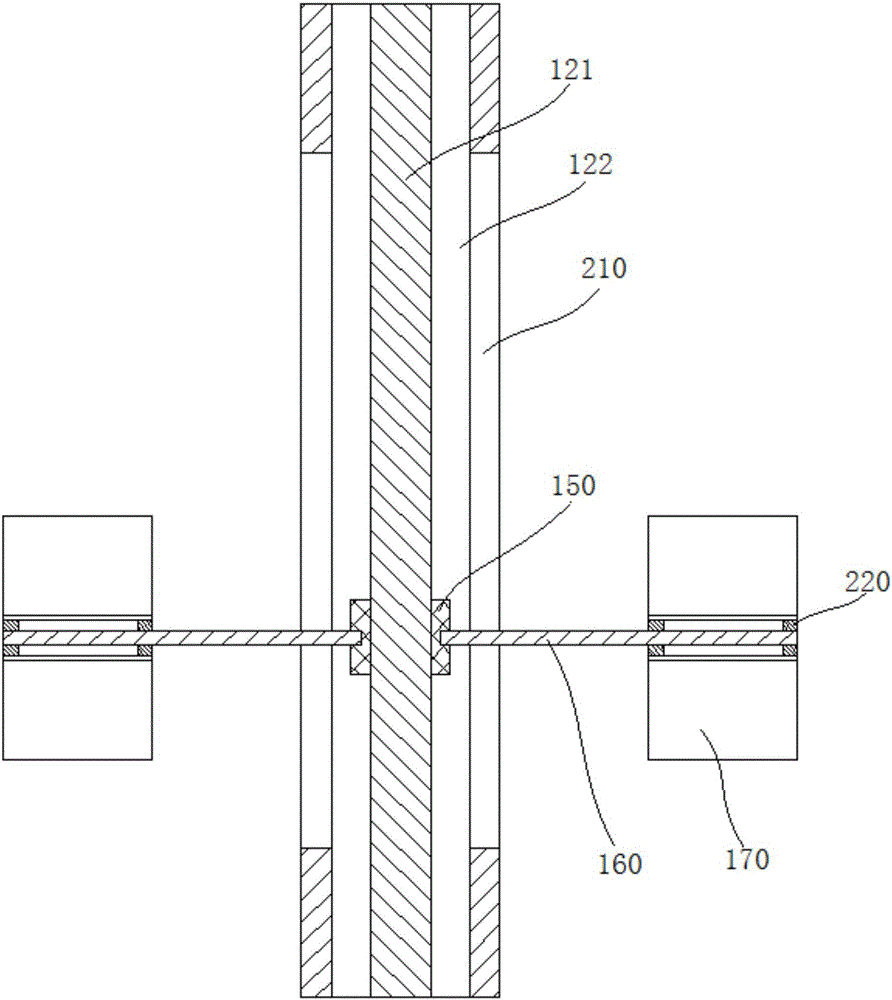

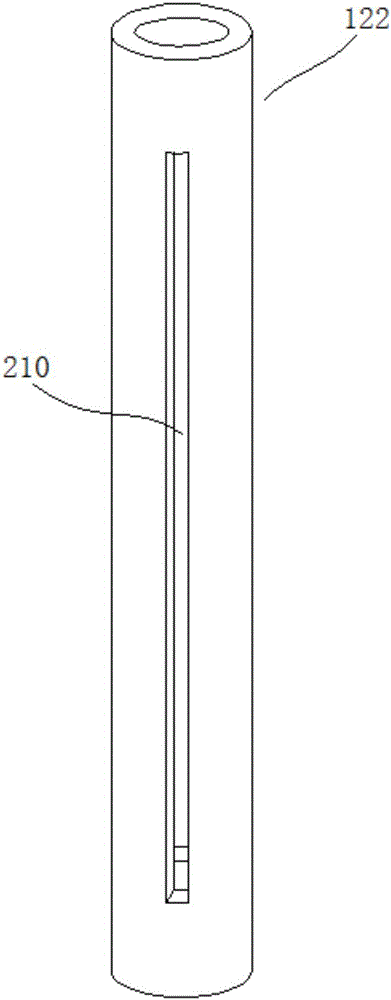

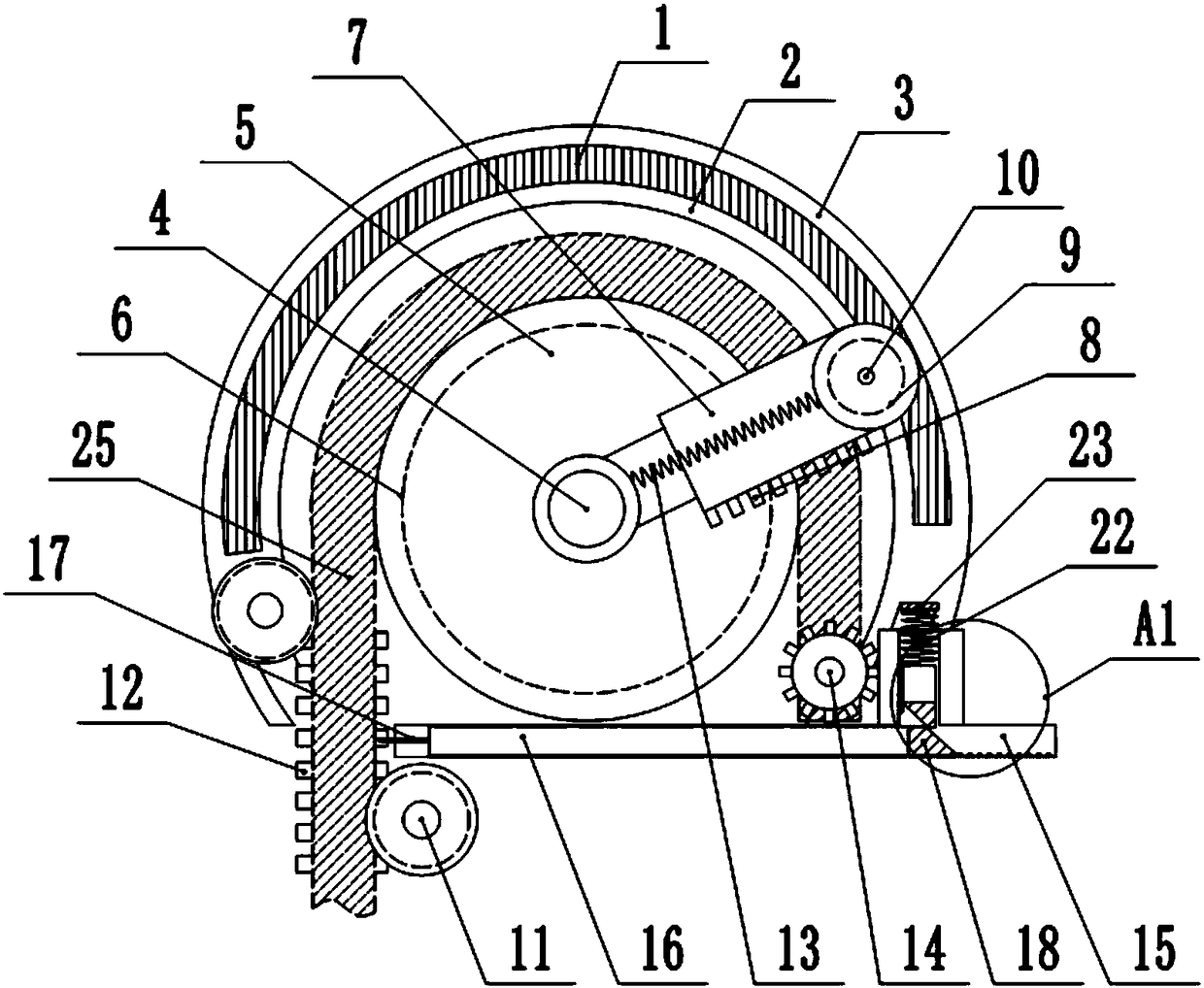

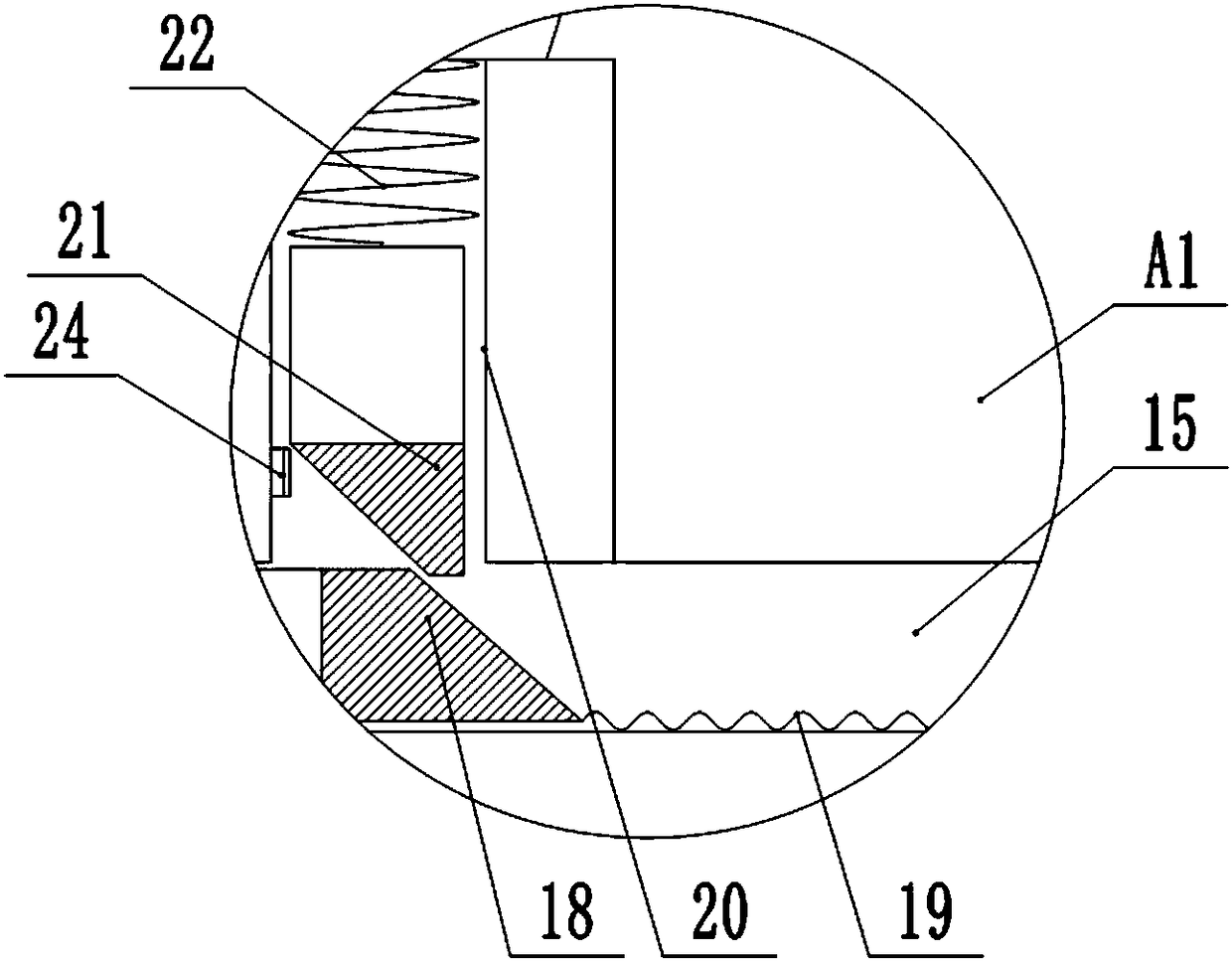

Bent pipe processing device

ActiveCN108421859AFit closelyEven by forceMetal-working feeding devicesStripping-off devicesDrive shaftEngineering

The invention relates to the field of bent pipe forming, and discloses a bent pipe processing device which comprises a frame and a driving shaft. A first sliding way and a second sliding way are arranged on the frame, the ends of the first sliding way and the second sliding way are communicated each other, the driving shaft is rotatably connected on the frame, a torsion spring is connected betweenthe driving shaft and the frame, the driving shaft is coaxially and rotatably connected with a forming disk, grooves are formed in the side wall of the forming disk, the driving shaft is coaxially and fixedly connected with a telescopic driving rod, a rack is arranged on the driving rod, a free end of the driving rod is rotatably connected with a traction disk, a telescopic spring is arranged between the traction disk and the forming disk, grooves are formed in the side walls of the traction disk, a rotating shaft is slidably connected in the first sliding way, a feeding roller and a transferring roller are vertically arranged on one side of the forming disk each other, a gear is arranged on the other side of the forming disk and can be engaged with the rack, and a cutting mechanism is arranged on the frame of one side of the gear. According to the device, formed bent pipes are automatically discharged.

Owner:江苏德祐精密钢管有限公司

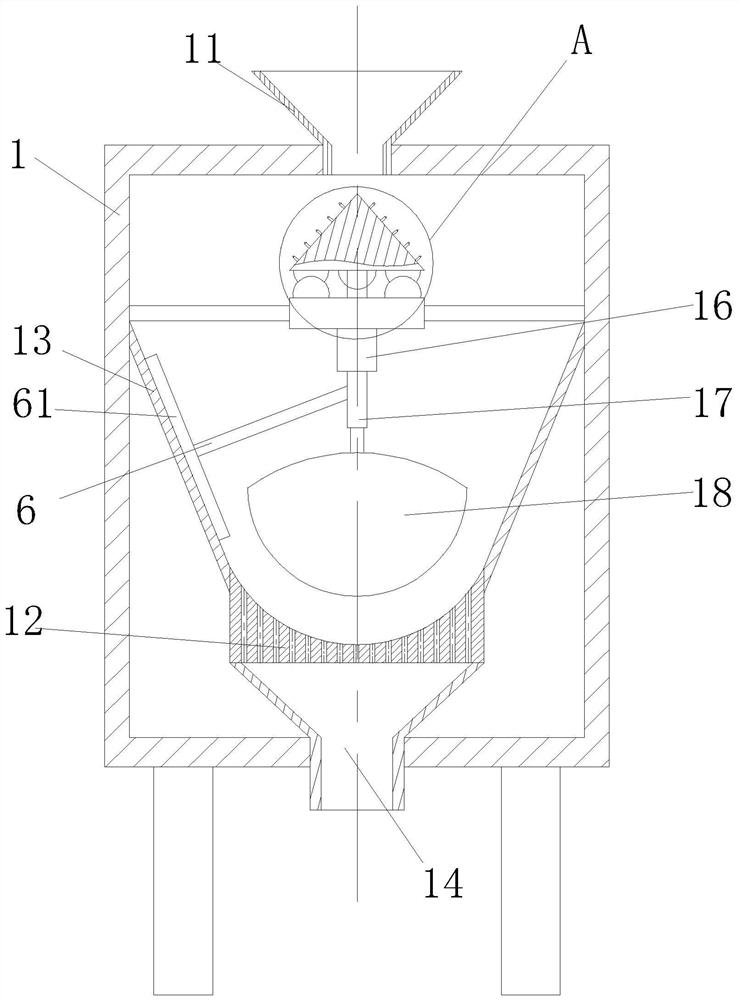

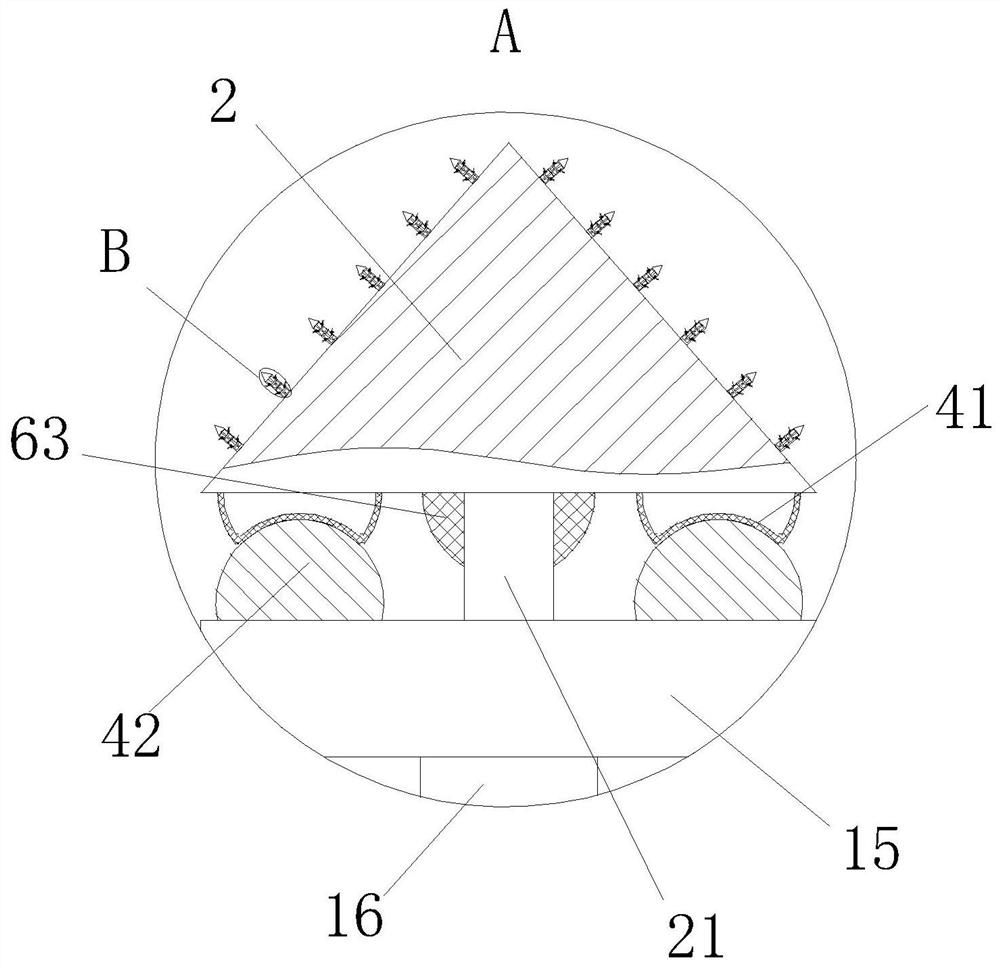

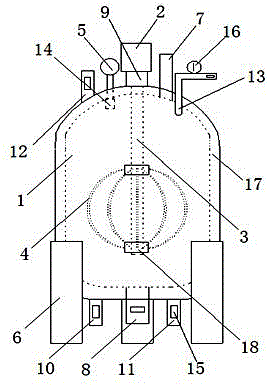

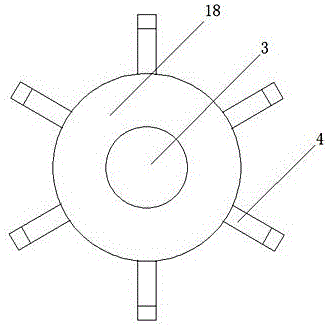

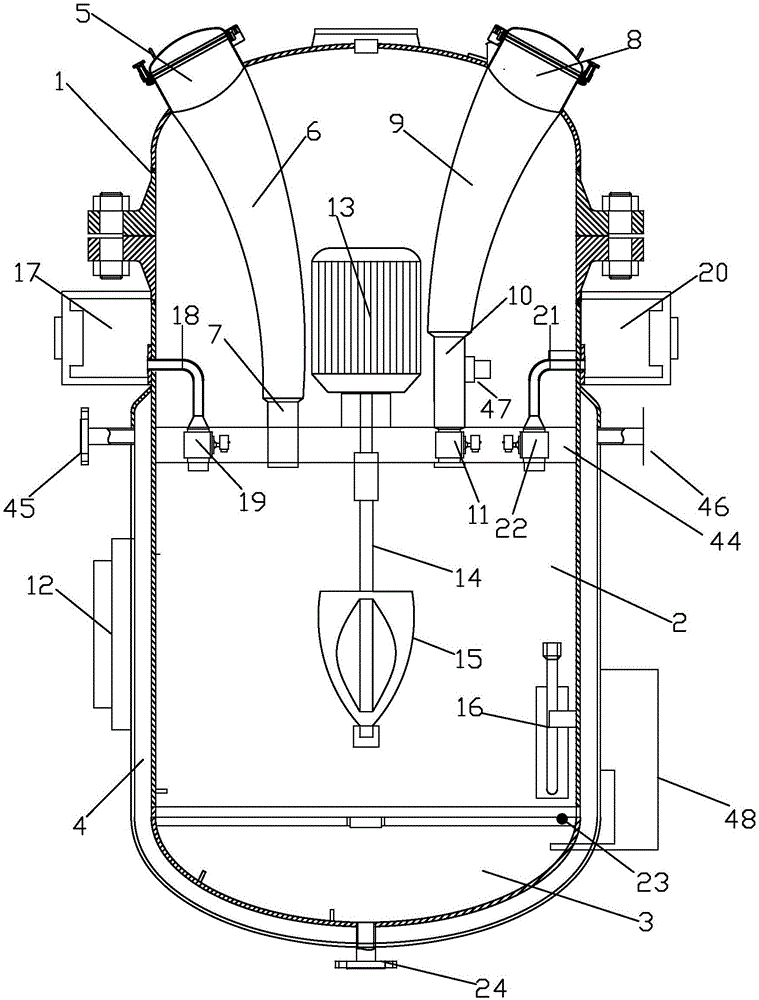

Reaction kettle for chemical production with temperature adjustment function and operating method of reaction kettle

InactiveCN106311120AIncrease reaction rateImprove utilization efficiencyChemical/physical/physico-chemical stationary reactorsThermometerCold medium

The invention discloses a reaction kettle for chemical production with a temperature adjustment function. The reaction kettle comprises a kettle body, a motor, a transmission shaft, a stirring rod and a thermometer and is characterized in that the kettle body is arranged on a bracket, a charging pipe, a discharging pipe, a stabilizing block, a cold medium inlet pipe I, a hot medium inlet pipe II, a medium outlet pipe and an exhaust pipe are arranged on the kettle body, the motor is arranged on the stabilizing block, the transmission shaft is arranged in the kettle body, the stirring rod is arranged between connecting blocks, and the thermometer is arranged on external wall of the kettle body. According to the reaction kettle, a sandwich layer is arranged on the kettle body and is connected with the cold medium inlet pipe I, the hot medium inlet pipe II and the medium outlet pipe, so that the feeding rate of the cold medium inlet pipe I or hot medium inlet pipe II can be adjusted according to a temperature in a chemical raw material production process, the internal temperature of the kettle body is maintained to a temperature around temperatures appropriate to a reaction of chemical raw materials, the reaction rate of the chemical raw materials can be promoted, and the utilization efficiency of the chemical raw materials is increased.

Owner:芜湖瑞德机械科技有限公司

Photovoltaic cell surface passivation film production equipment

PendingCN114300399AIncrease feeding rateImprove mechanical propertiesFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSolar cell

The invention discloses photovoltaic cell surface passivation film production equipment, and relates to the technical field of solar cell production equipment. The equipment comprises a machine body, a workbench and a coating unit, a horizontal conveying part, a vertical lifting part and a transferring part are arranged on one side of the machine body from the outer side to the position of the workbench, and a battery panel can be conveyed to the position adjacent to the vertical lifting part through a horizontal conveying belt and enters an obliquely-arranged bearing plate; according to the solar cell panel feeding and transferring device, automatic feeding and transferring of the solar cell panel can be achieved, the solar cell panel is moved to the bottom of the working table through the horizontal conveying piece, and the solar cell panel is transferred to the top of the vertical lifting piece through the vertical conveying belt and then is transferred through the suction plate on the transferring piece, and the suction plate is rotated to the working table after being lifted. The solar panels are transferred to the suction plate at the bottom of the workbench through the vertical lifting piece, and finally the suction plate rotates to the position of the workbench for film coating, so that automatic feeding of the solar panels can be completed, the production efficiency is greatly improved, and the automatic production process of photovoltaic cells is improved.

Owner:江苏龙恒新能源有限公司

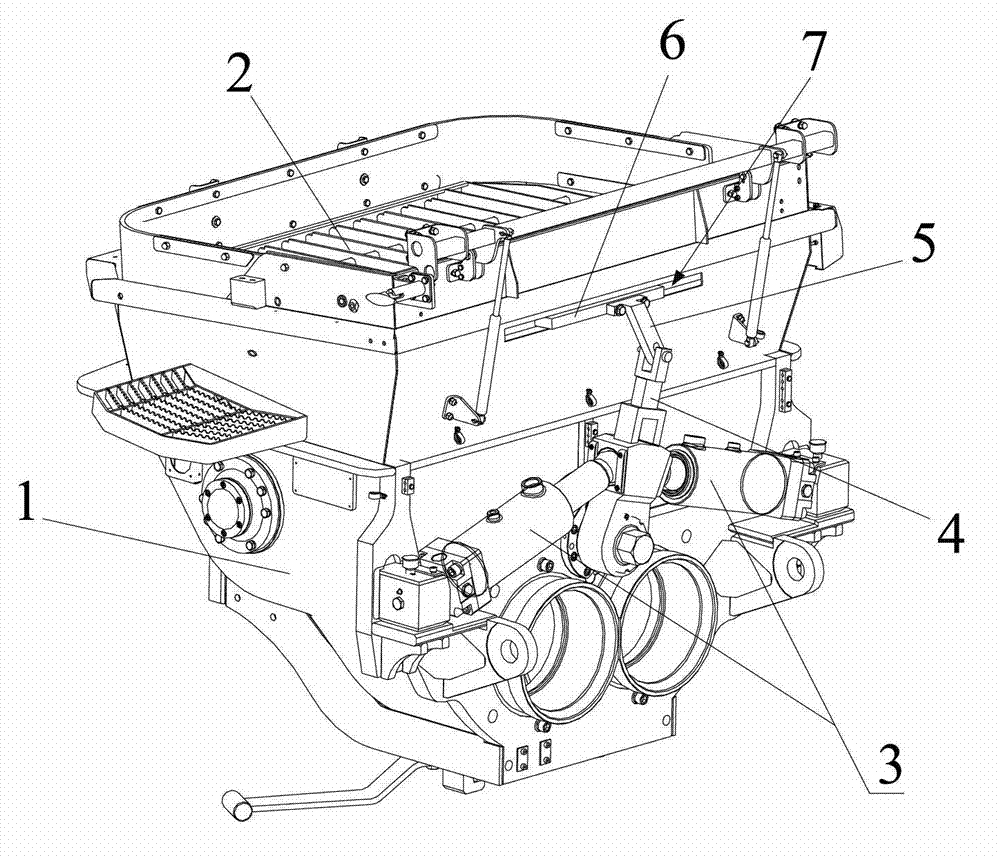

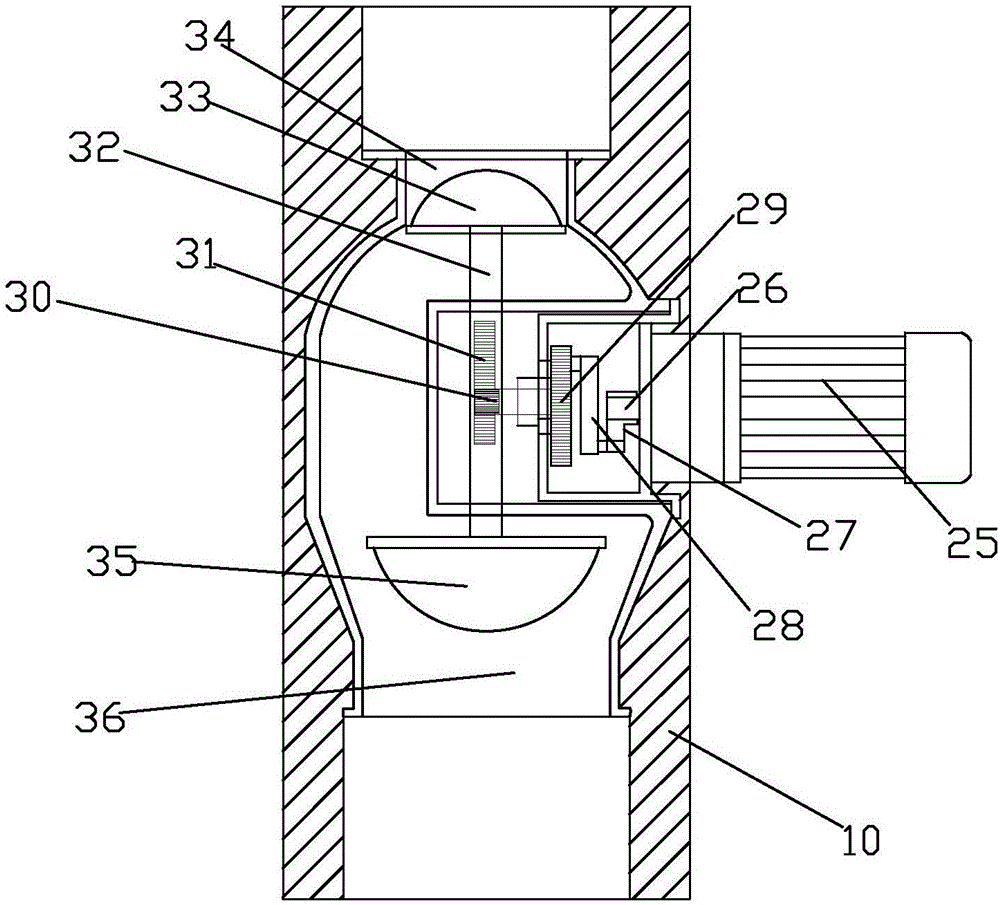

Pumping system and engineering machinery

ActiveCN102852336ALow costReduce procurement costsBuilding material handlingElectric machineryEngineering

The invention provides a pumping system; the pumping system comprises a hopper, a distribution valve and a swinging oil cylinder, wherein the hopper comprises a hopper body and a screen; the pumping system further comprises an earing; the screen is mounted at a material inlet of the hopper body; the screen is connected with a hopper body moving pair; the distribution valve is mounted in the hopper body; one end of the swinging oil cylinder is hinged on the hopper body and the other end of the swinging oil cylinder is used for driving the distribution valve to rotate; one end of the earing is connected with the other end of the swinging oil cylinder; the other end of the earing is connected with the screen in a rotating way; and while driving the distribution valve to rotate, the swinging oil cylinder can be used for driving the screen to move through the earing. The invention further provides engineering machinery. According to a technical scheme provided by the invention, the screen can be directly supplied with power by the swinging oil cylinder instead of a motor to vibrate; and as a vibrating device for swinging the screen is positioned behind the hopper and a swinging protective cover is arranged outside the hopper for protection, the whole hopper is simpler, beautiful and elegant.

Owner:SANY AUTOMOBILE MFG CO LTD

Industrial solid waste treatment device

The invention relates to the technical field of solid waste treatment, and discloses an industrial solid waste treatment device which comprises a box body. The upper surface of the box body is fixedlyconnected with a filter box, and the upper surface of the filter box is fixedly connected with a feeding pipe. According to the industrial solid waste treatment device, through the arrangement of structures such as the box body, a water storage cavity and feeding paddle, a first motor is started to drive the feeding paddle to rotate, so that waste in an arc-shaped funnel is conveyed into the boxbody, the feeding rate of the device is improved, and meanwhile the situation that the feeding pipe is blocked is avoided; through the arrangement of structures such as a filter plate, a drain pipe, the water storage cavity and a protective shell, waste can be effectively guided, and meanwhile part liquid in the waste is effectively filtered; through the arrangement of structures such as a secondmotor, a gear, smashing rollers and a rectangular shell, the second motor drives the gear to rotate, the gear drives the smashing rollers to rotate, and therefore the filtered waste can be further smashed through opposite rotation of the two smashing rollers.

Owner:ZHEJIANG QIANCHEN ECOLOGICAL ENVIRONMENTAL PROTECTION TECH CO LTD

Feeding mechanism for plastic pipe production extruder

ActiveCN110802827APrevent "bridging" phenomenon"Bridge" phenomenon to avoidProcess engineeringMechanical engineering

The invention relates to the field of plastic pipe production and processing devices, in particular to a feeding mechanism for a plastic pipe production extruder. The feeding mechanism comprises a hopper, a feeding pipe, an anti-blocking structure, a smashing structure, a screening structure, a sealing structure and a pressure relief structure. By installing the anti-blocking structure for preventing the 'bridging' phenomenon of powdery plastic raw materials in the hopper, the powdery plastic raw materials can be further smashed, the situation that the powdery plastic raw materials block the feeding pipe due to the gravity can be avoided, and the feeding speed can be increased; and besides, the anti-blocking structure can synchronously drive the smashing structure to work when working, caked powdery plastic raw materials can be thoroughly smashed by the work of the smashing structure, and thus it can be avoided that the caked powdery plastic raw materials block the feeding pipe, that is to say, the work of the smashing structure can react on the anti-blocking structure to make the working efficiency of the smashing structure higher.

Owner:浙江恒发管业有限公司

Optimized feeding device for steel ball rough grinding

ActiveCN107877367AImprove production and processing efficiencyIncrease feeding rateGrinding feedersSteel ballEngineering

The invention discloses an optimized feeding device for steel ball rough grinding, and relates to the technical field of steel ball production equipment. The optimized feeding device for steel ball rough grinding comprises a first supporting plate, a first motor is fixedly connected with one end of the surface of the top of the first supporting plate, a conveying belt is arranged at one end, awayfrom the first motor, of the top of the first supporting plate, the rotating end of the first motor is rotatably connected with a gear of the conveying belt through a belt, and a first discharging barrel is arranged on the annular surface of one end, away from the first motor, of the conveying belt; and fixed supporting frames are fixedly connected with the two ends of the surface of the bottom ofthe first supporting plate, and a feeding device is arranged at one end, away from the conveying belt, of the first discharging barrel. According to the optimized feeding device for steel ball roughgrinding, the purpose of improving the steel ball production efficiency is achieved, a to-be-machined steel ball in a rough grinding chamber is subjected to rapid rough grinding through cooperative using of a second motor and a third motor, and a rough grinding device is simple in structure, and easy and convenient to operate.

Owner:夏浚康

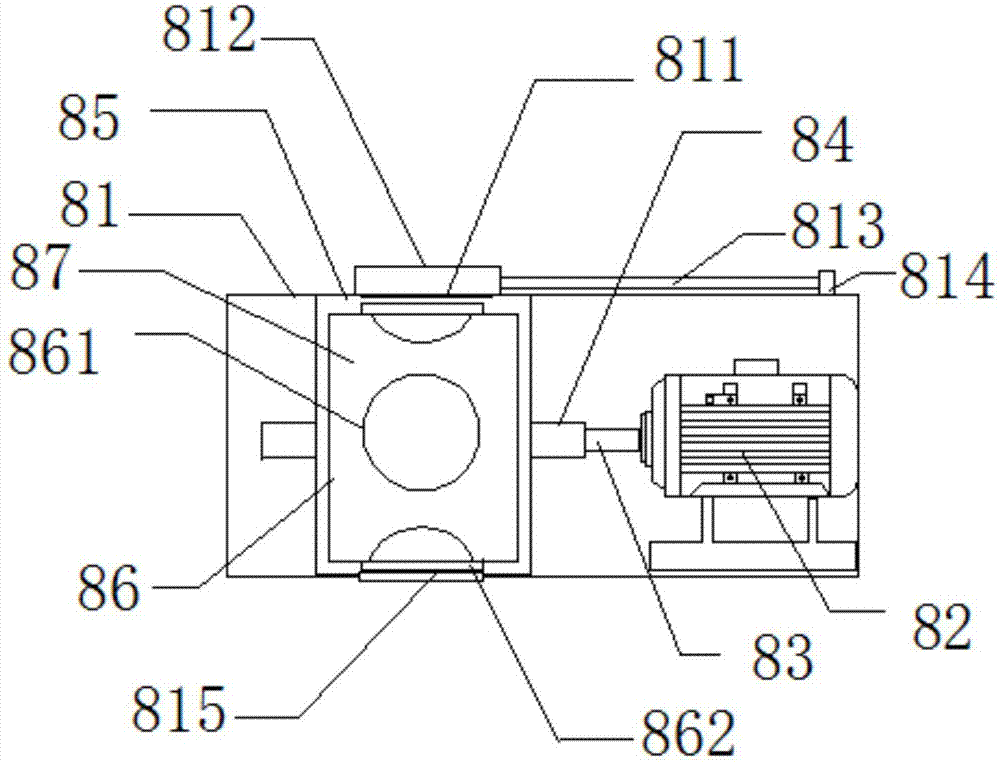

Intelligent reaction kettle and method for recycling mixed acid of hydrofluoric acid and hydrochloric acid

ActiveCN106732206AZero pollutionZero emissionCalcium/strontium/barium chloridesCalcium/strontium/barium fluoridesLiquid productRecovery method

The invention discloses an intelligent reaction kettle and a method for recycling mixed acid of hydrofluoric acid and hydrochloric acid. The reaction kettle is designed once again, so that the mixed acid recycling can be perfectly matched by using the reaction kettle, and time and labor can be saved. The method comprises the following steps: continuously adding barium carbonate powder into the reaction kettle filled with the mixed acid; controlling the pH value and a reaction endpoint; pumping and filtering after the reaction is completed; washing and drying the filter residues to obtain a barium fluoride product; and removing impurities of filtrate, refining to obtain a barium chloride aqueous solution product which can be used as a liquid product for direct external sale or concentrated into a solid product for external sale. By adopting the recycling product, the mixed acid is processed into barium fluoride and barium chloride products, so that the mixed acid can be completely recycled, waste can be turned into wealth, and the environment cannot be polluted.

Owner:QUZHOU XINBU CHEM TECH CO LTD

Mechanical arm accessory machining waste collecting device

The invention discloses a mechanical arm accessory machining waste collecting device. The mechanical arm accessory machining waste collecting device comprises a machining platform. Four supporting columns are arranged at the bottom of the machining platform. A stand column is vertically welded to one side of the upper portion of the machining platform. A beam is horizontally arranged on the top ofthe stand column. An electric guide rail is fixed to the bottom of the beam in the length direction through screws and provided with a sliding block. A telescopic air cylinder is fixed to the bottomof the sliding block. A pushing plate is fixed to a push rod of the telescopic air cylinder. A discharging port is formed in one side of the machining platform. A fixing support is welded to the bottom of the machining platform, and one end of the discharging port in the bottom of the machining platform is connected with an unloading guide plate. By means of the mechanical arm accessory machiningwaste collecting device, waste on the mechanical arm machining platform can be rapidly and conveniently removed, the tidiness of the machining platform is kept, and accordingly, the mechanical arm accessory machining quality is improved; and the waste can be rapidly guided into a waste box, the waste is prevented from being stacked and blocked at the discharging port, and the waste recycling efficiency is improved.

Owner:JINGDE COUNTY HANHAI NEBULA INTELLIGENTIZE TECH RES & DEV CO LTD

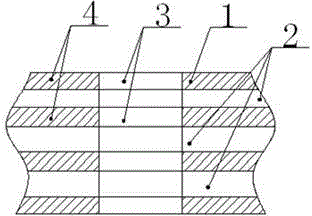

Processing method of finished holes of circuit board with inner-layer copper thickness of more than 420 micrometers

ActiveCN104690769ASolve sheddingNo tool wrapping phenomenonMetal working apparatusCopper wireMicrometer

The invention belongs to a processing method of finished holes of a circuit board with the inner-layer copper thickness of more than 420 micrometers. The processing method comprises the following steps: adopting a drilling head with phi 0.60 mm to uniformly drill a plurality of holes with phi of 0.60 mm around the finished holes (3) on the circuit board (4) of which the inner-layer copper thickness is more than 420 micrometers; adopting a drilling head with phi of 1.50 mm to drill a plurality of holes with phi of 1.50 mm; adopting a drilling head with phi of 2.00 mm to drill holes with phi of 2.00 mm at the centers of the finished holes (3); adopting a drilling head of 3.00 mm to drill holes with phi of 3.00 mm. The processing method disclosed by the invention has the advantages that the cutting force is effectively reduced, the drilling heat is lowered, and the problem that bonding pads on inner layers drop off is solved; the chip breaking effect is better; the phenomenon that copper wires wind cutters is avoided; the edges of the holes are smooth and tidy and do not have obvious burrs; the feeding rate of drilling is high.

Owner:DALIAN CHONGDA CIRCUIT

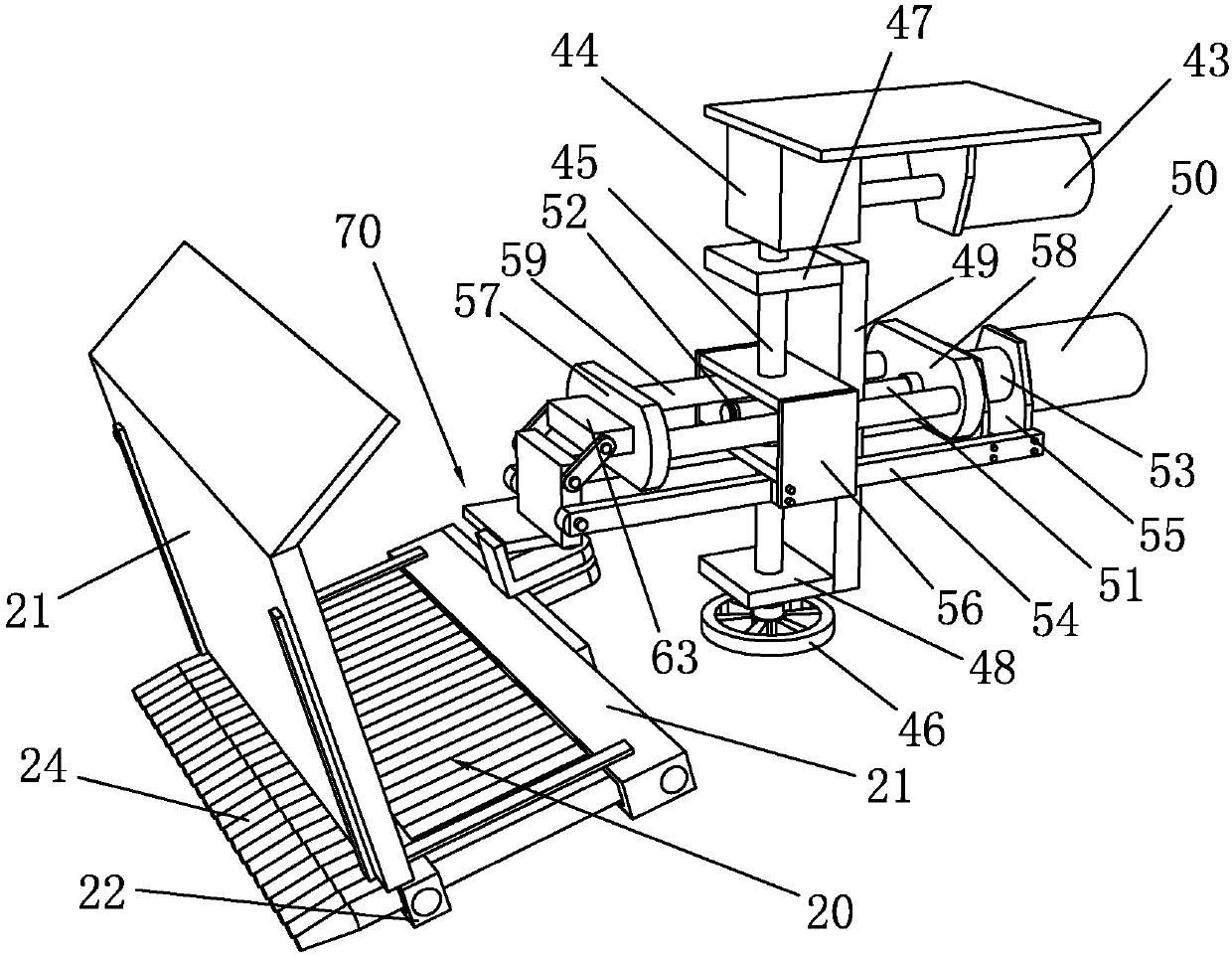

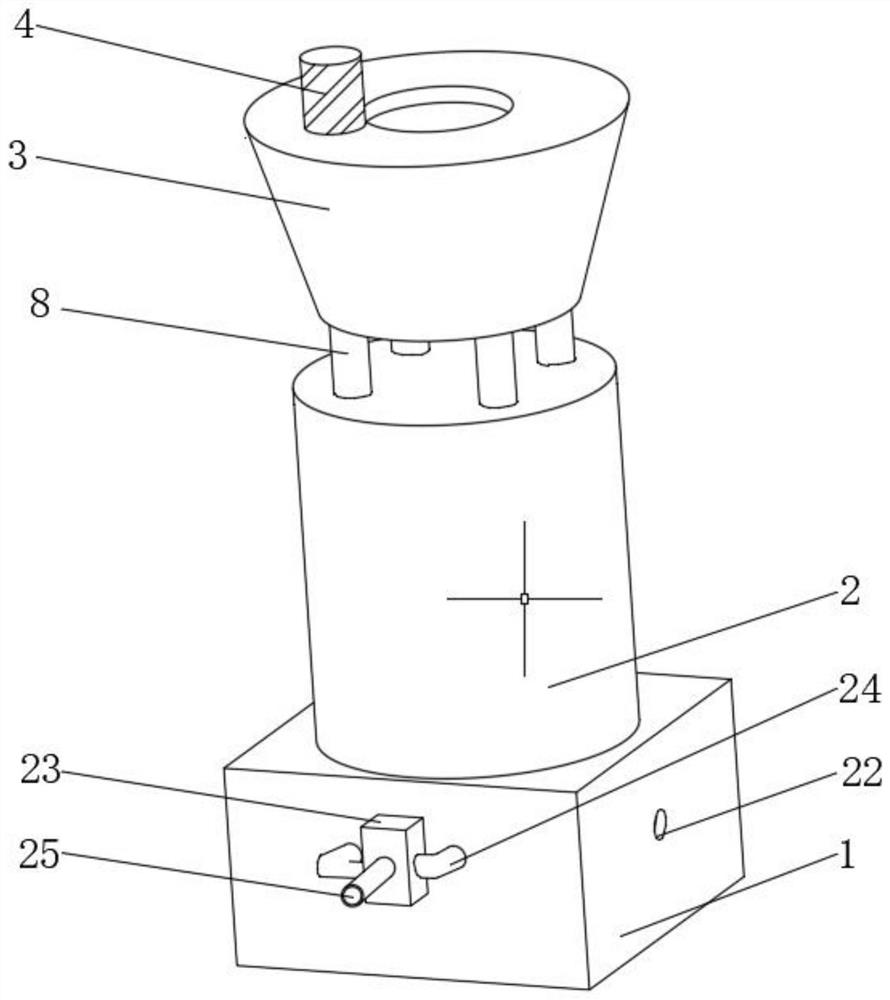

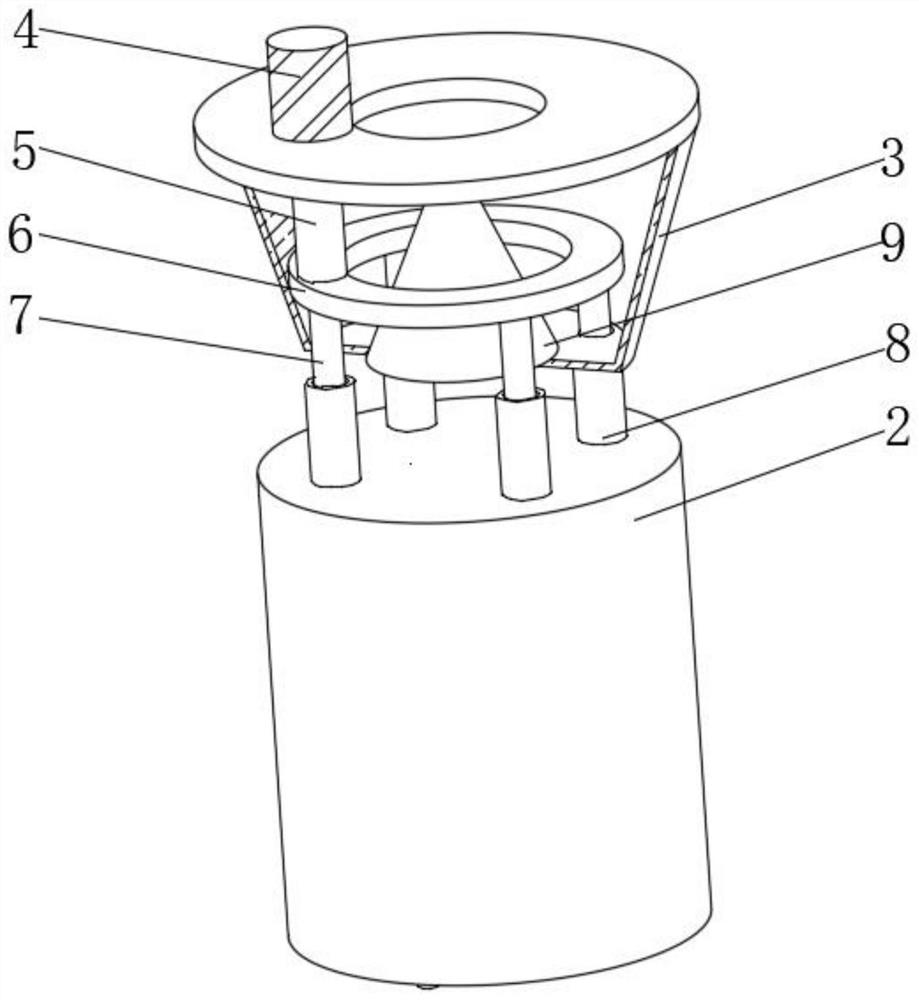

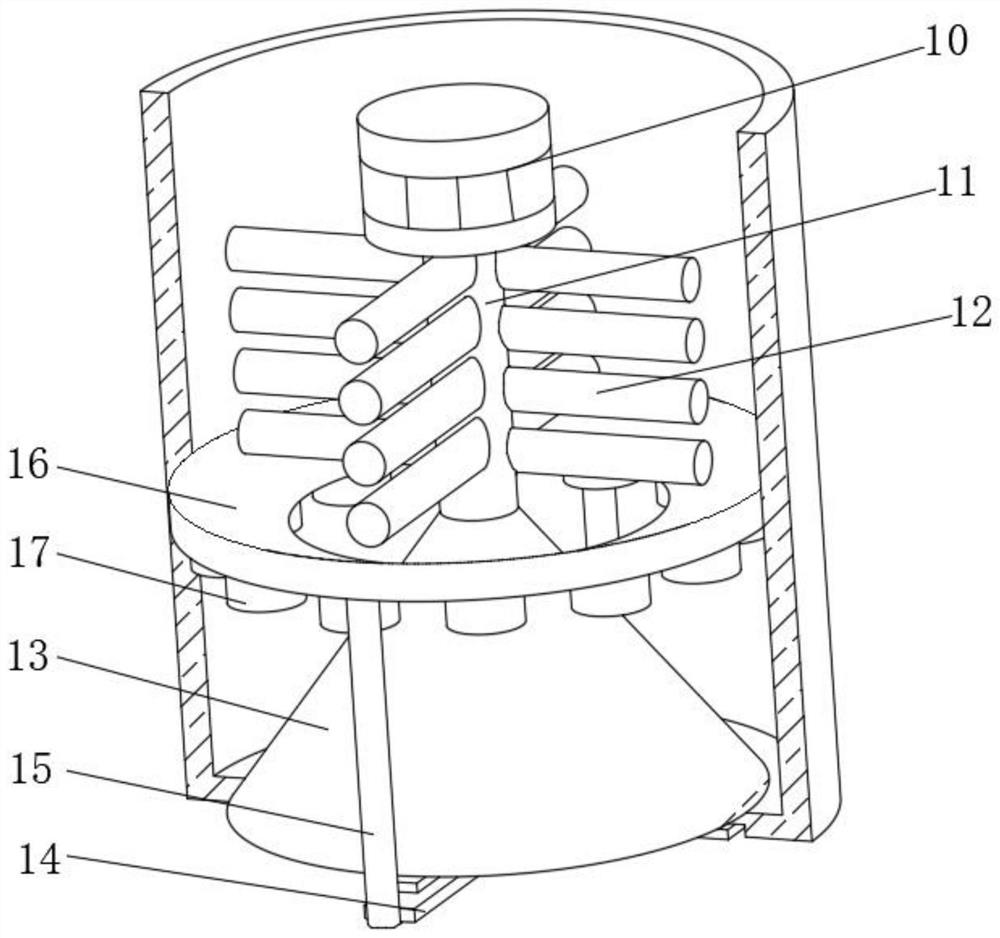

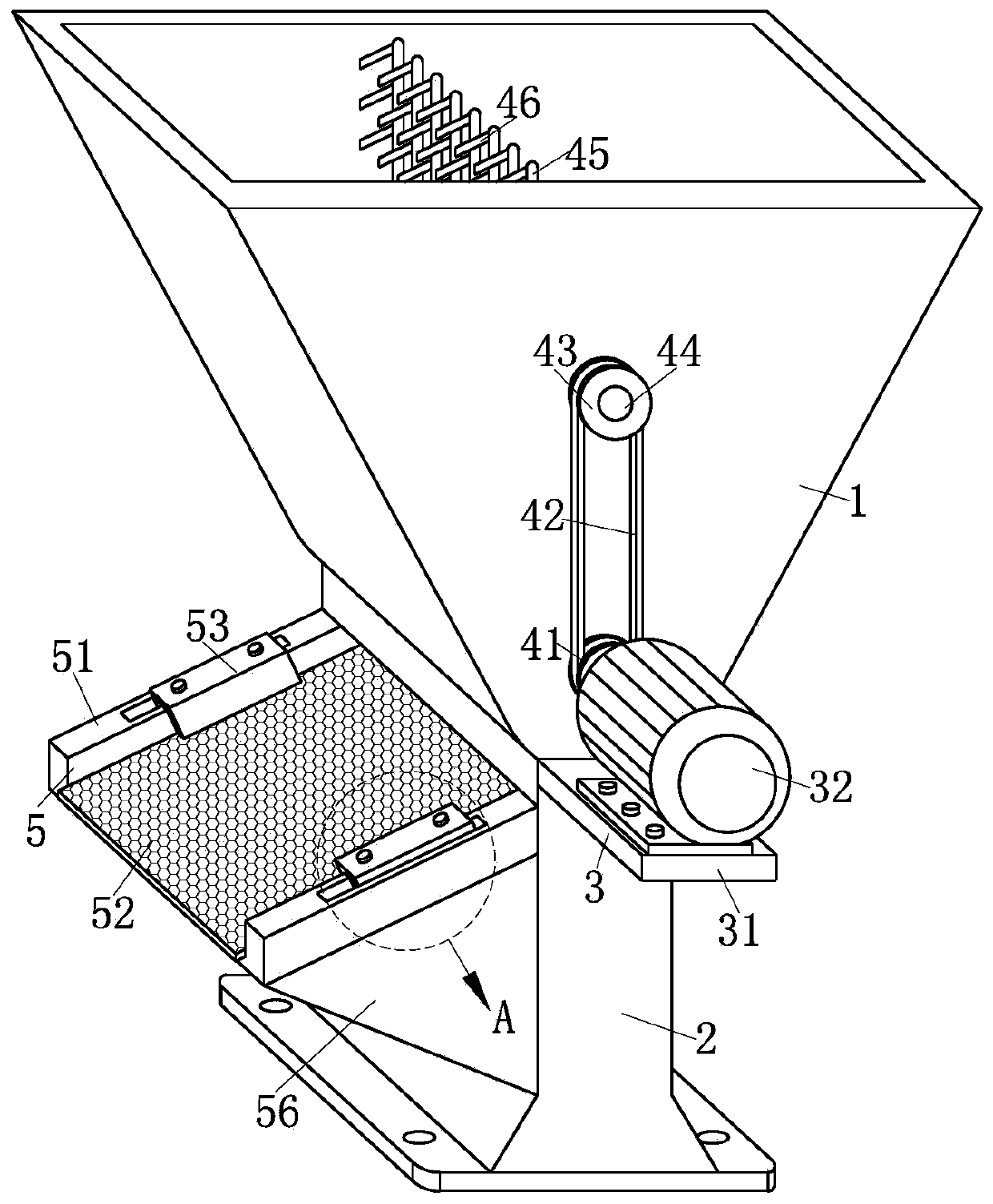

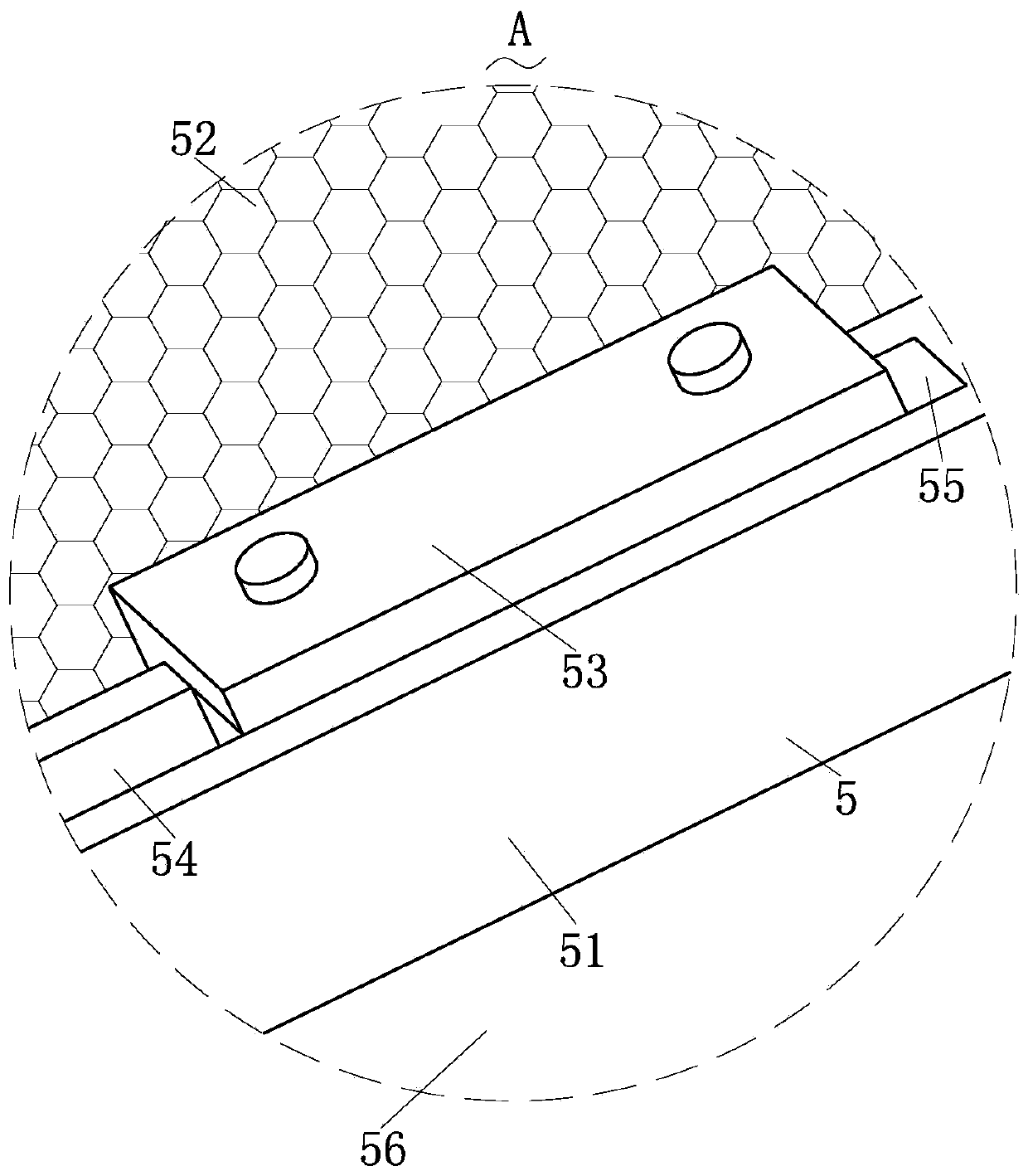

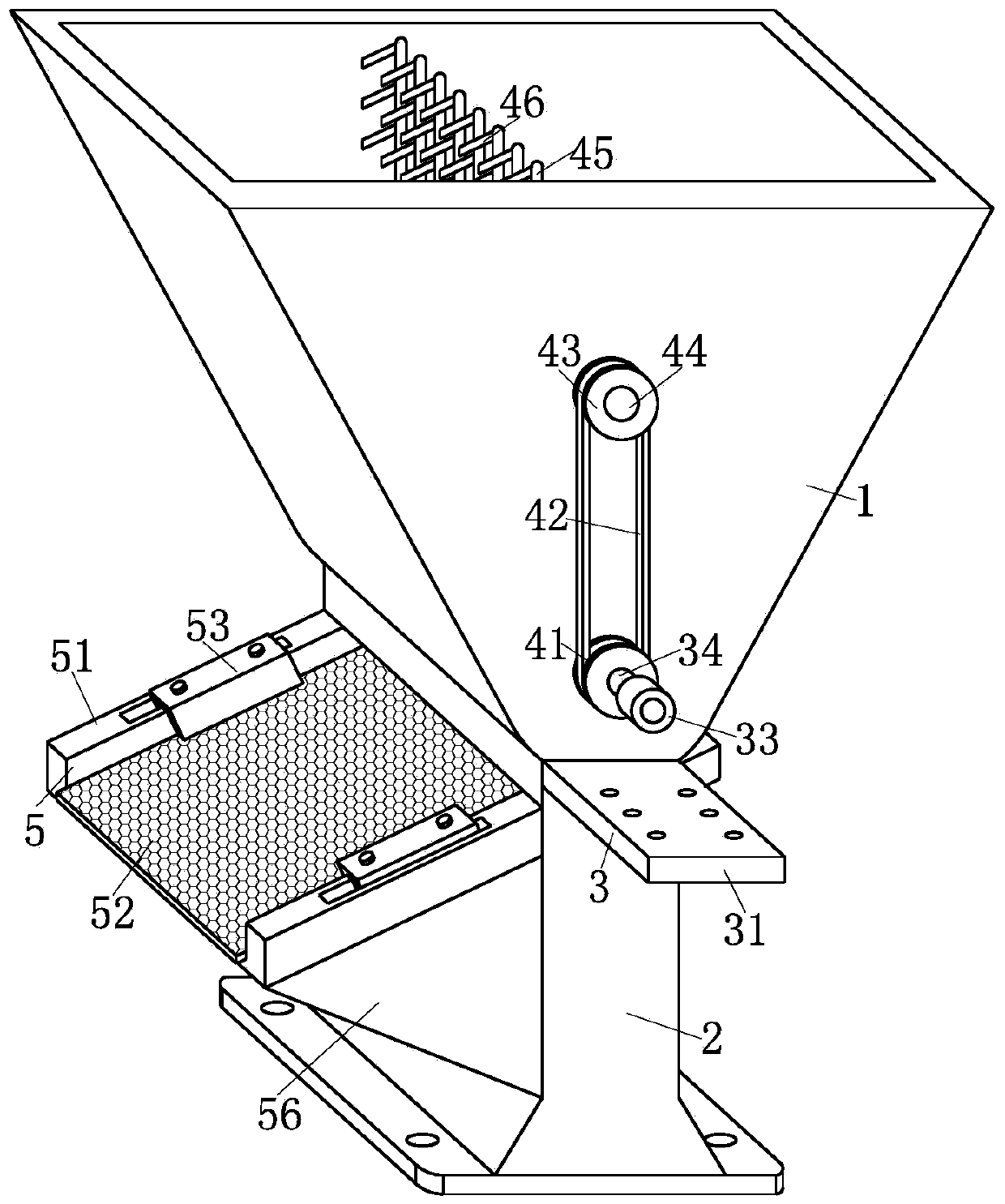

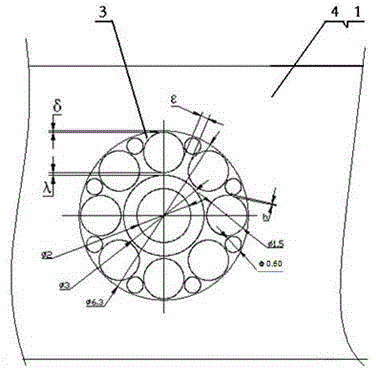

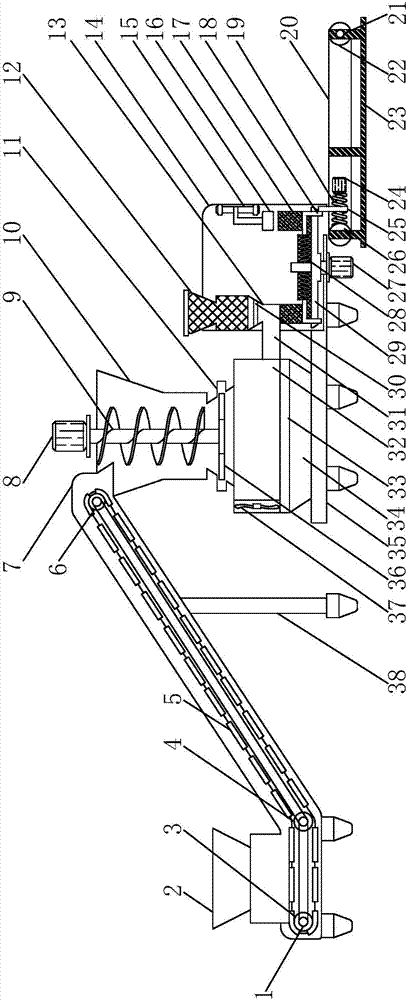

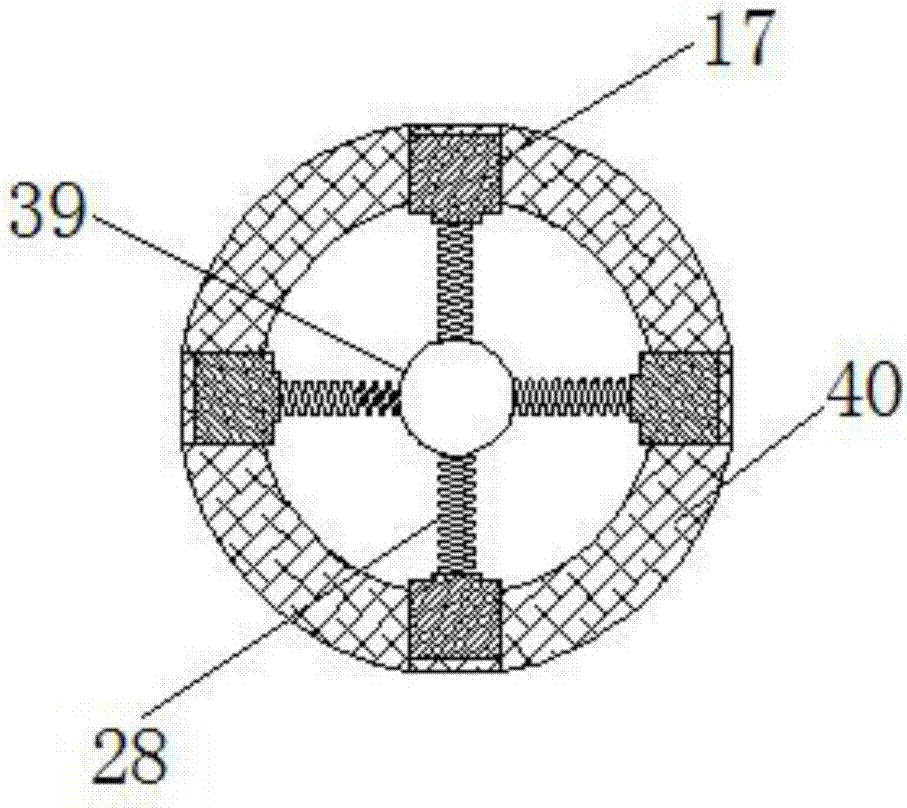

Biomass straw briquetting machine for efficiently producing

ActiveCN107033981APrevent blocking phenomenonIncrease feeding rateBiofuelsSolid fuelsEngineeringImpurity

The invention discloses a biomass straw briquetting machine for efficiently producing. The biomass straw briquetting machine comprises a stirring housing, pressing moulds, a dust collecting box, a base and a smashing blade. The dust collecting box is installed at one side above the base. The top end of the dust collecting box is fixedly provided with a cooling housing. A fan is installed at one side in the cooling housing. A smashing housing is fixed above the cooling housing. The top end of the smashing housing is provided with the stirring housing. A briquetting housing is installed on the base at one side of the dust collecting box. A workbench is installed at the central position of the bottom end of the briquetting housing. An annular material storage is installed above the workbench. The interior of the material storage is provided with four pressing moulds of which the neighboring included angle is 90 degrees. The biomass straw briquetting machine is capable of realizing the efficient briquetting discharge function of the biomass straw, and has the advantages of no blocking situation of the device, rapid feeding speed, large material storage, high briquetting efficiency, good briquetting effect, long service life of the device, simple and convenient operation and high working efficiency. In addition, the impurities cannot enter into the mould.

Owner:新沂城北新区城市建设发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com