Reaction kettle for chemical production with temperature adjustment function and operating method of reaction kettle

A technology of chemical production and reactors, applied in chemical instruments and methods, chemical/physical/physical chemical fixed reactors, chemical/physical processes, etc., can solve the waste of chemical raw materials, insufficient reaction of chemical raw materials, and cannot be adjusted in real time Reactor temperature and other issues to achieve the effect of improving utilization efficiency, reducing waste, and promoting reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

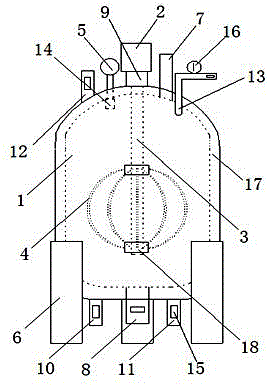

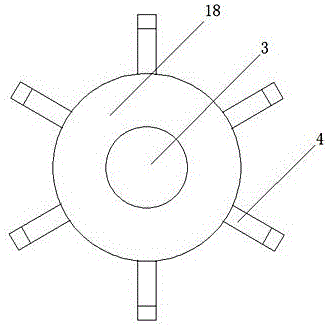

[0023] as attached figure 1 with 2 As shown, a reaction kettle for chemical production with a temperature adjustment function, including a kettle body 1, a motor 2, a transmission shaft 3, a stirring rod 4 and a thermometer 5, is characterized in that: the kettle body 1 is arranged on a support 6 , feed pipe 7, discharge pipe 8, stabilizing block 9, cold medium inlet pipe one 10, heat medium inlet pipe two 11, medium outlet pipe 12, exhaust pipe 13 are arranged on the kettle body 1, and on the kettle body 1. A temperature sensor 14 is provided on the inner wall. Valves 15 are provided on the discharge pipe 8, the cold medium inlet pipe 10, the hot medium inlet pipe 11, and the medium outlet pipe 12. On the kettle body 1 An interlayer 17 is provided, and the interlayer 17 is connected with the cold medium inlet pipe 10, the heat medium inlet pipe 11, and the medium outlet pipe 12. The exhaust pipe 13 is provided with a barometer 16, which can reflect the kettle body 1 in real ...

Embodiment 2

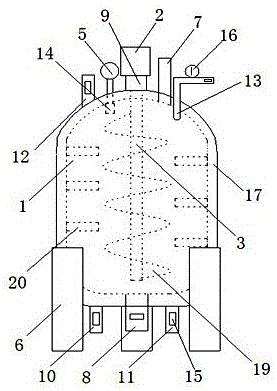

[0031] as attached image 3 As shown, a reaction kettle for chemical production with a temperature adjustment function, including a kettle body 1, a motor 2, a transmission shaft 3, a stirring rod 4 and a thermometer 5, is characterized in that: the kettle body 1 is arranged on a support 6 , feed pipe 7, discharge pipe 8, stabilizing block 9, cold medium inlet pipe one 10, heat medium inlet pipe two 11, medium outlet pipe 12, exhaust pipe 13 are arranged on the kettle body 1, and on the kettle body 1. The inner wall is provided with a temperature sensor 14 and a temperature conducting rod 20. Through the temperature conducting rod 20, the temperature in the interlayer 17 can be transferred to the kettle body 1 in time, so that the temperature in the kettle body 1 can reach the suitable temperature for the production of chemical raw materials. Described discharge pipe 8, cold medium inlet pipe one 10, hot medium inlet pipe two 11, and medium outlet pipe 12 are all provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com