Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37 results about "Industrial reactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

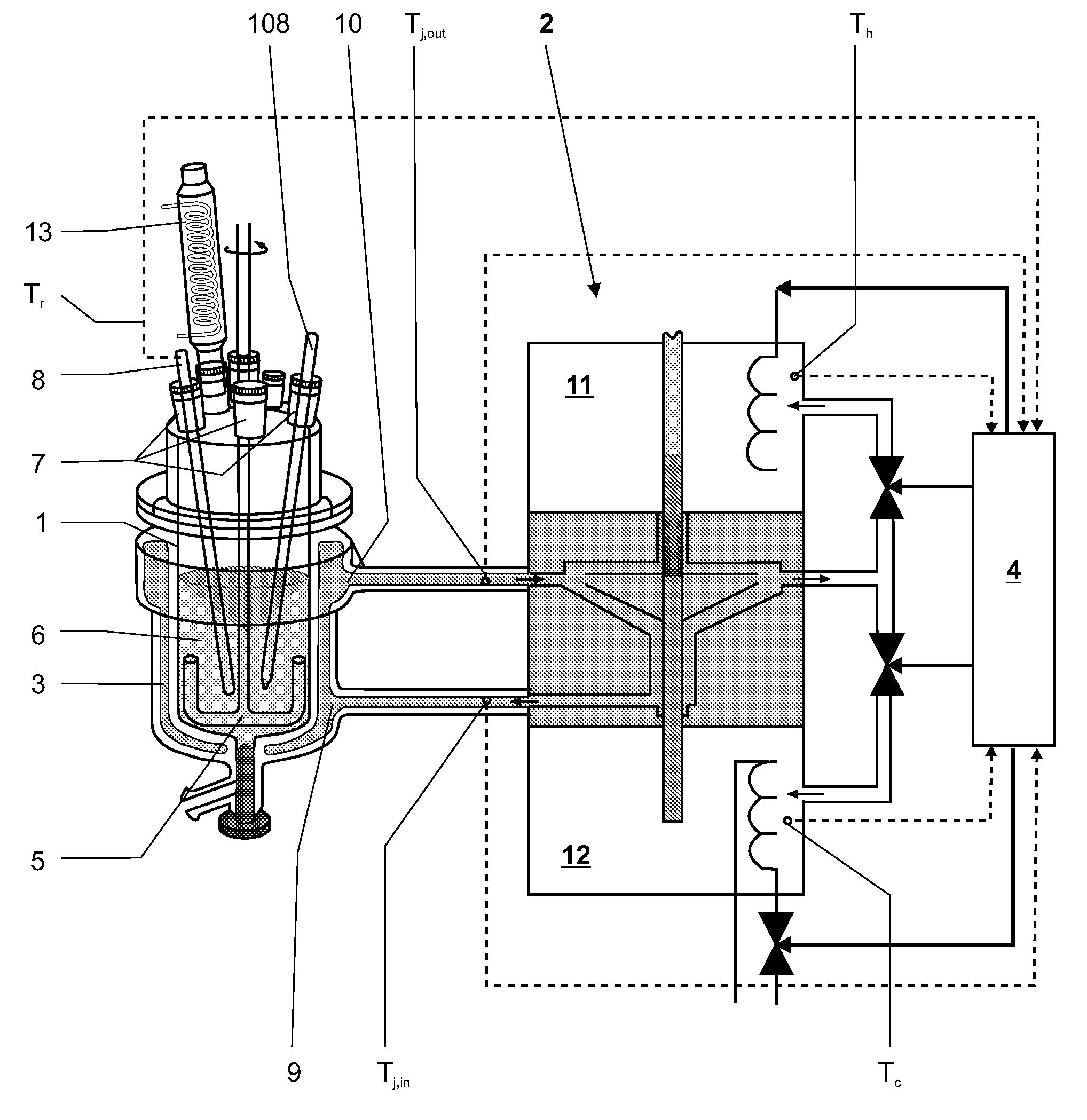

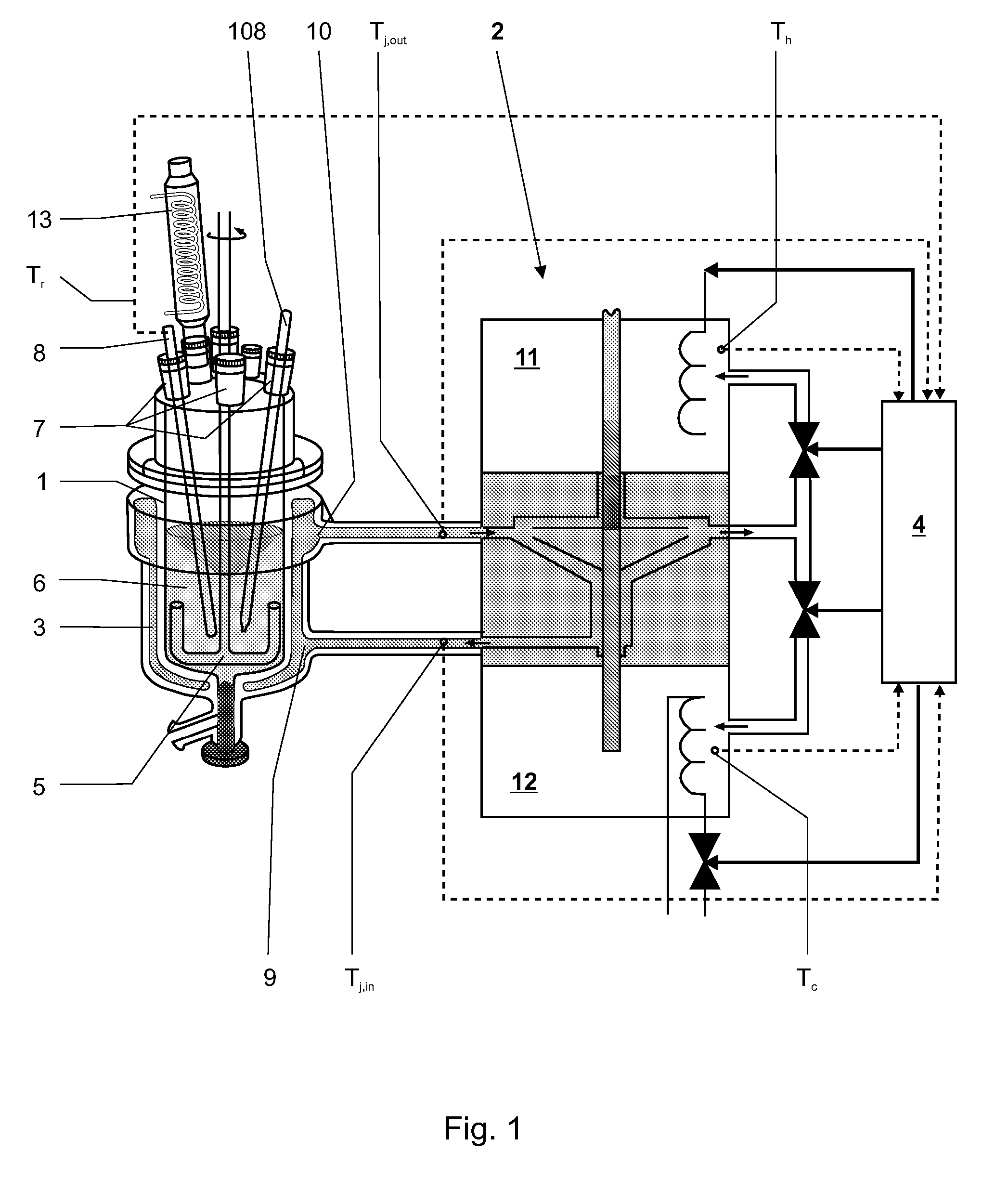

Method for simulating a process plant at laboratory scale

InactiveUS7476020B2Control the temperature of the reaction mixture fast and accuratelyRapid temperatureThermometer detailsSimulator controlIndustrial reactorLaboratory scale

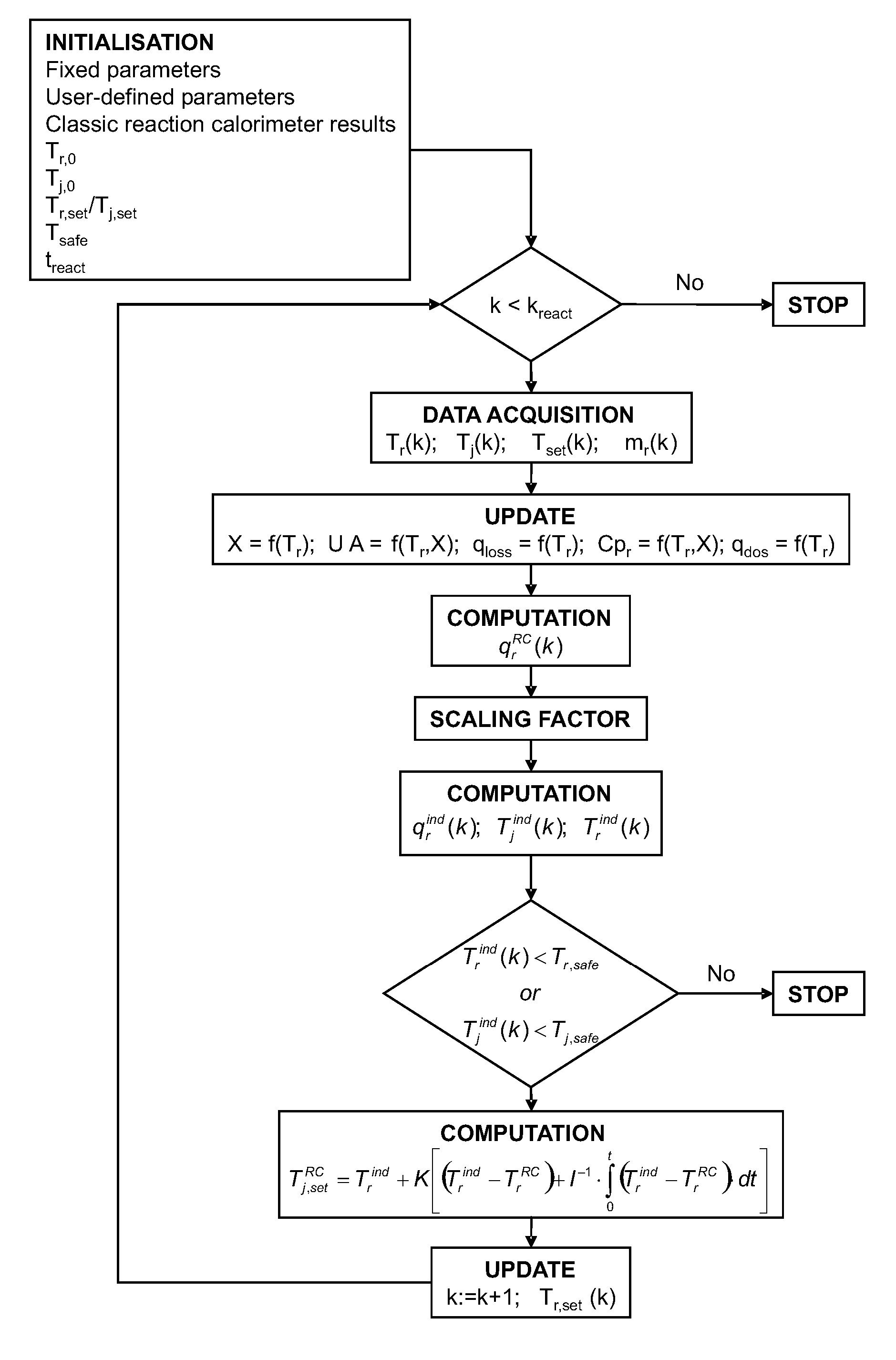

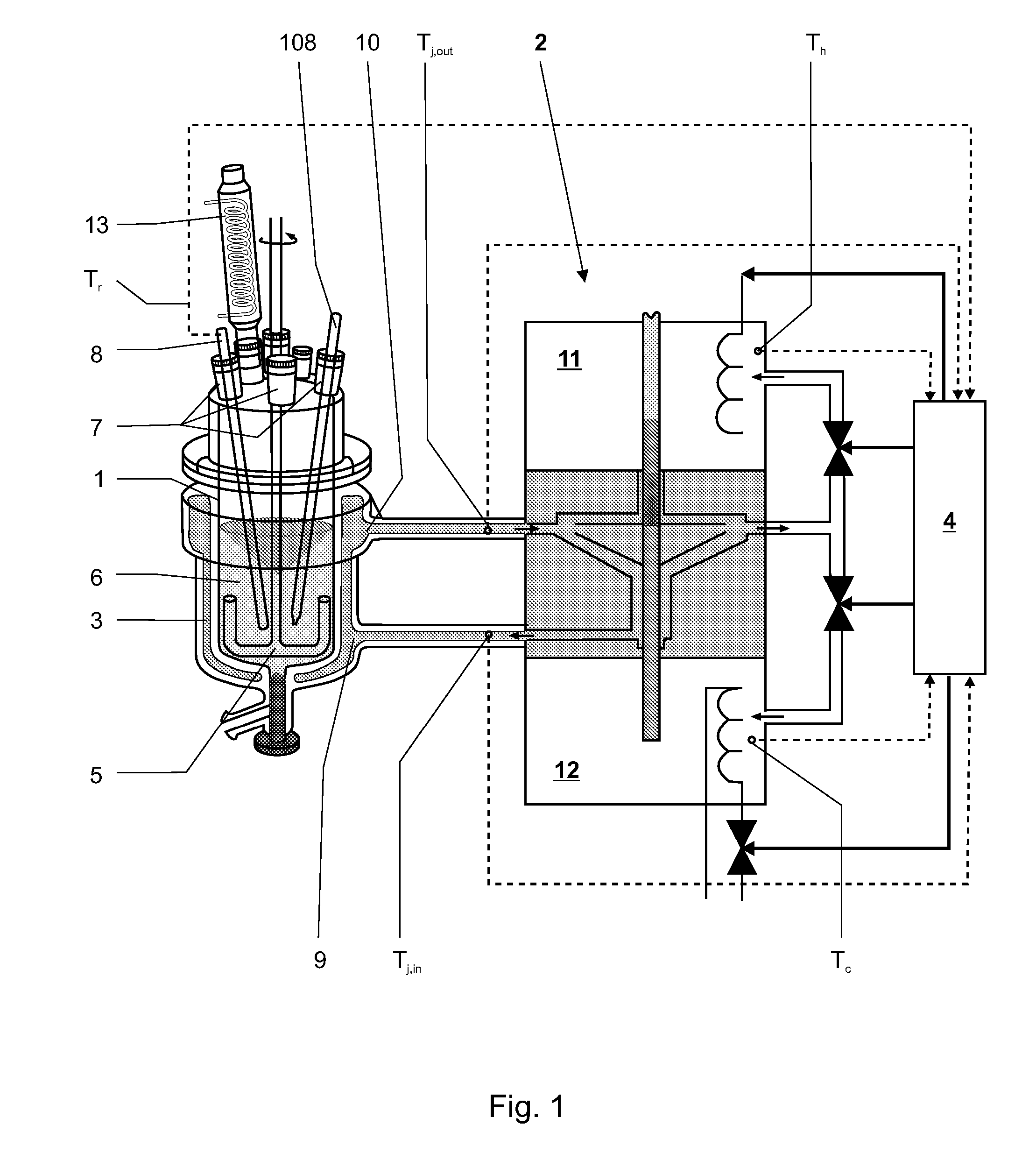

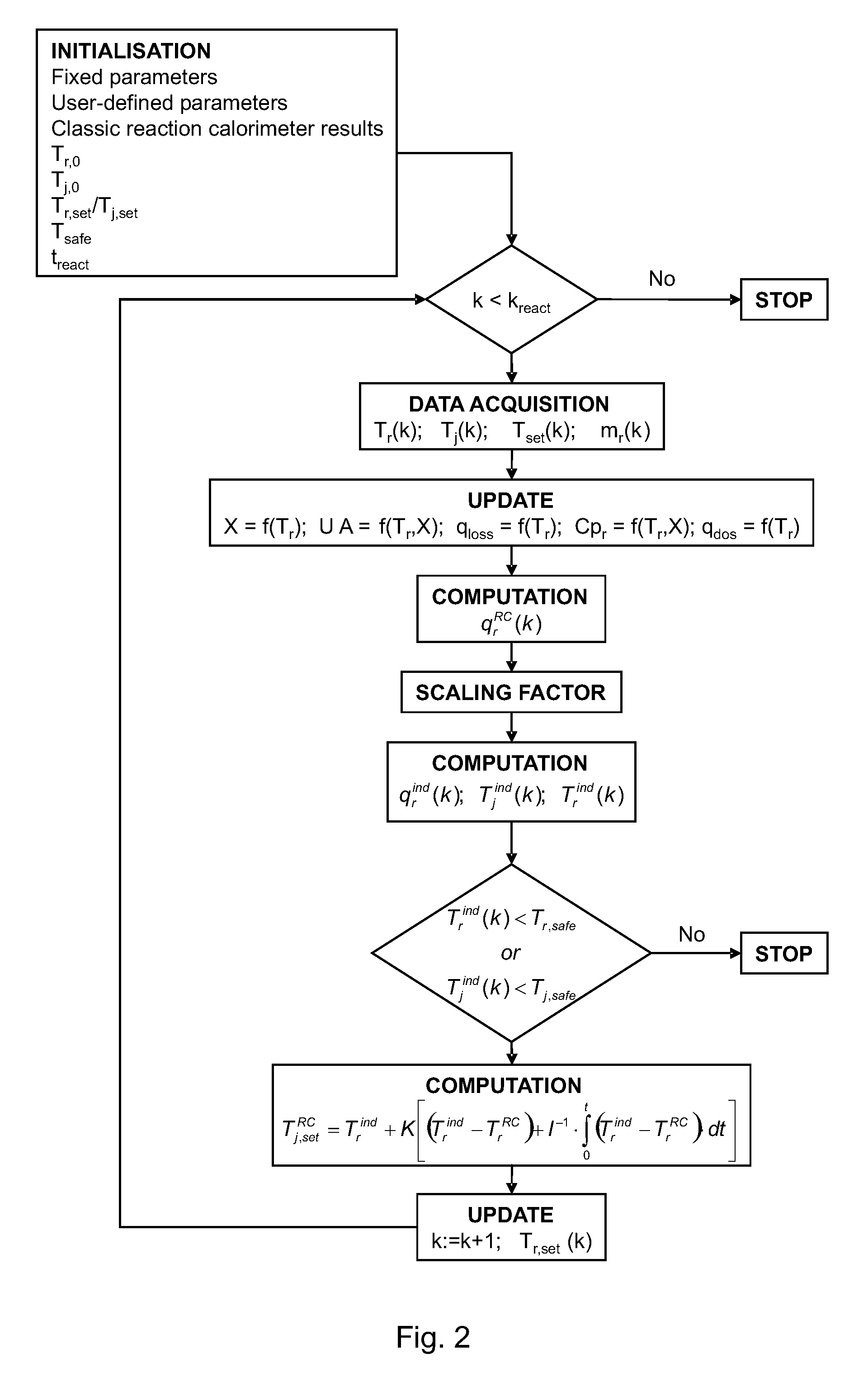

A method, a laboratory device and the use of both are provided for simulating the dynamic temperature behavior of at least one part of a process plant, particularly an industrial reactor. The method provides a temperature profile and / or temperature setpoints at given time intervals for controlling the laboratory device. The temperature profile and / or temperature setpoints are derived from a mathematical model that describes the dynamic temperature behavior of at least one part of the process plant. The temperature profile and / or the temperature setpoints are used by a program for controlling the laboratory device.

Owner:METTLER TOLEDO GMBH

Method for preparing liquid fuel from biomass through hydrogen-donor solvent

ActiveCN102051194ASimplify the cooling and condensation processLess investmentLiquid hydrocarbon mixture productionChemical reactionPetroleum product

The invention discloses a method for preparing a liquid fuel from biomass through a hydrogen-donor solvent. The method is as follows: under mild conditions, a proper catalyst and a hydrogen-donor solvent are used to directly perform liquefaction treatment on a biomass raw material without using hydrogen gas to produce high-quality fuel oil which can replace petroleum products. The method adopts the proper chemical reaction environment and solves the problems of the existing method that biomass can not be used to prepare oil in the physical environment of a large-scale industrial reactor through rapid pyrolysis; and by adopting the method provided by the invention, the reaction in the industrial equipment or experimental equipment has good repeatability, the technology is simple, the equipment configuration is less, the demand on pressure is lower than that of the high-pressure liquefaction technology, and hydrogen gas is not used for reaction. Thus, the method has wide application prospect in the development and utilization of biomass energy.

Owner:CHINA PETROLEUM & CHEM CORP +1

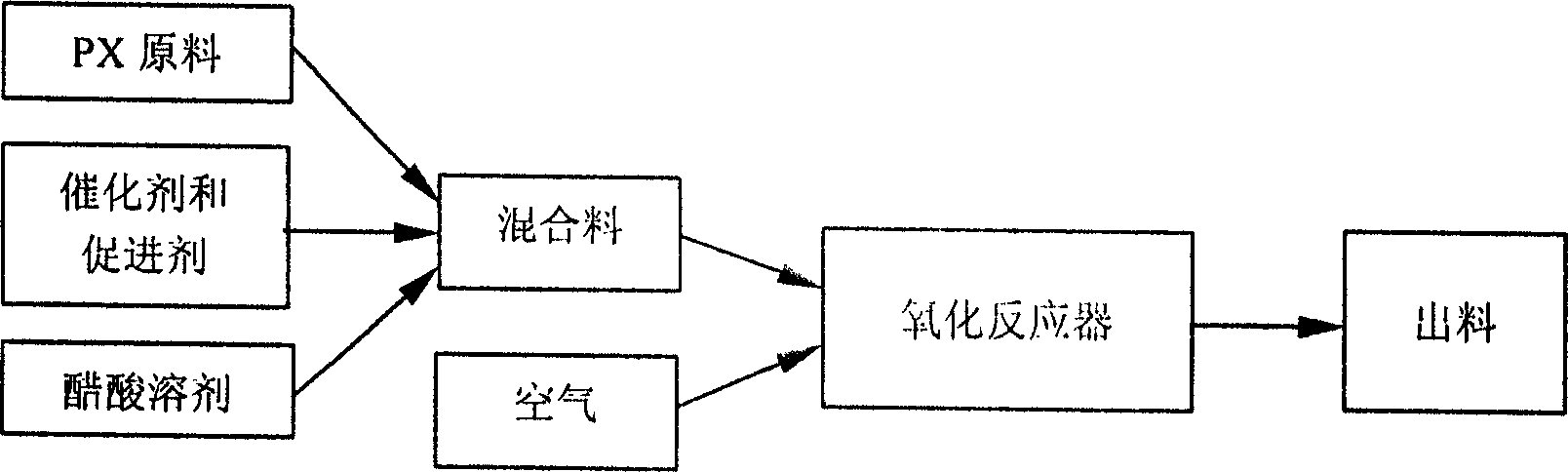

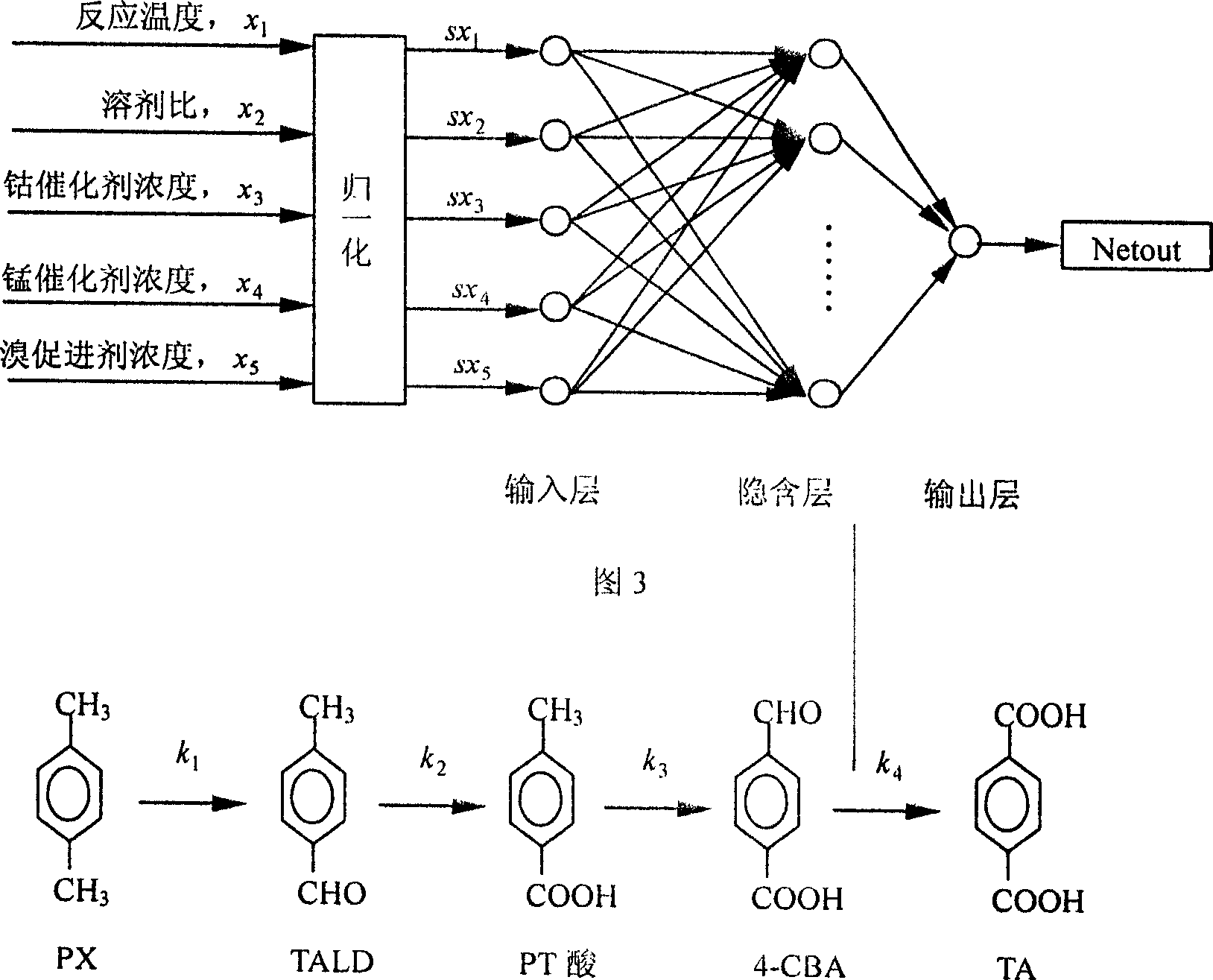

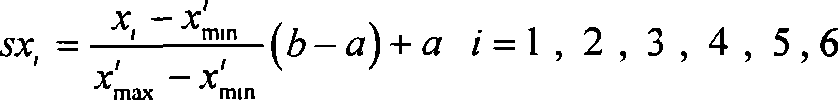

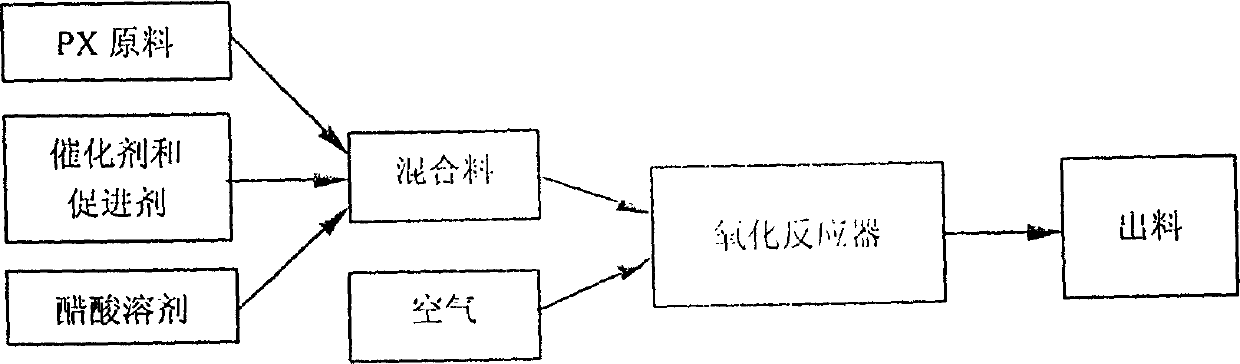

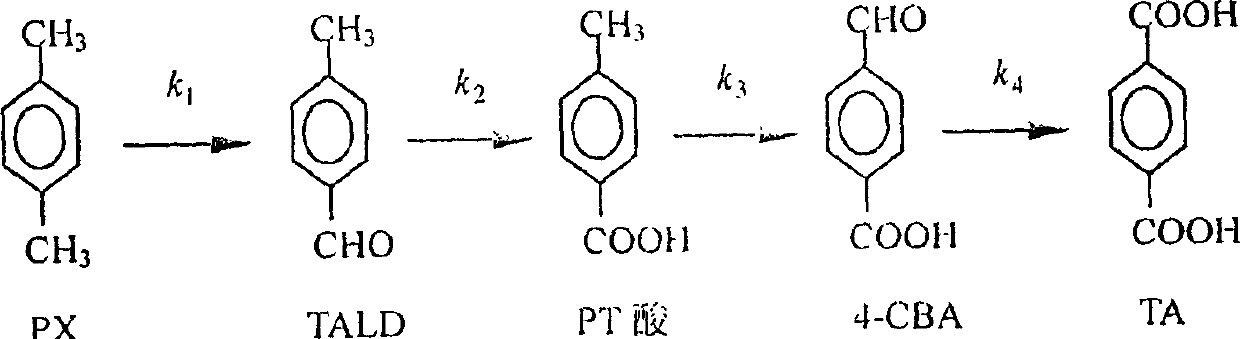

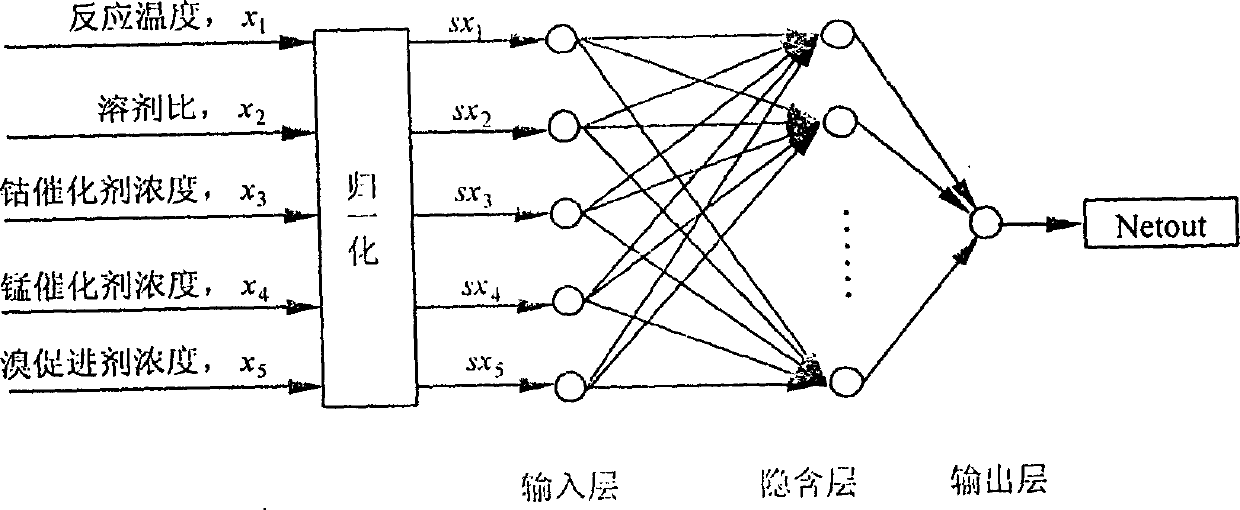

Establishing method of dynamic model of liquid phase catalytic paraxylene oxidizing reaction

InactiveCN1417192AOrganic compound preparationCarboxylic compound preparationIndustrial reactorDynamic models

The establishing method of dynamic model of liquid phase catalytic paraxylene oxidizing reaction comprises utilizing the reaction temperature x1 and mixed material composition including solvent ratiox2, Co catalyst concentration x3, Mr catalyst concentration x4, and Br promoter concentration x5 and the rate constant nerve net model to find out the rate constants ki, where i=1,2,3 and 4, of the steps in reaction network of industrial liquid phase catalytic paraxylene oxidizing reaction, and to find out the contents of PX, TALD, PT acid, 4-CBA, TA and other intermediate products and estimate products. The rate constant model can describe the effects of different factors on the reaction in the industrial reactor.

Owner:SINOPEC YANGZI PETROCHEM +1

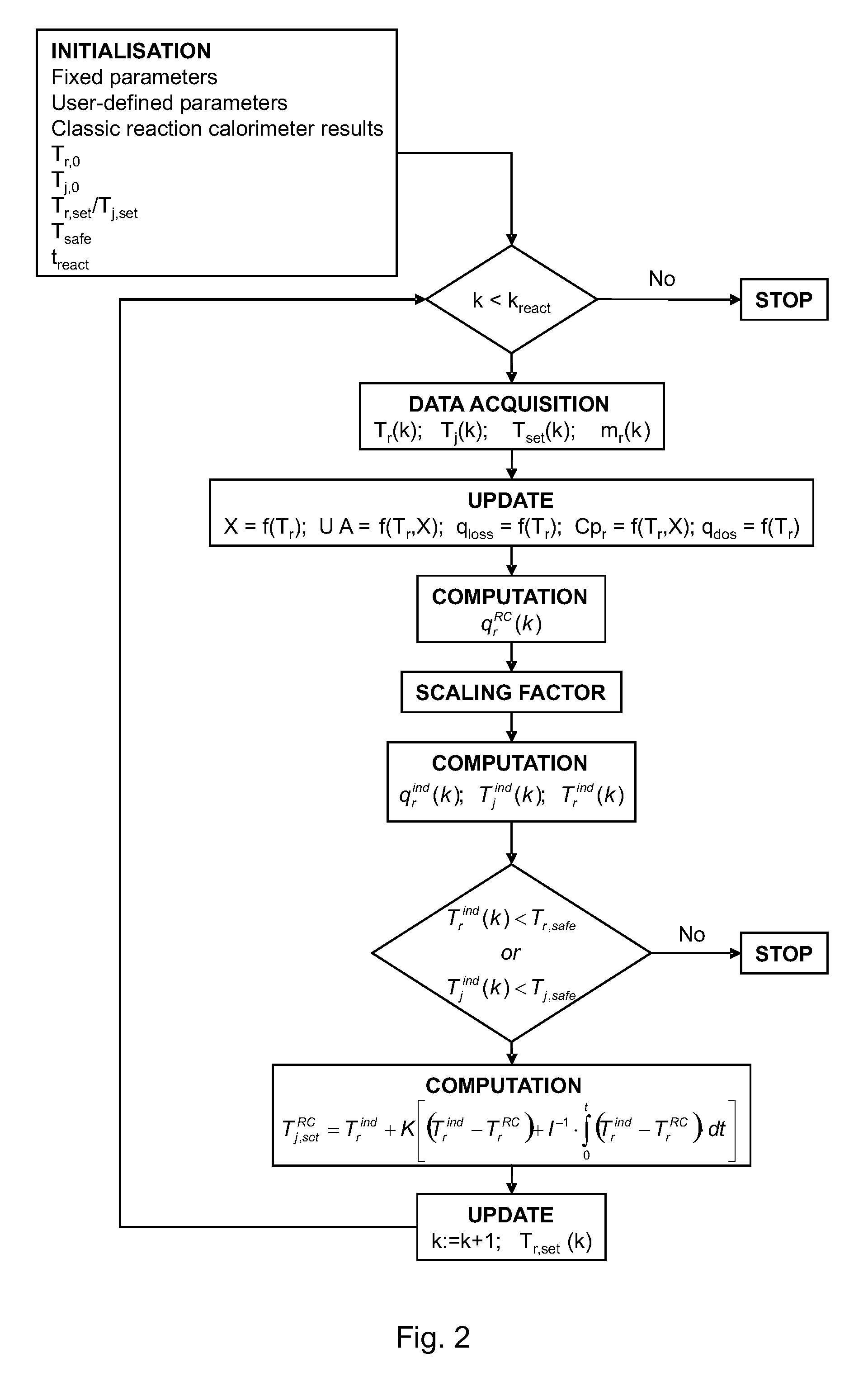

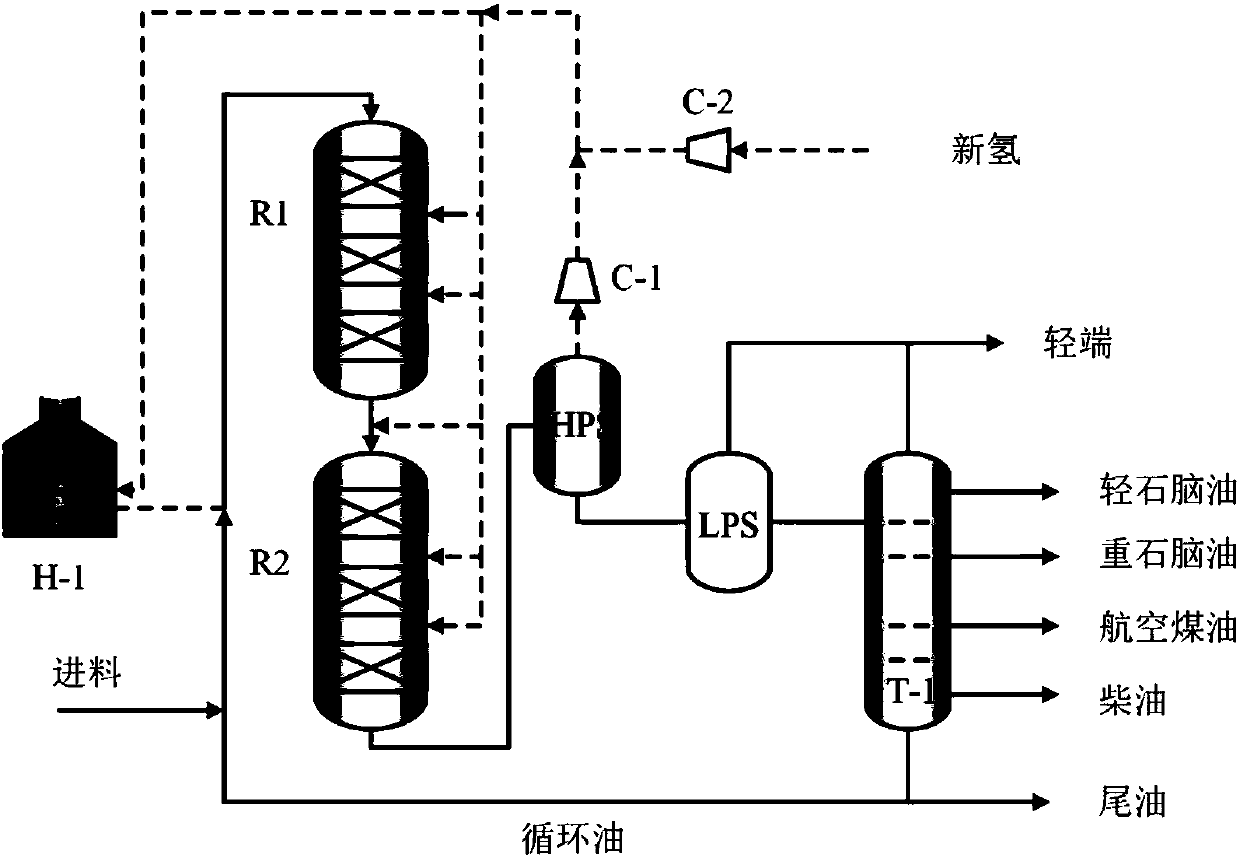

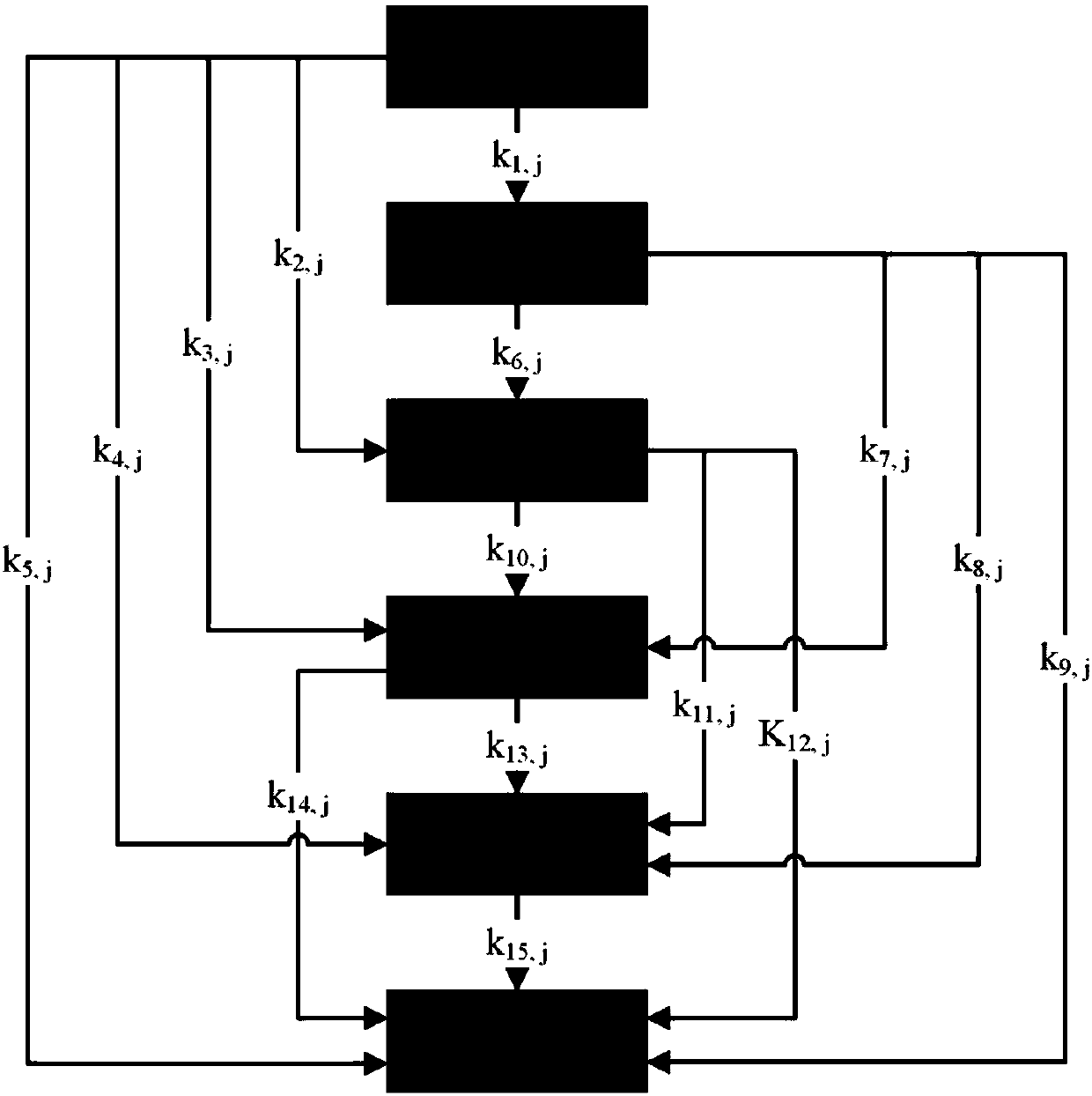

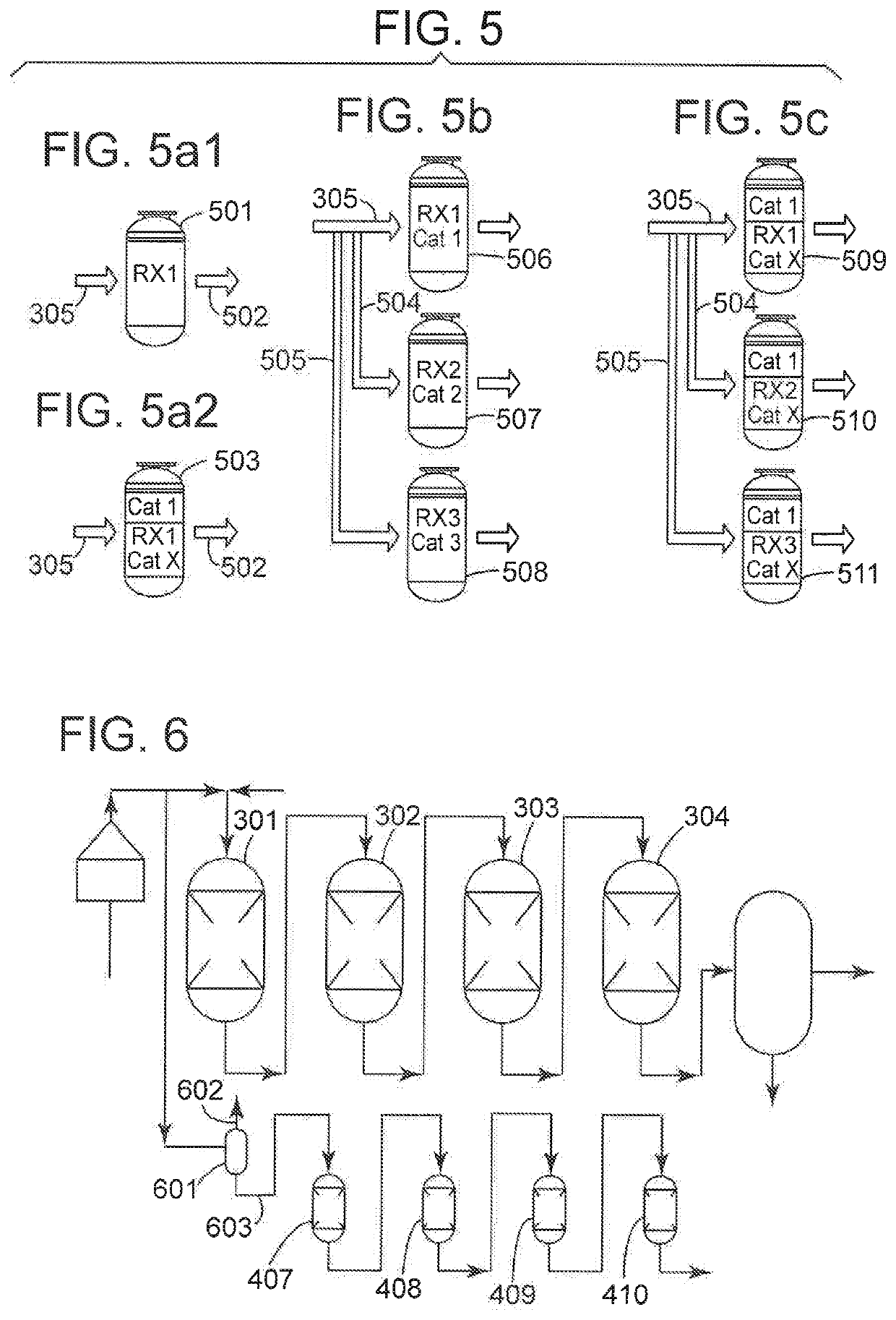

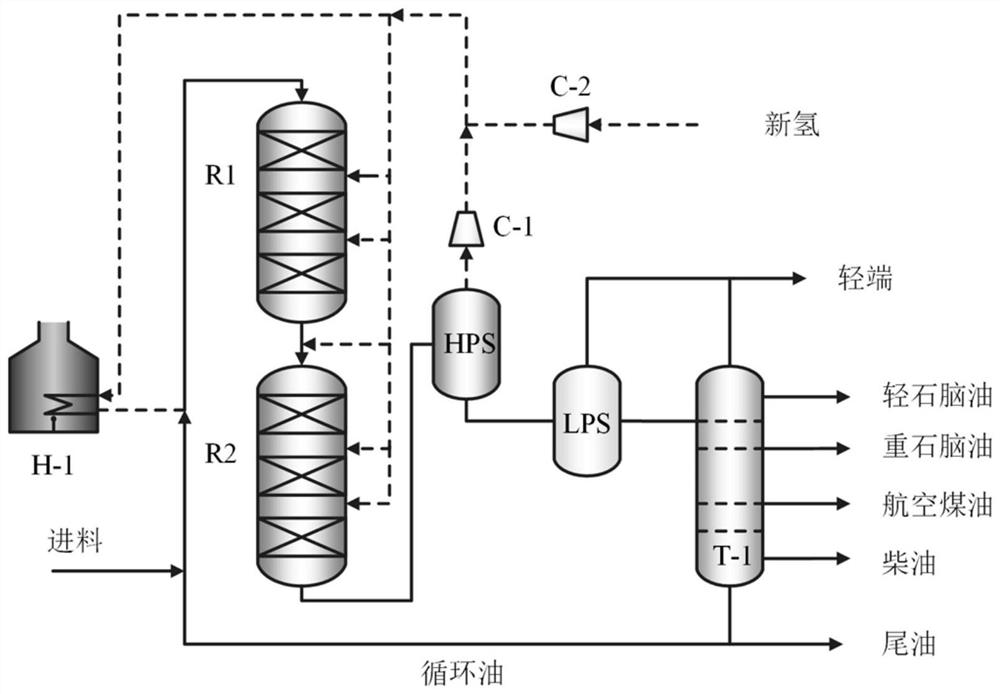

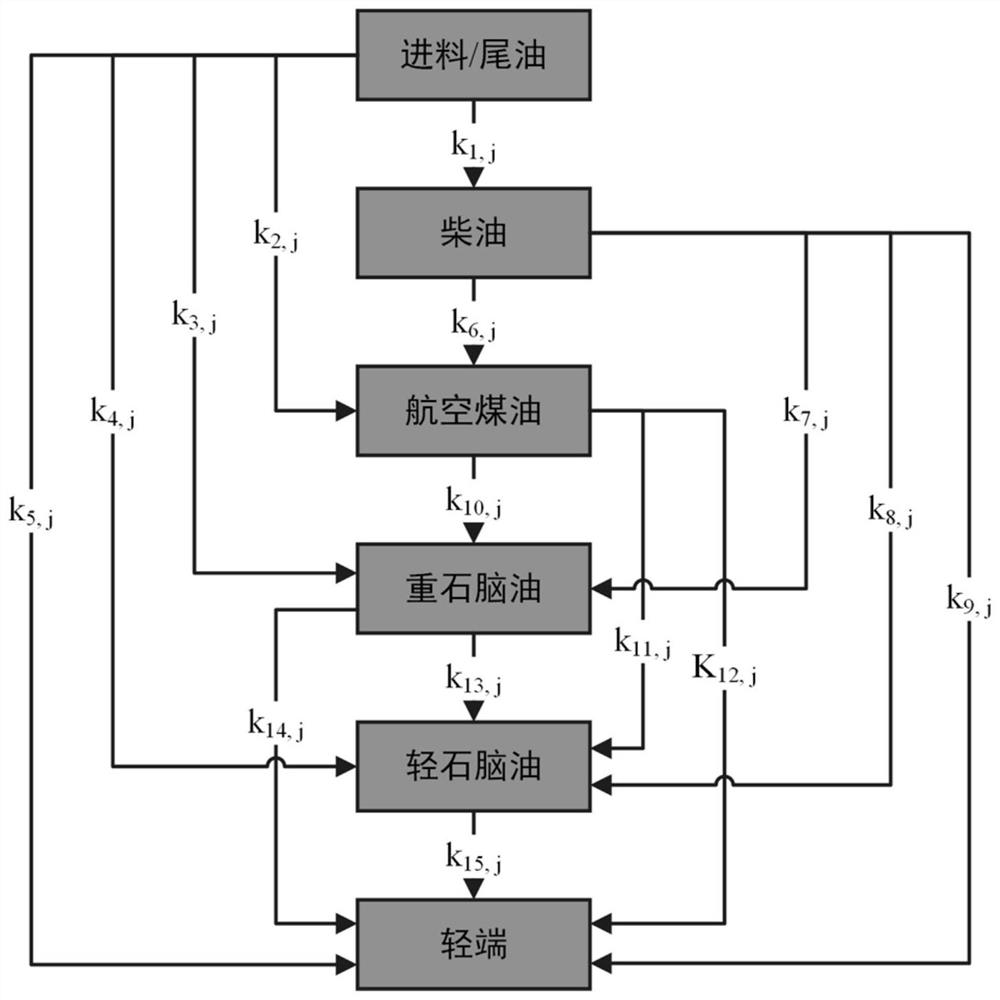

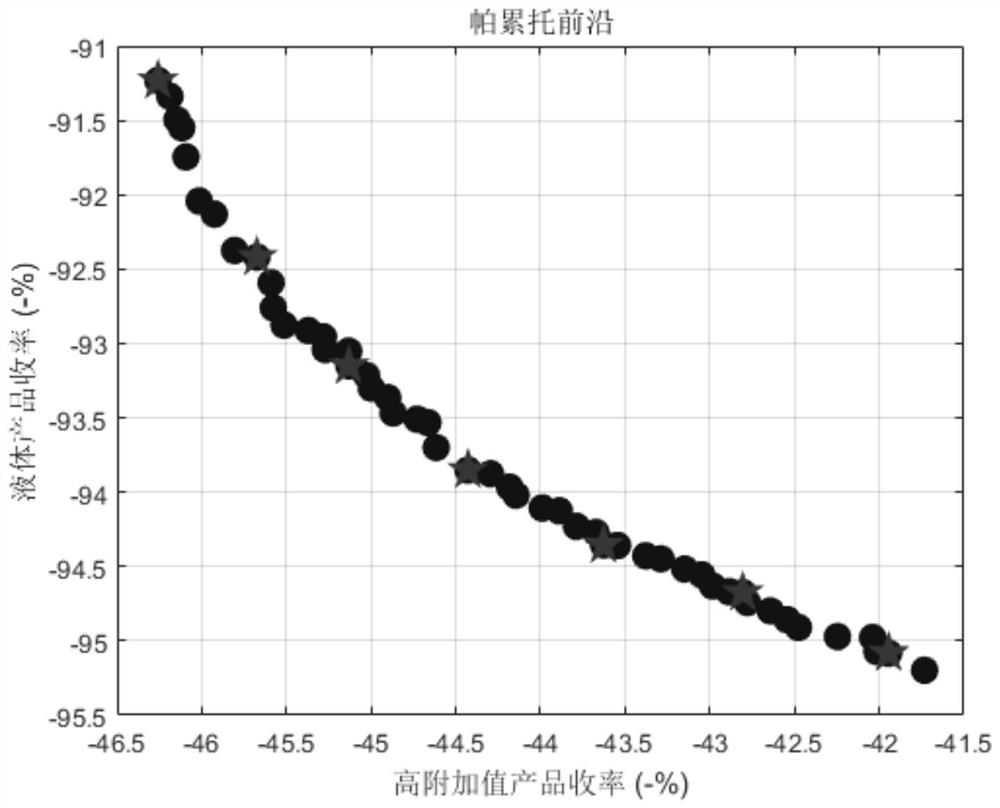

Modeling and optimization methods for wax-oil hydrogen cracking process

ActiveCN108108572AAccurately describe the actual reaction processEasy accessDesign optimisation/simulationSpecial data processing applicationsIndustrial reactorHydrogen

The invention relates to modeling and optimization methods for the wax-oil hydrogen cracking process. The modeling method includes the steps that according to an industrial hydrogen cracking device, design parameters and operating data which are required by modeling are determined, and a hydrogen cracking lumped partition method is determined, wherein the design parameters comprise lengths and diameters of all beds, and the operating data comprises the feeding flow, inlet-and-outlet temperatures of all the beds, the relative density and distillation range data of feeding and a product and theproduct yield; a hydrogen cracking reaction network, a reaction kinetic equation, a material balance equation and an energy balance equation are determined; a hydrogen cracking mechanism model is solved; based on actual industrial operating data, the hydrogen cracking lumped kinetic parameters are corrected. The modeling and optimization methods for the wax-oil hydrogen cracking process are wide in adaptation and can be used for simulating and optimizing hydrogen cracking industrial reactors with different reaction-bed number times and different product yield requirements.

Owner:EAST CHINA UNIV OF SCI & TECH

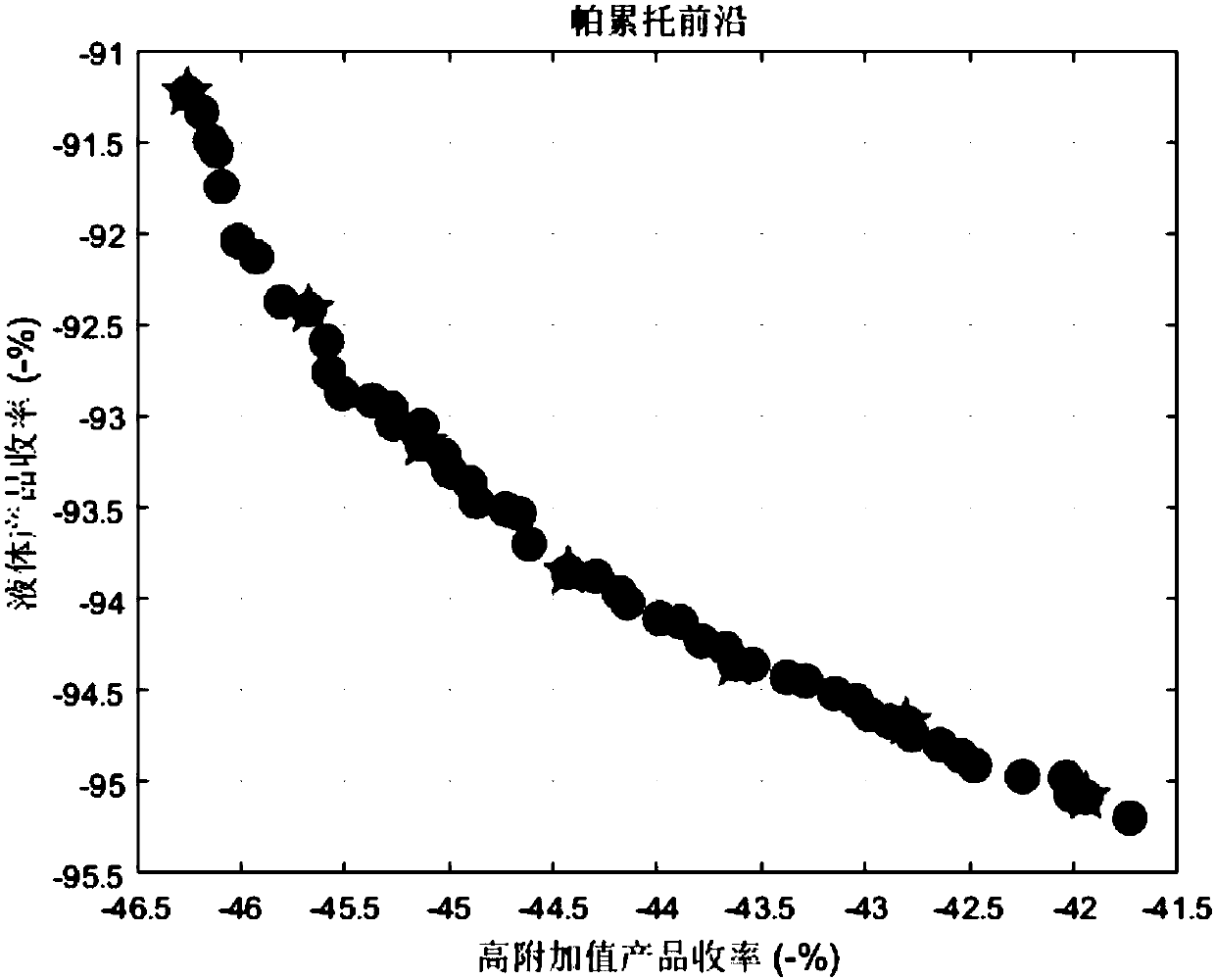

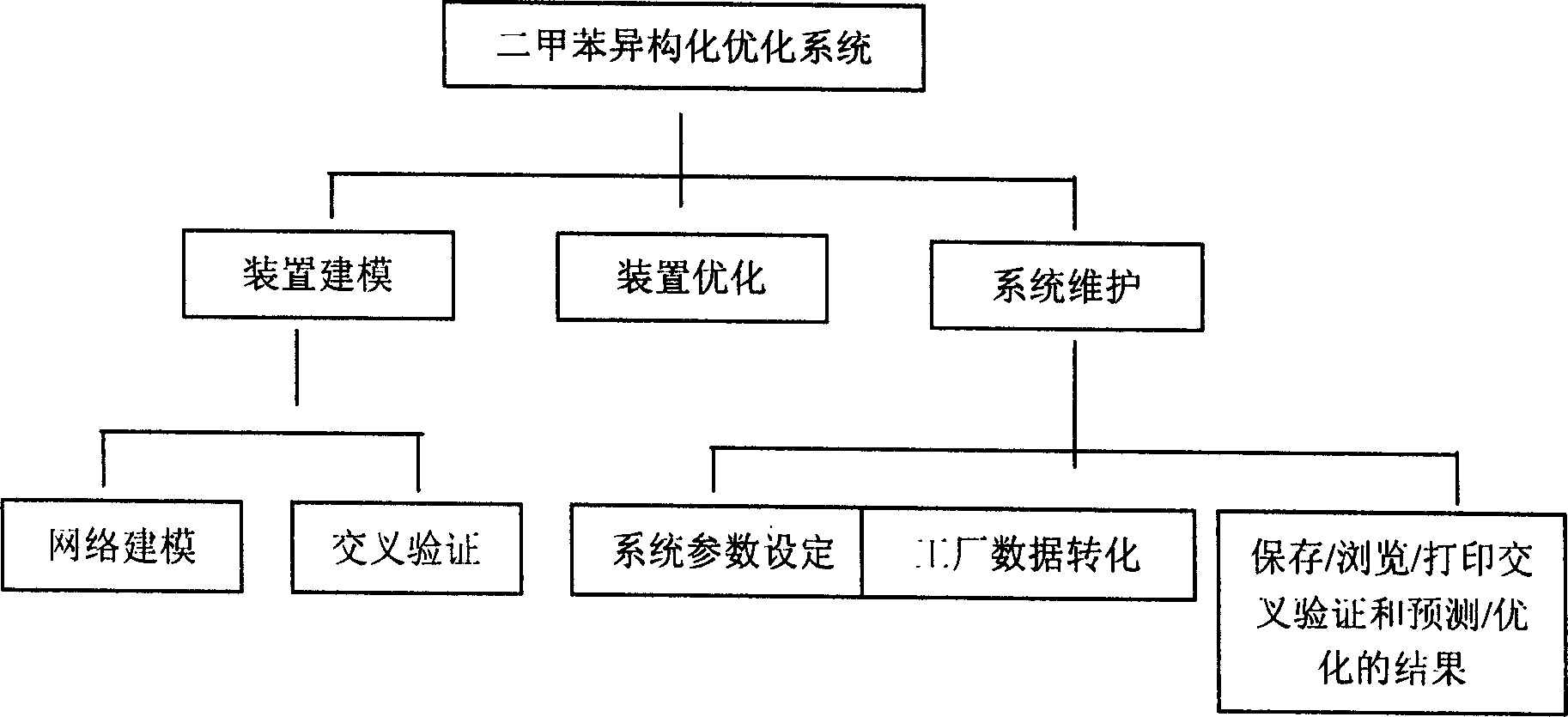

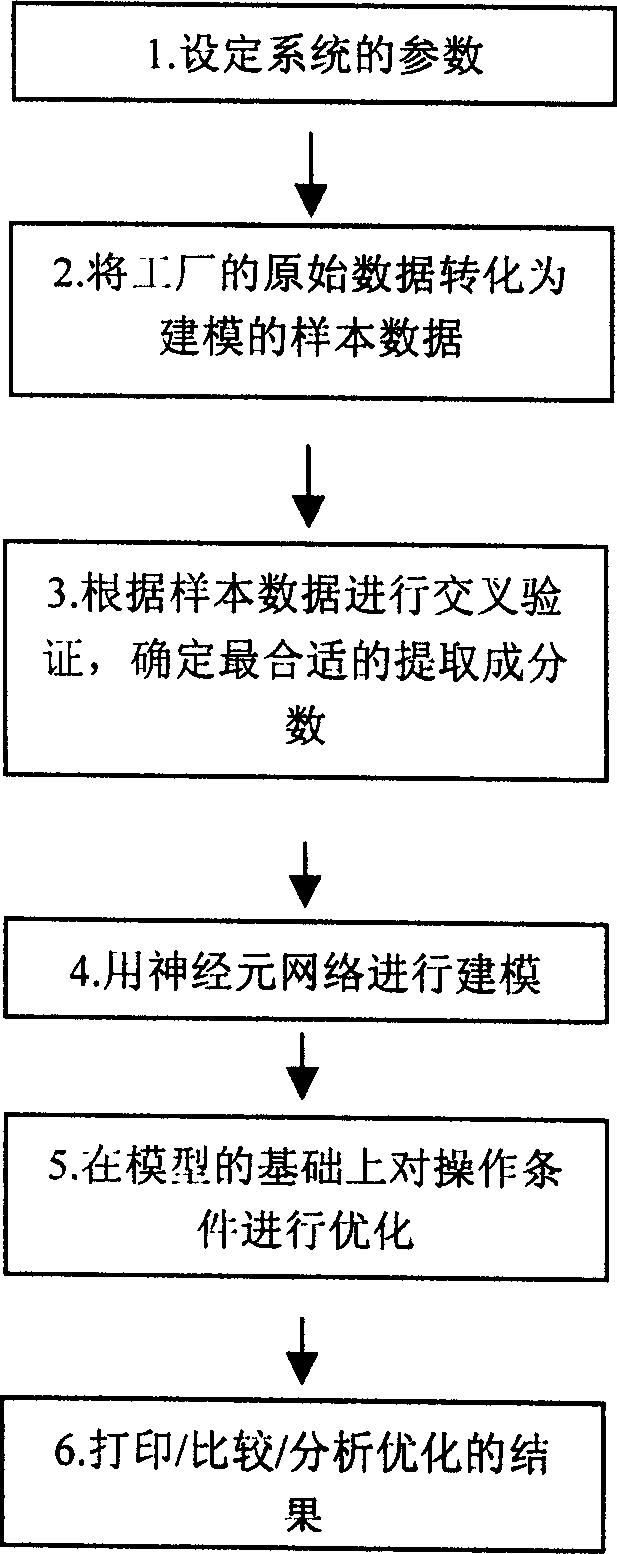

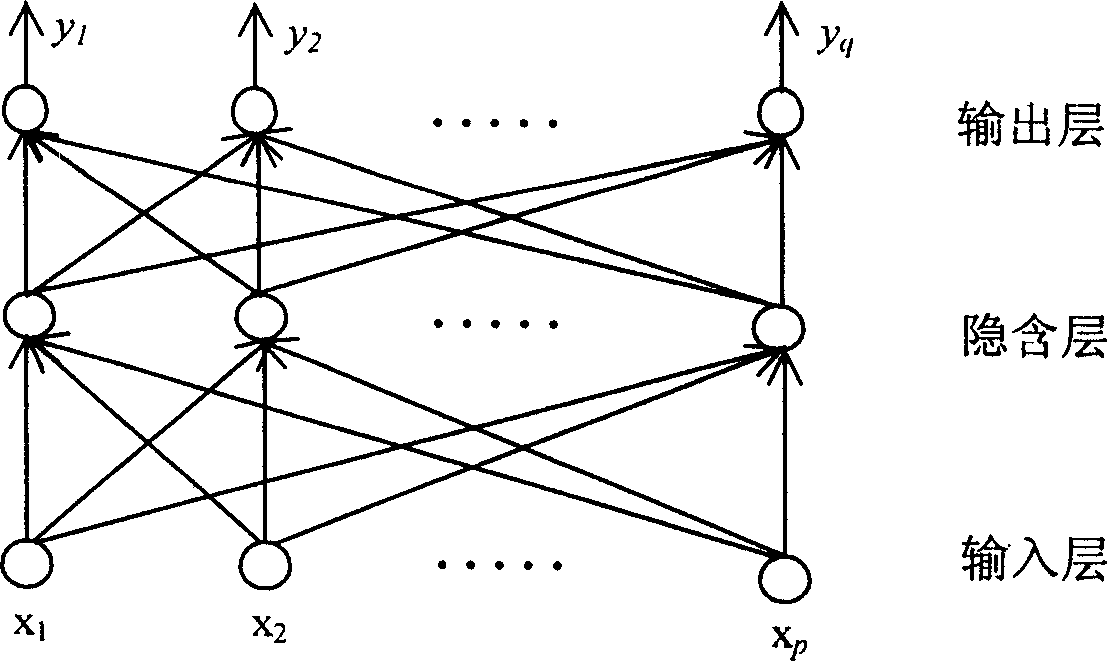

Method for optimizing operation condition of xylene isomerization reactor

InactiveCN1510018AConcise parsing formAvoid difficultiesHydrocarbon by isomerisationAdaptive controlIndustrial reactorIsomerization

A method for optimizing the operating parameters of the xylene isomerizing reactor includes such steps as combining the radial basic function RBF network of multi-variable interpolation with PLSR, inserting the default output generated by various sample data in the equation to obtain a regression model, using PLSR method to find out the regression question, choosing the ethylbenzene transform rate, isomerizing rate, C8 arylhydrocarbon output rate, etc as the dependent variables of said model, using the actual data of industrial reactor as the training samples, and performing the calculation to find out the optimal parameters.

Owner:SINOPEC YANGZI PETROCHEM +1

Method for simulating a process plant at laboratory scale

InactiveUS20070067149A1Quick and accurate controlControl the temperature of the reaction mixture fast and accuratelyThermometer detailsSimulator controlIndustrial reactorMathematical model

A method, a laboratory device and the use of both are provided for simulating the dynamic temperature behavior of at least one part of a process plant, particularly an industrial reactor. The method provides a temperature profile and / or temperature setpoints at given time intervals for controlling the laboratory device. The temperature profile and / or temperature setpoints are derived from a mathematical model that describes the dynamic temperature behavior of at least one part of the process plant. The temperature profile and / or the temperature setpoints are used by a program for controlling the laboratory device.

Owner:METTLER TOLEDO GMBH

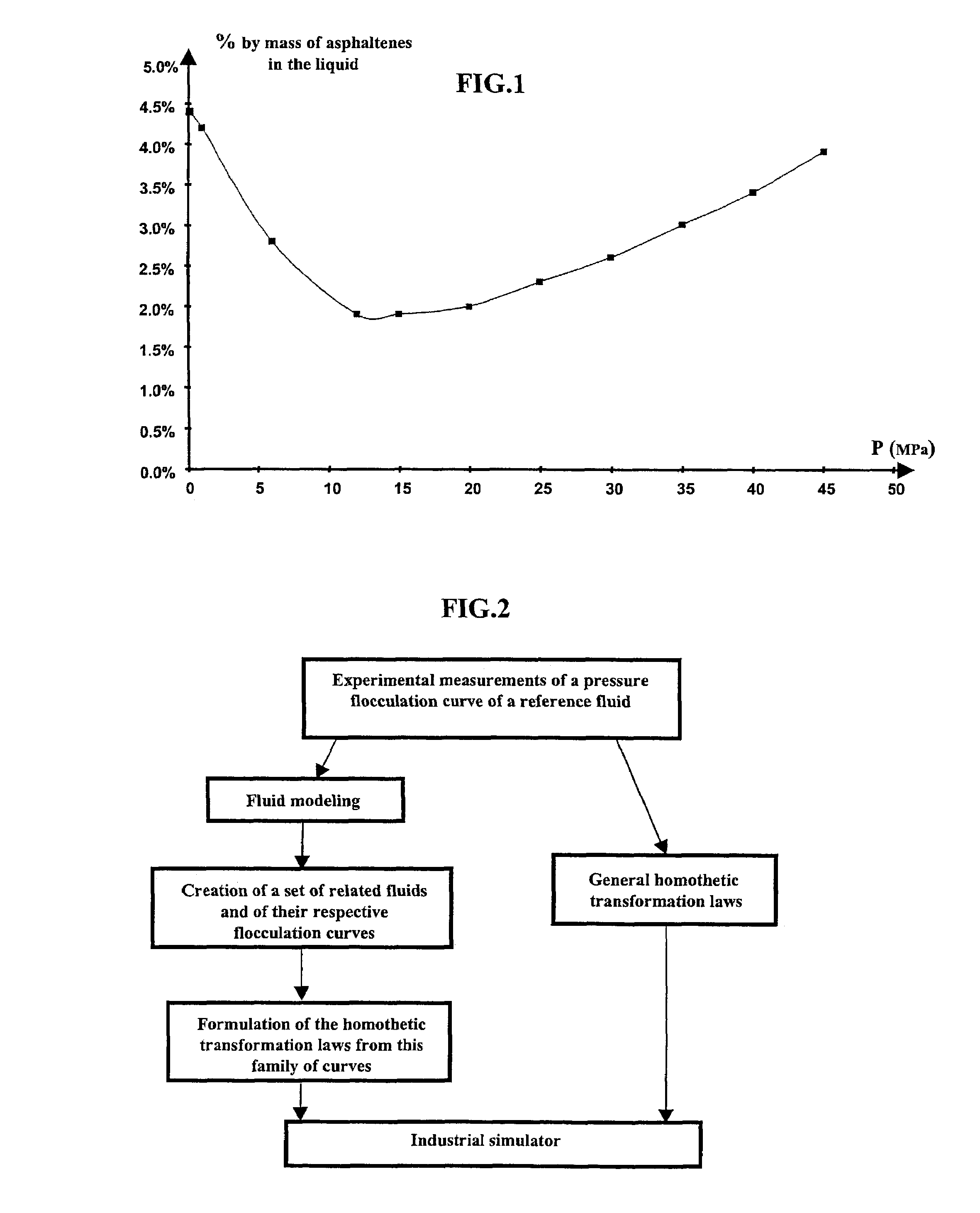

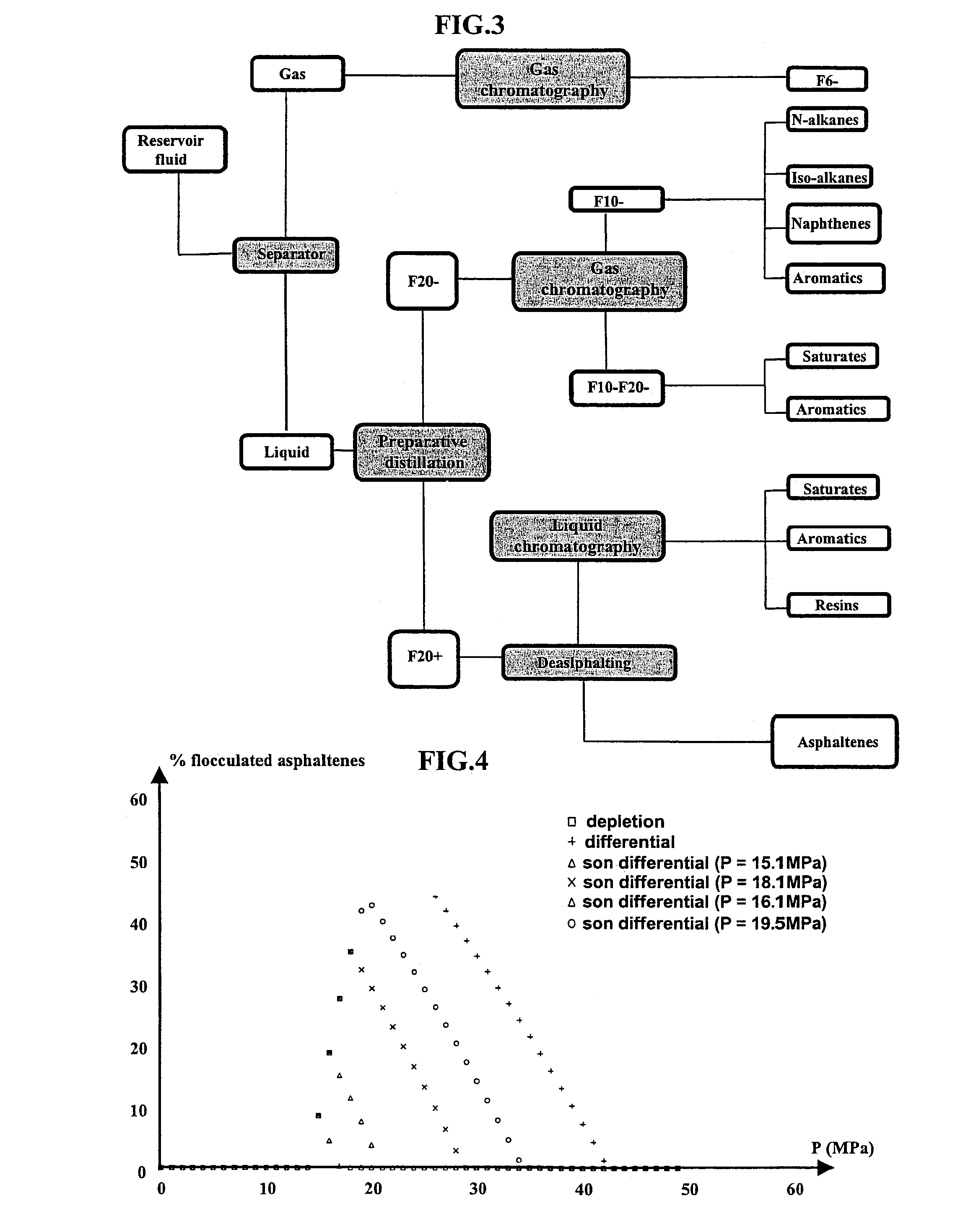

Method for modeling asphaltenes flocculation conditions in hydrocarbon-containing fluids related to a reference fluid

InactiveUS7343270B2Spare long and tedious studiesComputation using non-denominational number representationMaterial testing goodsExperimental researchIndustrial reactor

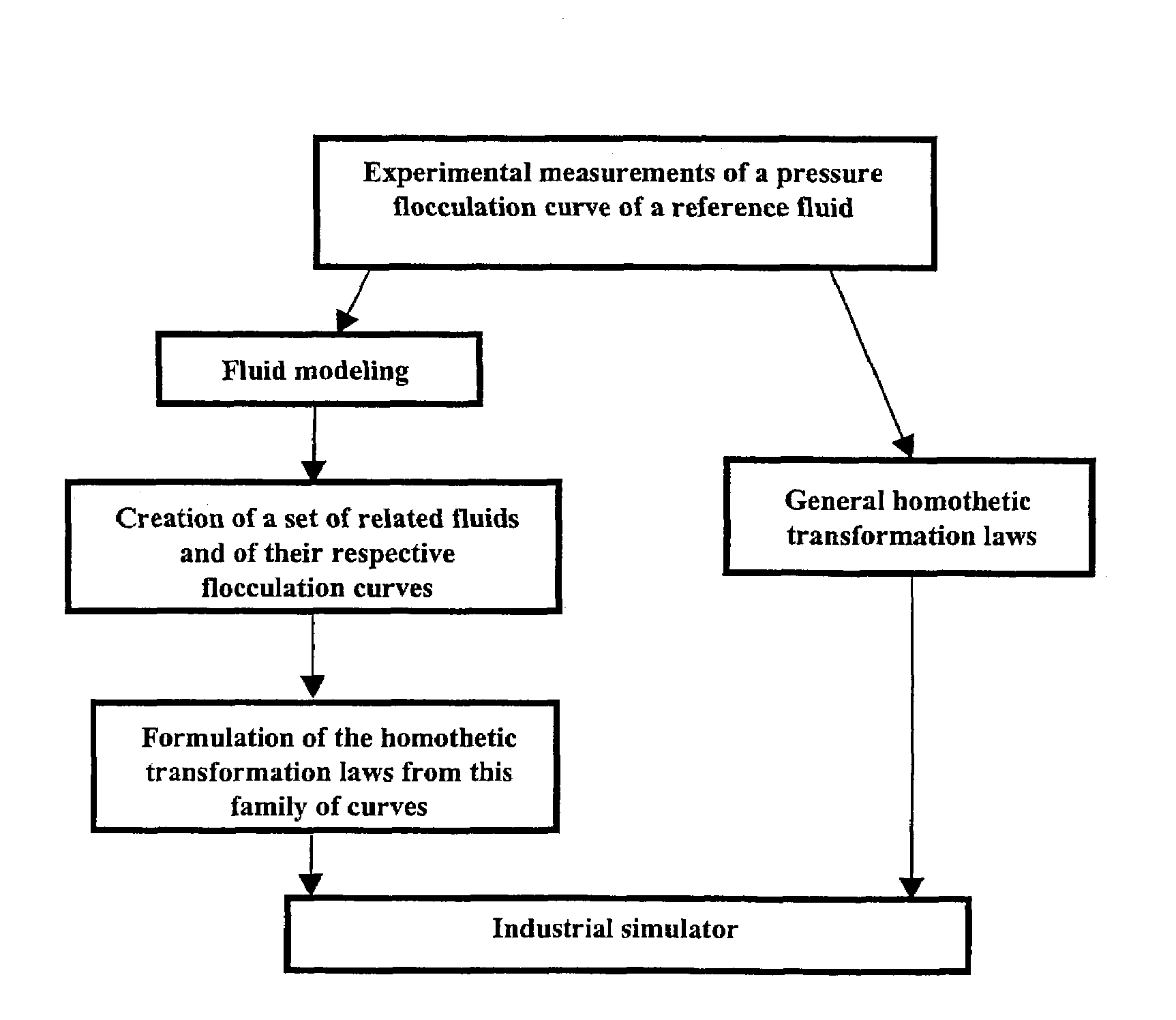

Method for modeling the flocculation conditions of hydrocarbon-containing fluids under pressure, related to a reference fluid. The asphaltenic properties are modeled from the results of an experimental study of a single asphaltenic reference fluid and by means of homothetic transformation laws. These reduced data allow to deal with asphaltenes flocculation in an industrial simulator working according to a simplified model. It is then possible to predict the amounts of asphaltenes that will flocculate in a reservoir or in a reactor during development, considering the variable pressure and composition conditions. Application: optimization of the development conditions of reservoirs or of an industrial reactor in which asphaltenic fluids undergo expansions.

Owner:INST FR DU PETROLE

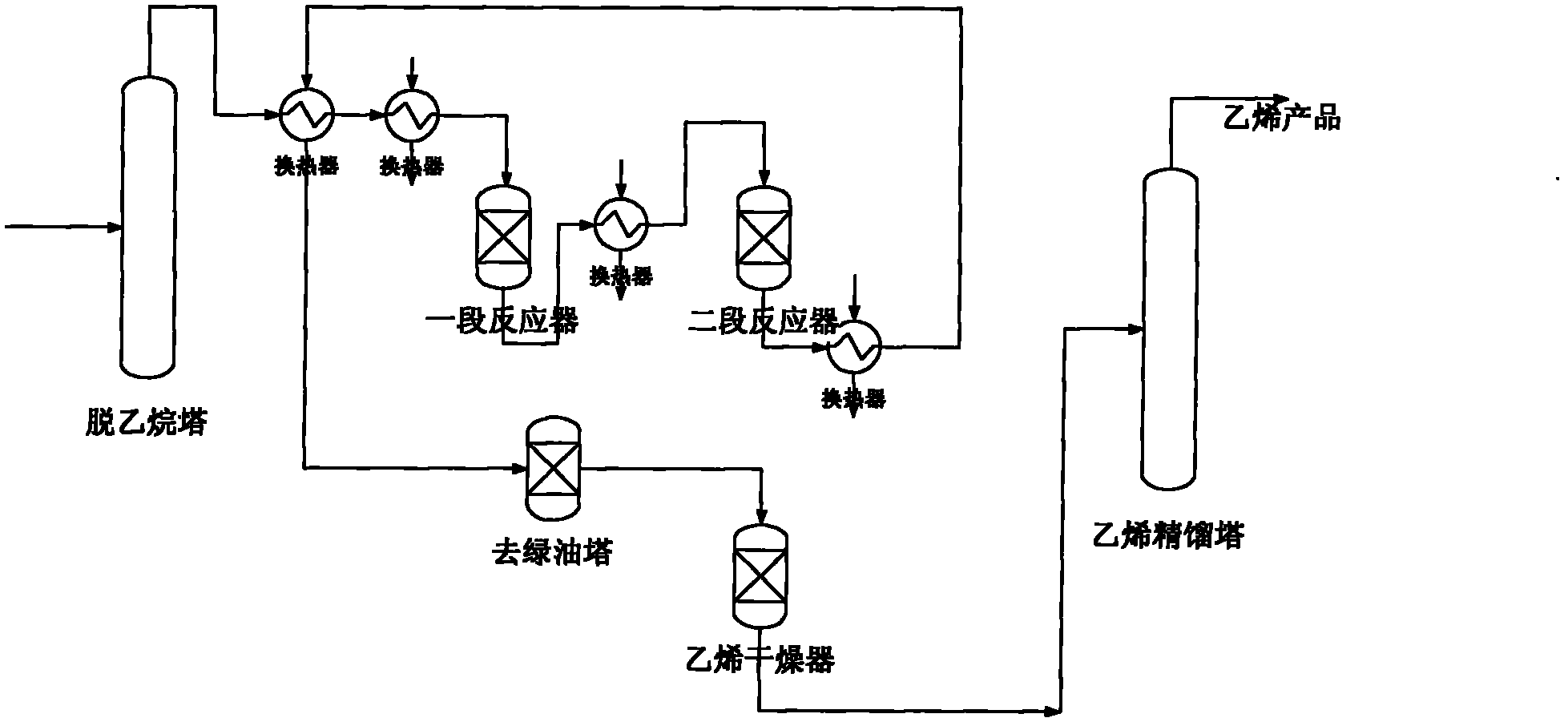

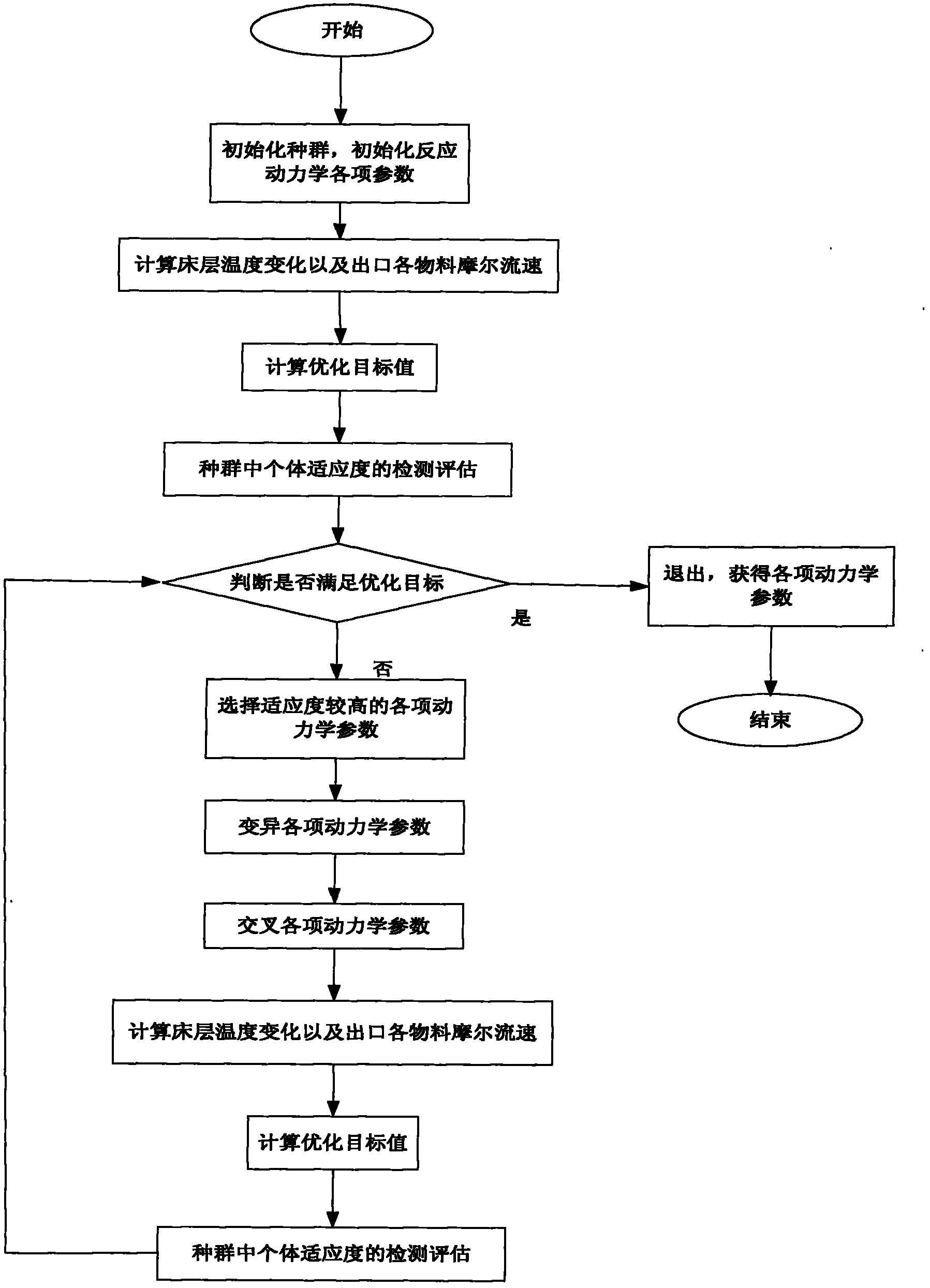

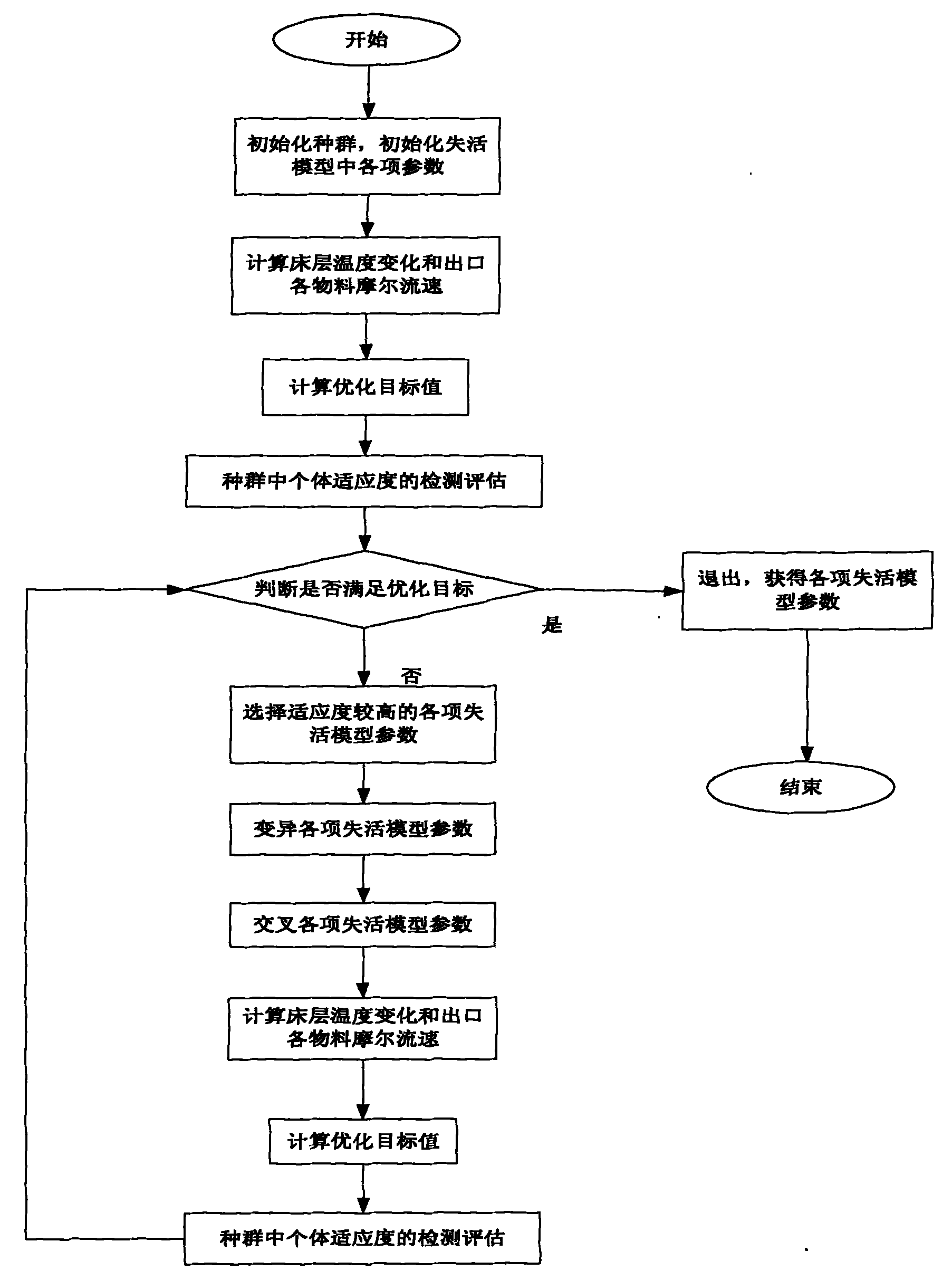

Method for optimizing process operation of catalytic hydrogenation reaction of acetylene in industrial device

ActiveCN102034000AAccurate descriptionTo achieve the purpose of saving energy and reducing consumptionSpecial data processing applicationsIndustrial reactorChemical reaction

The invention relates to a method for optimizing process operation of catalytic hydrogenation reaction of acetylene in an industrial device. The method has the following beneficial effects: based on a hydrogenation reactor model, the genetic algorithm is used for fitting the parameters of a dynamic model and a deactivation model so as to achieve the aim of precisely describing the chemical reaction process, and on the basis, the genetic algorithm is reused for optimizing the process operation conditions according to the practical industrial production goal, thus the influence of each factor in an industrial reactor on the reaction process can be described; and the models have higher industrial data fitting and predicting precision and good usability, and in addition, the modeling method is suitable for various catalytic hydrogenation reactions in fixed bed reactors and has wide applicability.

Owner:EAST CHINA UNIV OF SCI & TECH

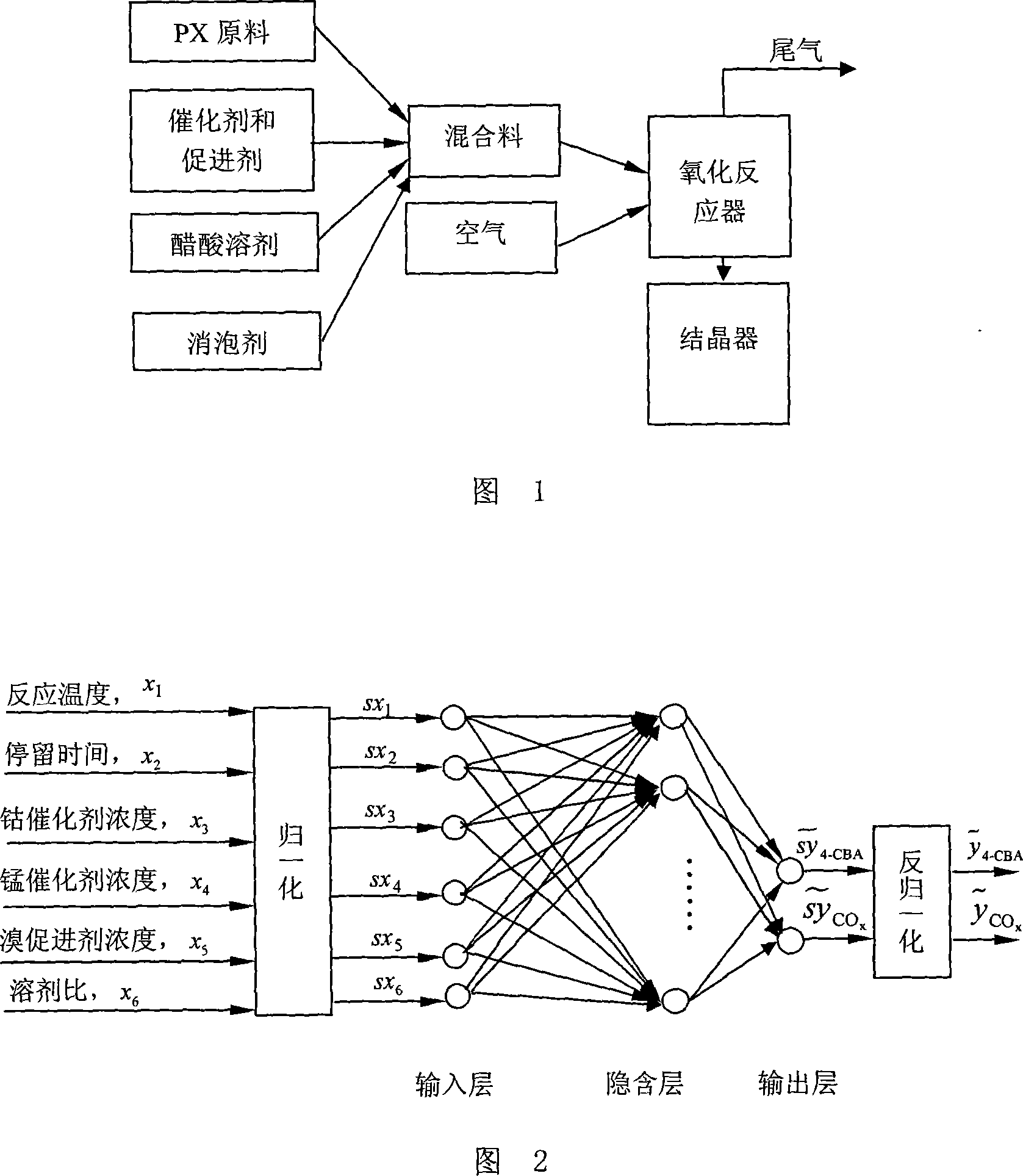

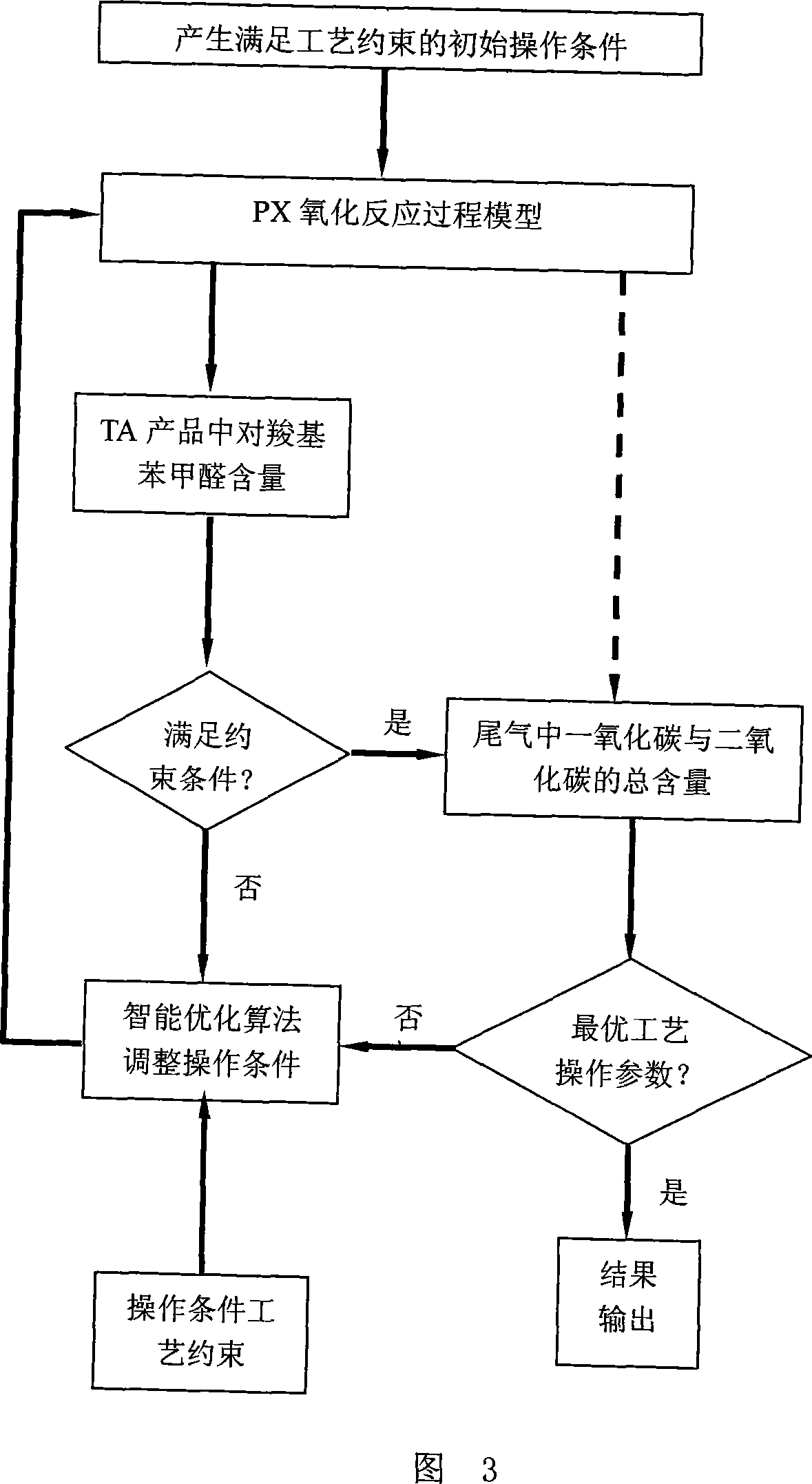

P-xylene oxidation reaction operation condition optimization method

InactiveCN101145029AReduce combustion lossReduce contentOrganic compound preparationCarboxylic compound preparationCarboxyl radicalBenzaldehyde

The present invention discloses an optimized technology of operating conditions of a xylene oxidation reactor which adopts Mitsui art, the optimized technology is that the reaction temperature of a reactor, the time that liquid stays in the reactor, the cobalt ion concentration of feeding of the reactor, the manganese ion concentration, the bromine ion concentration and the solvent ratio can be selected as the input variables of models during the xylene oxidation reaction; the content of carboxyl benzaldehyde in the products which can reflect the reacting results of the reactor, the total content of carbon monoxide and carbon dioxide in the exhaust gas which reflects burning loss of the reactor can be selected as the dependent variable of the models; the present invention can use the real production data of an industrial reactor as a training sample to build up a neural network model during the xylene oxidation reaction, and further to be optimized calculation on operating conditions of the reactor, so as to get the best operating conditions of the reactor make sure that the content of carboxyl benzaldehyde in the reacting products can meet the requirement, and the total content of carbon monoxide as well as carbon dioxide in the exhaust gas can be reduced to the minimum.

Owner:EAST CHINA UNIV OF SCI & TECH

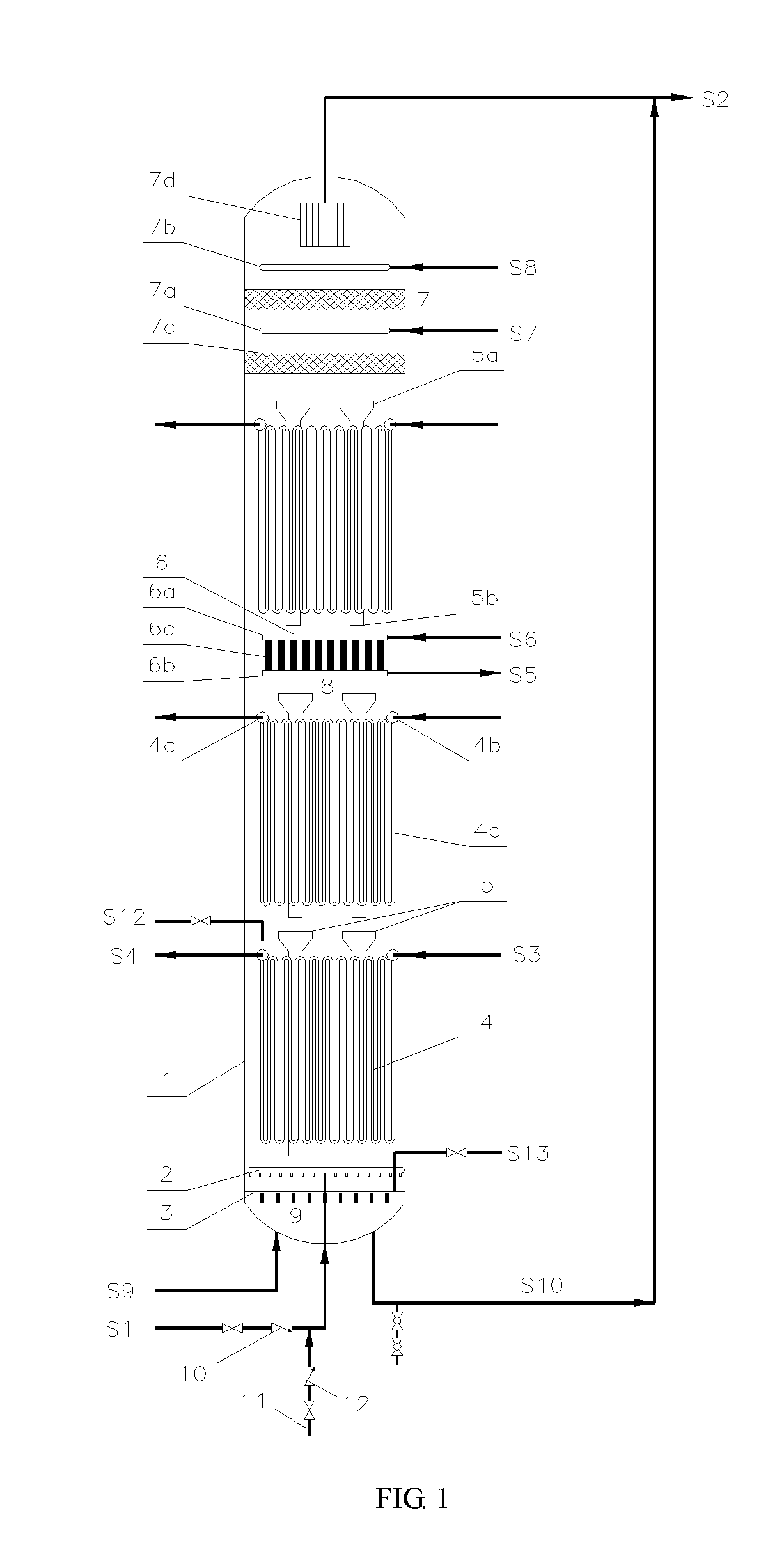

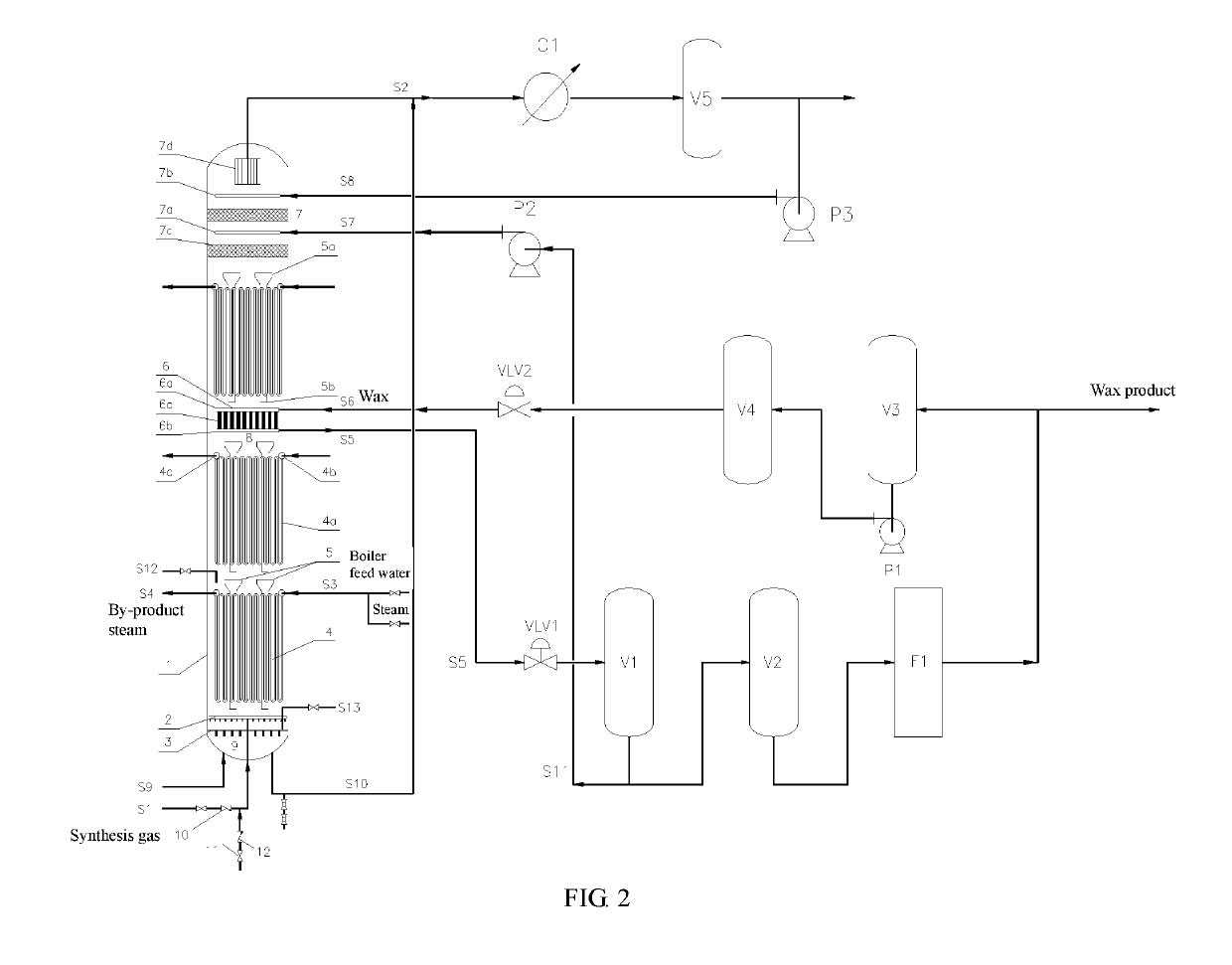

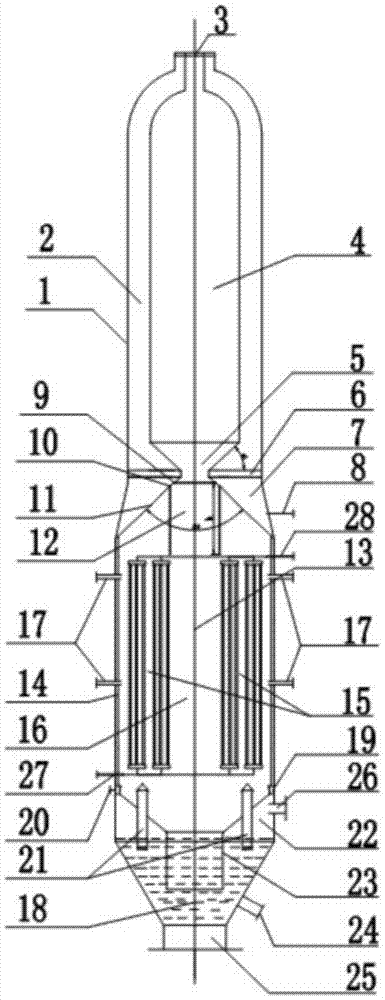

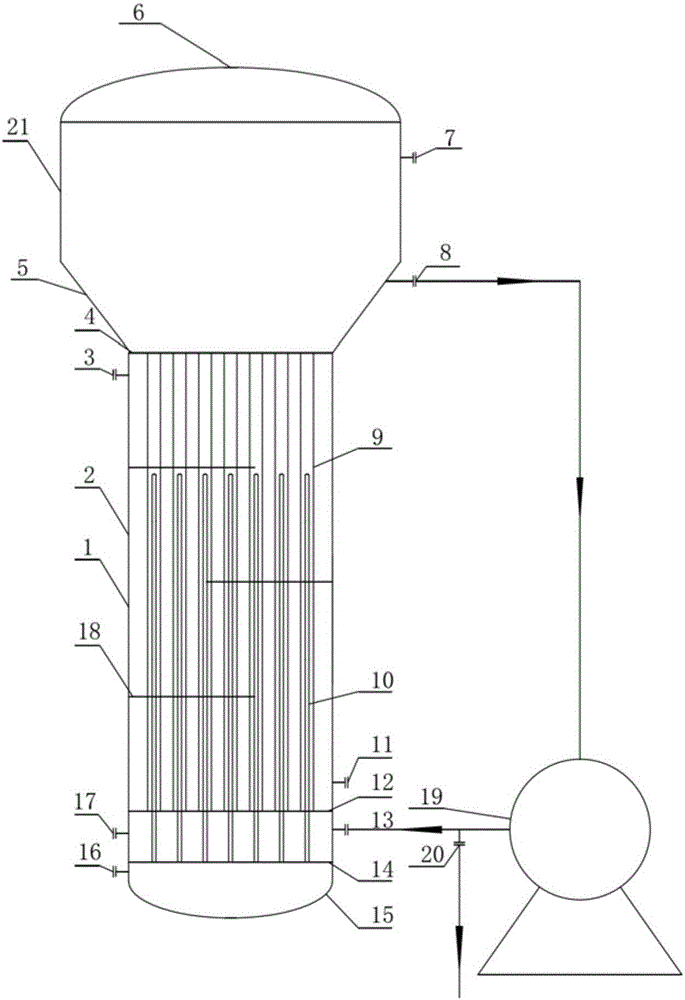

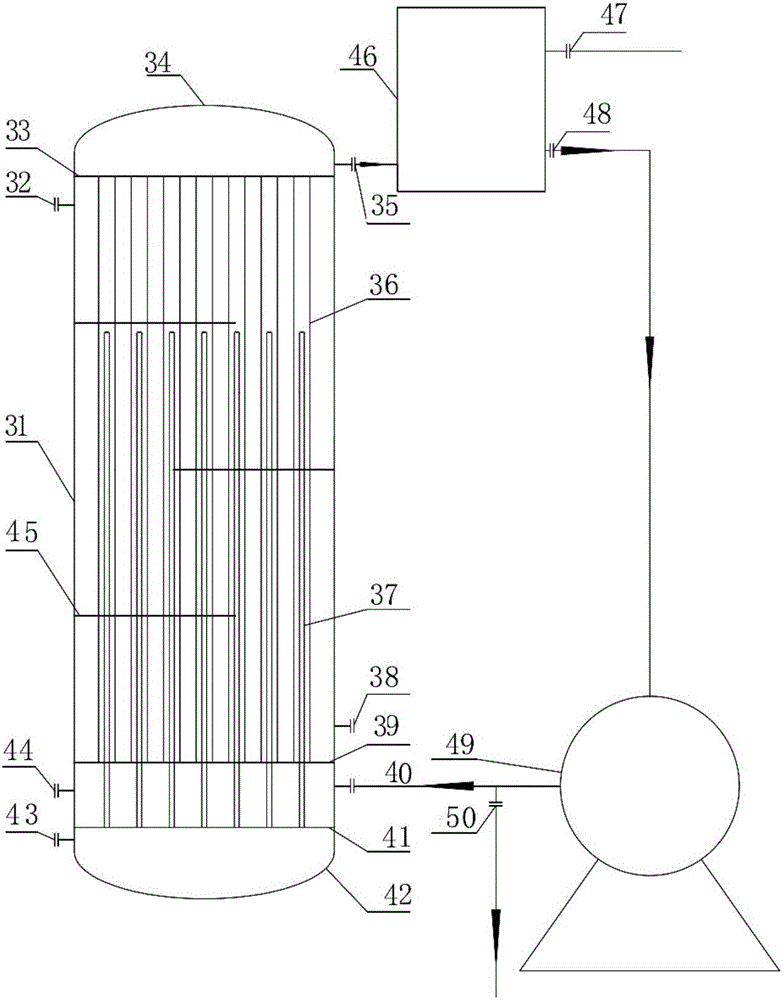

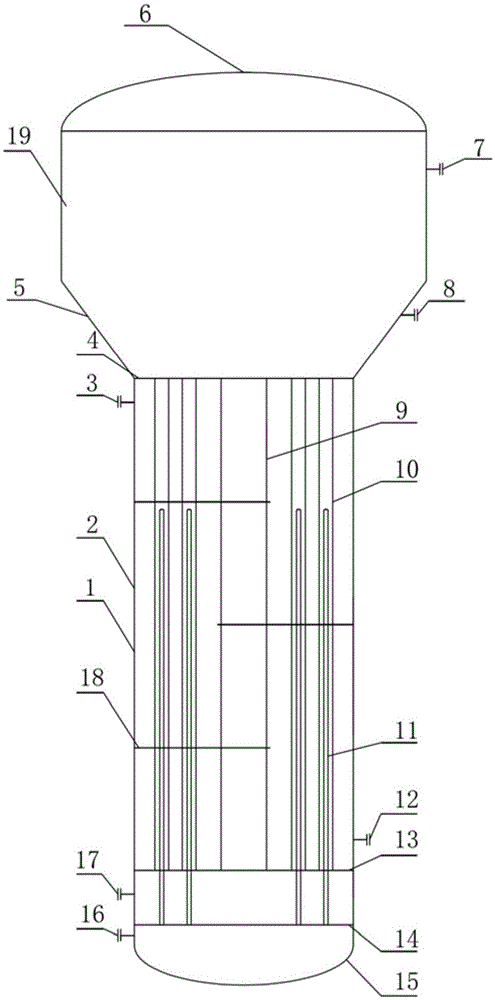

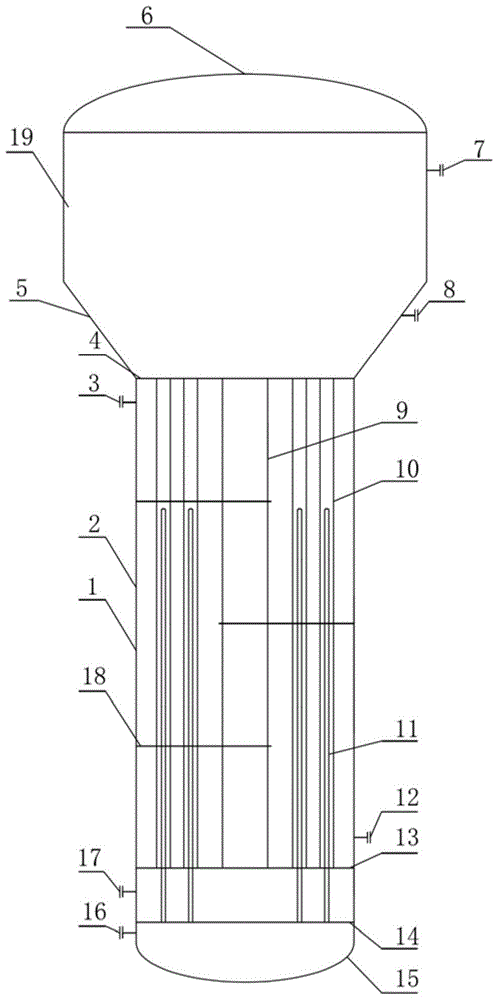

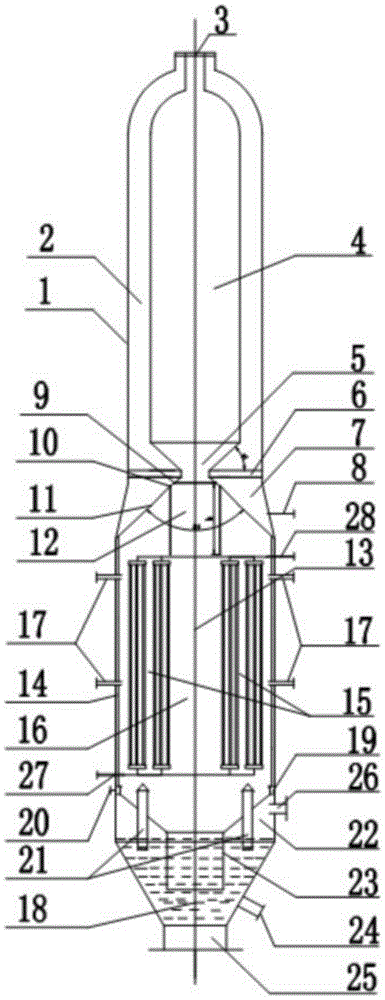

Gas-liquid-solid three-phase slurry bed industrial reactor capable of achieving continuous operation

ActiveUS10363535B1Stable and continuous industrial operationStable continuous operationLiquid hydrocarbon mixture productionChemical/physical processesConcentration gradientSlurry

A gas-liquid-solid three-phase slurry bed industrial reactor capable of achieving continuous operation comprises an inlet gas distribution component composed of a false bottom and inlet gas distribution tubes, one or more layers of heat exchange tube components used for heating / cooling the bed, one or more layers of liquid-solid separator components capable of being cleaned automatically, an outlet gas-liquid-solid entrainment separation component located in the upper portion of the interior of the reactor and used for removing liquid foam and solid entrainments, a plurality of layers of solid concentration uniform distribution devices used for reducing the catalyst concentration gradient and the inlet-outlet temperature difference of the reactor, a flow guiding device located on a component support beam and used for preventing catalyst accumulation, and auxiliary systems including a filter-backflush system and a washing system. Compared with the prior art, the reactor is low in energy consumption and solves the problems of blockage, backflow and dead zones, the temperature and liquid level are well controlled, catalysts can be easily added and discharged online, and stable and continuous operation of the reactor is achieved. The reactor is suitable for being applied to the Fischer-Tropsch synthesis process on an industrial scale.

Owner:SHANGHAI YANKUANG ENERGY R&D

Method for preparing phosphoric acid by adding reaction promoters

ActiveCN101597038AImprove recovery rateSolve the problem of temperature differencePhosphoric acidHigh concentrationO-Phosphoric Acid

The invention discloses a method for preparing phosphoric acid by adding reaction promoters; salt or nitrogen-containing organic compound reaction promoters are added in rock phosphate powder, silica powder, carbonaceous reducing agents (silica process), or in rock phosphate powder, limestone powder and carbonaceous reducing agents (calcium process) and are molded by mixing; the mixture is sent into a kiln and is heated up to reaction temperature by pre-heating and heating-up; the produced phosphorus steam is made into high-concentration phosphoric acid after air oxidation and hydration adsorption. By adopting the method, P2O5 content is high, the reaction temperature is reduced by 100 DEG C, the reaction time is shortened, and high reduction ratio of phosphorite is kept within a wider temperature range. The method solves the problem of temperature difference in an industrial reactor, and greatly reduces the energy consumption, solves the softening and melting problem of molding material and lays a foundation for the large-scale industrial production. In addition, the production efficiency is high, the energy consumption is low and the equipment investment is low.

Owner:HUBEI XINGFA CHEM GRP CO LTD

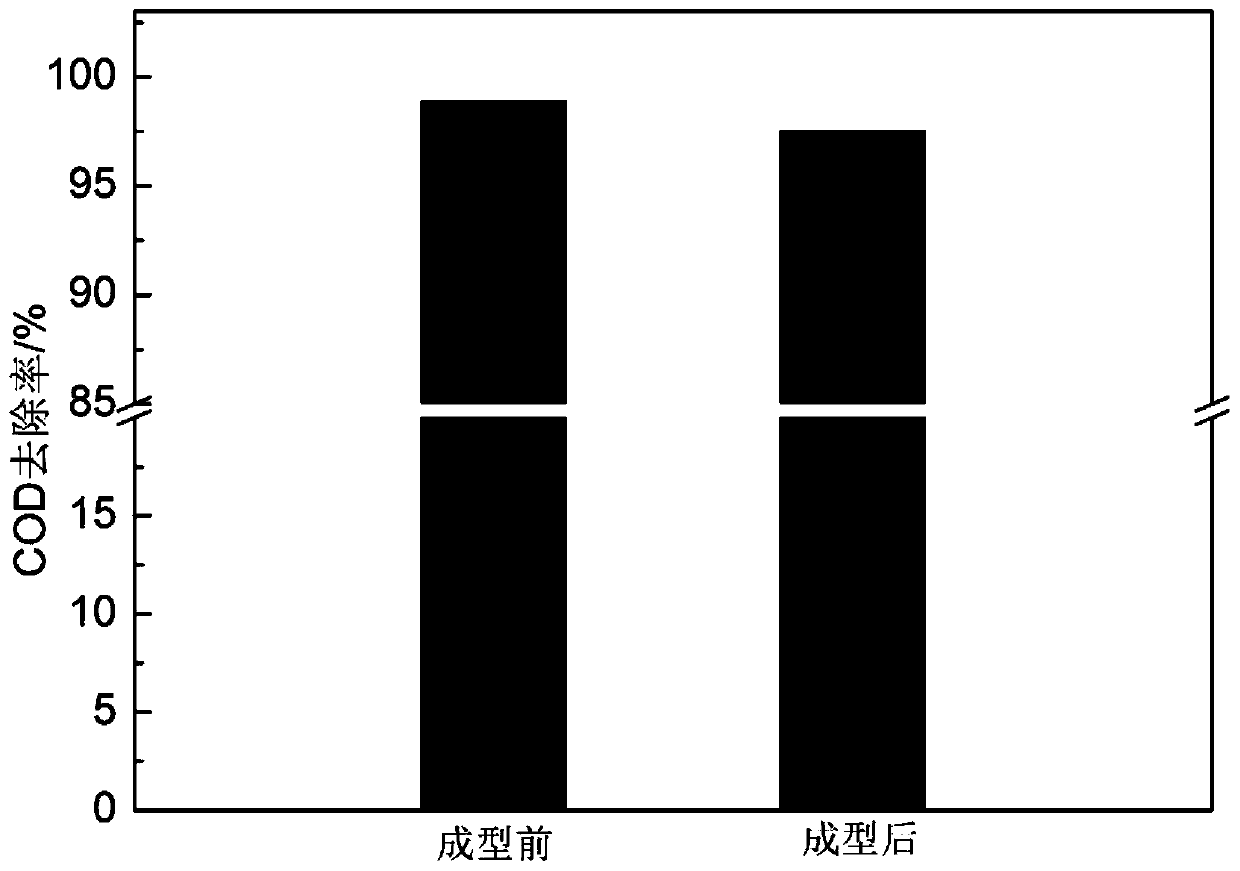

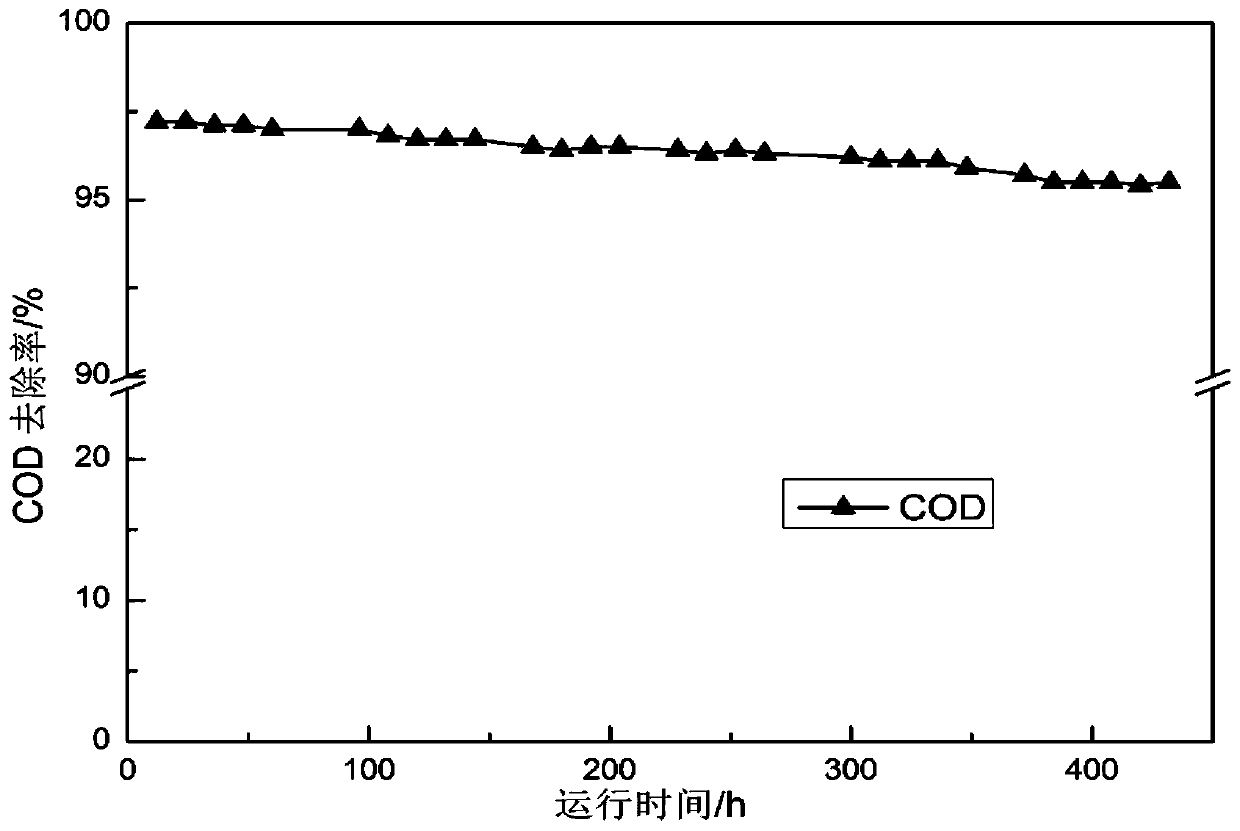

Method for molding catalyst applied to catalytic wet oxidation

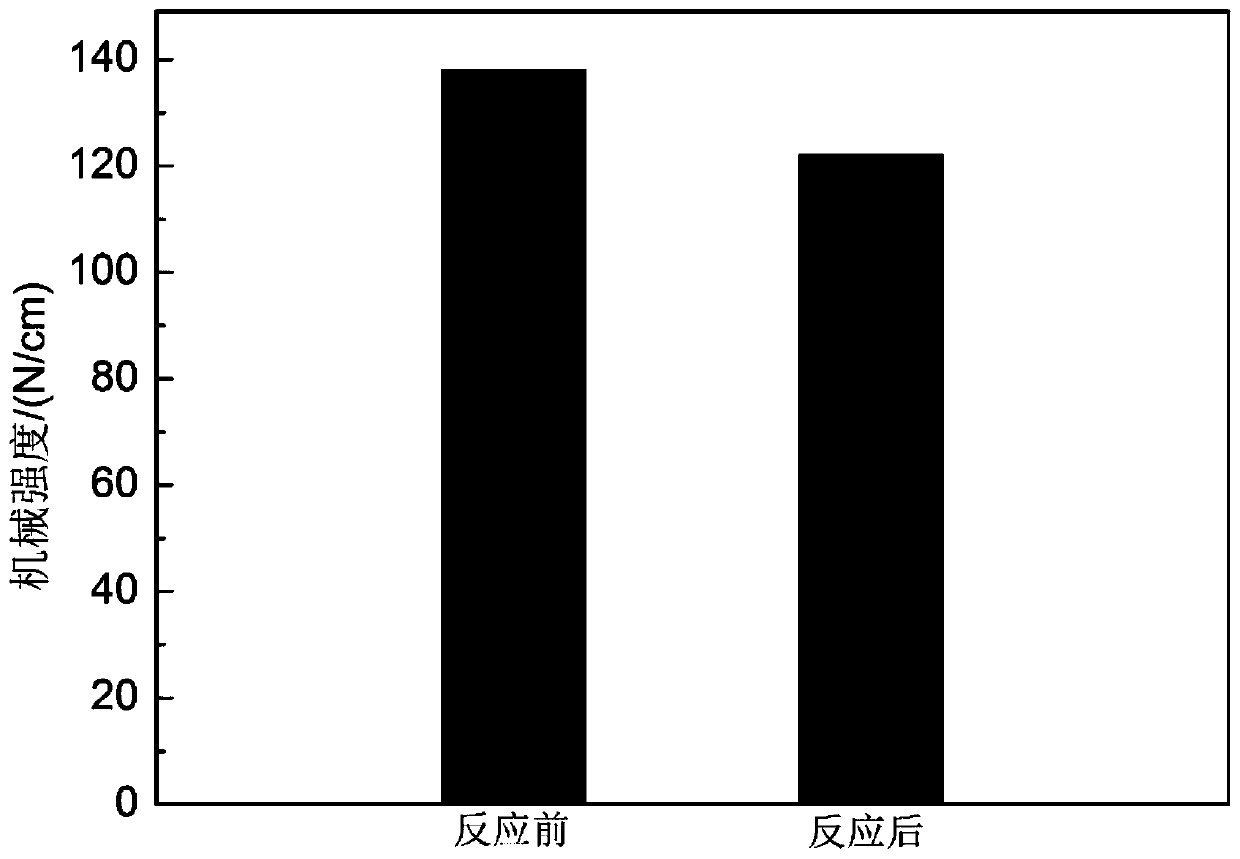

InactiveCN110252284AHigh hydrothermal stabilityConsistent activityWater/sewage treatmentWaste water treatment from textile industryIndustrial reactorUltimate tensile strength

The invention provides a method for molding a catalyst applied to catalytic wet oxidation, belonging to the technical field of wastewater treatment. The method is applied to a powder catalyst which can be applied to various industrial reactors only after molding. The method is characterized in that the powder catalyst is a transition metal powder catalyst; and in the process of molding, auxiliary binders, a squeezing agent and a pore structure modifier are added at first, then a binder is dropwise added while mixing and kneading, and then extrusion molding, drying and roasting are performed. According to the invention, a silica sol is added as the binder and nanometer ZrO2 and nanometer TiO2 are added as the auxiliary binders, so the hydrothermal stability of the catalyst can be effectively improved while the requirement on mechanical strength during industrial application of the catalyst is met; and the catalyst has almost the same activity before and after molding, and produces good COD removal effect on wastewater.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

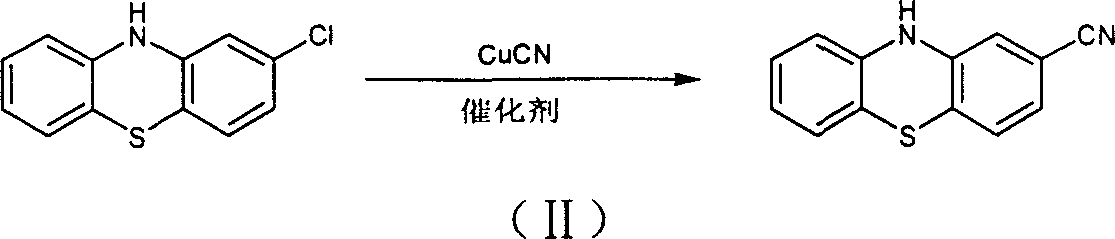

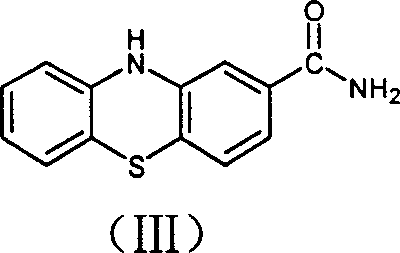

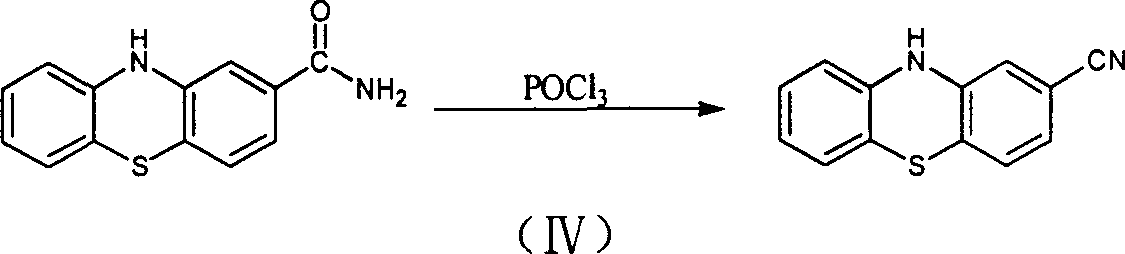

Preparation of 2-cyanophenthiazine

Owner:SHANXI UNIV

Chilling type single waste pan reactor

ActiveCN104498105ALow ash contentImprove utilization efficiencyEnergy inputGasification processes detailsIndustrial reactorChemical synthesis

The invention relates to a chilling type single waste pan reactor. The reactor consists of an upper gasification reaction chamber, a middle radiation heat exchange chamber and a lower chilling slag chamber, wherein the gasification reaction chamber is communicated with the radiation heat exchange chamber by virtue of a conical slag opening and a conical gas guide inlet; and the radiation heat exchange chamber is communicated with the chilling slag chamber by virtue of a funnel-shaped slag trap. At present, a chilling type reactor in the conventional industrial reactor is low in energy utilization efficiency, the efficiency needs to be improved, and the all waste pan reactor is complex in structure, high in investment cost, low in operating stability, low in raw gas vaporization ratio and large in ash content and is unsuitable to serve as chemical synthesis gas. Moreover, the chilling type single waste pan reactor disclosed by the invention simultaneously has the advantages of a waste pan reactor and a chilling reactor, the energy utilization efficiency of the reactor is improved by 4-5 percent compared with the chilling reactor, the ash content is reduced by 2mg / L compared with the all waste pan reactor, and the vaporization ratio is improved to 0.8 to 1.0. The reactor disclosed by the invention is suitable for IGCC power generation and combined generation chemical synthesis.

Owner:THE NORTHWEST RES INST OF CHEM IND

Establishing method of dynamic model of liquid phase catalytic paraxylene oxidizing reaction

InactiveCN1230412COrganic compound preparationCarboxylic compound preparationIndustrial reactorDynamic models

The establishing method of dynamic model of liquid phase catalytic paraxylene oxidizing reaction comprises utilizing the reaction temperature x1 and mixed material composition including solvent ratio x2, Co catalyst concentration x3, Mr catalyst concentration x4, and Br promoter concentration x5 and the rate constant nerve net model to find out the rate constants ki, where i=1,2,3 and 4, of the steps in reaction network of industrial liquid phase catalytic paraxylene oxidizing reaction, and to find out the contents of PX, TALD, PT acid, 4-CBA, TA and other intermediate products and estimate products. The rate constant model can describe the effects of different factors on the reaction in the industrial reactor.

Owner:SINOPEC YANGZI PETROCHEM +1

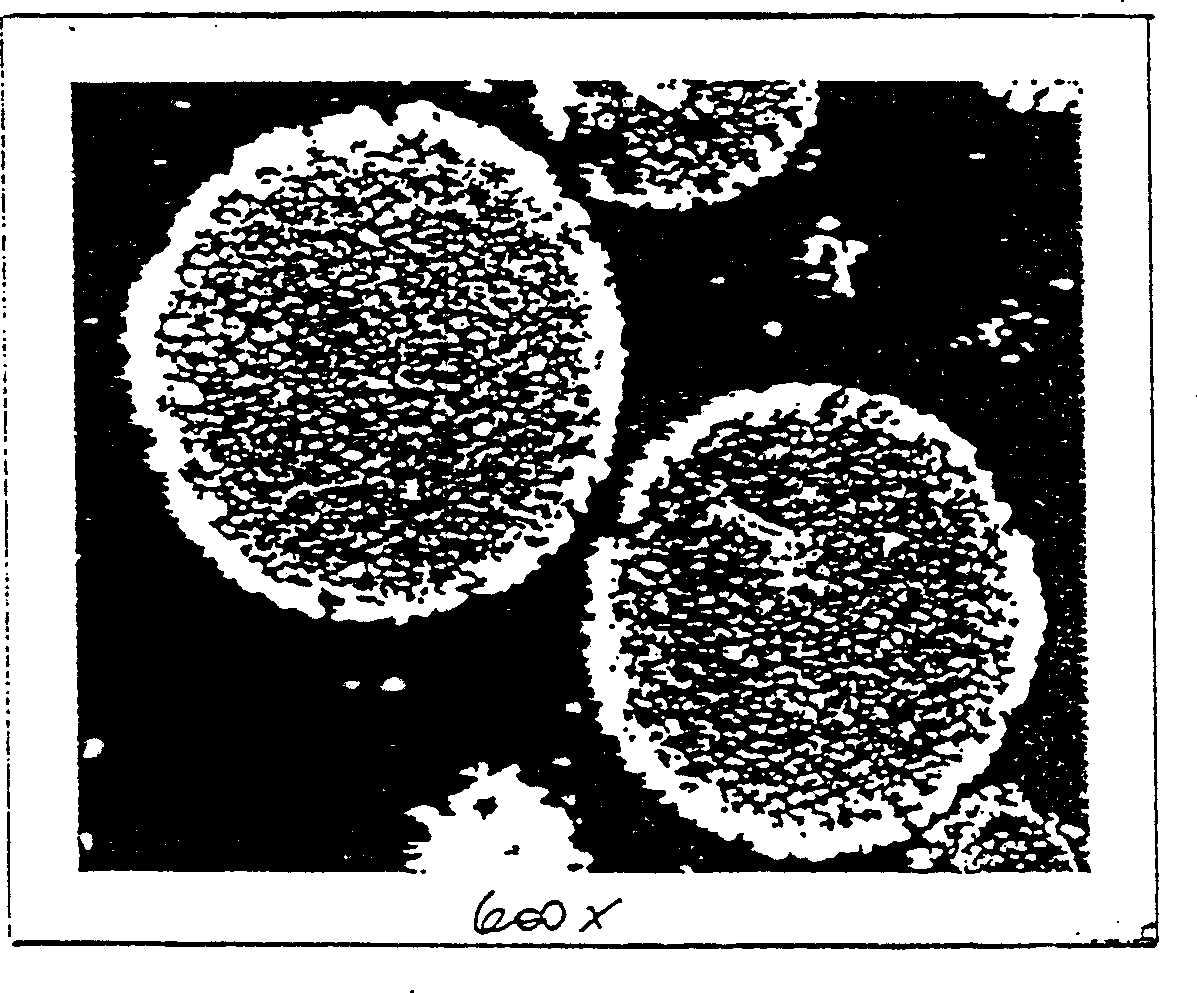

Method for preparing zeolite catalyst

The present invention relates to a process for the preparation of zeolitic catalysts comprising zeolite and oligomeric silica, which can be used in industrial reactors. The process consists in directly mixing the suspension, resulting from the synthesis of the zeolite, with an oligomeric silica sol, obtained from the hydrolysis of a tetra-alkyl ortho silicate in the presence of tetraalkylammonium hydroxide, and in subjecting the mixture to rapid drying, by feeding to a spray-dry.

Owner:ENICHEM SPA +1

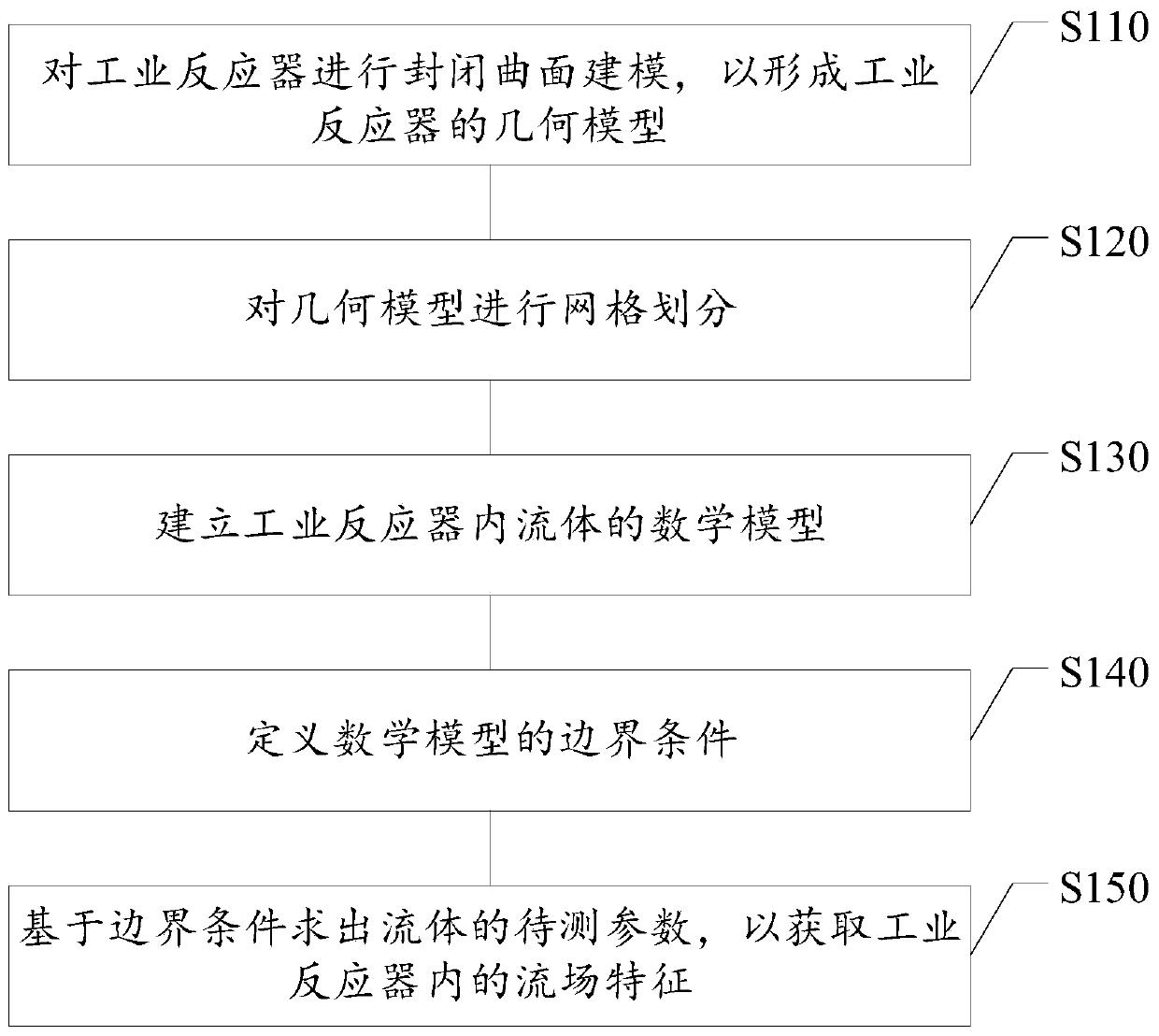

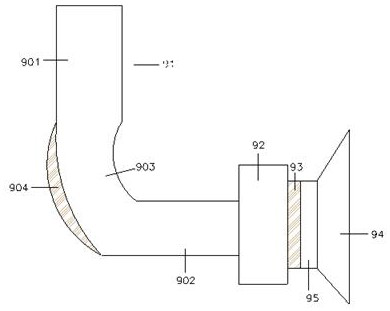

Simulation calculation method for fluid in industrial reactor with spray gun

The invention relates to the technical field of industrial reactors, in particular to a simulation calculation method for fluid in an industrial reactor with a spray gun. The simulation calculation method comprises the following steps: carrying out closed curved surface modeling on an industrial reactor to form a geometric model of the industrial reactor; conducting meshing on the geometric model;establishing a mathematical model of the fluid in the industrial reactor; defining boundary conditions of the mathematical model; and calculating based on the boundary conditions to obtain to-be-measured parameters of the fluid so as to obtain flow field characteristics in the industrial reactor. According to the simulation calculation method, the flow characteristics of the fluid in the industrial reactor can be obtained, so that the industrial reactor is designed in a targeted manner.

Owner:CHINA ENFI ENGINEERING CORPORATION

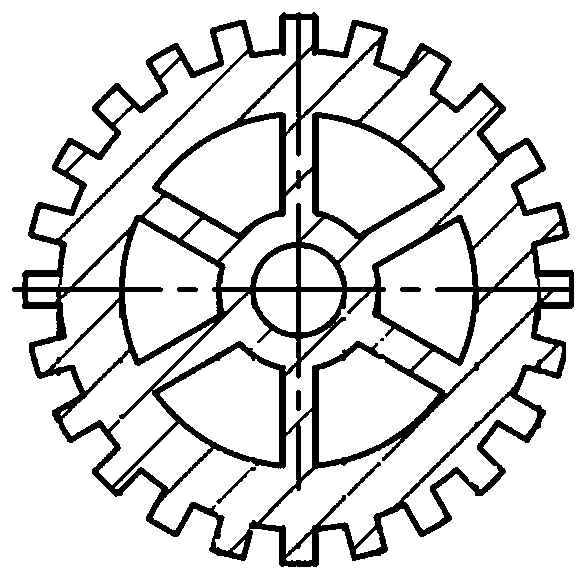

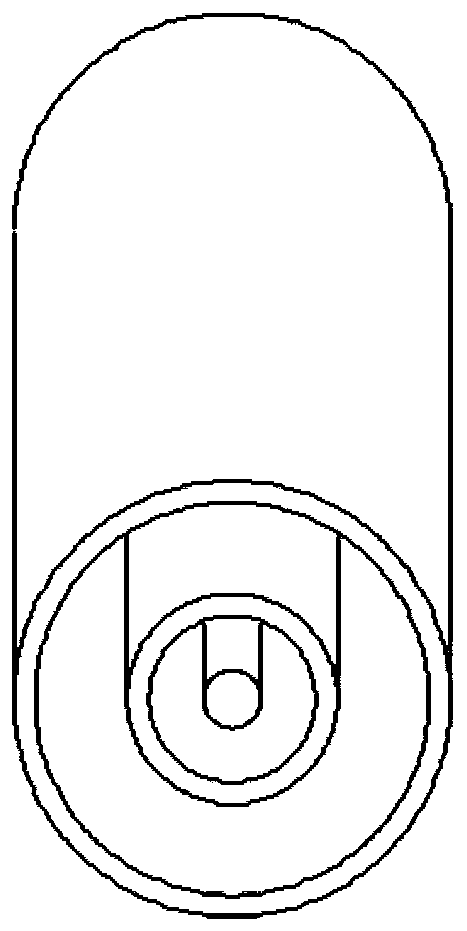

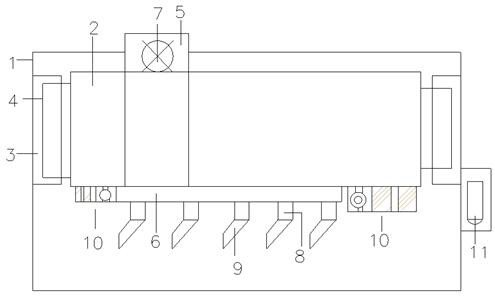

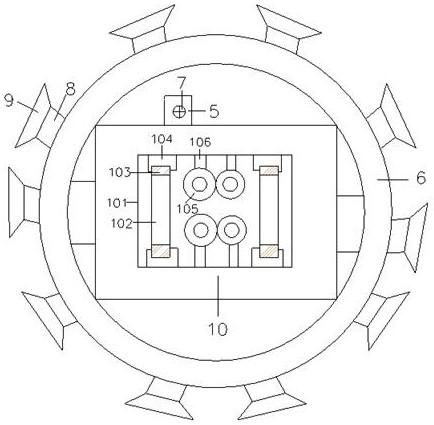

Reactor for synthesis of alkylate oil

ActiveCN105062554ASmall sizeImprove contact effectLiquid hydrocarbon mixtures productionHydrocarbonsIndustrial reactorStraight tube

The invention discloses a reactor for synthesis of alkylate oil. The reactor comprises a reactor cylinder 1, which consists of a straight tube section 2, a wide diameter section 21 and a transition section 5 between the straight tube section and the wide diameter section. An inner tube lower tube plate 14 and an outer tube lower tube plate 12 are disposed at the lower part of the straight tube section, and an upper tube plate 4 is arranged at the joint of the straight tube section and the transition section. The upper end and lower end of an outer tube 9 are respectively connected to an upper tube plate and the outer tube lower tube plate, the middle-upper part of an inner tube 10 is disposed in the outer tube, the upper end of the inner tube is a blind end, the lower end of the inner tube is connected to the inner tube lower tube plate, and the inner tube is provided with holes. Compared with existing industrial reactors, the reactor provided by the invention has good acid hydrocarbon contact effect, accelerates the reaction rate, reduces the reactor size, at the same time lowers alkyl-olefin ratio, and can strictly control the reaction temperature and reduce reaction by-product, thereby increasing the yield and quality of alkylate synthetic oil, and reducing the energy consumption needed by isobutene circulation.

Owner:TIANJIN UNIV

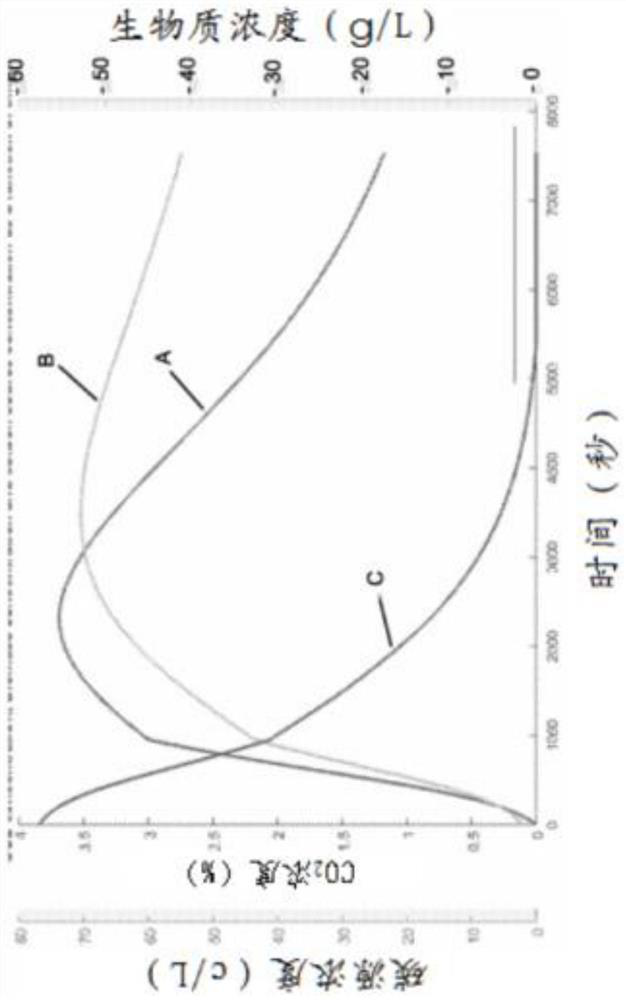

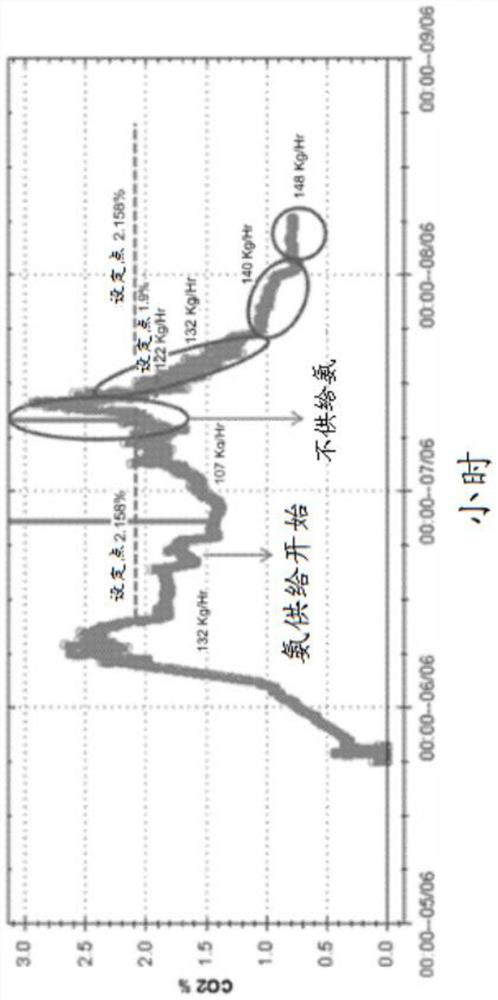

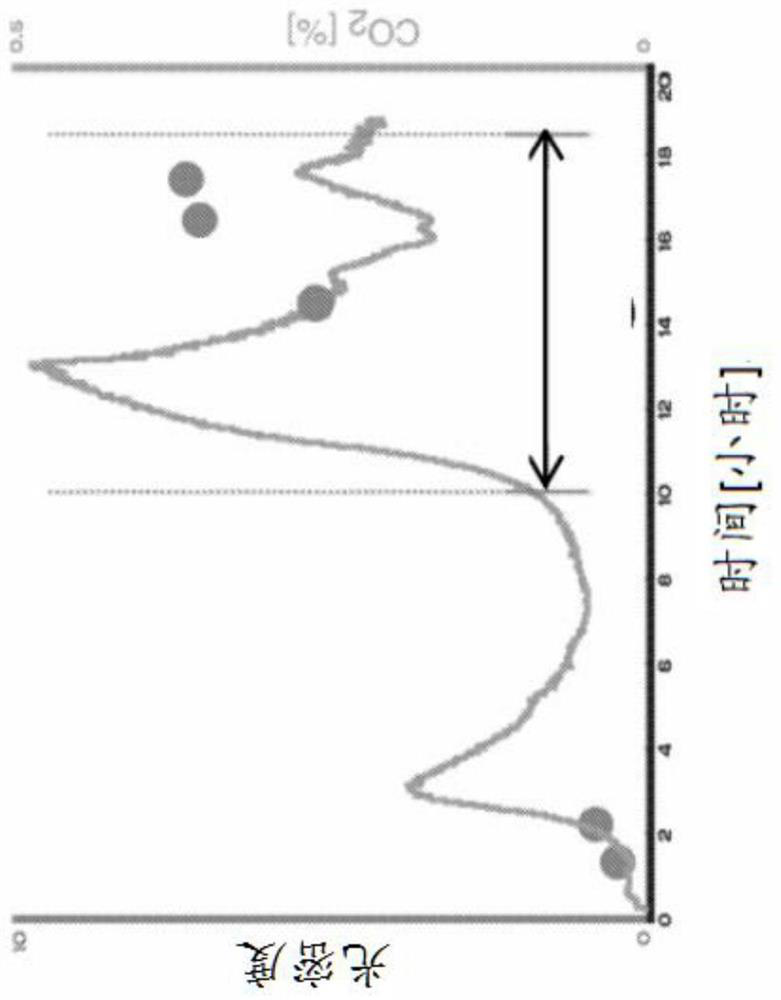

Systems methods and computational devices for automated control of industrial production processes

A method of automated control of an industrial reactor-based production process comprises the steps of: a) collecting data associated with performance of a production process of a reactor; b) defining a set of monitored parameters and a set of controlled parameters in the production process; c) defining a model comprising a set of equations mimicking a dynamic behavior of the process of a reactor, wherein in the model, changes in the monitored parameters are linked to changes in the controlled parameters; and d) creating a trained agent obtained by iterative machine learning training code and using the model, wherein the trained agent capable of making decisions regarding controlled parameters to be applied to the reactor based on monitored parameters of the production process.

Owner:瓦尤森斯有限公司

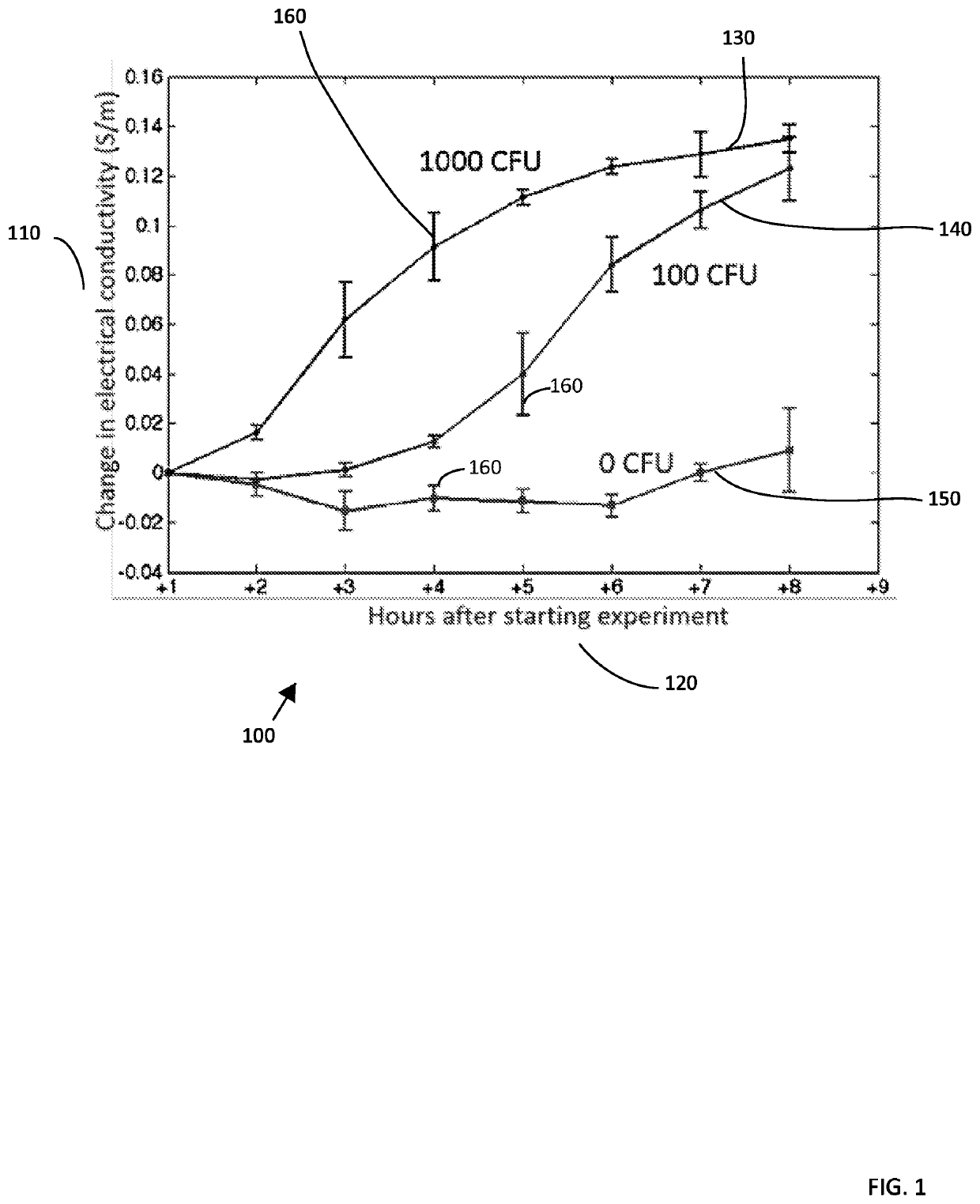

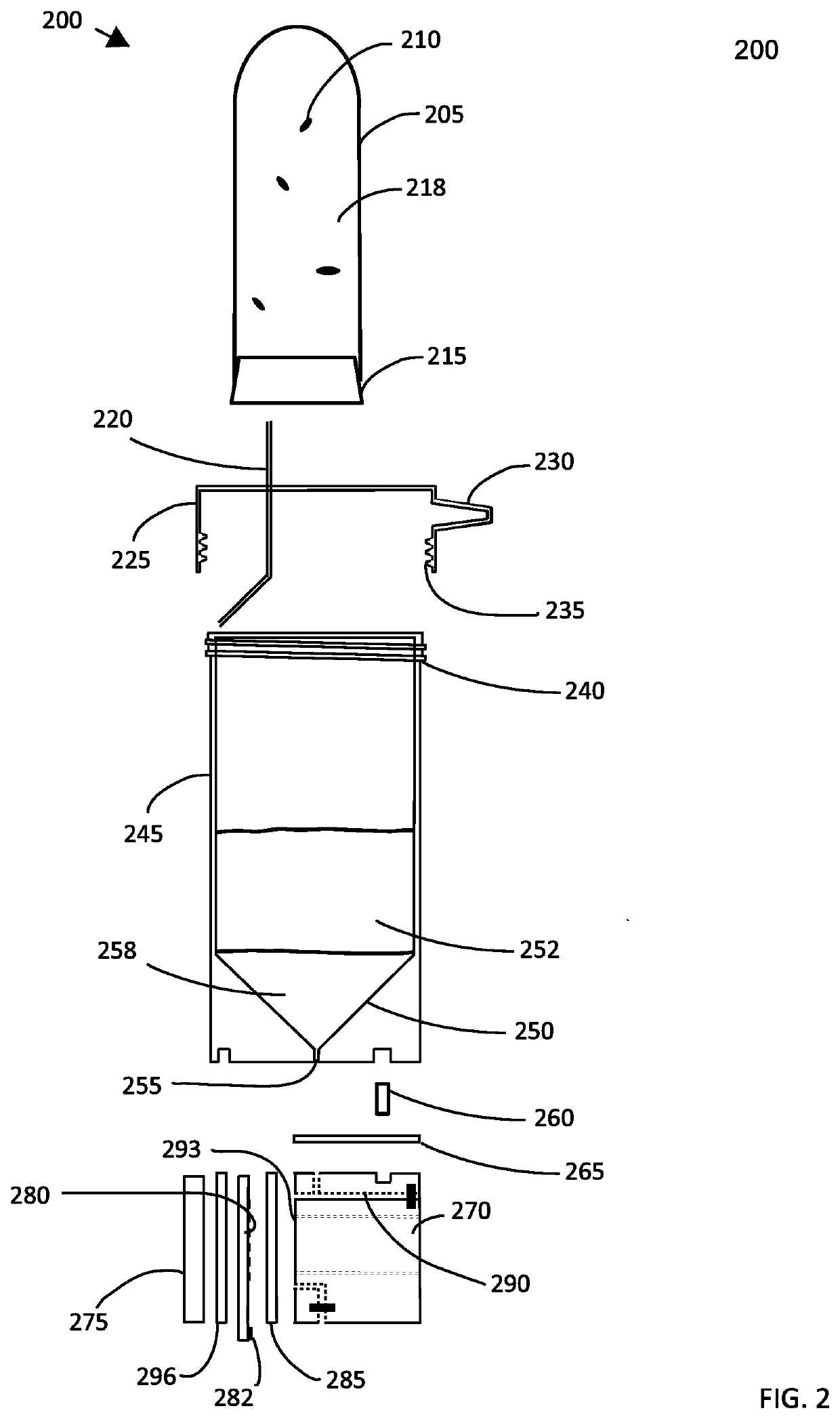

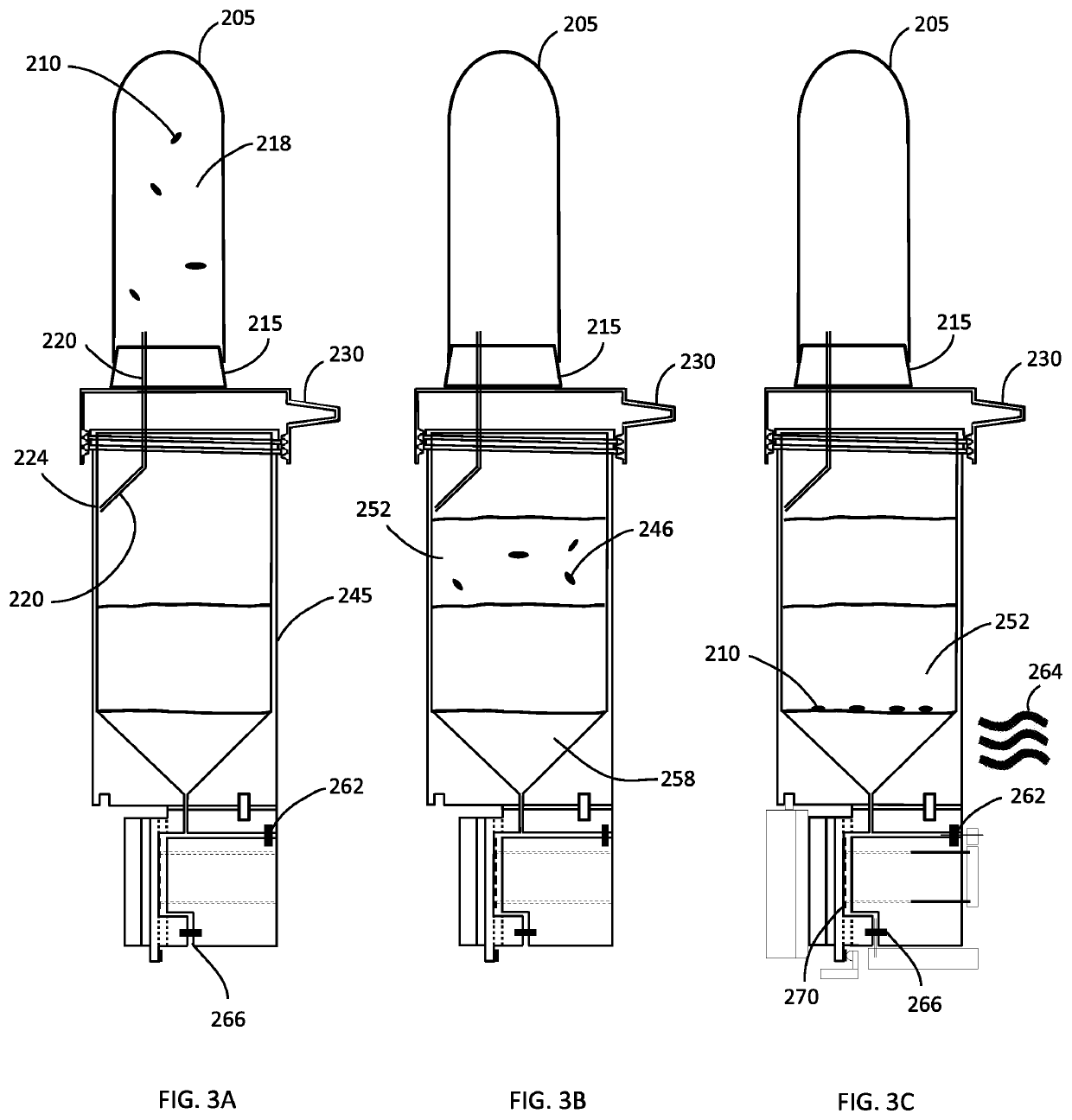

Method and Apparatus for Isolating and Detecting Biological and Other Particles

ActiveUS20210331166A1Accelerate microbiology laboratory turn-around-timeNot easy to cross contaminationDielectrophoresisHeating or cooling apparatusEngineeringElectrode array

An apparatus and method for isolating bacterial particles in a sample using a container with material in temporary fluid blocking position to lower orifice in the container, a separation medium having an electrical conductivity lower than and physical density greater than that of the sample above the material that supports a sample concentrate after passing through the separation medium when exposed to centrifugal force, a heating element for liquefying the material to permit flow into a chamber past an electrode array that attracts and holds subject particles. The system allows rapid detection and isolation of particles from samples from animal, human, environmental sites, a bio-industrial reactor or a food or beverage production facility requiring relatively small volumes, short incubation times resulting in structurally intact particles for further analysis. Testing may be completed in a single unit that requires decreased technician manipulation, fewer steps and a decrease in cross-contamination.

Owner:AINCOBIO LLC

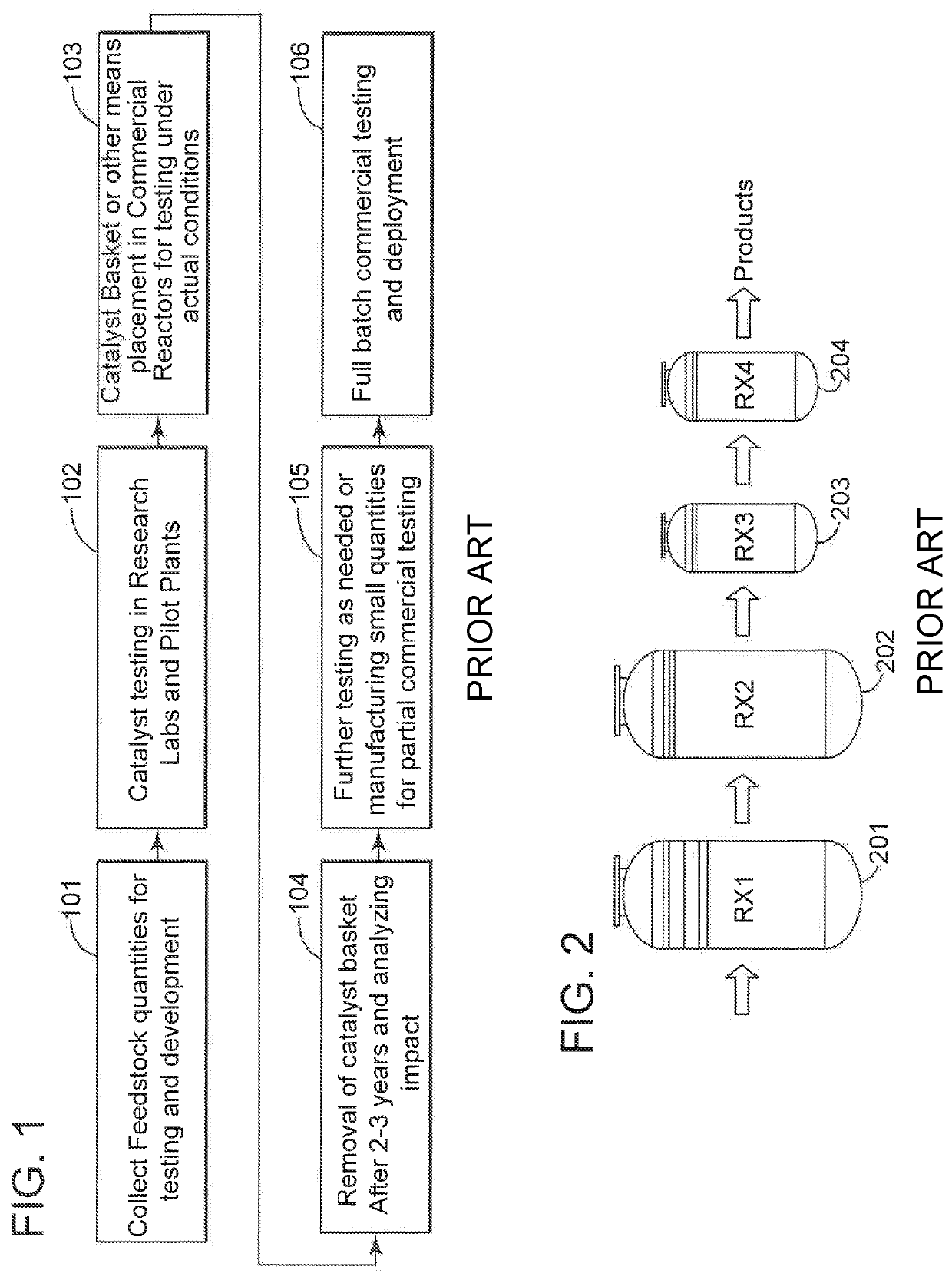

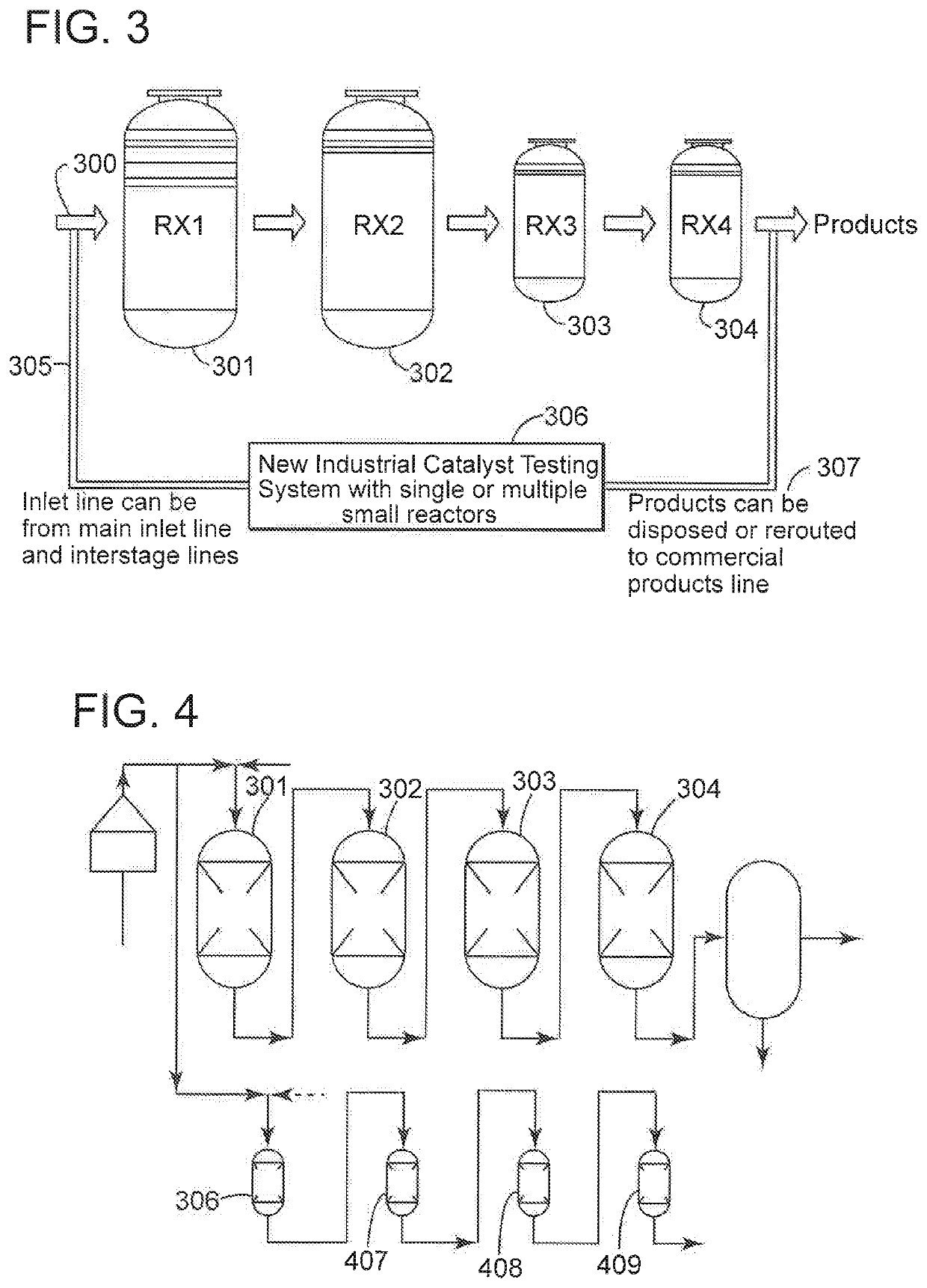

System and apparatus for testing and/or evaluating an industrial catalyst

ActiveUS11346826B2Low costShorten the timeChemical analysis using catalysisSequential/parallel process reactionsIndustrial reactorPtru catalyst

The invention relates to an integrated process for assessing one or more properties of a catalyst. In the method, a standard chemical reactor or reactors is / are provided, and a bypass means is also provided, to transport a sample of whatever is added to the industrial reactor, to the test reactor. Both gases and liquids are transferred to the test reactor.

Owner:SAUDI ARABIAN OIL CO

A Modeling and Optimization Method for Wax Oil Hydrocracking Process

ActiveCN108108572BAccurately describe the actual reaction processEasy accessDesign optimisation/simulationSpecial data processing applicationsIndustrial reactorEnergy balance equation

The invention relates to a modeling and optimization method for wax oil hydrocracking process. The modeling method of the present invention includes determining the design parameters and operating data required for modeling according to the industrial hydrocracking unit, and determining the hydrocracking lump division method, wherein the design parameters include the length and diameter of each bed, and the The above operation data include feed flow, inlet and outlet temperature of each bed, relative density of feed and product, distillation range data and product yield; determine hydrocracking reaction network, reaction kinetic equation, material balance equation and energy balance equation ; Solution of hydrocracking mechanism model; Correction of lumped kinetic parameters of hydrocracking based on actual industrial operation data. The invention has wide adaptability and can be used for simulating and optimizing hydrocracking industrial reactors with different requirements of reaction bed layers and product yield.

Owner:EAST CHINA UNIV OF SCI & TECH

Reactor for synthesis of alkylate oil

ActiveCN105062553ASmall sizeImprove contact effectLiquid hydrocarbon mixtures productionHydrocarbonsIndustrial reactorReaction rate

The invention discloses a reactor for synthesis of alkylate oil. The reactor is composed of a straight tube section, a wide radius section and a transition section between the straight tube section and the wide radius section. An inner pipe lower pipe plate is disposed at the lower part of the straight tube section, an outer pipe lower pipe plate is arranged above the inner pipe lower pipe plate, and an upper pipe plate is arranged at the joint of the straight tube section and the transition section. The upper end and lower end of a downcomer are respectively connected to the upper pipe plate and the outer pipe lower pipe plate, the outer pipe upper end and lower end are respectively connected to the upper pipe plate and the outer pipe lower pipe plate, the inner pipe is disposed inside the outer pipe, the upper end of the inner pipe is a blind end, the lower end of the inner pipe is connected to the inner pipe lower pipe plate, and the inner pipe is provided with holes. Compared with existing industrial reactors, the reactor provided by the invention has better acid hydrocarbon contact effect, accelerates the reaction rate, reduces the reactor size, at the same time lowers alkyl-olefin ratio, and can strictly control the reaction temperature and reduce reaction by-product, thereby increasing the yield and quality of alkylate synthetic oil, and reducing the energy consumption needed by isobutane circulation.

Owner:TIANJIN UNIV

A reactor for the synthesis of alkylated oil

ActiveCN105062553BSmall sizeImprove contact effectLiquid hydrocarbon mixtures productionHydrocarbonsIndustrial reactorStraight tube

The invention discloses a reactor for synthesis of alkylate oil. The reactor is composed of a straight tube section, a wide radius section and a transition section between the straight tube section and the wide radius section. An inner pipe lower pipe plate is disposed at the lower part of the straight tube section, an outer pipe lower pipe plate is arranged above the inner pipe lower pipe plate, and an upper pipe plate is arranged at the joint of the straight tube section and the transition section. The upper end and lower end of a downcomer are respectively connected to the upper pipe plate and the outer pipe lower pipe plate, the outer pipe upper end and lower end are respectively connected to the upper pipe plate and the outer pipe lower pipe plate, the inner pipe is disposed inside the outer pipe, the upper end of the inner pipe is a blind end, the lower end of the inner pipe is connected to the inner pipe lower pipe plate, and the inner pipe is provided with holes. Compared with existing industrial reactors, the reactor provided by the invention has better acid hydrocarbon contact effect, accelerates the reaction rate, reduces the reactor size, at the same time lowers alkyl-olefin ratio, and can strictly control the reaction temperature and reduce reaction by-product, thereby increasing the yield and quality of alkylate synthetic oil, and reducing the energy consumption needed by isobutane circulation.

Owner:TIANJIN UNIV

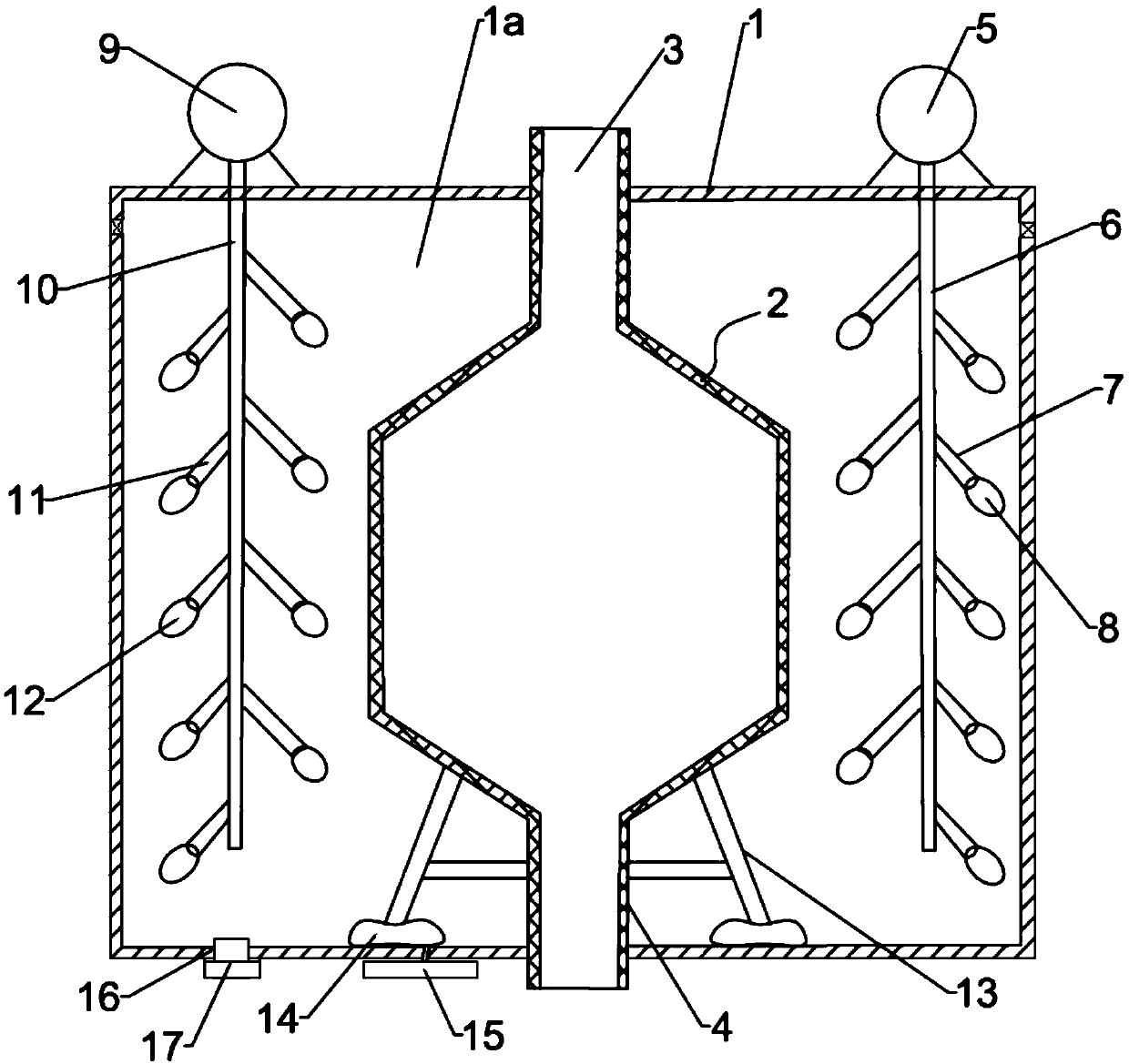

A special cleaning device for industrial reactors

ActiveCN109482595BLong spray distanceExpand the spraying areaHollow article cleaningDrying gas arrangementsIndustrial reactorElectric machinery

The invention relates to a special cleaning device for an industrial reaction kettle, which includes a reaction kettle and a fixed shaft. The reaction kettle is provided with connecting pieces, and the connecting pieces are matched with mounting buckles provided on both sides of the fixed shaft. The fixed shaft The water inlet provided on the top is connected to the annular pipe at the bottom of the fixed shaft, the water inlet is provided with a one-way valve, and the bottom of the annular pipe is provided with a plurality of evenly distributed water outlets, and the plurality of water outlets The nozzle device is connected, and a drying device is arranged in the middle of the fixed shaft, and the drying device is connected to a motor, and the motor is fixed on the outside of the reaction kettle. The invention is fixed by suspension, easy to load and disassemble, low in cost, stable in structure, improves the flushing force through 360° surrounding high-pressure flushing, and uses a drying device for drying to speed up the usable time of the reaction kettle, and has high comprehensive economic benefits.

Owner:江苏福赛乙德药业有限公司

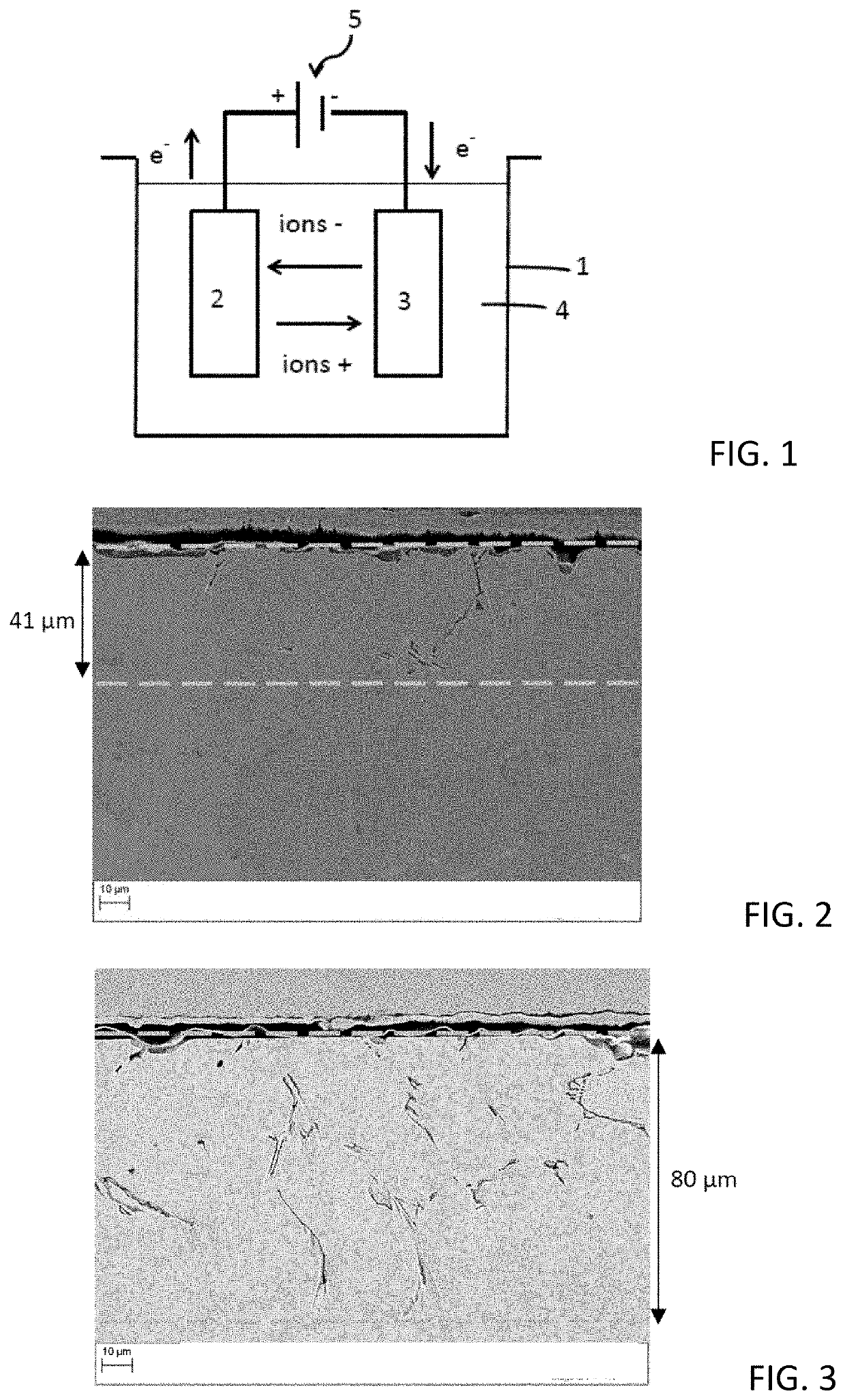

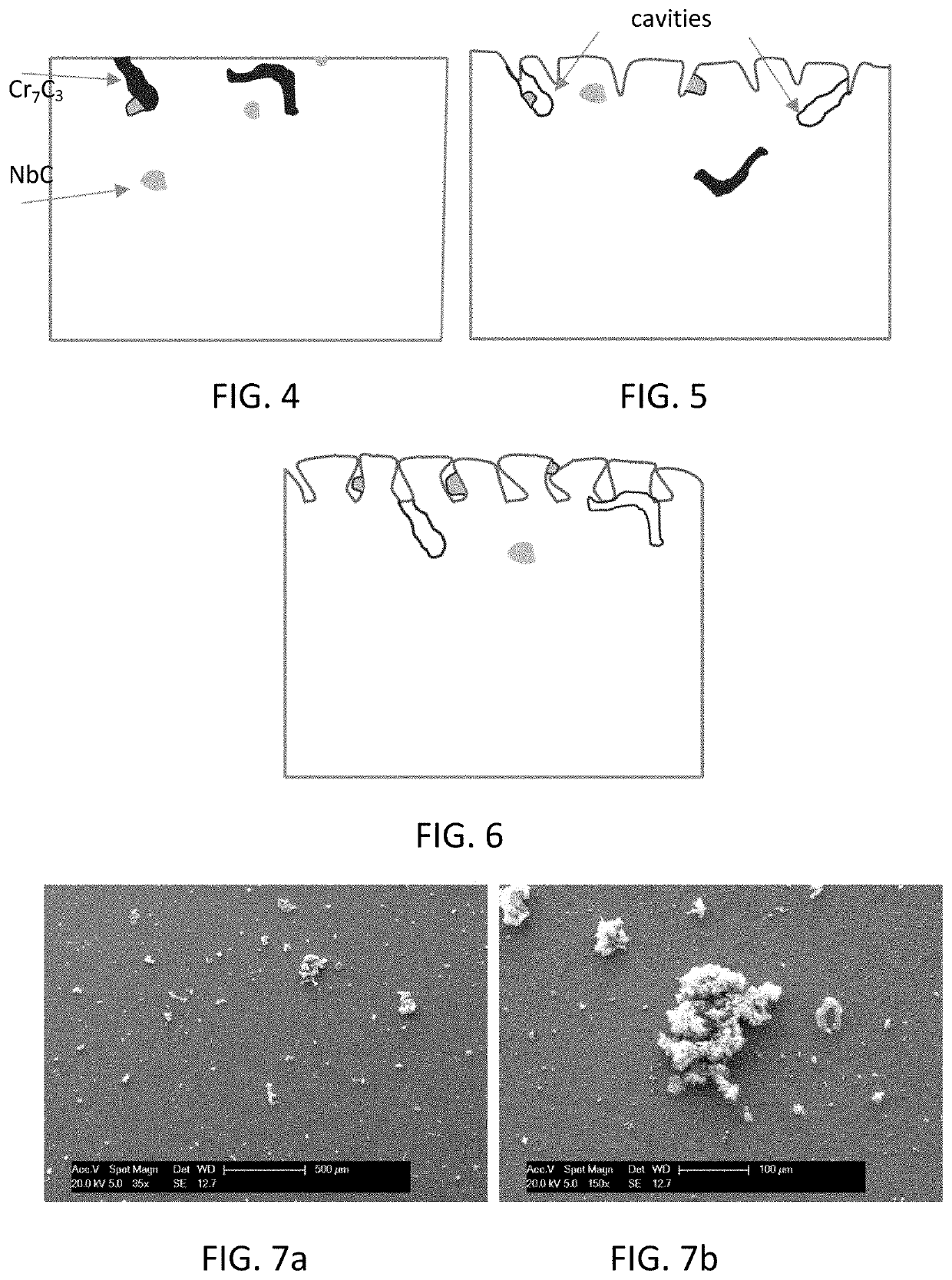

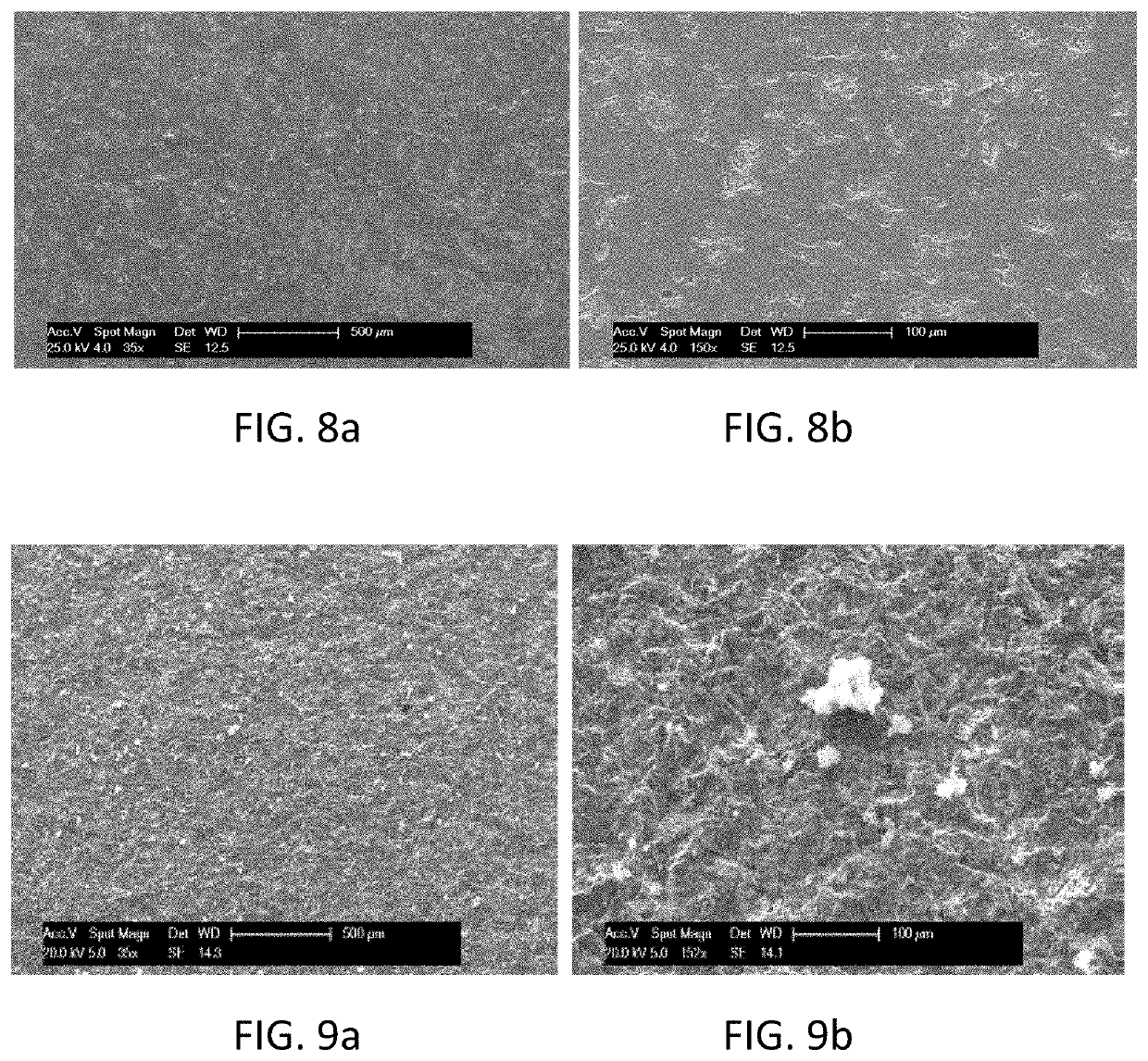

Chemical Wall-Treatment Method That Reduces the Formation of Coke

InactiveUS20190390362A1Reduce formationReduces coke formationSolid state diffusion coatingChromium carbideIndustrial reactor

The invention relates to a process for the treatment of a wall made of Fe—Ni—Cr metal alloy of an industrial reactor which reduces the formation of coke on the said wall when it is subjected to operational conditions favourable to coking, the metal alloy comprising, within its structure, carbides, some of which show on the surface. The process comprises a chemical surface treatment stage, during which at least a part of the carbides initially present in the alloy is dissolved by electrolytic decomposition, under conditions suitable for dissolving at least a part of these carbides, in particular chromium carbides.

Owner:TOTAL RAFFINAGE CHIM +3

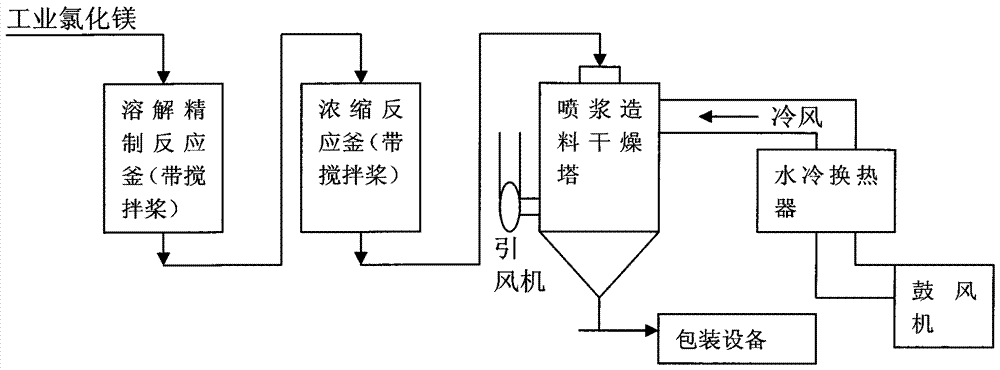

A kind of technological method of making edible magnesium chloride by shotcrete granulation

Owner:南通江海港建设工程有限公司

Furnace body in cooling section of industrial reaction furnace

ActiveCN108007208BImprove cooling effectImprove efficiencyFurnace cooling arrangementsControl devices for furnacesIndustrial reactorMetallurgy

The invention discloses an industrial reaction furnace cooling section furnace body. The furnace body comprises an outer furnace body with a cooling cavity, wherein a cooling furnace body is arrangedin the cooling cavity, the top of the cooling furnace body penetrates through the outer furnace body through an upper through pipe and communicates with the outside, and the bottom of the cooling furnace body penetrates through the outer furnace body and communicates with the outside through a lower through pipe; a first motor is arranged on the outer side wall of the top of the outer furnace body, and a first rotating rod driven by the first motor is arranged in the cooling cavity, wherein the first rotating rod is arranged close to the cooling furnace body; first fixed rods which extend obliquely downwards are arranged on the first rotating rod in sequence at equal intervals; rod heads of the first fixed rods are hinged to first scattered vanes which swing vertically; the first fixed rods and the first rotating rod are sequentially provided with flow dispersing grooves in a communicating mode, and the flow guide grooves are provided with drainage tubes externally connected with cooling liquid; and the cooling liquid flows into the cooling cavity through the drainage pipes, part of the cooling liquid can be transferred to the outer side wall of the cooling furnace body from bottomto top, part of the cooling liquid can be scattered and atomized by the lifted and rotated first scattered vanes, so that the use efficiency is higher.

Owner:海盐鸳鸯丝绸印染股份有限公司

A Chilled Single Waste Pot Reactor

ActiveCN104498105BLow ash contentImprove utilization efficiencyEnergy inputGasification processes detailsIndustrial reactorChemical synthesis

The invention relates to a chilling type single waste pan reactor. The reactor consists of an upper gasification reaction chamber, a middle radiation heat exchange chamber and a lower chilling slag chamber, wherein the gasification reaction chamber is communicated with the radiation heat exchange chamber by virtue of a conical slag opening and a conical gas guide inlet; and the radiation heat exchange chamber is communicated with the chilling slag chamber by virtue of a funnel-shaped slag trap. At present, a chilling type reactor in the conventional industrial reactor is low in energy utilization efficiency, the efficiency needs to be improved, and the all waste pan reactor is complex in structure, high in investment cost, low in operating stability, low in raw gas vaporization ratio and large in ash content and is unsuitable to serve as chemical synthesis gas. Moreover, the chilling type single waste pan reactor disclosed by the invention simultaneously has the advantages of a waste pan reactor and a chilling reactor, the energy utilization efficiency of the reactor is improved by 4-5 percent compared with the chilling reactor, the ash content is reduced by 2mg / L compared with the all waste pan reactor, and the vaporization ratio is improved to 0.8 to 1.0. The reactor disclosed by the invention is suitable for IGCC power generation and combined generation chemical synthesis.

Owner:THE NORTHWEST RES INST OF CHEM IND

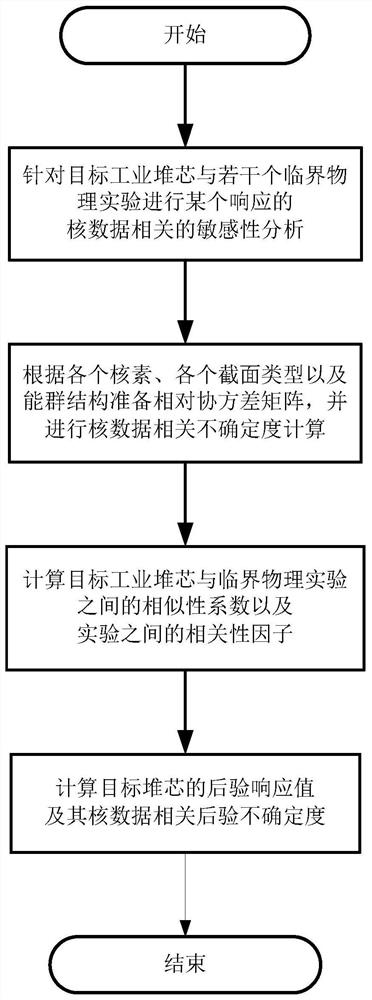

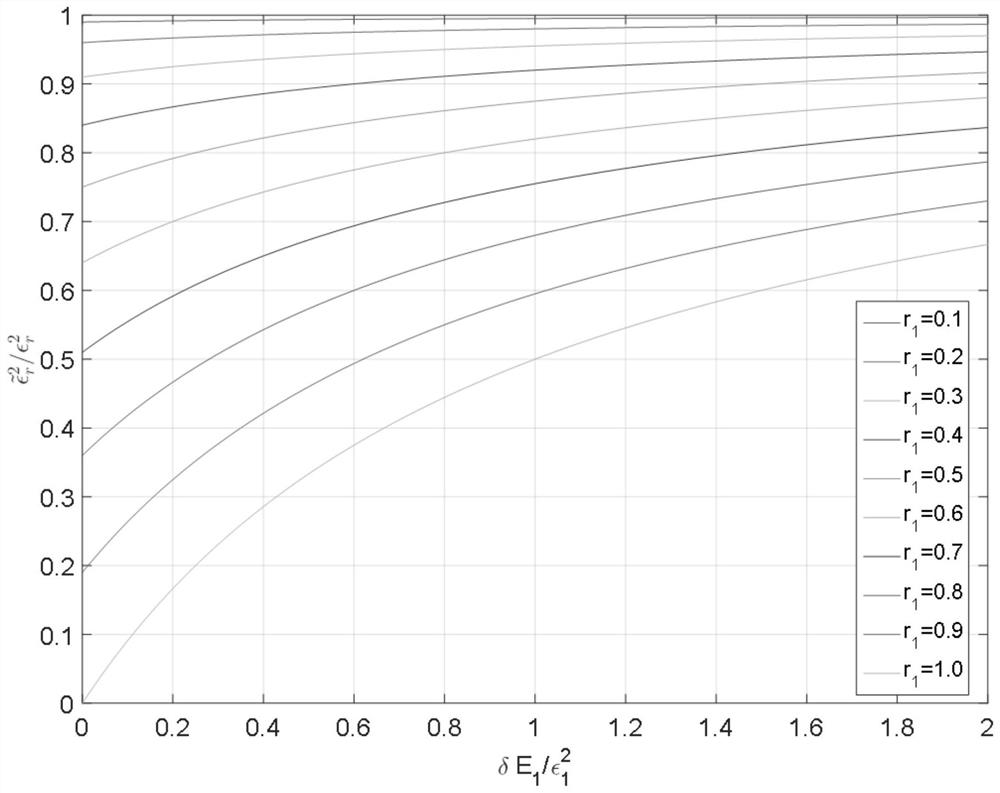

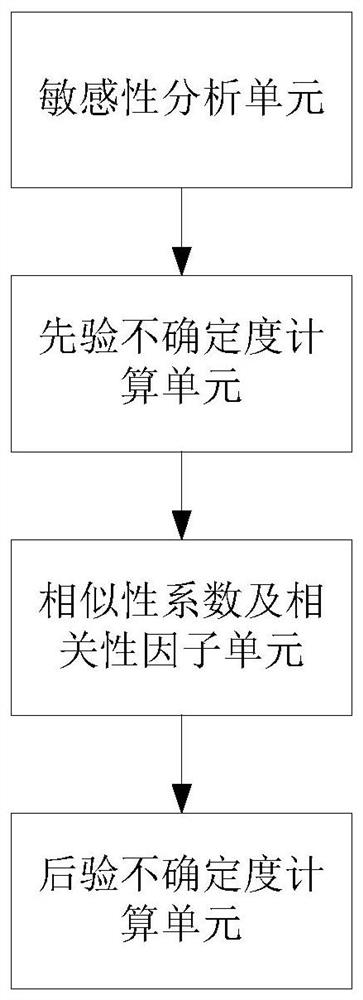

Method, device and equipment for reducing kernel data correlation calculation uncertainty and medium

PendingCN114065126AReduce computational uncertaintyAvoid adjustmentComplex mathematical operationsIndustrial reactorSensitive analysis

The invention discloses a method, a device, equipment and a medium for reducing the uncertainty of nuclear data correlation calculation. The method comprises the following steps: carrying out nuclear data correlation sensitivity analysis on a target industrial reactor core and a plurality of critical physical experiments, and obtaining sensitivity coefficients of physical response parameters of all reactor cores to all nuclear data; forming a sensitivity vector of the physical response parameter of the target industrial reactor core to the nuclear data and a sensitivity vector of each critical physical experiment; constructing a relative covariance matrix according to all the nuclear data, and combining the sensitivity vector to obtain the nuclear data related uncertainty of the target industrial reactor core and the critical physical experiment; calculating a similarity coefficient between the target industrial reactor core and the critical physical experiment and a correlation factor between the experiments; and according to the similarity coefficient and the correlation factor, calculating the nuclear data correlation posteriori of the target reactor core and the nuclear data correlation uncertainty of the posteriori. According to the method, critical physical experiment data can be fully utilized, and a nuclear data adjustment process is avoided.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com