Reactor for synthesis of alkylate oil

An alkylate oil and reactor technology, applied in the directions of hydrocarbons, hydrocarbons, chemical instruments and methods, etc., can solve problems such as acid-hydrocarbon contact problems, and achieve lower alkene ratio, lower energy consumption, and strict control. The effect of reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

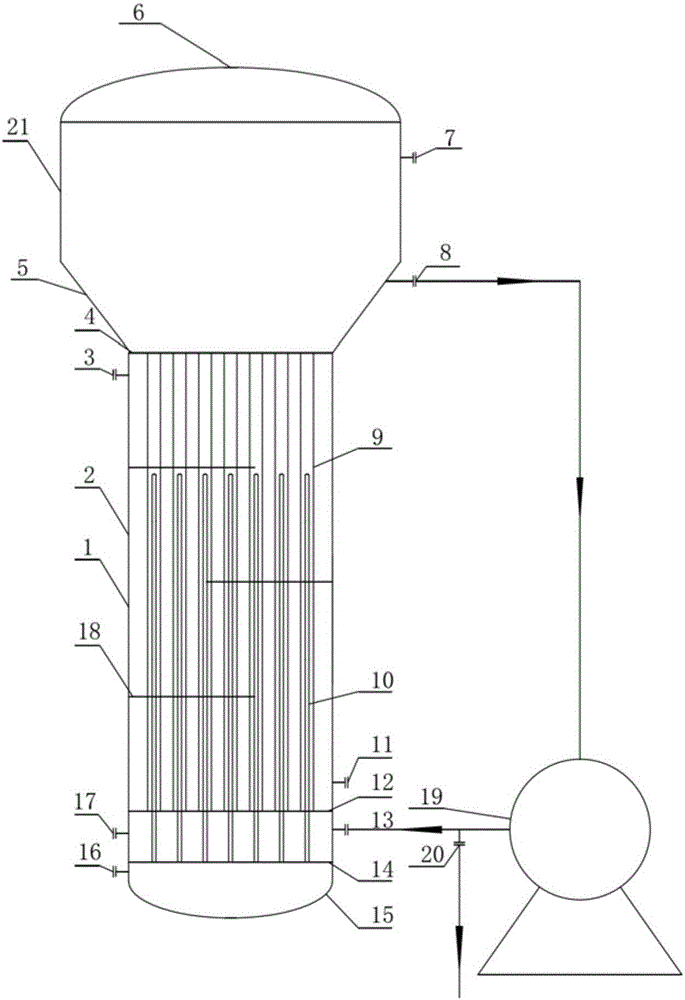

[0018] A reactor for synthesis of alkylated oil, including a reactor cylinder 1, the reactor cylinder is composed of a straight cylinder section 2, a wide diameter section 21, and a transition section 5 between the straight cylinder section and the wide diameter section, the wide diameter section The upper end of the section is connected with an upper head 6, the lower end of the straight section is connected with a lower head 15, the lower part of the straight section is provided with an inner tube lower tube plate 14, and the lower part of the straight tube section and above the inner tube lower tube plate is provided with an outer tube lower tube plate. The tube sheet 12 is provided with an upper tube sheet 4 at the junction of the straight section and the transition section; the upper and lower ends of the outer tube 9 are respectively connected with the upper tube sheet and the lower tube sheet of the outer tube, and the middle and upper part of the inner tube 10 is arrange...

Embodiment 2

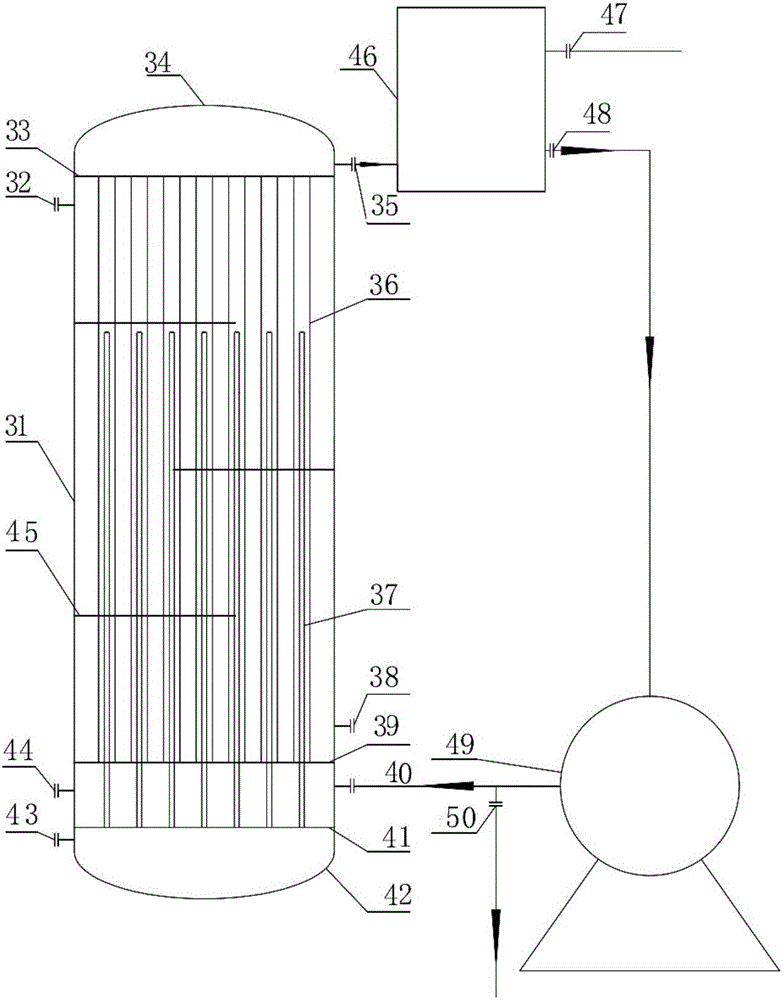

[0025] Another reactor used for the synthesis of alkylated oil includes a reactor cylinder 31, an upper head 34 and a lower head 42, an inner tube lower tube sheet 41 is arranged at the lower part of the reactor cylinder, and a lower tube plate 41 is arranged in the reactor cylinder The lower part of the body and the lower tube plate of the inner tube are provided with the lower tube plate 39 of the outer tube, and the upper tube plate 33 is arranged at the junction of the reactor cylinder body and the upper head. The outer tube is connected to the lower tube plate, the middle and upper part of the inner tube 37 is arranged inside the outer tube, the upper end of the inner tube is a blind end, the lower end of the inner tube is connected to the lower tube plate of the inner tube, the inner tube is provided with a hole, and the top of the inner tube Located between the upper tube sheet and the lower tube sheet of the outer tube, a baffle baffle 45 is arranged outside the inner a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com