A Chilled Single Waste Pot Reactor

A technology for reactors and reactor shells, applied in the field of chilled single-waste pot reactors, which can solve problems such as complex equipment structure, low device operation efficiency, and high labor intensity for reactor maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

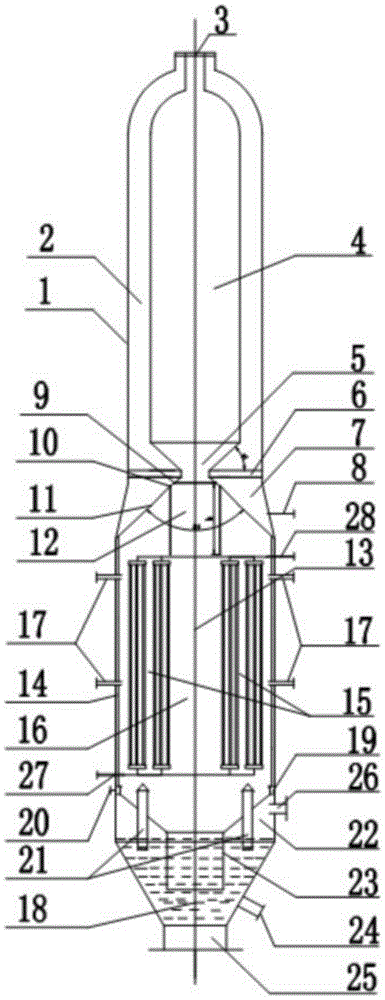

[0081] Embodiment 1: Chilling type single waste pot reactor of the present invention

[0082] The quenching type single waste pot reactor of the present invention is composed of an upper gasification reaction chamber 4, a middle radiation heat exchange chamber 13 and a lower quenching slag chamber 18. The gasification reaction chamber 4 passes through a conical slag opening 5 and a conical The gas guide port 12 communicates with the radiation heat exchange chamber 13 , and the radiation heat exchange chamber 13 communicates with the chilled slag chamber 18 through a funnel-shaped slag collector 23 and an air guide pipe 21 .

[0083] The wall of the gasification reaction chamber 4 is composed of a reactor shell 1 made of SA387Gr11CL2 material and a refractory material layer 2 fixed on the inner wall of the reactor shell 1 .

[0084] The refractory material layer 2 is a fire-facing refractory brick sold by Henan Burma Co., Ltd. under the trade name high chrome brick LIRR-HK90, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com