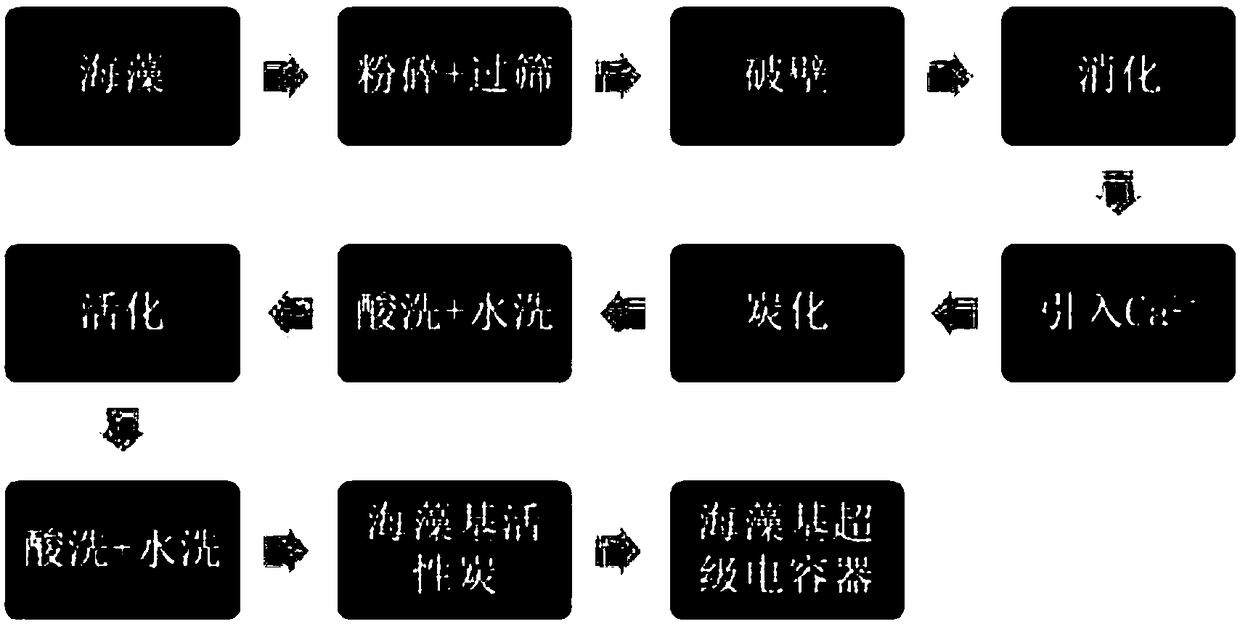

Preparation method of alga-based active carbon precursor for super capacitor

A supercapacitor and activated carbon technology, which is applied in the field of electrochemical applications, can solve the problems of large differences in supercapacitor properties, uneven product structure, and difficult industrial preparation, and achieve the effects of lowering temperature, developing pore structure, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The present embodiment relates to a kind of preparation method of activated carbon precursor for supercapacitor based on seaweed, comprises the steps:

[0074] In step 1, the sargassum raw material is washed repeatedly with clean water to remove salt and impurities, dried at 120° C. for 24 hours, crushed, and passed through an 80-mesh sieve.

[0075] Step 2: Weigh 10 g of the Sargassum powder obtained in Step 1, mix it with 80 ml of deionized water, and break the wall under 60 Hz ultrasound for 30 min.

[0076] Step 3: Mix the product obtained in Step 2 with sodium carbonate at a mass ratio of 4:1, and mechanically stir in a water bath at 40°C for 5 hours.

[0077] Step 4, the product obtained in step 3 and CaCl 2 Mix at a mass ratio of 4:1, mechanically stir in a water bath at 40°C for 30 minutes, and dry at 105°C for 48 hours to obtain a seaweed-based precursor.

[0078] Implementation effect: After elemental analysis and EDS analysis, the product obtained is a prec...

Embodiment 2

[0080] The present embodiment relates to a kind of preparation method of activated carbon precursor for supercapacitor based on seaweed, comprises the steps:

[0081] In step 1, the sargassum raw material is repeatedly washed with tap water to remove salt and impurities, dried at 120° C. for 24 hours, crushed, and passed through an 80-mesh sieve.

[0082] Step 2: Weigh 10 g of Sargassum powder obtained in Step 1 and soak in 80 ml of 1% formaldehyde solution for 24 hours.

[0083] Step 3: Mix the product obtained in Step 2 with sodium carbonate at a mass ratio of 4:1, and mechanically stir in a water bath at 40°C for 5 hours.

[0084]Step 4: Combine the product obtained in Step 3 with CaCl 2 Mix at a mass ratio of 4:1, mechanically stir in a water bath at 40°C for 30 minutes, and dry at 105°C for 48 hours to obtain a seaweed-based precursor.

[0085] Implementation effect: After elemental analysis and EDS analysis, the product obtained is a precursor based on calcium alginate...

Embodiment 3

[0087] This example relates to a method for preparing activated carbon for supercapacitors based on seaweed-based precursors, comprising the following steps:

[0088] Step 1: Weigh 20 g of the precursor prepared in Example 1, place it in a tube furnace, raise the temperature up to 600° C. at a rate of 5° C. / min, and keep at this temperature for 2 hours. Nitrogen is used as a protective gas, and the rate of feeding is 1.5L / min.

[0089] In step 2, the product obtained in step 1 was acid-washed with 15 wt% hydrochloric acid at 80°C, then washed with deionized water at 80°C until neutral, and dried at 105°C for 12 hours to obtain seaweed-based activated carbon.

[0090] Implementation effect: The electrode material for supercapacitors prepared by mixing the carbon material with the conductive agent and the binder at a mass ratio of 8:1:1 was used for constant current charge and discharge tests with 6mol / L KOH as the electrolyte. The specific capacitance value reaches 168F / g when...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance value | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com