A method and application for preparing a thermally conductive preform by blending industrial by-product oil and waste plastics

A technology of industrial by-products and waste plastics, applied in plastic recycling, chemical instruments and methods, products, etc., can solve the problems of high cost, high requirements for equipment conditions, complicated preparation steps, etc., and achieve convenient production, high applicability, The effect of mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

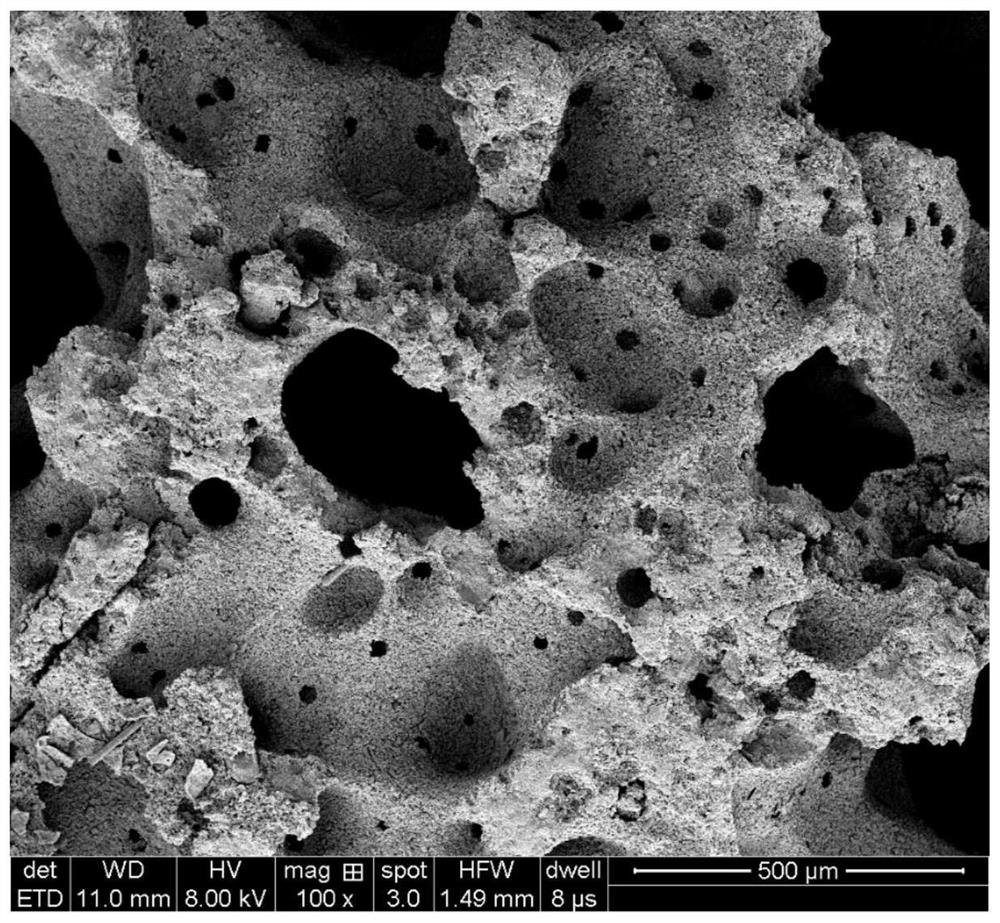

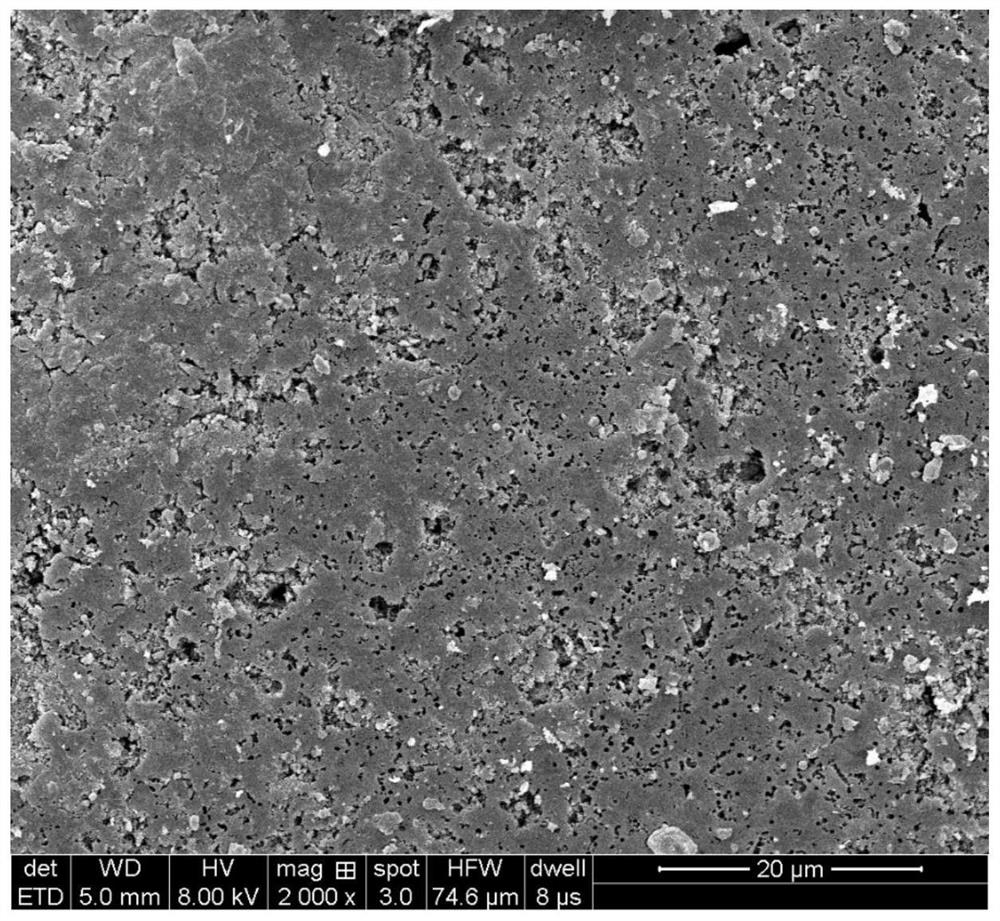

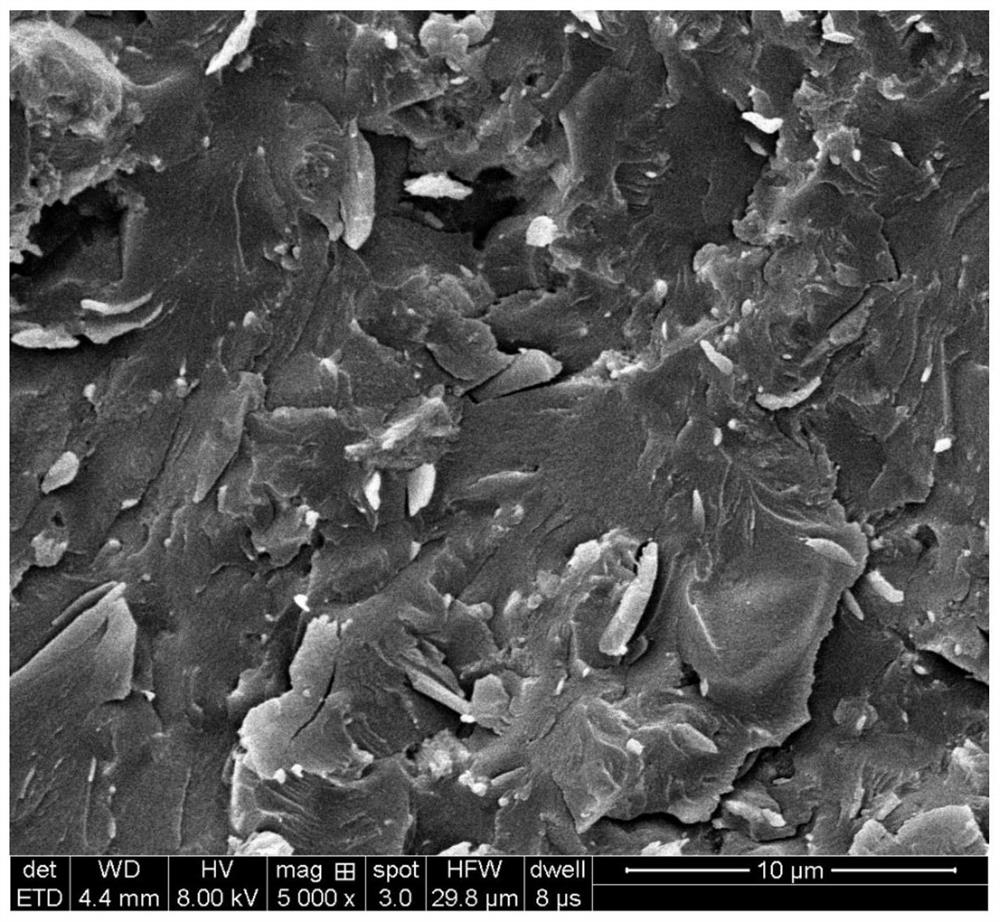

Image

Examples

Embodiment 1

[0046] Pulverize the thermosetting waste plastics, sieve the particles with the required mesh number of 60 meshes with a standard sieve, and then fully stir and mix them with the catalytic cracking oil slurry. The mixing ratio of the thermosetting waste plastics and industrial by-product oil is 1:1. Get 500g mixture, put it in the still, set the heating rate of the reaction still to be 1 ℃ / min, fill with inert gas, start vacuum distillation after emptying, the distillation cut fraction temperature is 450 ℃, and the temperature in the still is 350 ℃. °C. After the distillation, take out the distillation residue pitch, put it into the carbonization furnace, and set up a three-stage heating program: 1. In an inert atmosphere, the temperature is raised from room temperature to 500 °C, the heating rate is 10 °C / min, the stay is 5h, and the temperature is naturally cooled to room temperature. 2. In an air atmosphere, the temperature is raised from room temperature to 310°C, the heat...

Embodiment 2

[0048] Pulverize the thermosetting waste plastics, sieve the particles with the required mesh number of 100 meshes with a standard sieve, and then fully stir and mix them with coal tar. The mixing ratio of thermosetting waste plastics and industrial by-product oil is 1:3. Get 500g mixture, put it in the still, set the heating rate of the reactor to be 5 ℃ / min, fill with inert gas, start underpressure distillation after emptying, the distillation cut fraction temperature is 500 ℃, and the temperature in the still is 300 ℃. °C. After the distillation is over, take out the distillation residue pitch, put it into the carbonization furnace, and set up a three-stage heating program: 1. In an inert atmosphere, the temperature is raised from room temperature to 450 °C, the heating rate is 8 °C / min, the stay is 5h, and the temperature is naturally cooled to room temperature. 2. The temperature is raised from room temperature to 280°C in an air atmosphere, the heating rate is 1°C / min, t...

Embodiment 3

[0050] Pulverize the thermosetting waste plastics, sieve the particles with the required mesh number of 80 meshes with a standard sieve, and then fully stir and mix them with the pharmaceutical residues. The mixing ratio of the thermosetting waste plastics and industrial by-product oil is 1:2. Get 500g mixture, put it in the still, set the heating rate of the reaction still to be 1 ℃ / min, fill with inert gas, start vacuum distillation after emptying, the distillation cut fraction temperature is 450 ℃, and the temperature in the still is 350 ℃. °C. After the distillation is over, take out the distillation residue pitch, put it into the carbonization furnace, and set a three-stage heating program: 1. In an inert atmosphere, the temperature is raised from room temperature to 480 °C, the heating rate is 5 °C / min, and the temperature is kept for 6h, and naturally cooled to room temperature. 2. The temperature is raised from room temperature to 350°C in an air atmosphere, the heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com