Method for preparing zeolite catalyst

A zeolite catalyst and zeolite technology are applied in catalyst activation/preparation, preparation of organic compounds, preparation of lactams, etc., and can solve problems such as expensive, inability to separate catalysts and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Synthetic H 2 O / SiO 2 MFI zeolite with molar ratio=4

[0074] 19.1 kg of a 40% by weight aqueous solution of tetrapropylammonium hydroxide (TPA-OH) were charged to a 100 liter autoclave. 32.0 kg of tetraethylorthosilicate (TEOS) was added.

[0075] The temperature was raised to 190°C and the mixture was crystallized under autopressure for 2 hours.

[0076] The mixture was cooled to room temperature and the cloudy slurry was discharged from the reactor.

[0077] 100 grams of the slurry were centrifuged to obtain 18 grams of solid, identified by XRD as pure MFI phase. The crystallization rate was 100%.

Embodiment 2

[0079] synthetic binding phase

[0080] 40% 4.6 kg TPAOH, 24.2 kg water and 20.8 kg TEOS were charged continuously into a 100 liter autoclave. The mixture was heated to 60°C for 1 hour to facilitate decomposition. After cooling, the clear sol was taken out.

Embodiment 3

[0082] Prepared catalyst (30% SiO 2 -70% MFI)

[0083] 15.0 kg of the slurry prepared according to the method of Example 1 was mixed with 9.5 kg of the solution prepared according to the method of Example 2. The mixture was heated to 70°C for 3 hours.

[0084] The slurry obtained was atomized with a Niro Mobile Minor HI-TEC atomizer, fed with a 1.5 mm nozzle at a feed rate of about 5 liters / hour and an outlet temperature of 100°C.

[0085] Discharge the product from the bottom of the container.

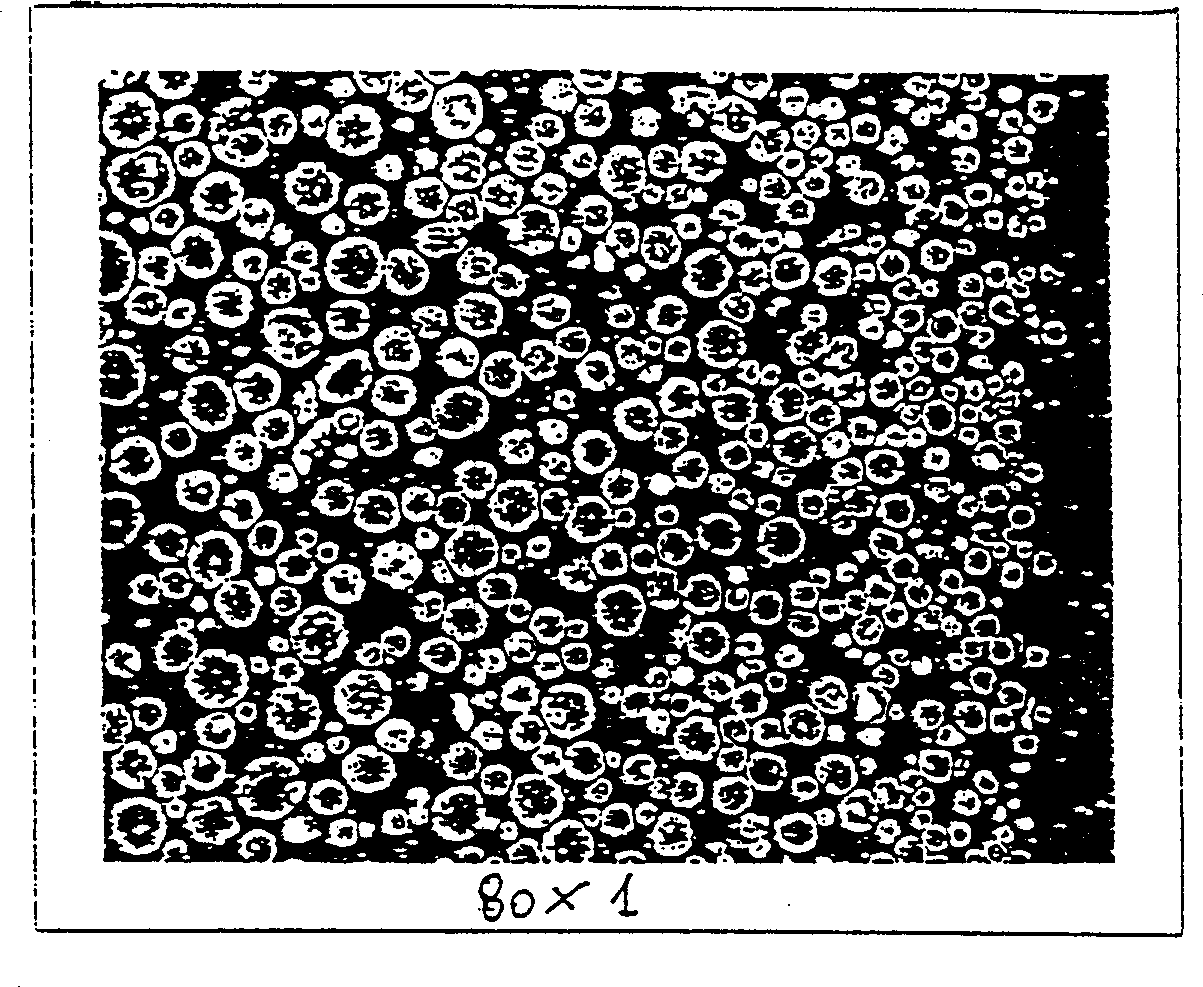

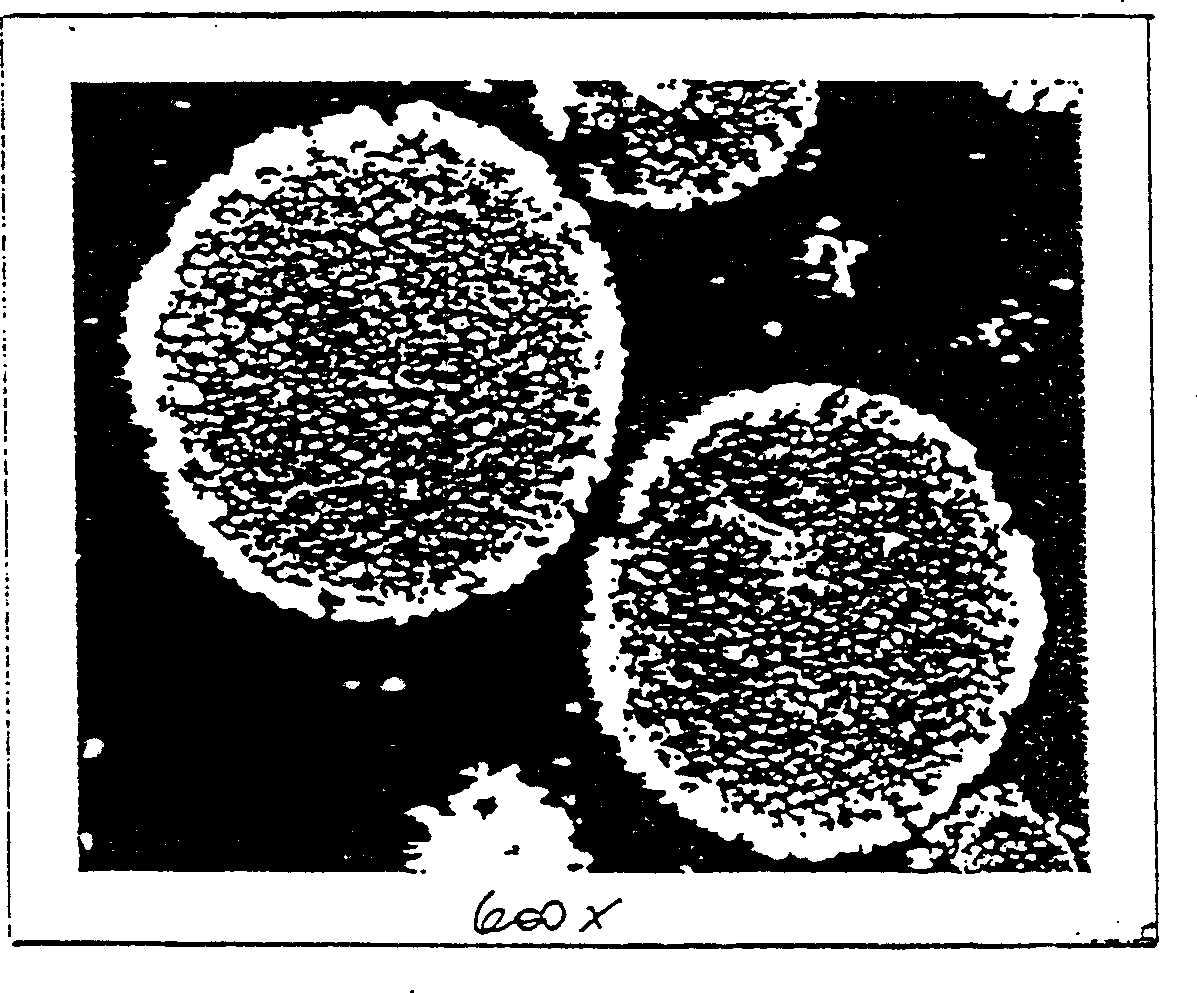

[0086] The morphology of the product, determined by means of SEM analysis on cut samples, is shown in Figures 1a (80x magnification), b (600x magnification). A specific spherical shape can be seen, consisting of a dense shell in which a low-density phase is wrapped.

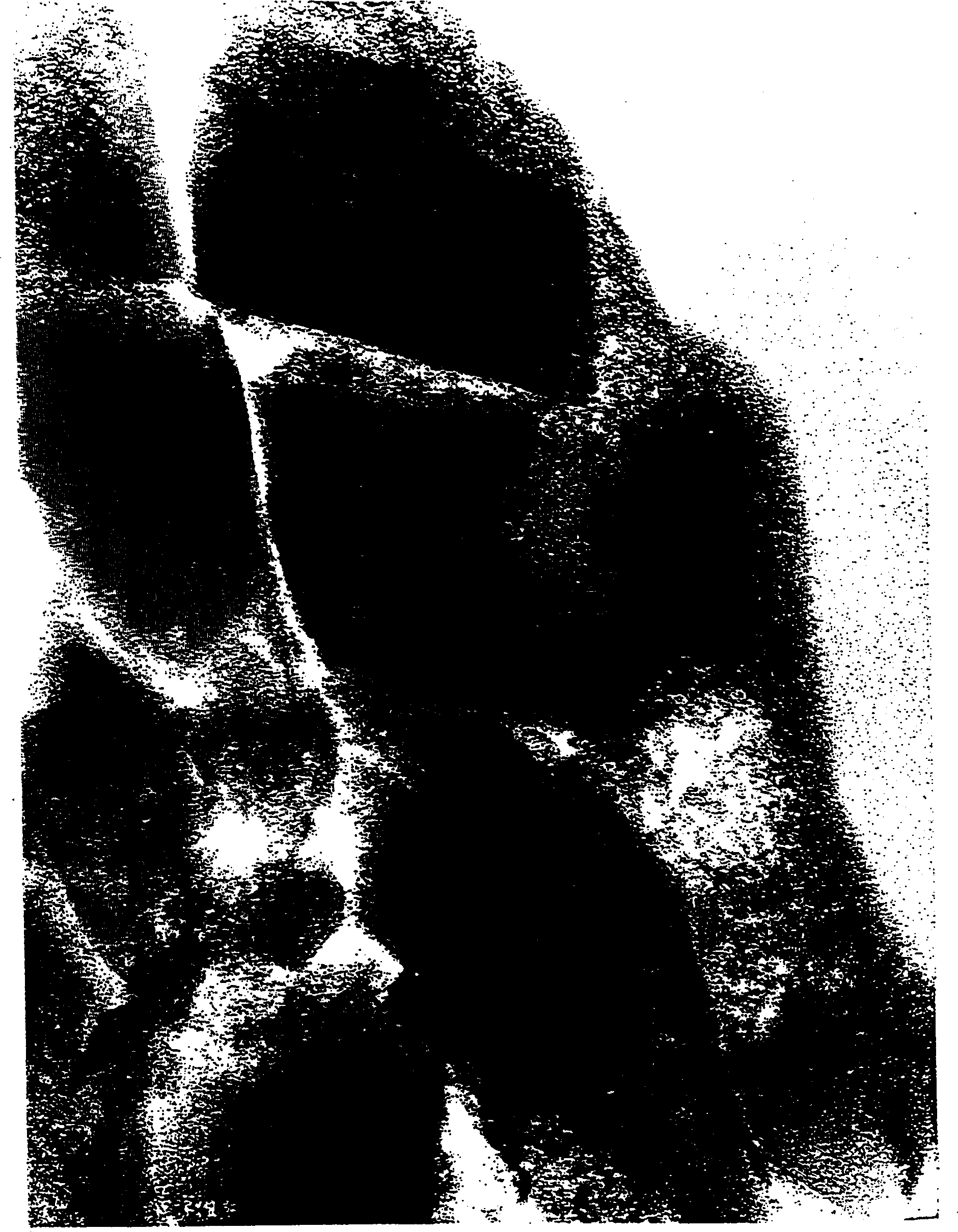

[0087] figure 2 Shown is a TEM image (transmission electron microscope) of a magnified section (400000× magnification) of a sphere, showing the different composition between the substantially amorphous outer shell a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com