A kind of technological method of making edible magnesium chloride by shotcrete granulation

A technology of spray granulation and process method, applied in the direction of magnesium chloride, magnesium halide, etc., can solve the problems of troublesome screening, low productivity, poor particle size of edible magnesium chloride, etc., and achieve good fluidity, high product efficiency and simple process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

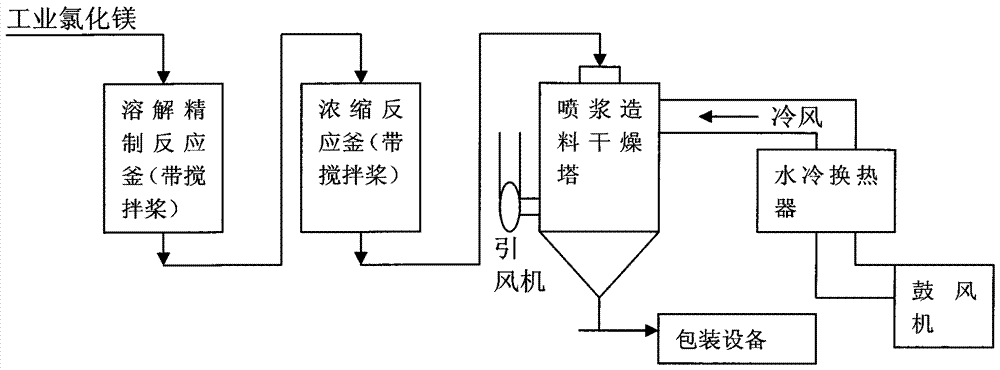

[0021] A process method for preparing edible magnesium chloride by spraying granulation method, including:

[0022] (1). Dissolution and refining reaction: industrial magnesium chloride is refined by dissolving, decolorizing, removing heavy metals, and filtering through a refining reactor, and the filtrate is transported to the concentration reactor;

[0023] (2). Concentration reaction: Concentrate the filtrate to saturation, at which time the magnesium chloride content is 47%, heat it to 100°C, and send it to the top of the tower for spraying;

[0024] (3) Shotcrete: spray the concentrated liquid on the top of the shotcrete drying tower, control the speed to 500 rpm, adjust the flow rate, and adjust according to the particle size: large particle flow decreases, small particle flow Increase, the blower sends the 30℃ cold air cooled by the water-cooled heat exchanger into the shotcrete drying tower to fully contact the shotcrete material, instantly cools and solidifies the slurry, so...

Embodiment 2

[0026] A process method for preparing edible magnesium chloride by spraying granulation method, including:

[0027] (1). Dissolution and refining reaction: industrial magnesium chloride is refined by dissolving, decolorizing, removing heavy metals, and filtering through a refining reactor, and the filtrate is transported to the concentration reactor;

[0028] (2). Concentration reaction: Concentrate the filtrate to saturation. At this time, it contains 46% magnesium chloride, heat it to 80°C, and send it to the top of the feed tower for spraying;

[0029] (3) Shotcrete: spray the concentrated liquid on the top of the shotcrete drying tower, control the speed to 500 rpm, adjust the flow rate, and adjust according to the particle size: large particle flow decreases, small particle flow Increase, the blower sends the 25℃ cold air cooled by the water-cooled heat exchanger into the shotcrete drying tower to fully contact the shotcrete material, instantly cool and solidify the slurry, so a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com