High-speed cold rolled steel strip uncoiling automatic guiding and feeding device

A cold-rolled steel strip, high-speed technology, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of reducing feeding efficiency, offset jamming, etc., and achieve the effect of increasing the feeding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

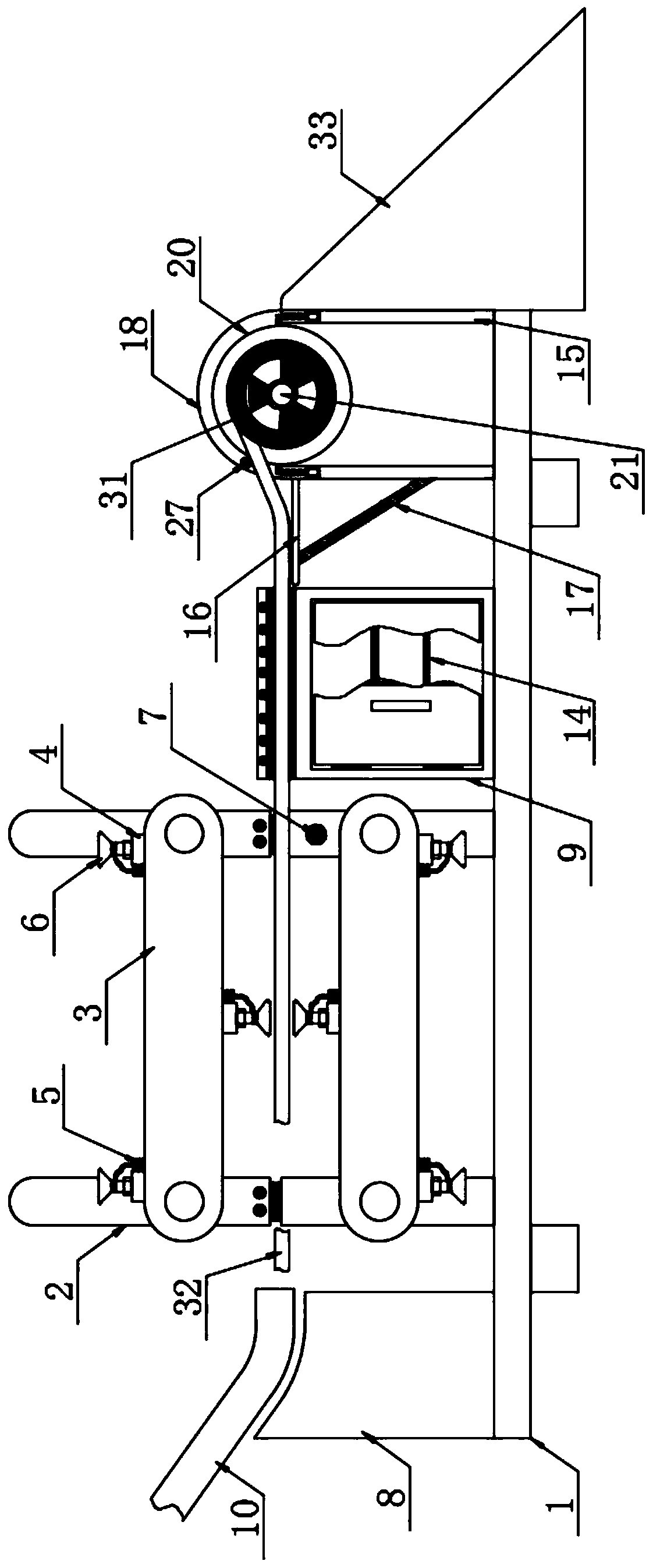

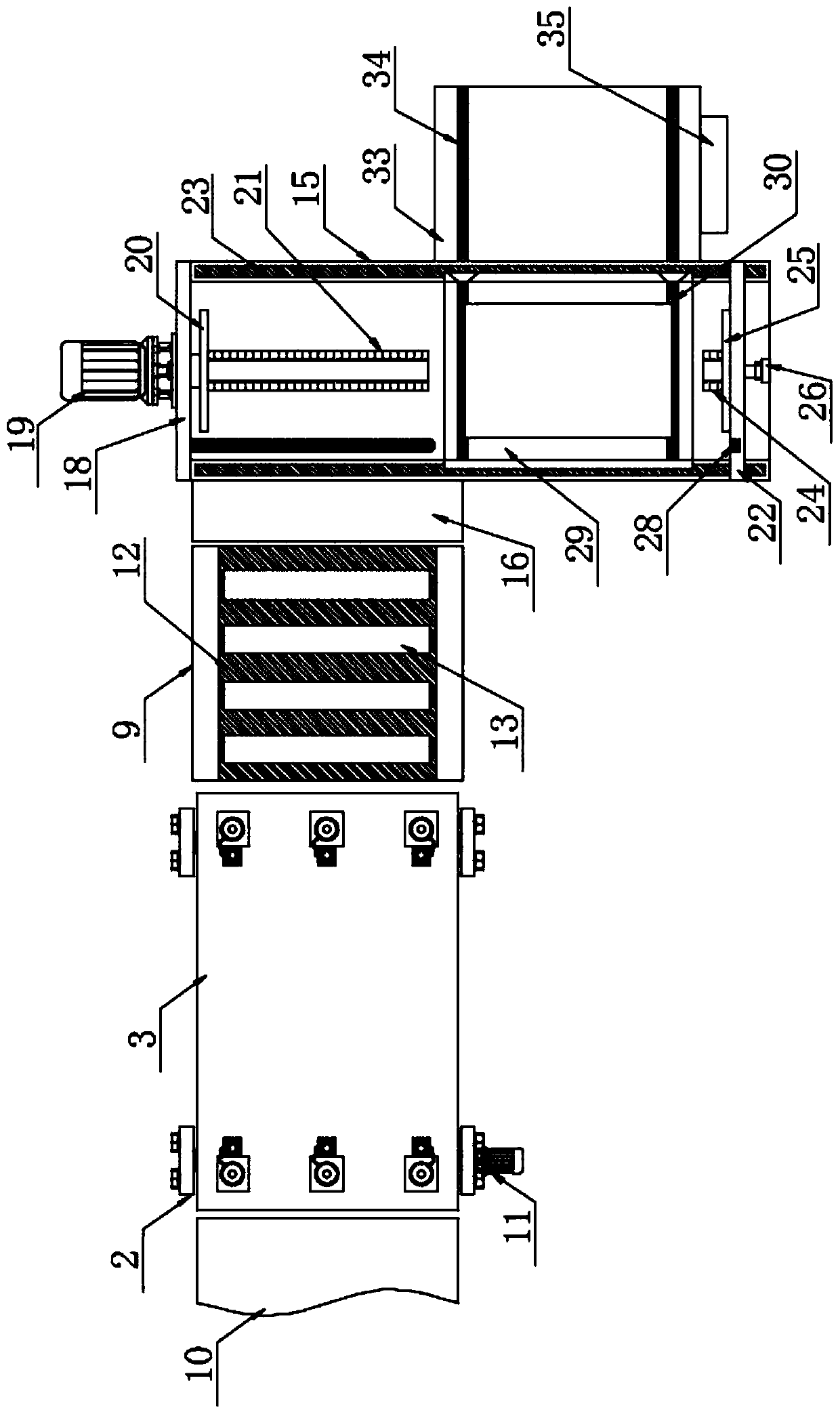

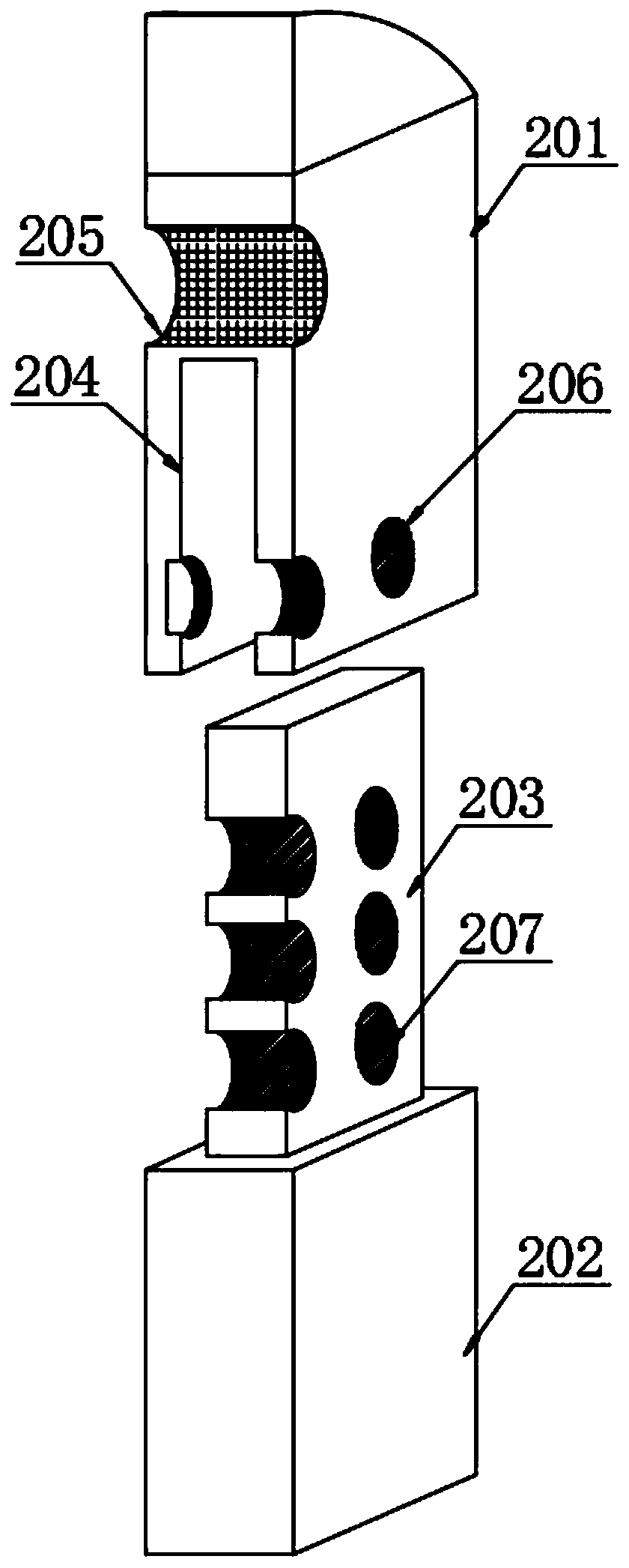

[0030] The present invention provides such Figure 1-5 and Figure 8 A high-speed cold-rolled steel strip uncoiling automatic lead-in feeding device shown includes a base 1, adjusting plates 2 are arranged on both sides of the top of the base 1, and a conveyor belt 3 is arranged between two sets of adjusting plates 2 , the surface of the conveyor belt 3 is fixed with a first electric push rod 4, the end of the first electric push rod 4 is fixedly connected with a vacuum suction cup 6, and one side of the first electric push rod 4 is fixed with a vacuum pump 5, The vacuum chuck 6 is connected to the vacuum pump 5 through a connecting pipe, and an infrared detector 7 is fixed inside a group of the adjustment plates 2, wherein the infrared detector 7 is a DT-7380 infrared detector. It is beneficial to detect the real-time position of the vacuum chuck 6, and transmit the electric signal to the PLC controller 35, and then the PLC controller 35 controls the working conditions of th...

Embodiment 2

[0042] The difference from Example 1 is that referring to the description Figure 6-7 , the bottom of the first limiting groove 30 is provided with a fitting groove 38, and a plurality of springs 41 are evenly distributed inside the fitting groove 38, which is beneficial to move the reel 31 wound with the steel strip 32 from the inclined platform 33 When rolling into the material holder 29, an upward elastic force is provided to the reel 31 by the spring 41, to slow down the pressure on the material holder 29 when the reel 31 falls, to prolong the service life of the material holder 29, the bottom of the material holder 29 A plurality of vertical rods 43 are evenly distributed, and the vertical rods 43 are fixedly connected with the bottom of the material holder 29, and the bottom ends of the vertical rods 43 are fixedly connected with rollers 42, which can greatly reduce the impact on the material holder 29 when it moves along the material rack 15. At the same time, the frict...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com