Raw material premixing device for plastic production process

A production process and pre-mixing technology, which is applied in the field of raw material pre-mixing devices in the plastic production process, can solve problems such as single, plastic raw materials cannot be mixed, and affect the quality of plastic finished products, so as to reduce wear and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] This embodiment provides a stirring device, which can preferably perform multi-stage mixing of plastic production raw materials, so that the plastic production raw materials can be mixed more fully.

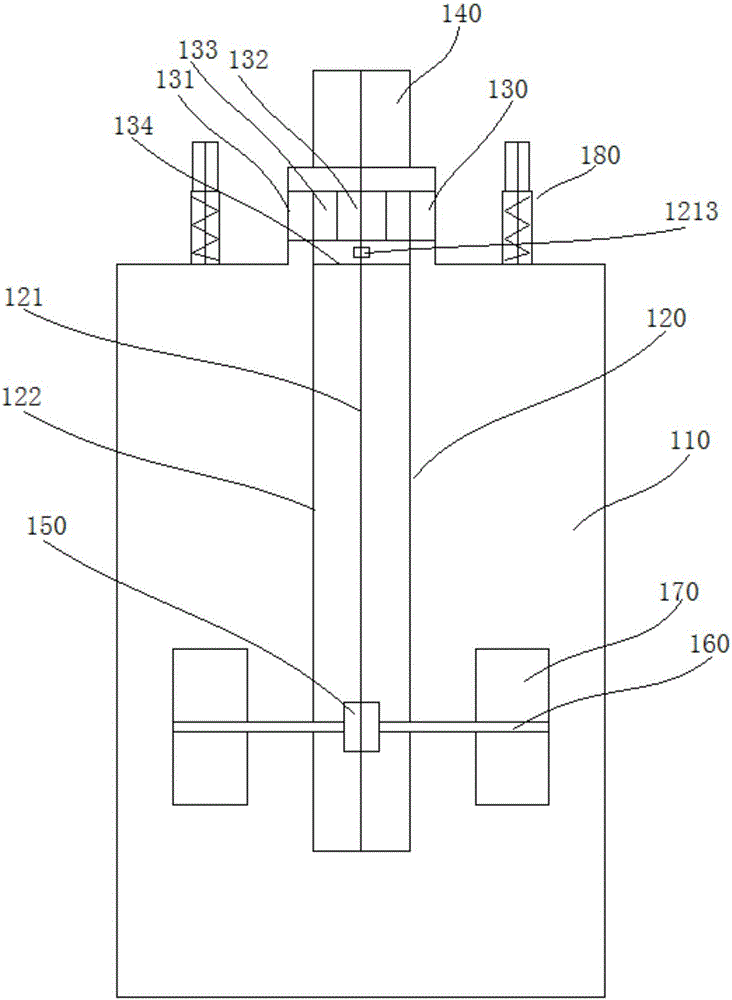

[0099] Such as figure 1 As shown, the stirring device of this embodiment includes a cylinder 110, and the cylinder 110 is provided with a stirring shaft 120, and the stirring shaft 120 is connected with a stirring motor 140 through a planetary gear 130; the planetary gear 130 includes a ring gear 131, a sun gear 132 , the planetary gear 133 and the planetary carrier 134, the ring gear 131 is fixedly connected with the barrel 110, the stirring motor 140 is used to drive the sun gear 132, and the sun gear 132 drives the planetary carrier 134 through the planetary gear 133.

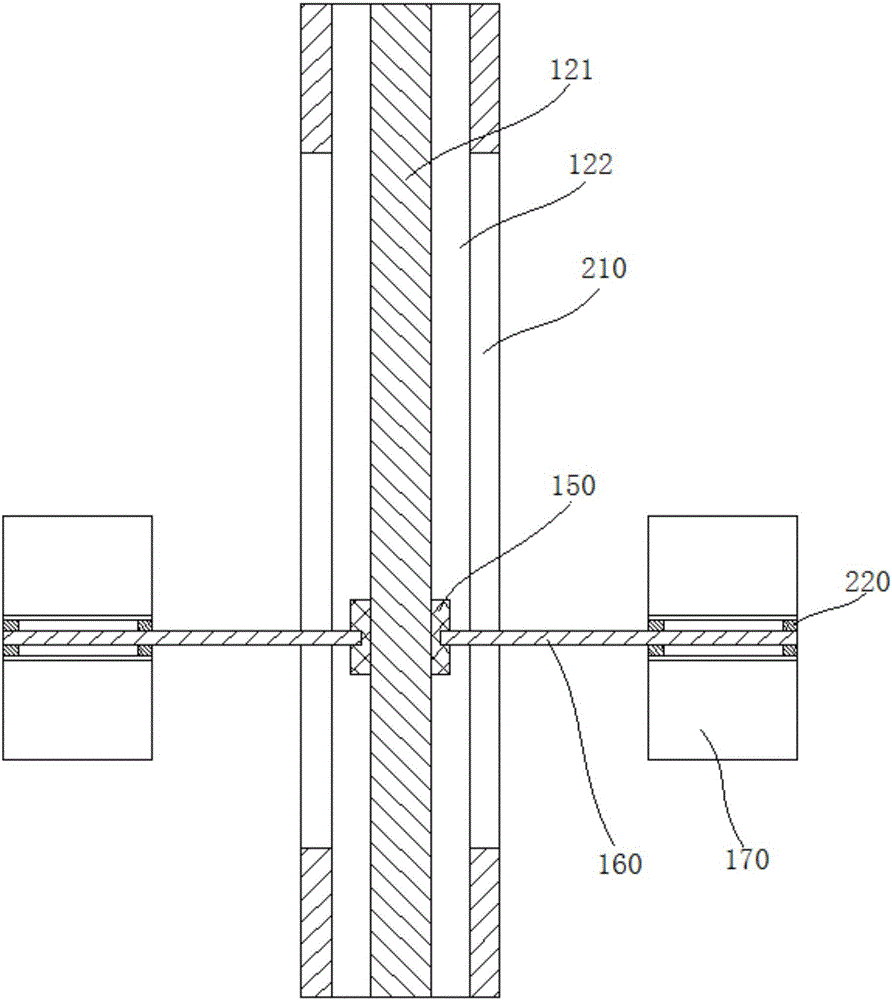

[0100] Such as figure 2 , 3As shown, the stirring shaft 120 includes a screw shaft 121 and a sleeve shaft 122, the screw shaft 121 is coaxially arranged at the sun gear 132 with the sun gear 132, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com