Photovoltaic cell surface passivation film production equipment

A technology for production equipment and photovoltaic cells, which is applied in circuits, electrical components, and final product manufacturing. It can solve problems such as wasting manpower, reducing automated production processes, and affecting production efficiency, reducing labor consumption, and improving mechanization and automated production. Process, ensure stable and accurate transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

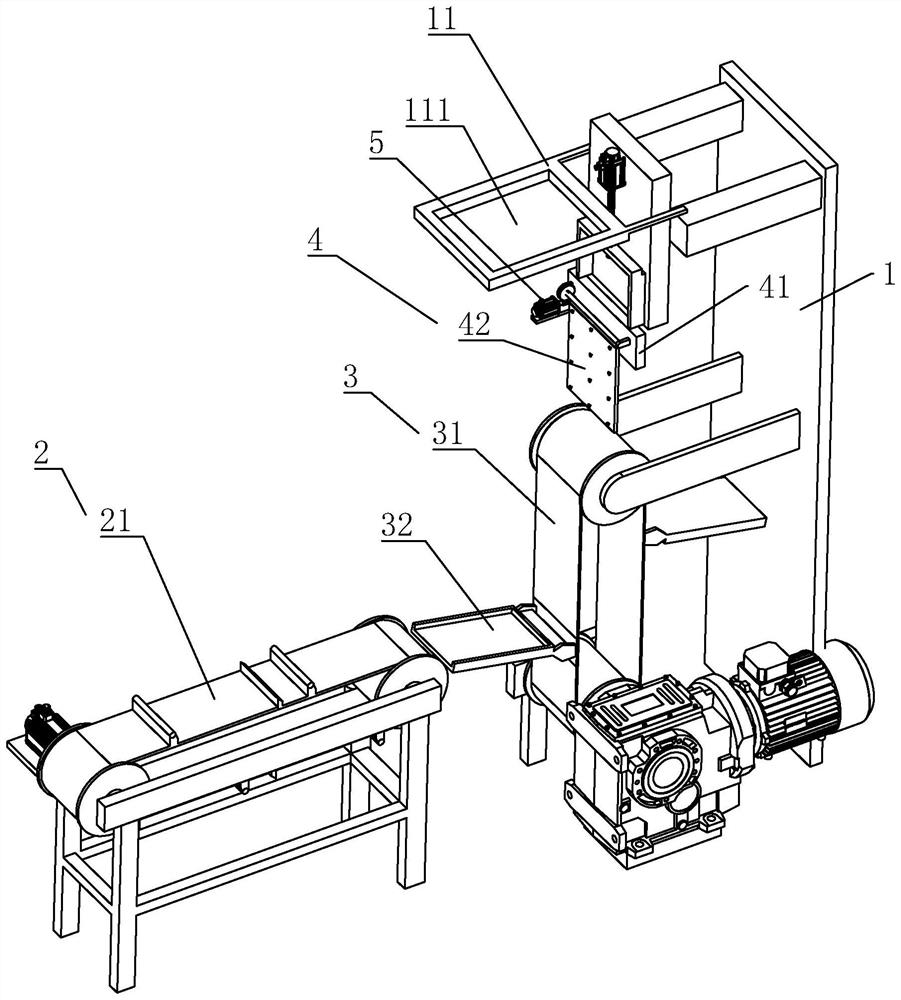

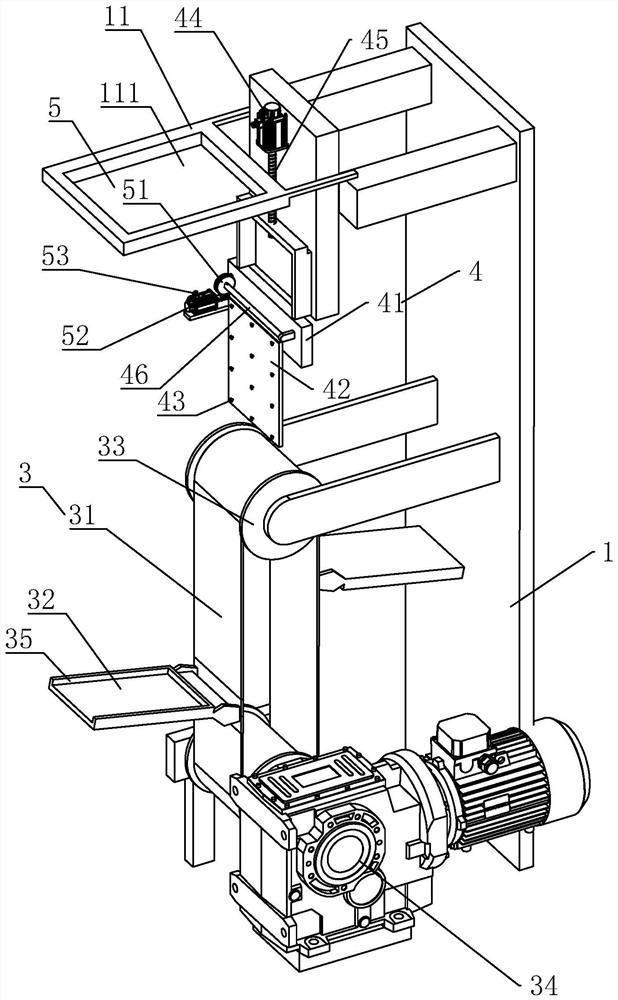

[0030] This embodiment provides a production equipment for the passive film on the surface of photovoltaic cells, the structure is as follows Figure 1-3 As shown in the figure, it includes a body 1, a workbench 11 and a coating unit. One side of the body 1 is from the outside to the workbench 11, and is provided with a horizontal conveying member 2, which is used to accept the battery substrate to the next unit and complete the horizontal transfer of the battery substrate. The vertical lifting member 3 corresponding to the position of receiving the battery substrate on the horizontal conveyor belt 21 and transferring it to the vertical horizontal plane and the transfer member 4 for transferring the battery plate and sending it to the workbench 11 .

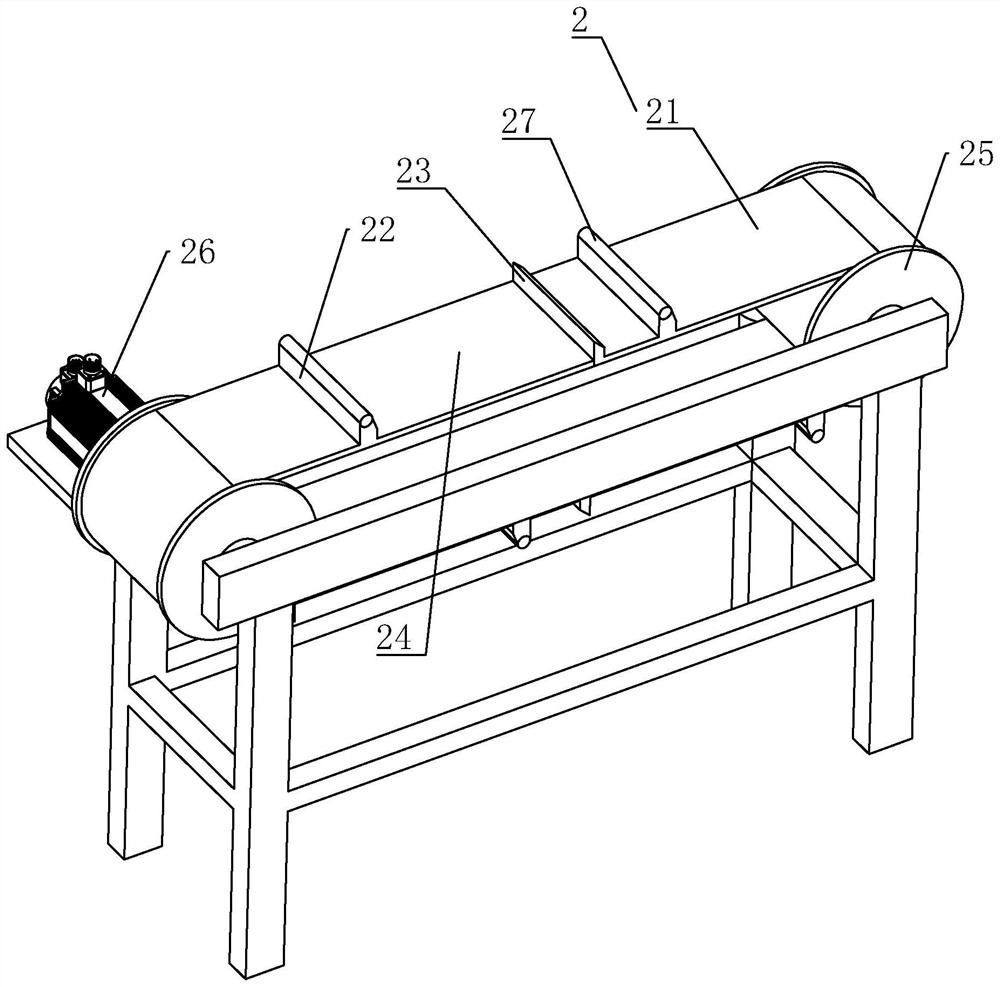

[0031] like Figure 1-3 As shown, the horizontal conveying member 2 includes a horizontal conveyor belt 21 rotatably arranged in the horizontal direction. The horizontal conveyor belt 21 is composed of several groups of front baf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com