Tank body circular seam welding machine

A technology of circular seam welding and tank body, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., which can solve the inconvenience of observing the specific conditions of workpiece welding, reduce welding work efficiency and precision, and low quality of tank body welding and other issues to achieve the effect of improving welding efficiency and welding quality, improving welding efficiency and precision, and facilitating welding operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

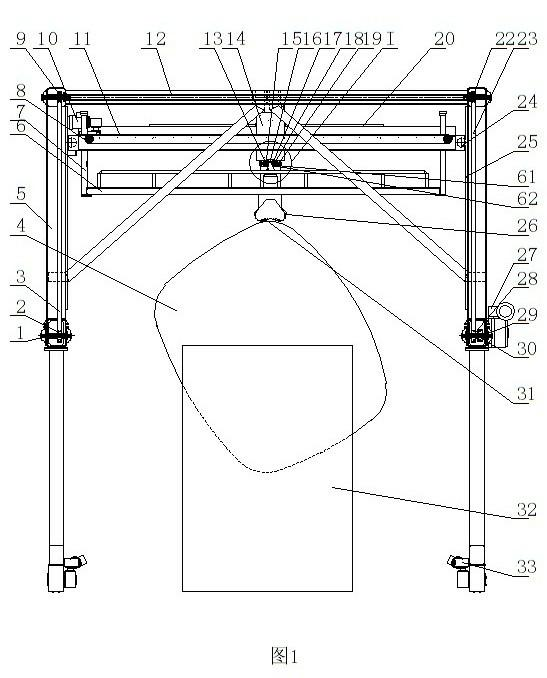

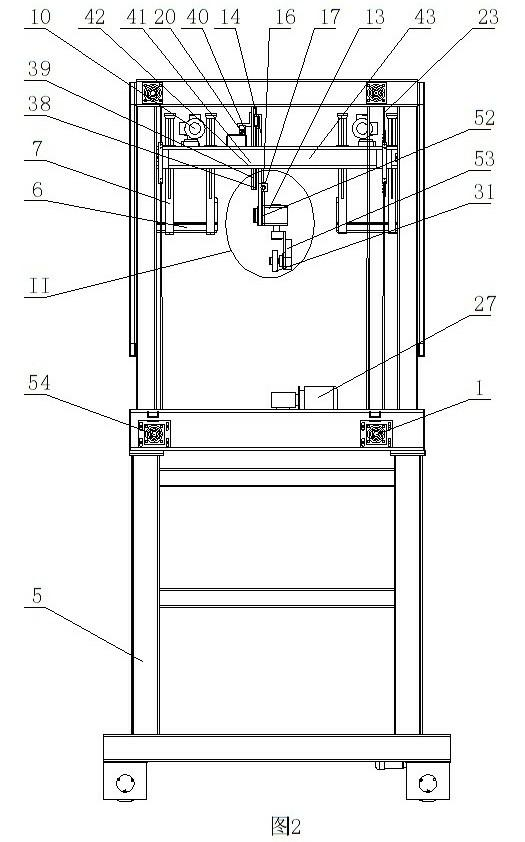

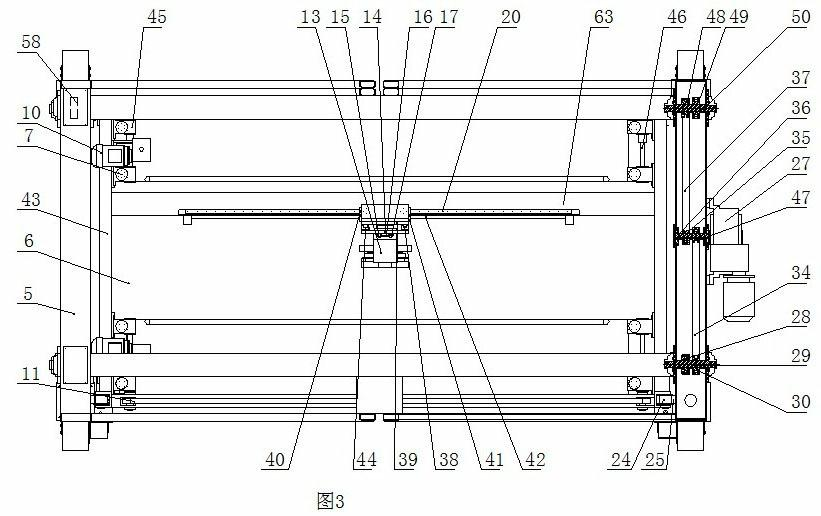

[0009] The tank girth welding machine according to the present invention comprises a frame 5, a lifting mechanism is installed on the frame 5, a lifting platform 43 is installed on the lifting mechanism, the lifting platform 43 is slidingly matched with the frame 5, and the frame 5 is paired with the lifting platform 43 It plays a guiding role to ensure that the lifting platform 43 can be vertically lifted under the drive of the lifting mechanism; a working platform lifting mechanism is installed on the lifting platform 43, and an operating platform 6 is installed on the working platform lifting mechanism. The lower relative lifting platform 43 lifts; the first horizontal guide rail 42 is installed horizontally on the lifting platform 43, and the first slide block 41 is installed on the first transverse guide rail 42, and the fixed slide plate 39 is installed on the first slide block 41, and the fixed slide plate 39 can be relatively first. The lateral rail 42 moves laterally. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com