Manufacturing method of cross-shaped box type joint

A manufacturing method and box-changing technology, which is applied in manufacturing tools, buildings, building structures, etc., can solve the problems of huge influence on welding quality and appearance, complicated splicing and welding process, and inability to complete internal welding, and achieve optimal welding. Process, convenient operation, avoid the effect of stress concentration problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

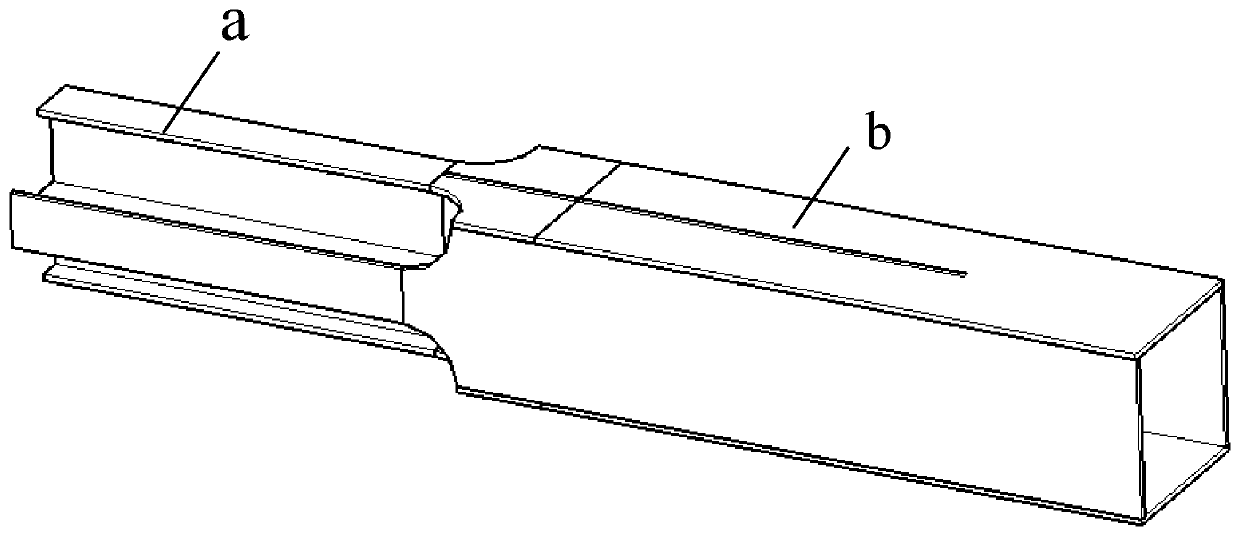

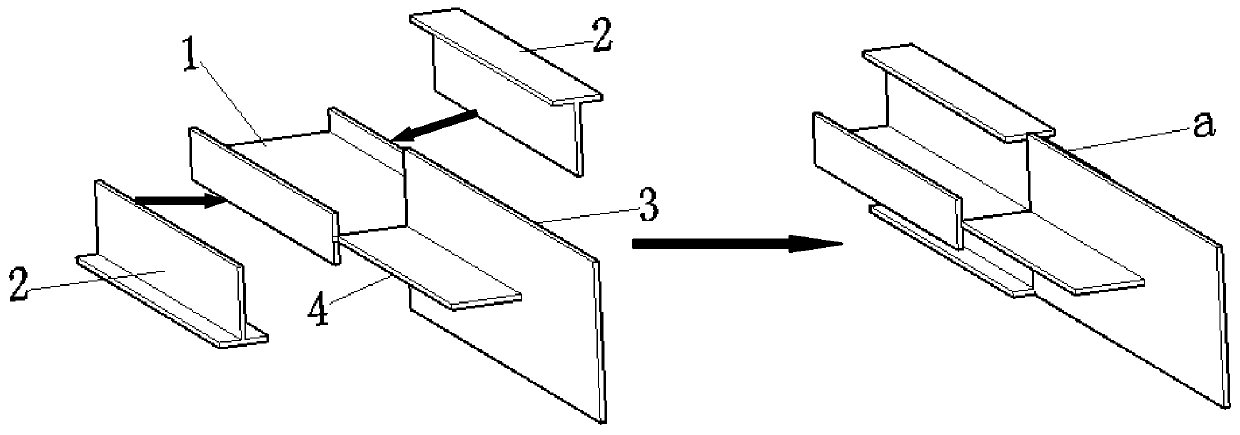

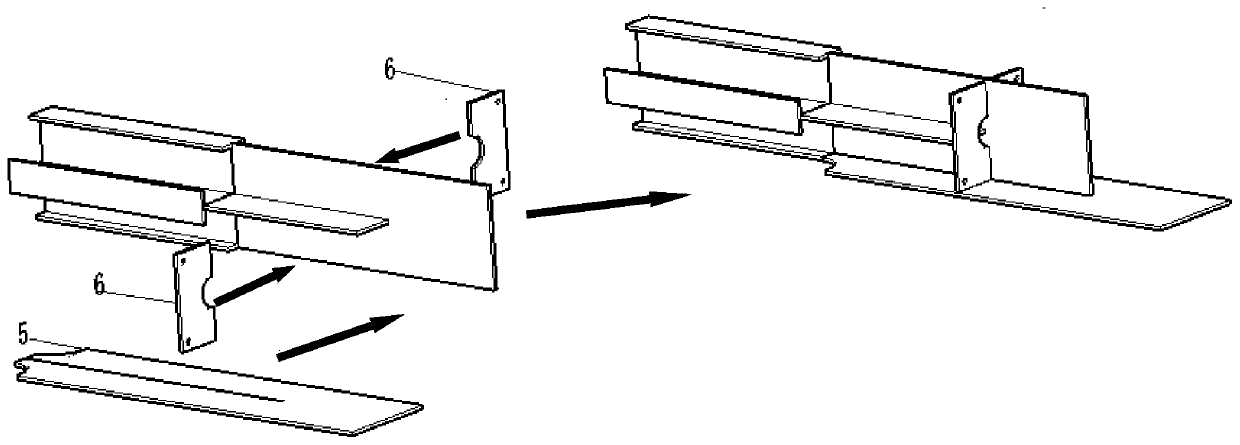

[0035] Embodiments of the present invention will now be described with reference to the drawings. The method for making a cross-shaped box-shaped joint provided by the present invention is mainly suitable for the joint construction of the transitional connection between concrete and steel structures in high-rise buildings, and the combined construction of special-shaped cross-sections between cross columns and box-shaped columns, but it cannot be limited to this. It can be used in other same or similar construction techniques.

[0036] The present invention focuses on the assembly method of the cross-transformer box-type joint, and does not repeat the relatively mature steel plate blanking production and specific size grooves. The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0037] combine Figure 1-Figure 5 As shown, a method for making a cross-shaped box-shaped node, including the assembly and splicing of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com