Clamping operation workbench for door frame combination welding and mounting

A workbench and door frame technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as neglecting research and updating, cumbersome door frame welding process, and small door frame size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific embodiment:

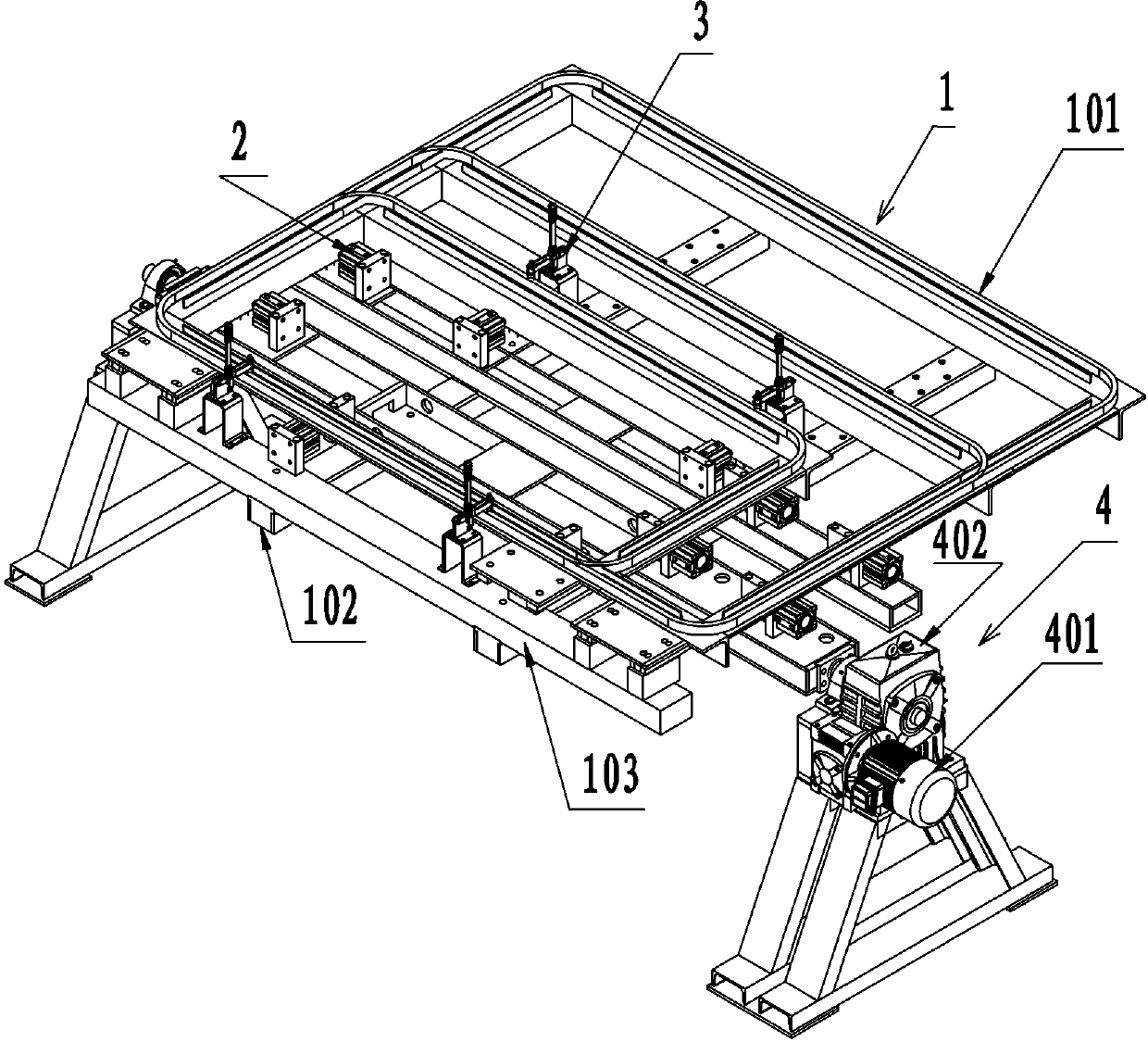

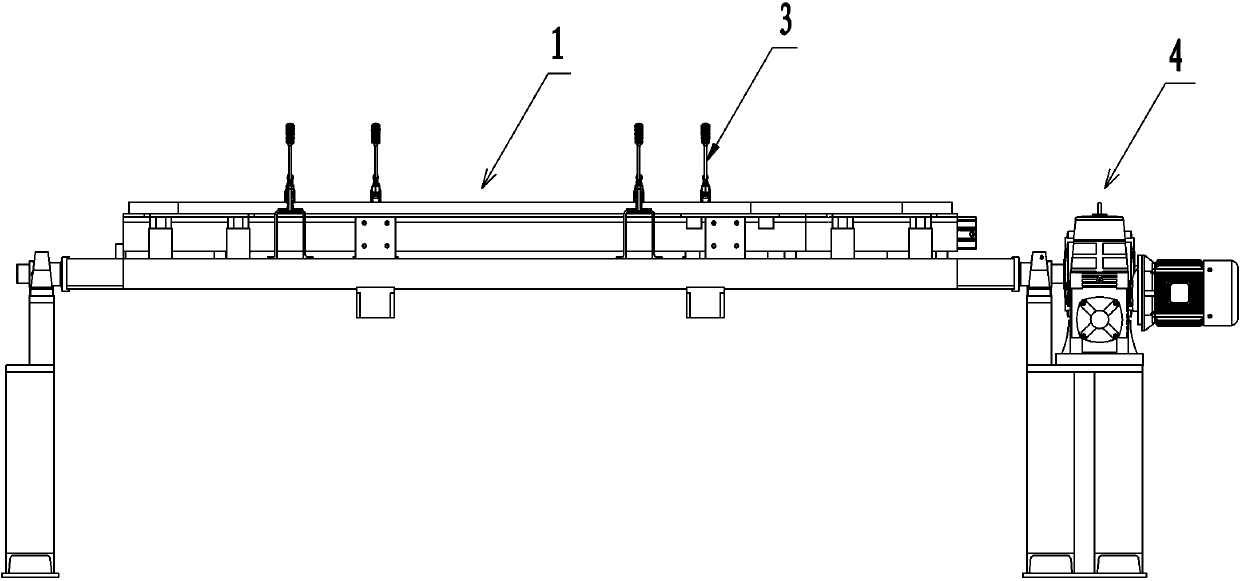

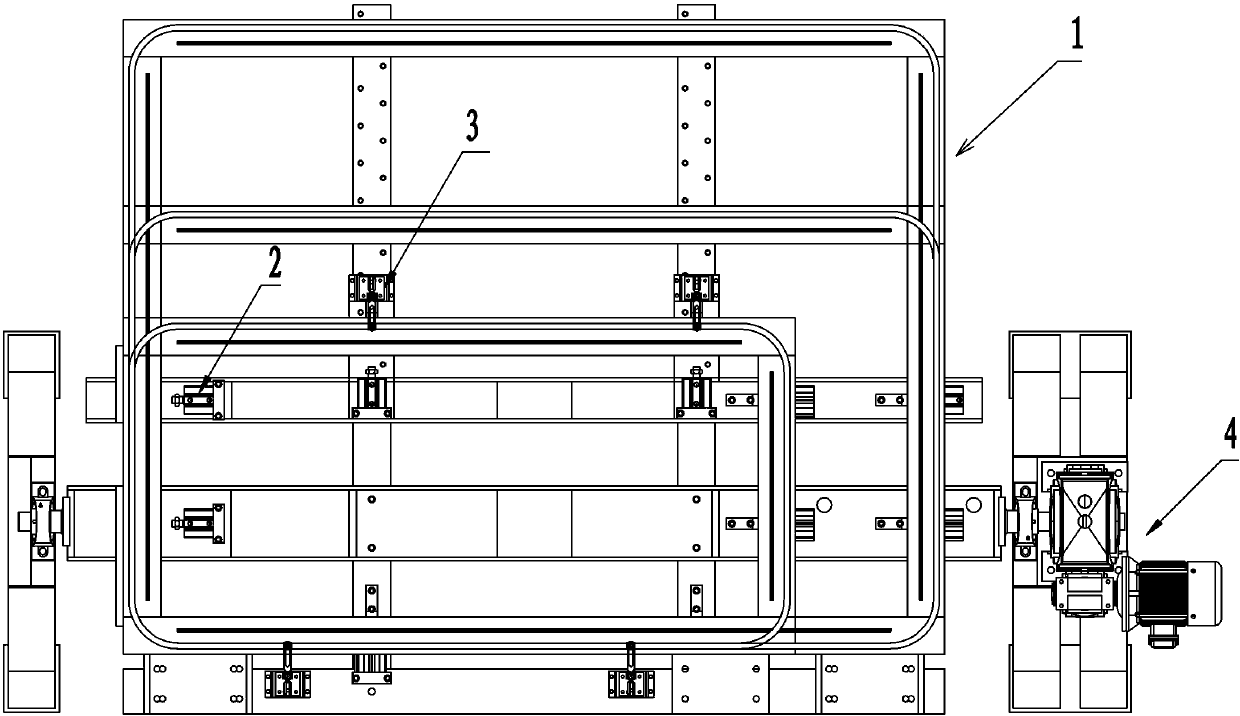

[0013] See attached figure 1 To attach Figure 4 As shown, a clamping workbench for door frame combined welding installation described in this embodiment, the clamping workbench includes a workbench 1, a plurality of groups arranged on the workbench 1 are used for positioning and clamping The positioning cylinder 2 and the pressing device 3 of the door frame and the turning device 4 arranged on one side of the workbench 1 can drive the workbench to turn 180°. Among them, in order to enable the clamping workbench to clamp and fix door frames of different sizes and specifications, this solution also sets the pressing device 3 on one side of the door frame to form a sliding connection with the workbench 1, specifically, When the door frame assembly to be welded is placed on the workbench as a whole according to the installation and combination position, the three sides around...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com