Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Reduce welding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

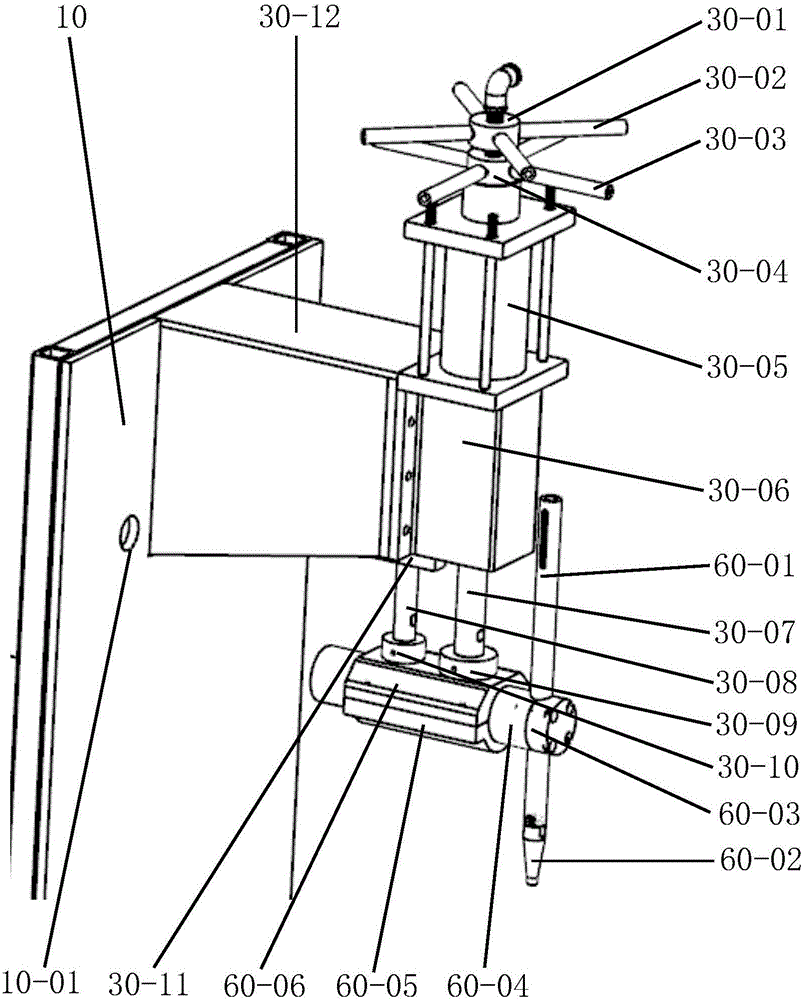

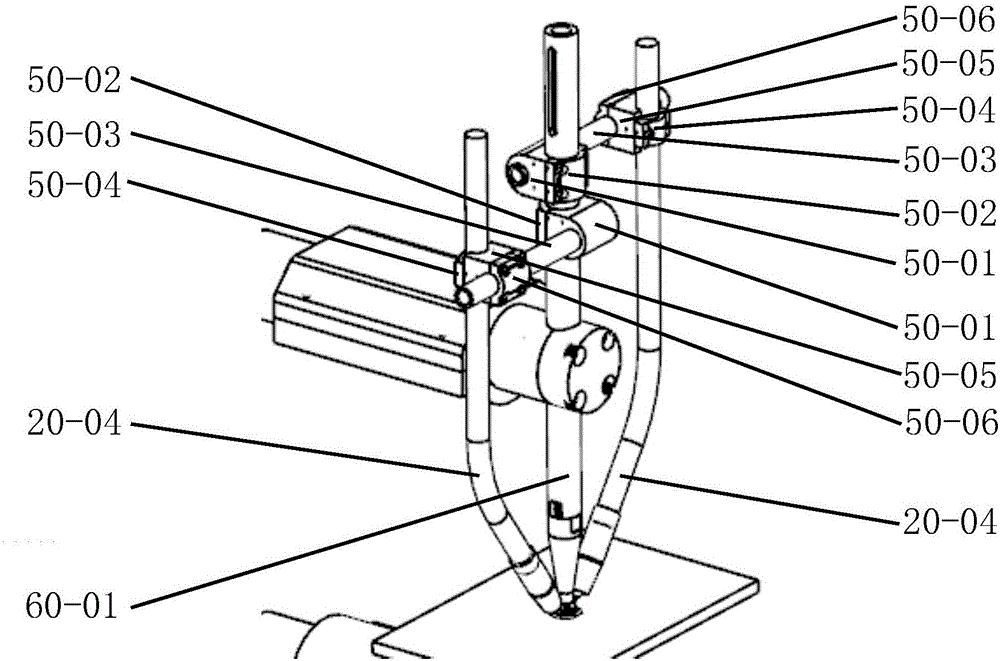

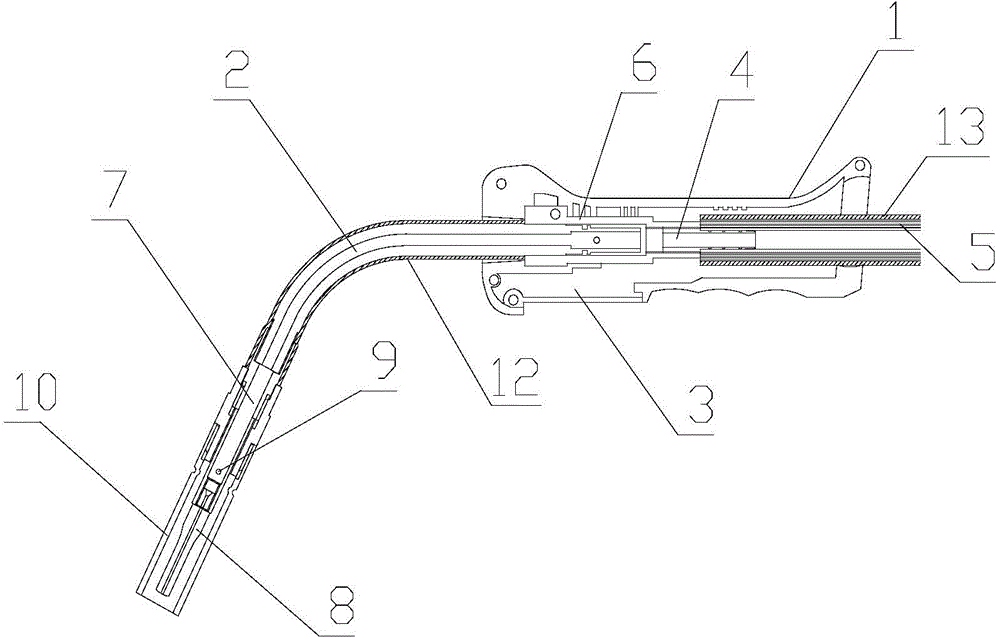

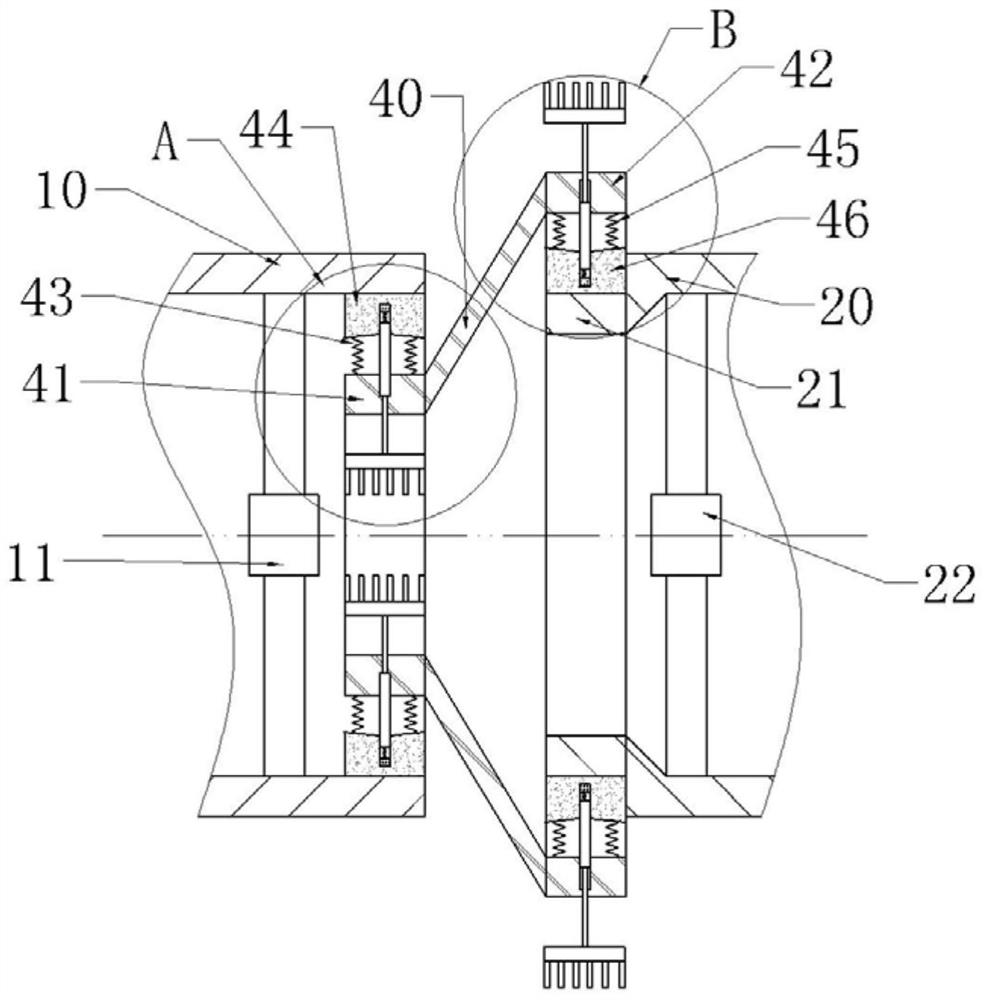

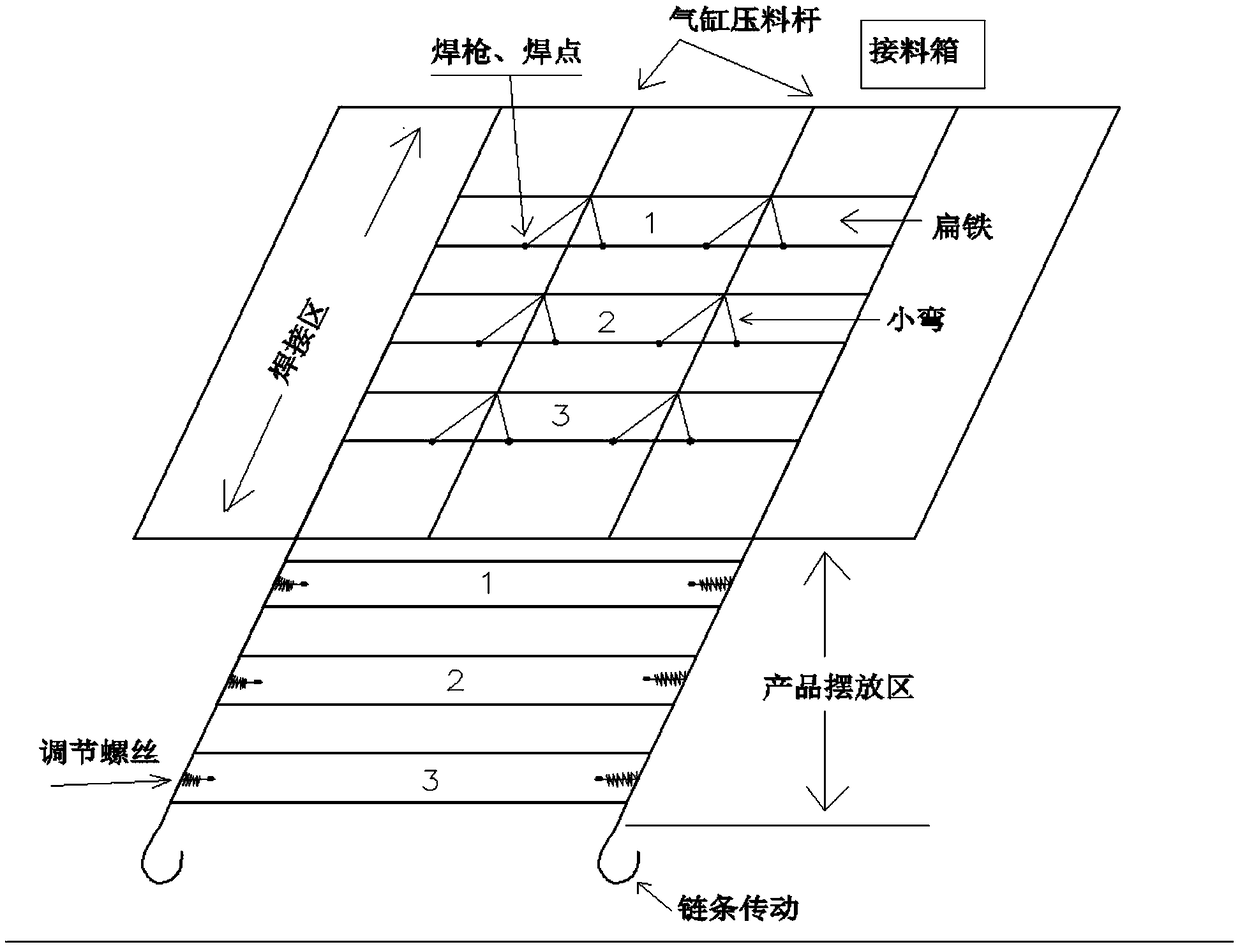

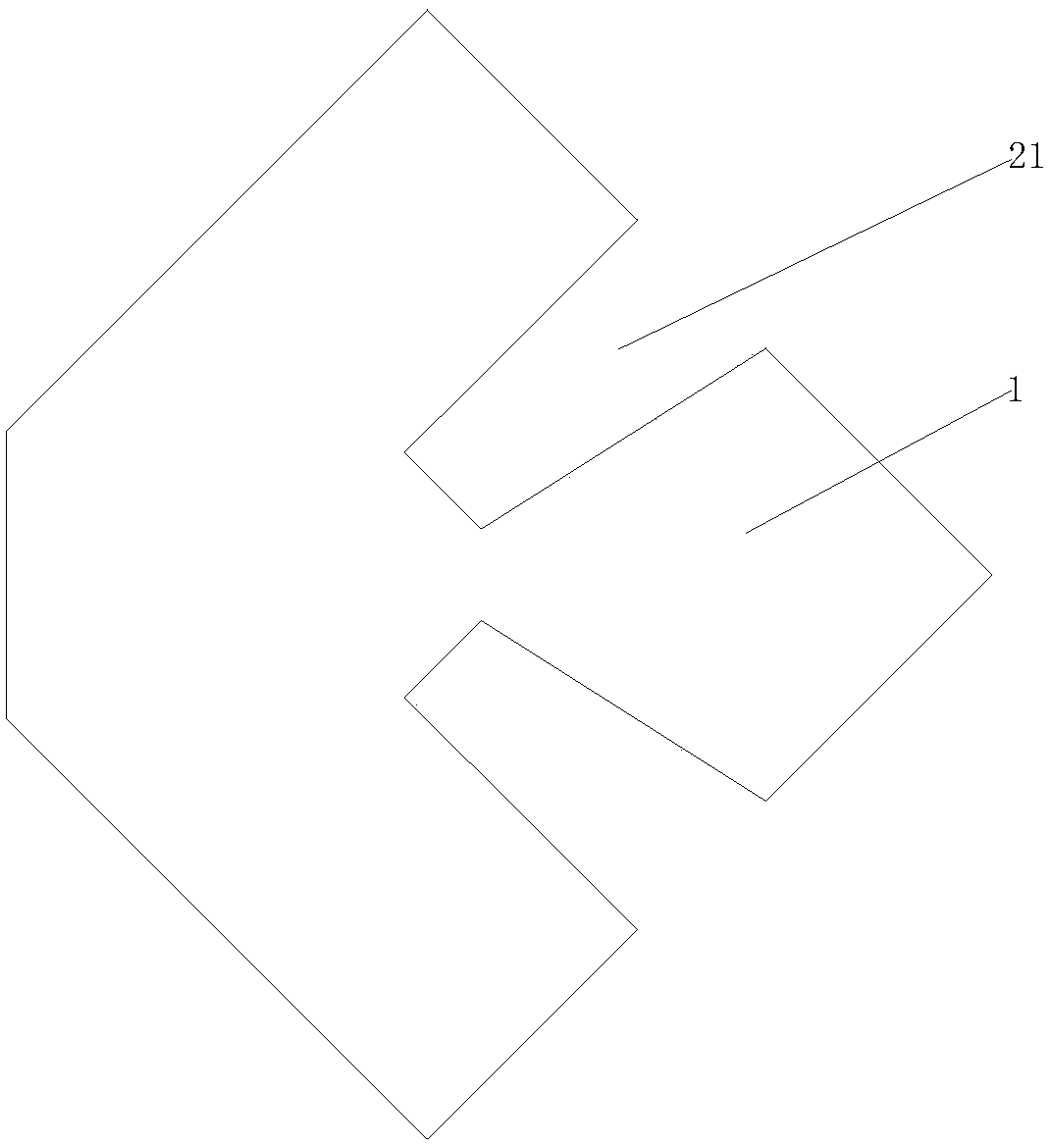

Welding method and equipment for multifunctional threaded fastener

ActiveCN105880895AImprove welding efficiencyImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStud welding

The invention discloses a welding method and equipment for a multifunctional threaded fastener. The welding method comprises MAG welding, TIG welding, MIG welding, stud welding and MIG brazing. The threaded fastener and a workpiece are positioned by a positioning mechanism of the equipment, a welding gun is clamped by a clamping mechanism, a pressing force is transmitted to a pressing mechanism by a power component, the threaded fastener and the workpiece are pressed by the pressing mechanism, the welding gun is driven to move downwards at the same time, and the threaded fastener and the workpiece are welded by a welding mechanism. Compared with existing arc welding equipment for welding the threaded fastener, the method and the equipment have the advantages that the efficiency is improved by 2 to 4 times; moreover, the problems of poor stability of conventional resistance projection welding of the threaded fastener, incapability in welding medium- and high-carbon steel, alloy steel, dissimilar metals and dissimilar materials, incapability of welding on the sidewall of a U-shaped sheet metal part, various hollow and solid pipe fittings and thick plates, incapability of abreast welding of the threaded fastener and the workpiece and the like are solved. In addition, the invention further provides MIG-brazed and flame-brazed fastener and a workpiece used for welding a threaded fastener and positioned by a light beam.

Owner:何强

Welding method of three-layer dual-face stainless steel composite board

InactiveCN107717185AGuaranteed post-weld performanceComplicated processingArc welding apparatusWelding/soldering/cutting articlesShielding gasSpot welding

The invention discloses a welding method of a three-layer dual-face stainless steel composite board and belongs to the technical field of welding. The welding method is used for welding the stainlesssteel+ carbon steel+ stainless steel three-layer dual-face stainless steel composite board, the thickness of the stainless steel is not smaller than 2 mm, and the overall thickness is smaller than 15mm. The welding method comprises the following steps that oxide on the surface of the composite board is removed; a groove is not formed before welding, and two welding boards are connected in the same horizontal face; stainless steel welding materials are adopted for spot welding; and a keyhole TIG welding method is adopted for one-time welding forming, no filler wire is filled in the welding process, and protective gas is high-purity argon gas. The welding method of the three-layer dual-face stainless steel composite board has the advantages of being high in welding efficiency, good in welding quality and simple in process.

Owner:SHOUGANG CORPORATION

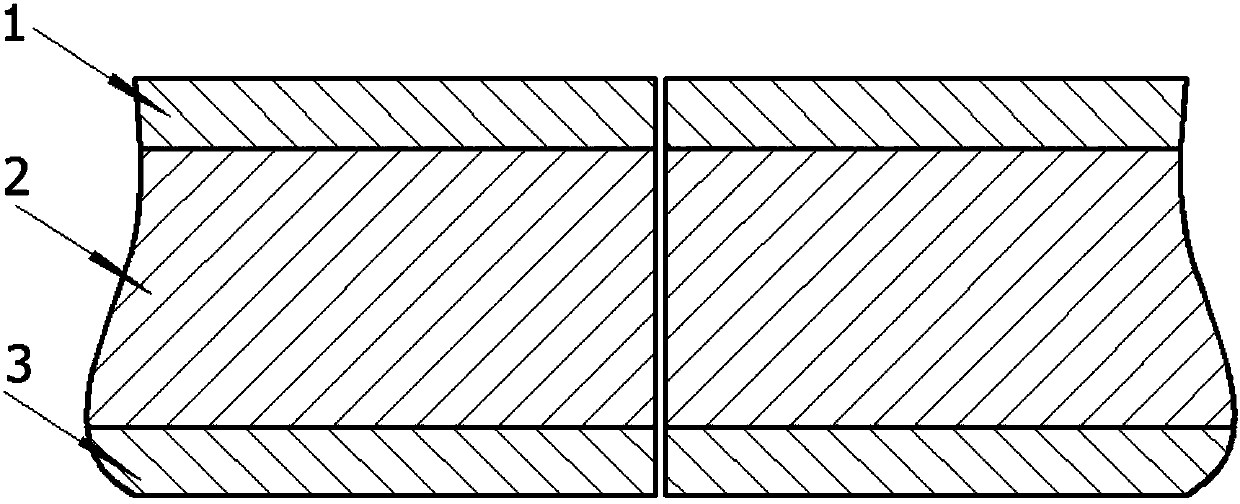

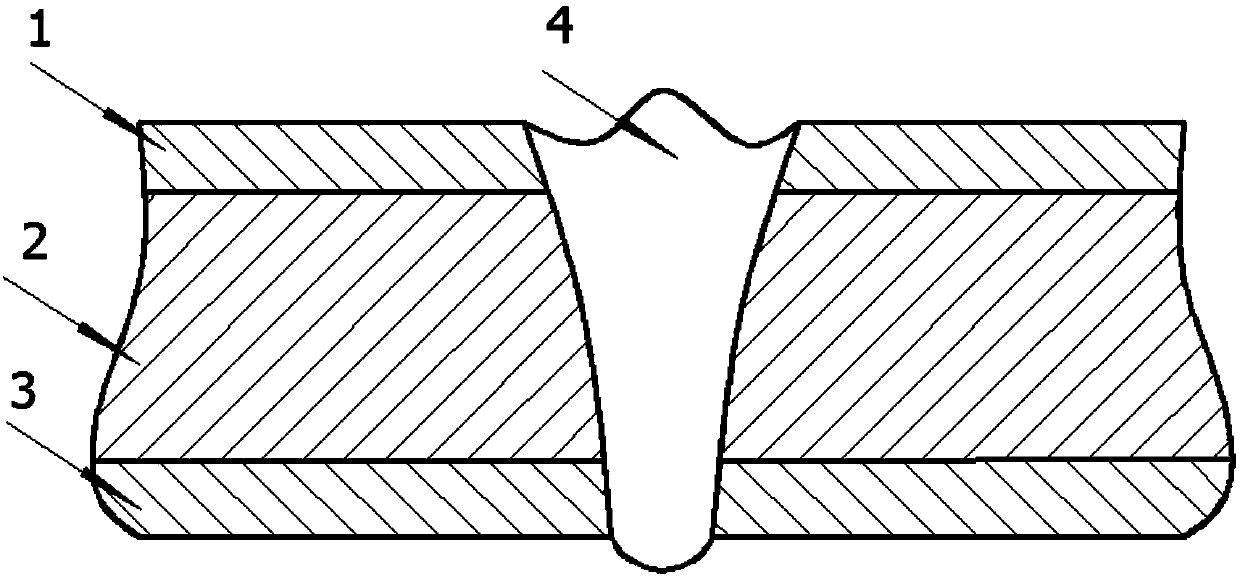

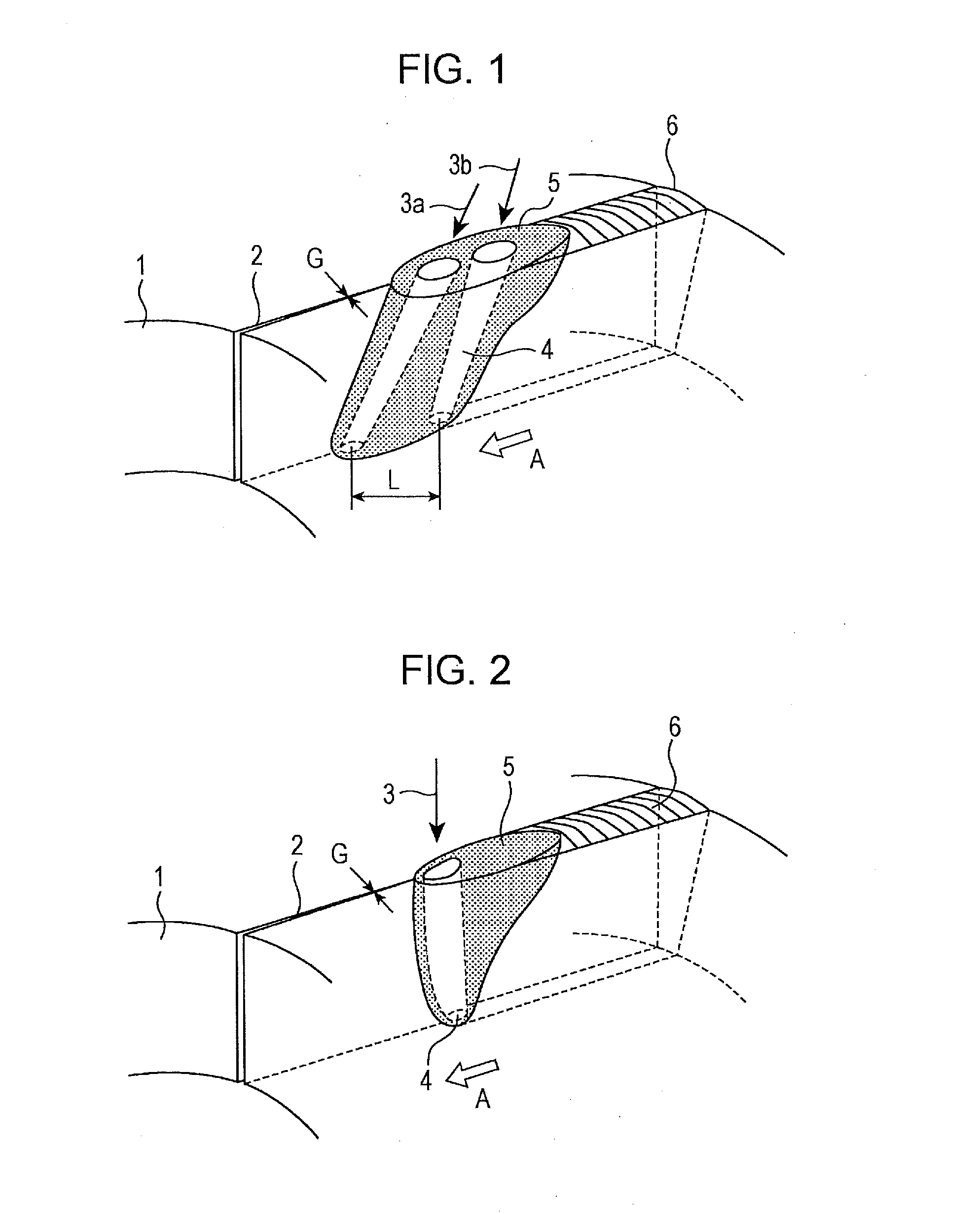

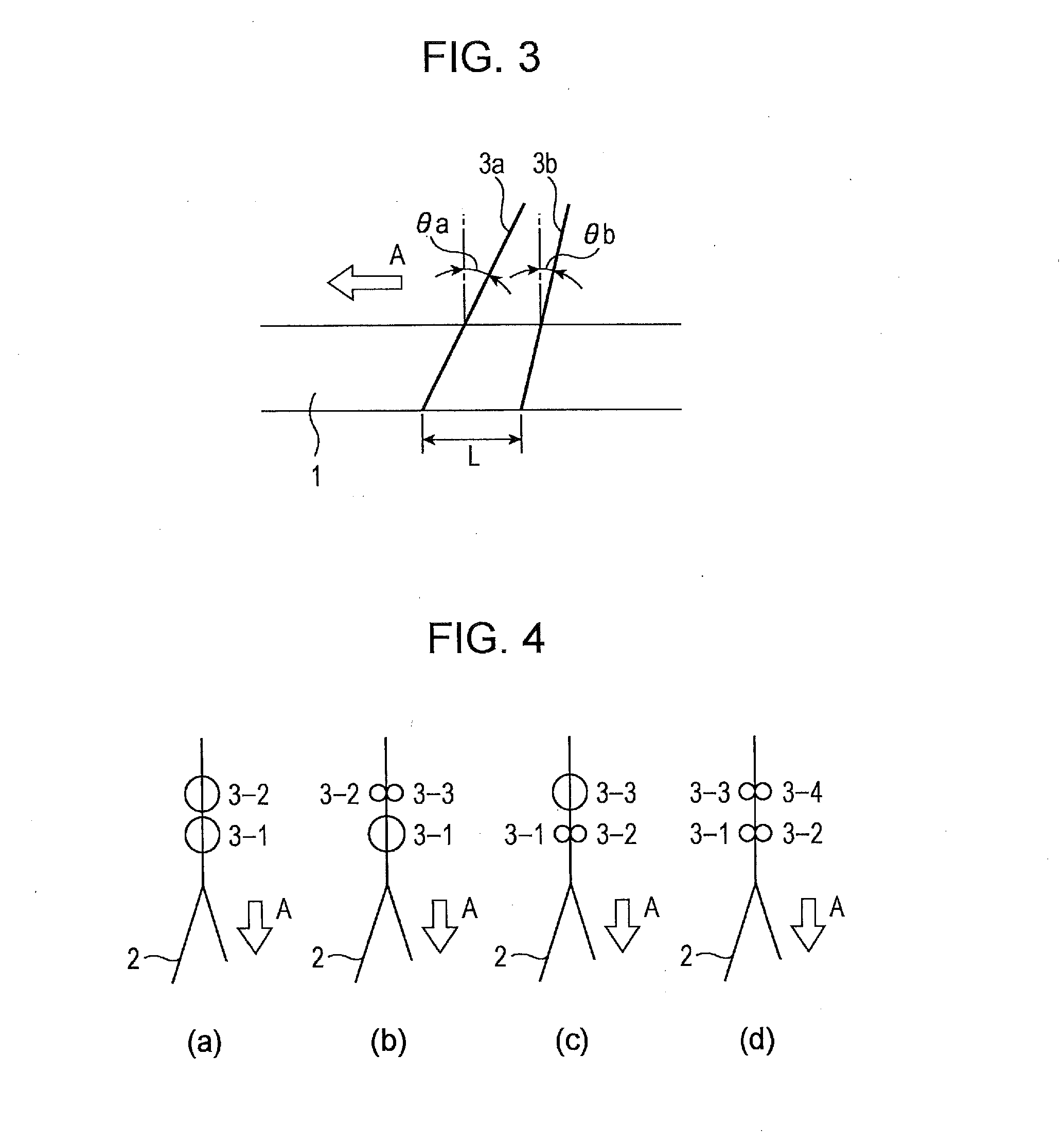

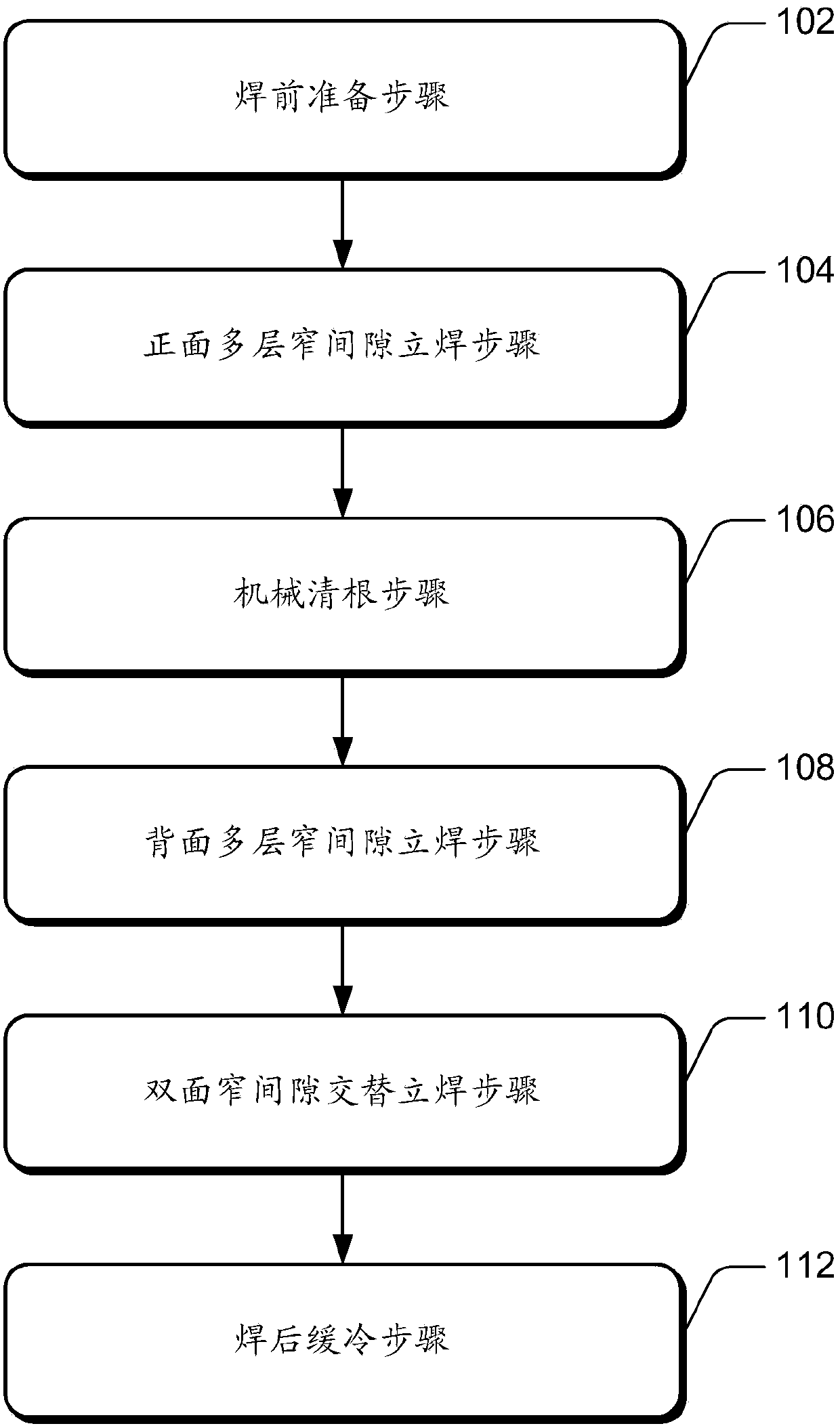

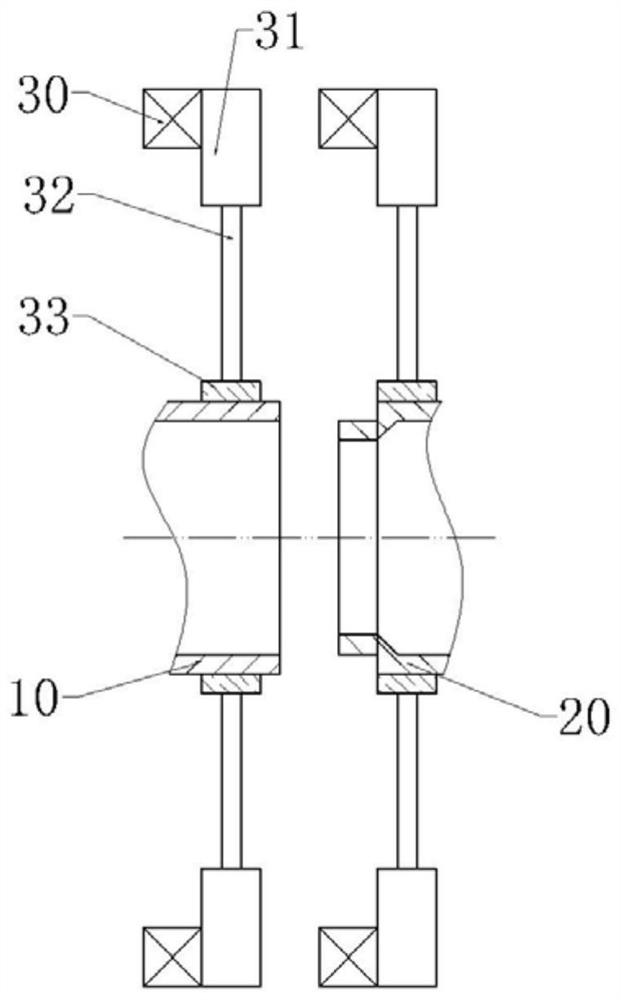

Method of manufacturing laser welded steel pipe

ActiveUS20140124481A1Quality improvementReduce welding efficiencyArc welding apparatusWelding/soldering/cutting articlesLight beamLaser beams

A method of manufacturing a laser welded steel pipe by forming a steel strip into a cylindrical open pipe and performing laser welding on edges that includes: emitting two laser beams along the edges from an upper surface side of the open pipe, the two laser beams being transmitted through different optical fibers with in-focus spot diameters exceeding 0.3 mm; emitting leading and trailing laser beams each inclined toward a direction in which welding proceeds at an incident angle with respect to a direction perpendicular to an upper surface of the open pipe; setting the incident angle of the leading laser beam to be larger than the incident angle of the trailing laser beam; and setting a gap between a center point of the leading laser beam and a center point of the trailing laser beam on a back surface of the open pipe to 1 mm or larger.

Owner:JFE STEEL CORP

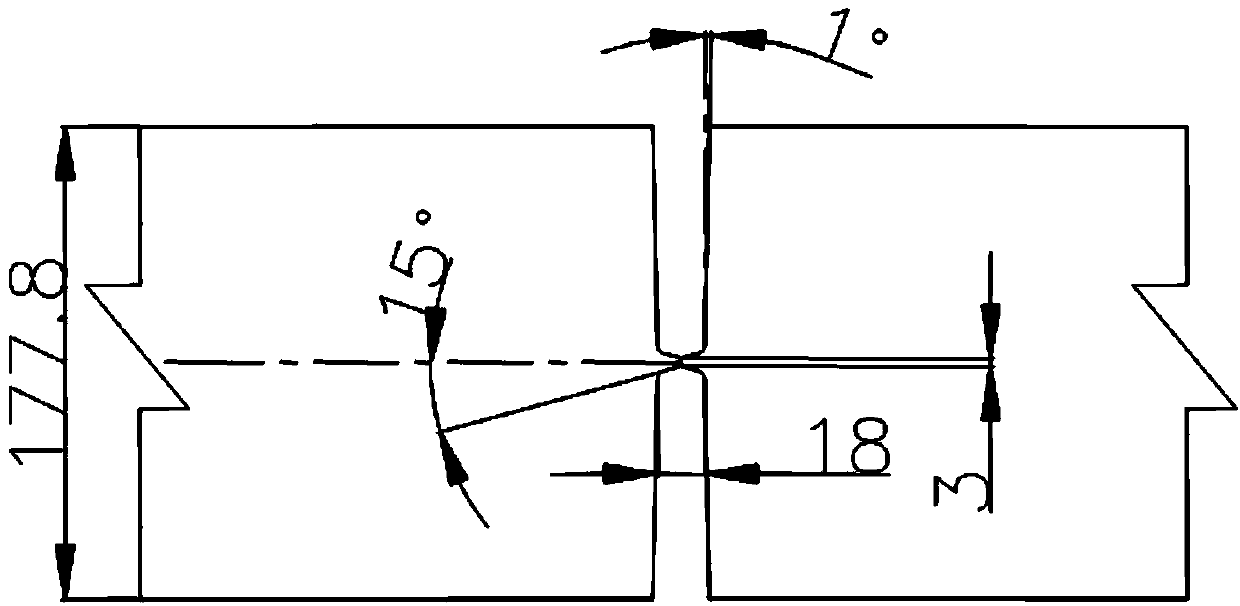

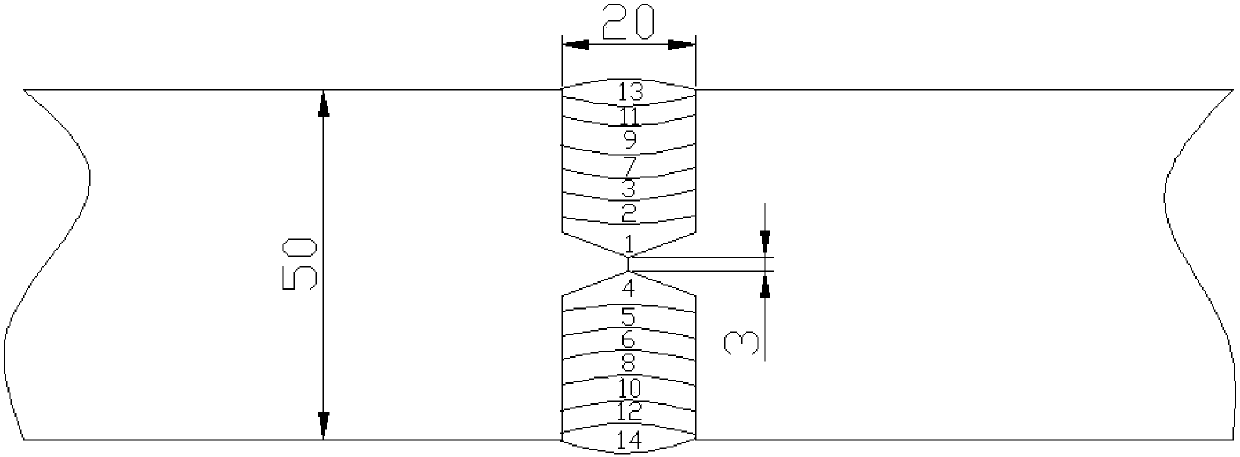

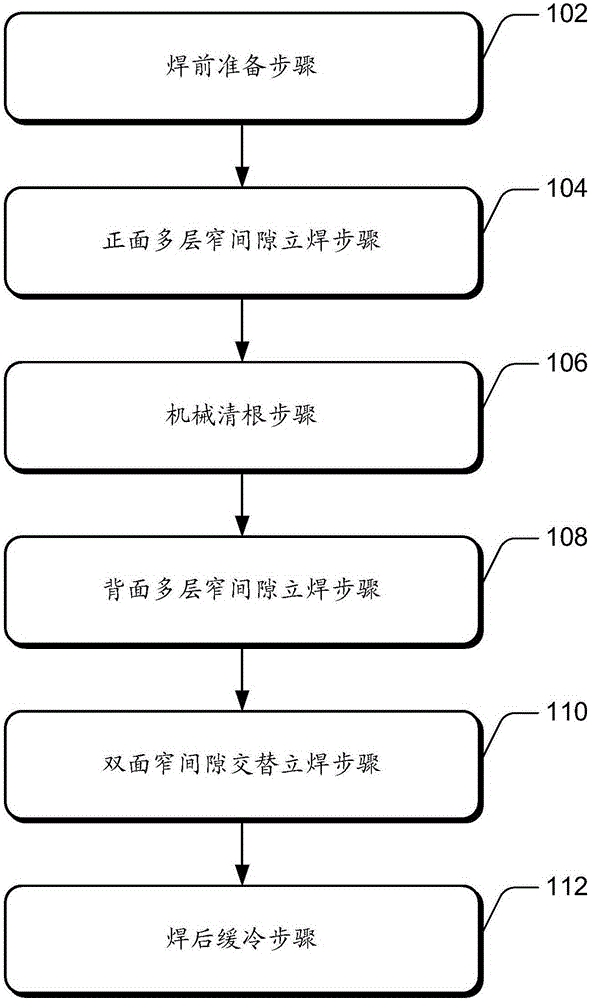

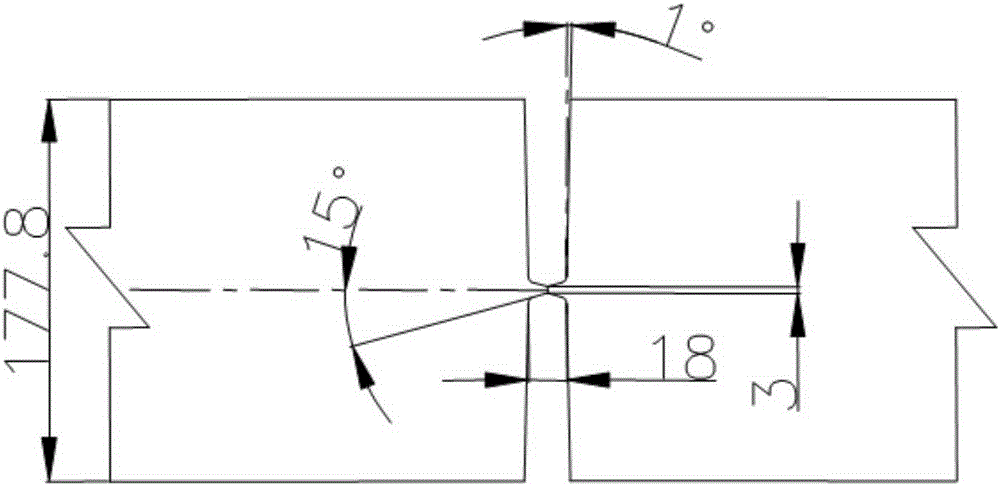

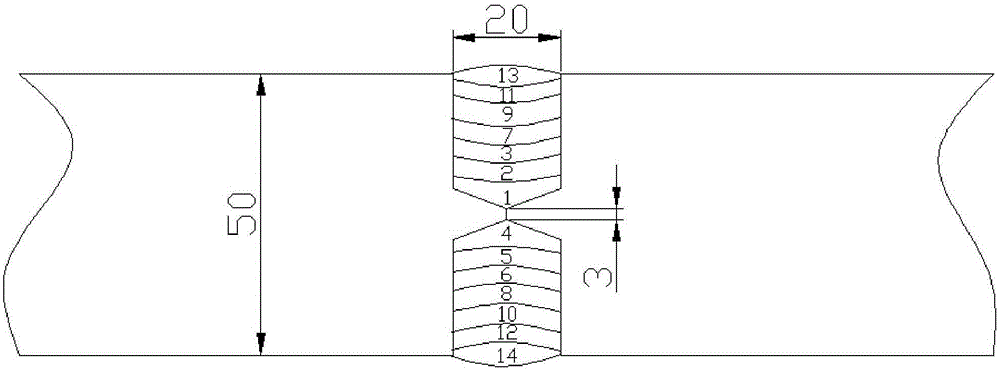

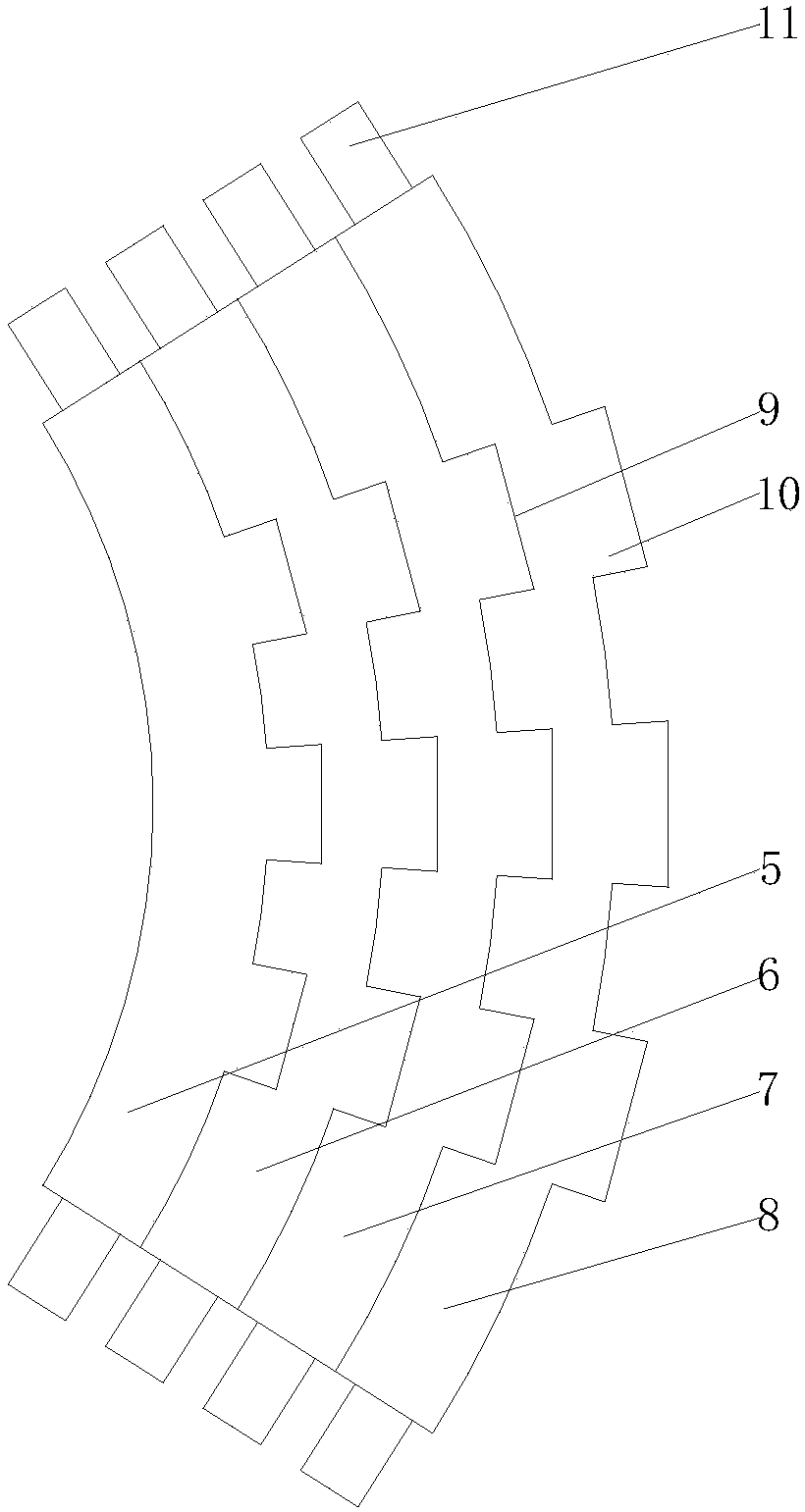

Narrow-gap melting polar reactive gas shielded arc welding technology

ActiveCN103801808AGroove filling volume is largeReduce welding efficiencyArc welding apparatusWelding/soldering/cutting articlesMaterial consumptionElectric arc

The invention discloses a narrow-gap melting polar reactive gas shielded arc welding technology. The technology comprises a pre-welding preparation step, a positive multilevel narrow-gap vertical welding step, a mechanical back gouging step, a back multilevel narrow-gap vertical welding step, a both-side narrow-gap alternated vertical welding step and a postwelding retarded cooling step. Aiming at the characteristics of large racks of pile legs, thick walls, large bevel filler level, low welding efficiency and large cold cracking tendency, the narrow-gap melting polar reactive gas shielded arc welding disclosed by the invention provides a new technology with high efficiency, good quality, energy saving and low material consumption. Compared with traditional welding, by the adoption of the technology disclosed by the invention, the production efficiency is increased by 3 to 5 times, welding filler level is reduced by 50%, impact toughness at a low temperature of 40 DEG C below zero achieves more than 69J, and welding quality is also effectively guaranteed.

Owner:SHANGHAI ZHENHUA HEAVY IND

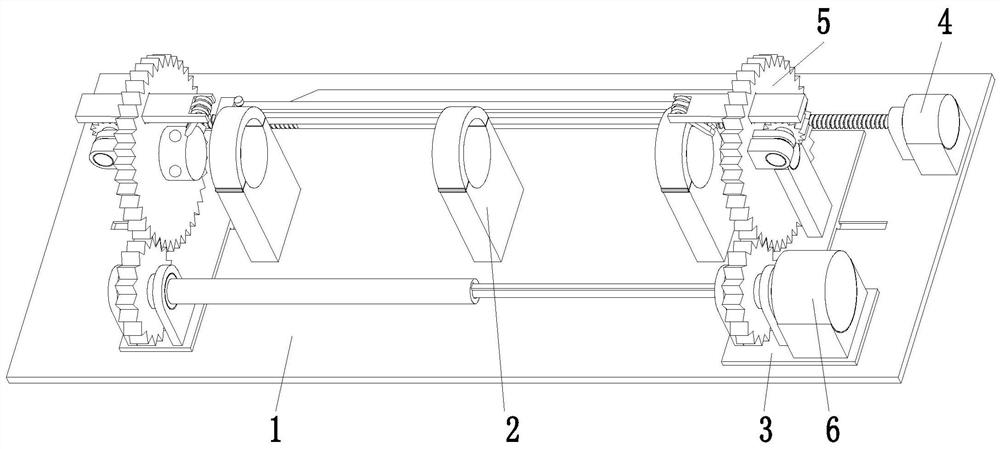

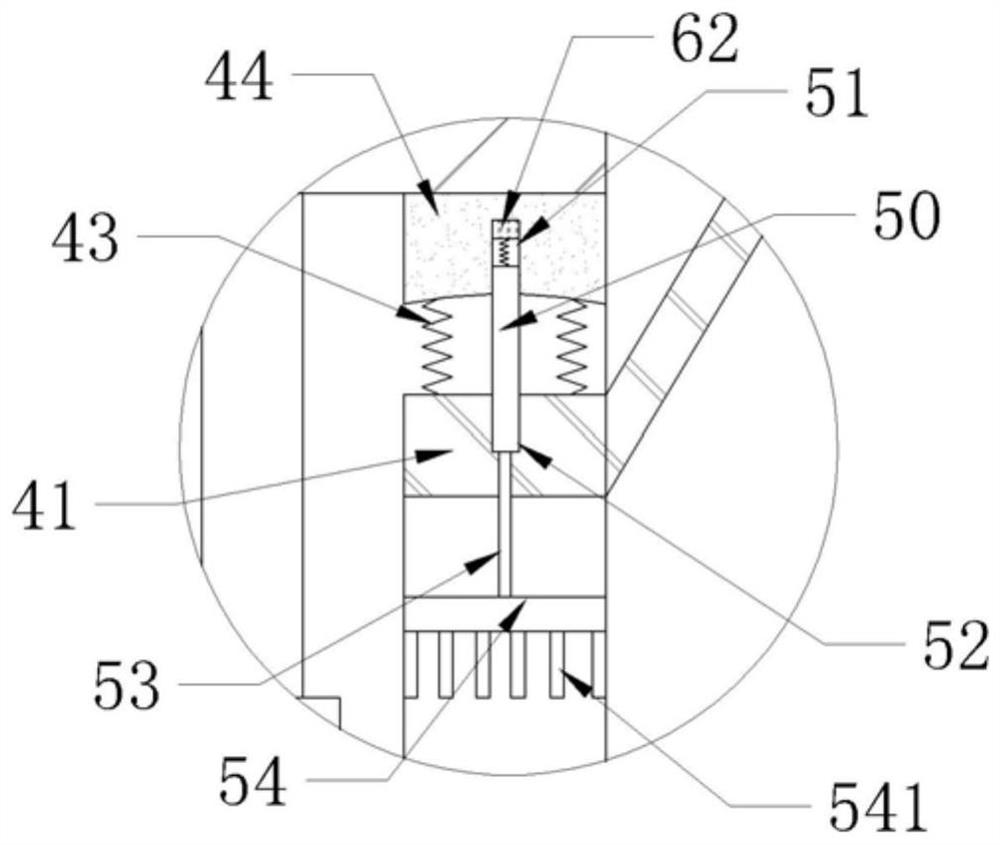

Lifting and rotatable device for circuit board welding

InactiveCN107825036AReduce welding efficiencyConvenient welding workWelding/cutting auxillary devicesAuxillary welding devicesGear wheelEngineering

The invention discloses a lifting and rotating circuit board welding device, comprising a bottom plate, a first fixing block and two second fixing blocks are arranged on the upper surface of the bottom plate, and the two second fixing blocks are both located on the first The rear side of a fixed block, and the upper surface of the first fixed block is fixedly connected with the lower surface of the first rotating shaft through two first electric push rods, and the surface of the first rotating shaft is sleeved with two first bearings. The device for welding circuit boards that can be lifted and rotated can place The height of the board is adjusted, which is convenient for workers to weld the circuit board, so that the position of the circuit board can be adjusted by rotating the board and moving the board left and right, so that workers do not need to hold the board to weld the board. Thereby improving the welding efficiency of workers to the circuit board.

Owner:江苏万通塑业有限公司

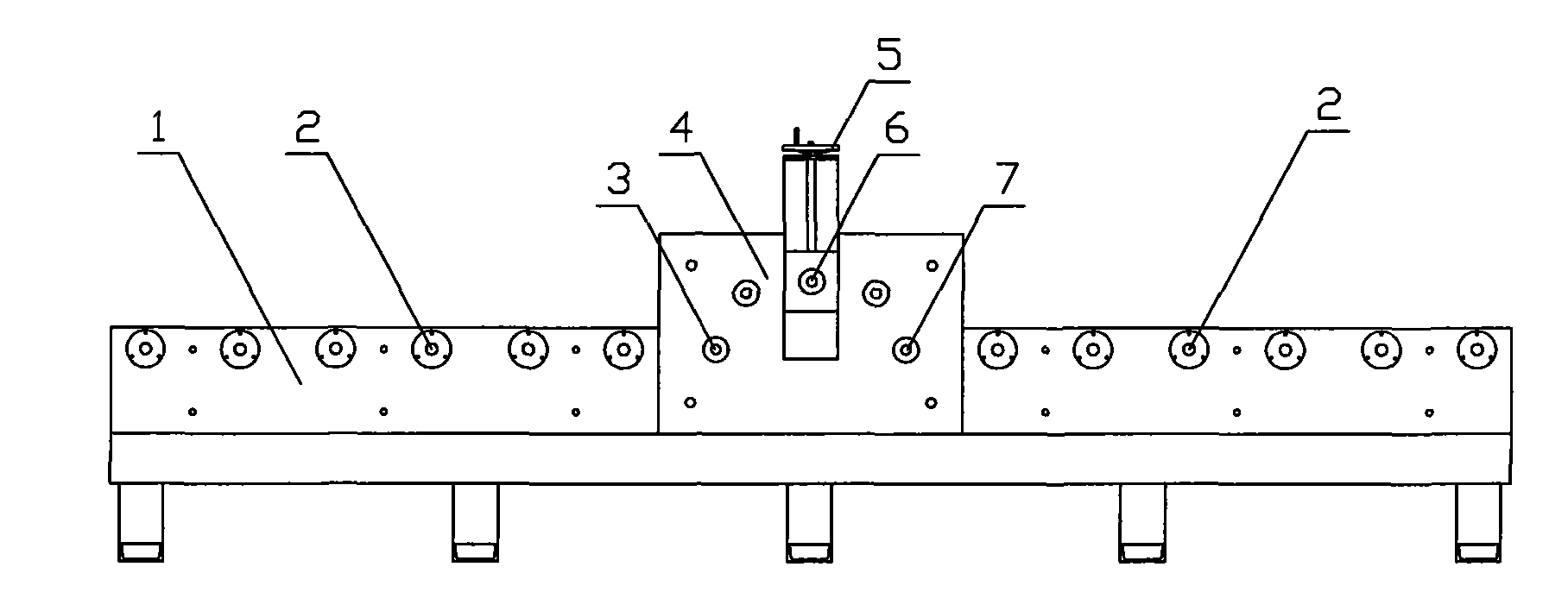

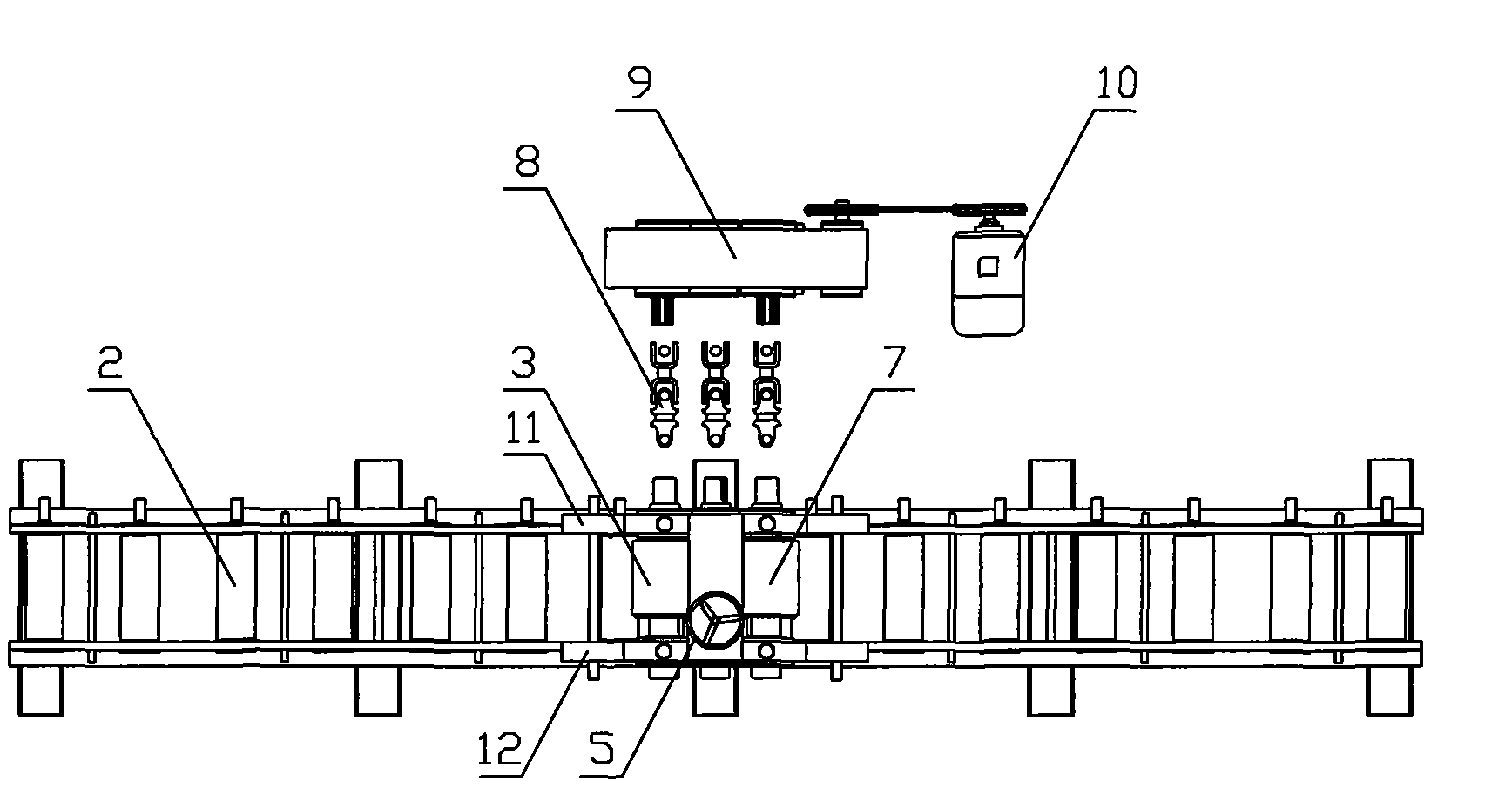

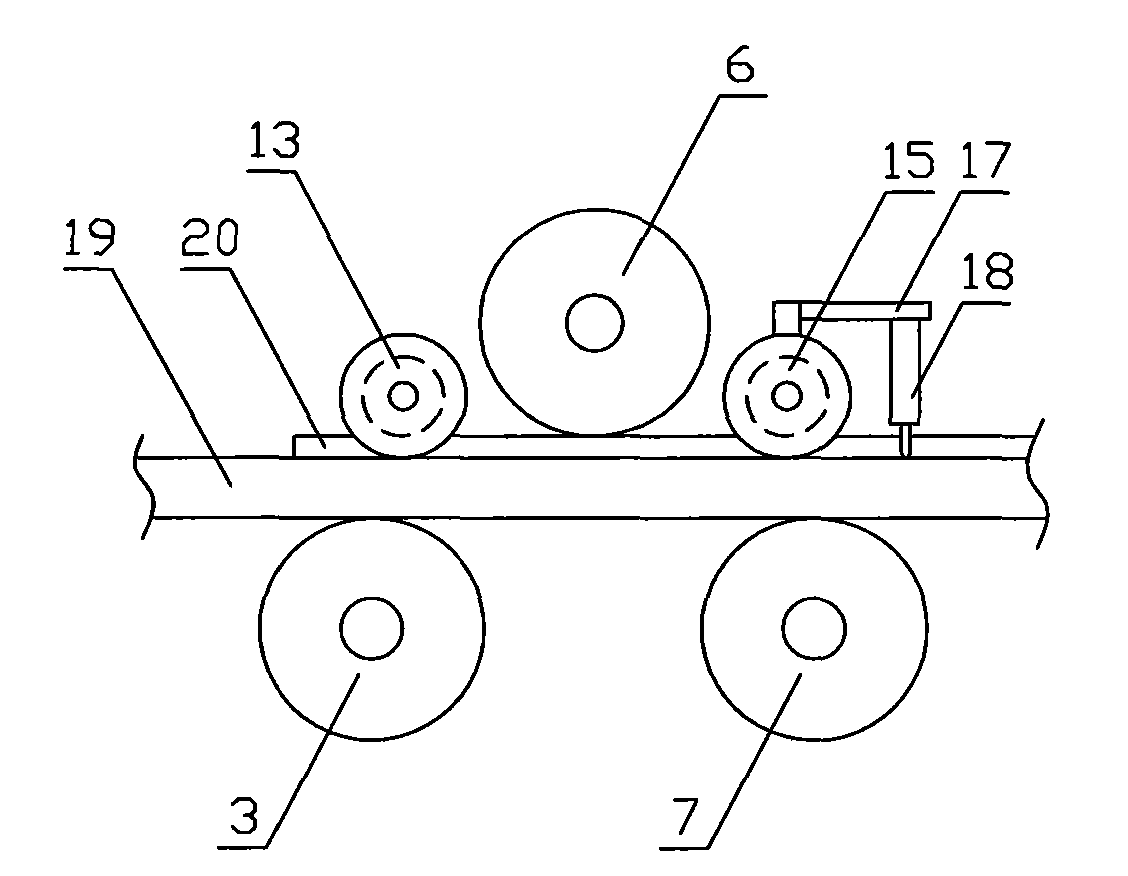

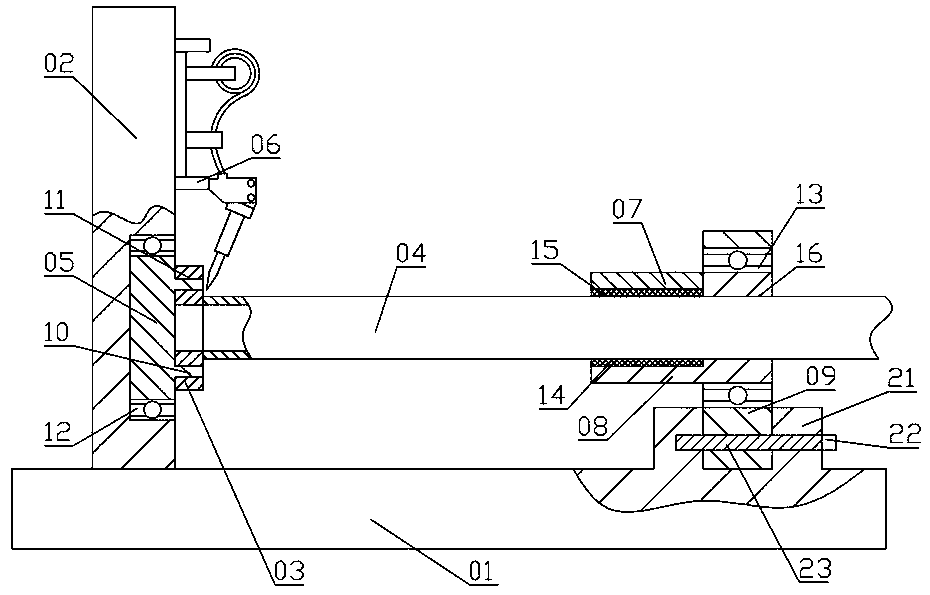

Welding device for gantry-shaped steel of forklift

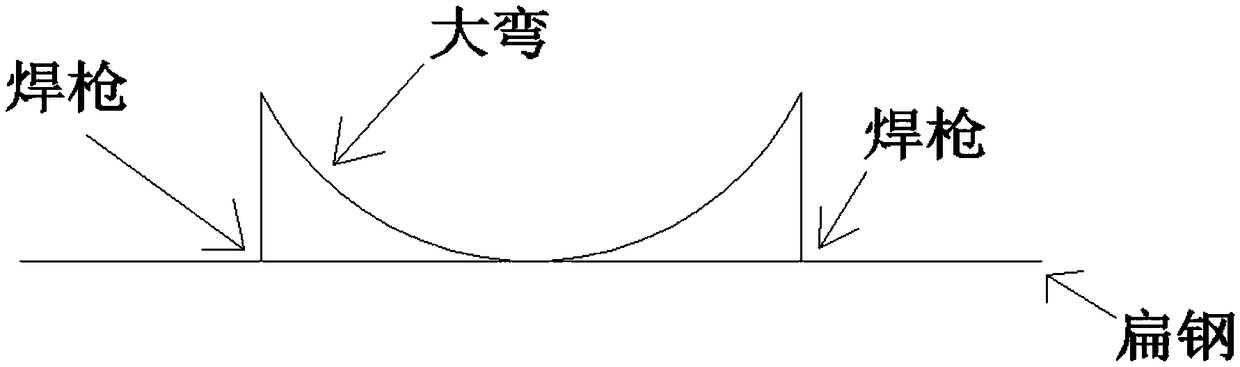

InactiveCN101590578AGood technical effectReduce welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelUniversal joint

The invention relates to the field of manufacturing a forklift, and discloses a welding device for gantry-shaped steel of a forklift. The device comprises a welding platform and a welding gun arranged on the welding platform; the welding platform is arranged on a material guide platform which is provided with a plurality of guide wheels form left to right; the welding platform comprises a front support plate, a rear support plate and an upper driving wheel, a left driving wheel and a right driving wheel which are arranged between the front support plate and the rear support plate; and the upper driving wheel, the left driving wheel and the right driving wheel are connected with a gear box by an universal joint, the gear box is connected with a motor, and the left driving wheel and the right driving wheel are connected with the guide wheel. By welding both faces and positioning fillets by a fillet positioning mechanism, the device achieves the effects of accurate positioning and welding, insusceptibility to welding deformation, high welding efficiency, and cost conservation, and has wide application prospect in the field of manufacturing the forklift.

Owner:ZHEJIANG MAXIMAL FORKELEVATOR

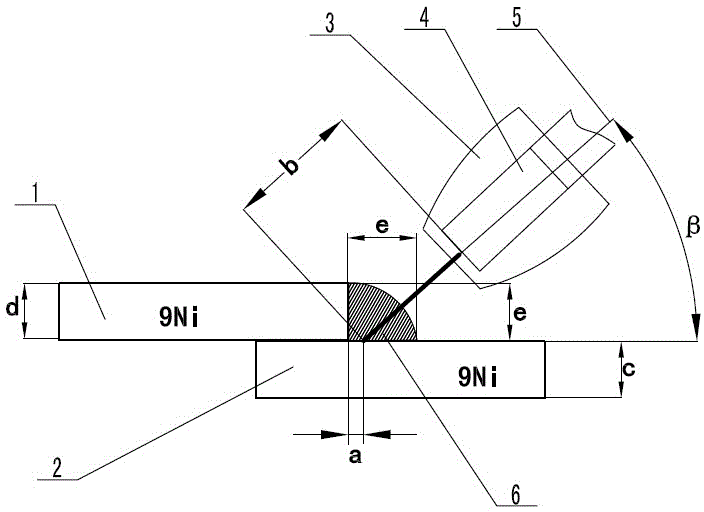

Welding technique for base plate of LNG low-temperature tank

InactiveCN104625359ASatisfy the pressure bearing capacity requirementsHigh hardnessArc welding apparatusDomestic vesselsFillet weldCurrent range

The invention discloses a welding technique for a base plate of an LNG low-temperature tank and belongs to the technical field of welding of LNG low-temperature tanks. According to the welding technique, two 9Ni steel plates with the thicknesses ranging from 6 mm to 9 mm are made to be in lap joint in the horizontal direction and overlap to form an overlap joint, the end face is cleaned, a preparation for welding is made, and then submerged-arc welding is conducted by means of alternating current, wherein the arc voltage ranges from 25 V to 29 V, the welding current ranges from 260 A to 290 A, the wire extension length ranges from 25 mm to 35 mm, the welding speed ranges from 22 in / min to 25 in / min, the welding wire angle ranges from 55 degrees to 65 degrees, and a full fillet weld with a welding foot with the length ranging from 6 mm to 9 mm is formed. By the adoption of the welding technique, submerged-arc welding of the base plate of the LNG low-temperature tank can be achieved, the problems that during submerged-arc welding, a lap fillet weld is poorly formed, hot cracks are formed during welding, and burning through occurs easily during welding are solved, the two 9Ni steel plates with the thicknesses ranging 6 mm to 9 mm can be welded in a single-pass mode at a time during actual operation, and welding efficiency is remarkably improved.

Owner:SINOPEC TENTH CONSTR

Welding gun for protecting carbon dioxide gas

InactiveCN105312734AImprove insulation performanceUnrestricted operating positionArc welding apparatusShielding gasEngineering

The invention relates to a welding gun for protecting carbon dioxide gas. The welding gun comprises a welding gun base and an elbow pipe body arranged at the front end of the welding gun base, wherein a handle is arranged on the welding gun base; a gas pipe joint is arranged at the tail end of the handle through a gas inlet nut in a sleeving way and is connected with a protective gas inlet; a cable is arranged outside the gas pipe joint; a front gun body is arranged in the welding gun base; a mounting hole is formed in the front gun body; the handle and the elbow pipe body are connected by internal threads and external threads on the elbow pipe body; a connecting rod is arranged at the front end of the elbow pipe body in a sleeving way and is connected with a current contact nozzle; a gas outlet is formed in the front end of the connecting rod; a spray pipe is arranged outside the current contact nozzle in a sleeving way; an insulator for insulating the gun body from the spray pipe is arranged between the connecting rod and the spray pipe. The spray pipe is arranged on the welding gun for protecting the carbon dioxide gas, disclosed by the invention, can be used for protecting gas from dispersing; in addition, the welding gun is good in insulating property and is not limited to an operating position, so that the welding efficiency is greatly improved; the welding gun has the advantages of concentrated electric arc temperature, small heat input, high speed and good protection effect.

Owner:张建生

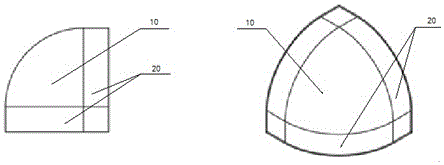

Novel one-eighth sphere corner aluminum alloy end socket and manufacturing method

ActiveCN106838307ASolve corner stress concentrationSolve welding difficultiesPipe elementsPressure vesselsStress concentrationActual use

The invention discloses a novel one-eighth sphere corner aluminum alloy end socket. The one-eighth sphere corner aluminum alloy end socket is used for replacing eight top corners of a vehicle-mounted rectangular box, namely the eight top corners of the vehicle-mounted rectangular box are replaced with eight spherical round corners, straight edge sections are additionally arranged on three edges of the spherical round corners, and the three edges of the spherical round corners and three edges of the vehicle-mounted rectangular box are assembled and spliced in the same plane conveniently; and the spherical round corners are one-eighth spherical round corners. The novel one-eighth ball corner aluminum alloy end socket is mainly used for solving the problems that the eight top corners of the vehicle-mounted rectangular box are concentrated in stress, difficult to weld, low in welding efficiency, prone to breakage by impact, not attractive enough and the like, and actual use requirements are met.

Owner:ANHUI XINLIANXIN HEAVY HEAD

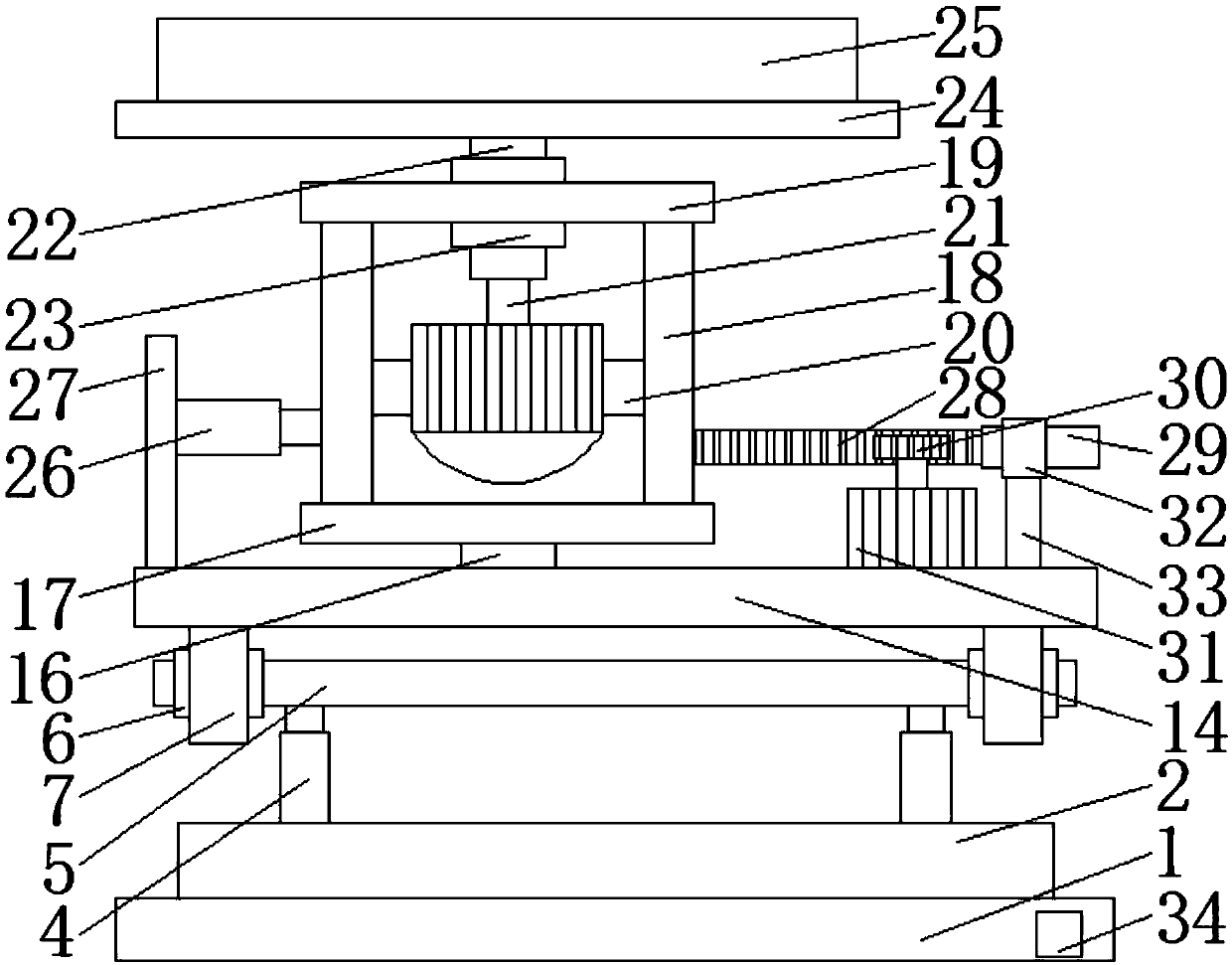

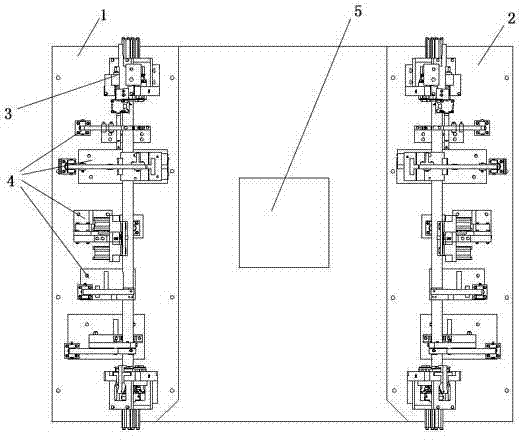

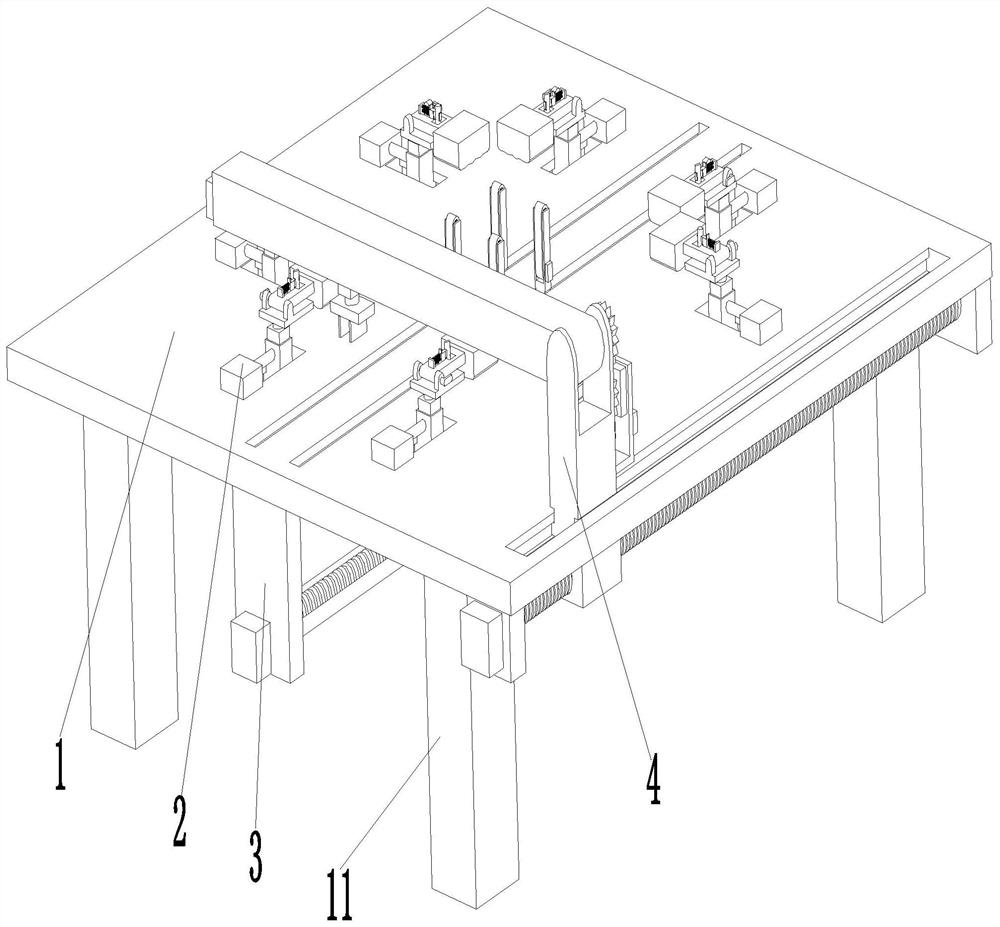

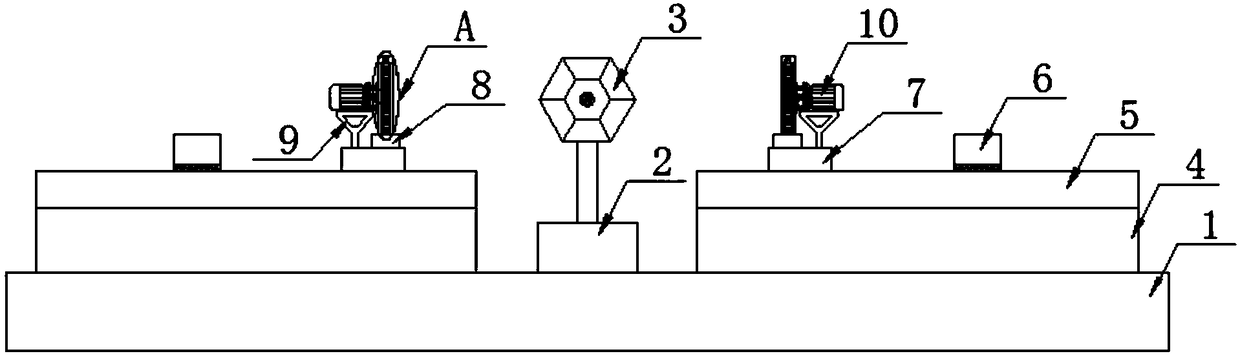

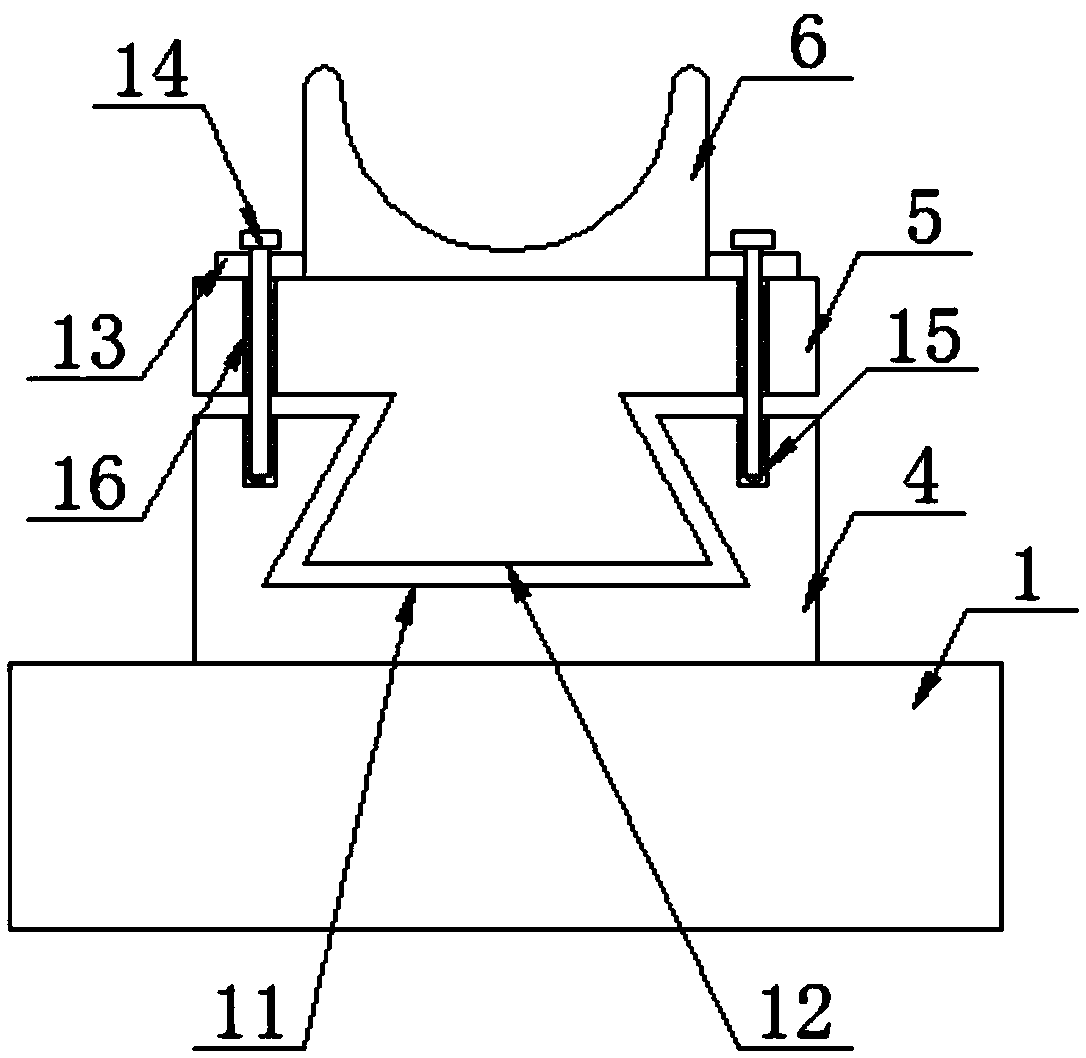

Automatic welding device and method for vehicle console installing support

InactiveCN103934604AGuaranteed welding efficiencyReduce labor costsWelding/cutting auxillary devicesElectrode holder supportersEngineeringWelding

The invention aims to provide an automatic welding device for a vehicle console installing support. The automatic welding device comprises a workbench I, a workbench II, pipe clamping devices, fixtures and a welding robot. The workbench I and the workbench II are arranged oppositely in parallel. The workbench I and the workbench II are respectively provided with the pipe clamping devices and the fixtures. The pipe clamping devices and the fixtures on the workbench I and the pipe clamping devices and the fixtures on the workbench II are in mirror distribution correspondingly. The welding robot is arranged between the workbench I and the workbench II and can rotate 360 degrees. A welding gun arranged on the welding robot can cover welding points of parts corresponding to all the fixtures on the workbench I and the workbench II. The invention further provides an automatic welding method for the vehicle console installing support. The automatic welding device and method have the advantages that welding efficiency is high, welding quality is stable, and production cost is low.

Owner:韦建军 +4

Movable type pressure welding machine of stainless steel composite board blank

ActiveCN102896447AQuality assuranceDoes not affect normal productionWelding/cutting auxillary devicesAuxillary welding devicesProduction lineMovable type

The invention provides a movable type pressure welding machine of a stainless steel composite board blank, which is characterized in that a rack with a movable wheel at the bottom is provided with hoisting rollers and a supporting platform is arranged between the hoisting rollers; the rack is provided with a pressure machine and a frame beam with a rail is arranged at the top of the rack; and a welding machine with a walking wheel is arranged on the rail of the frame beam. The pressure machine, the welding machine, the hoisting rollers and the supporting platform are organically integrated on the movable type rack; after the stainless steel composite board blank is flattened and pressed, the stainless steel composite board blank is moved out of a production line along the rack, so as to rapidly and conveniently finish continuous welding work; work stations are reduced, the other rack can be moved into the production line and the normal production of the production line is not influenced; and furthermore, the quality of the stainless steel composite board blank can be better guaranteed. The movable type pressure welding machine has the characteristics of compact whole structure, small occupied area, convenience for movement, high efficiency for flattening, pressing and welding, accurate control, convenience for operation and the like; and continuous, automatic and mechanical production requirements are completely met.

Owner:KUNMING IRON & STEEL GRP CO LTD

Power transmission tower foot welding process

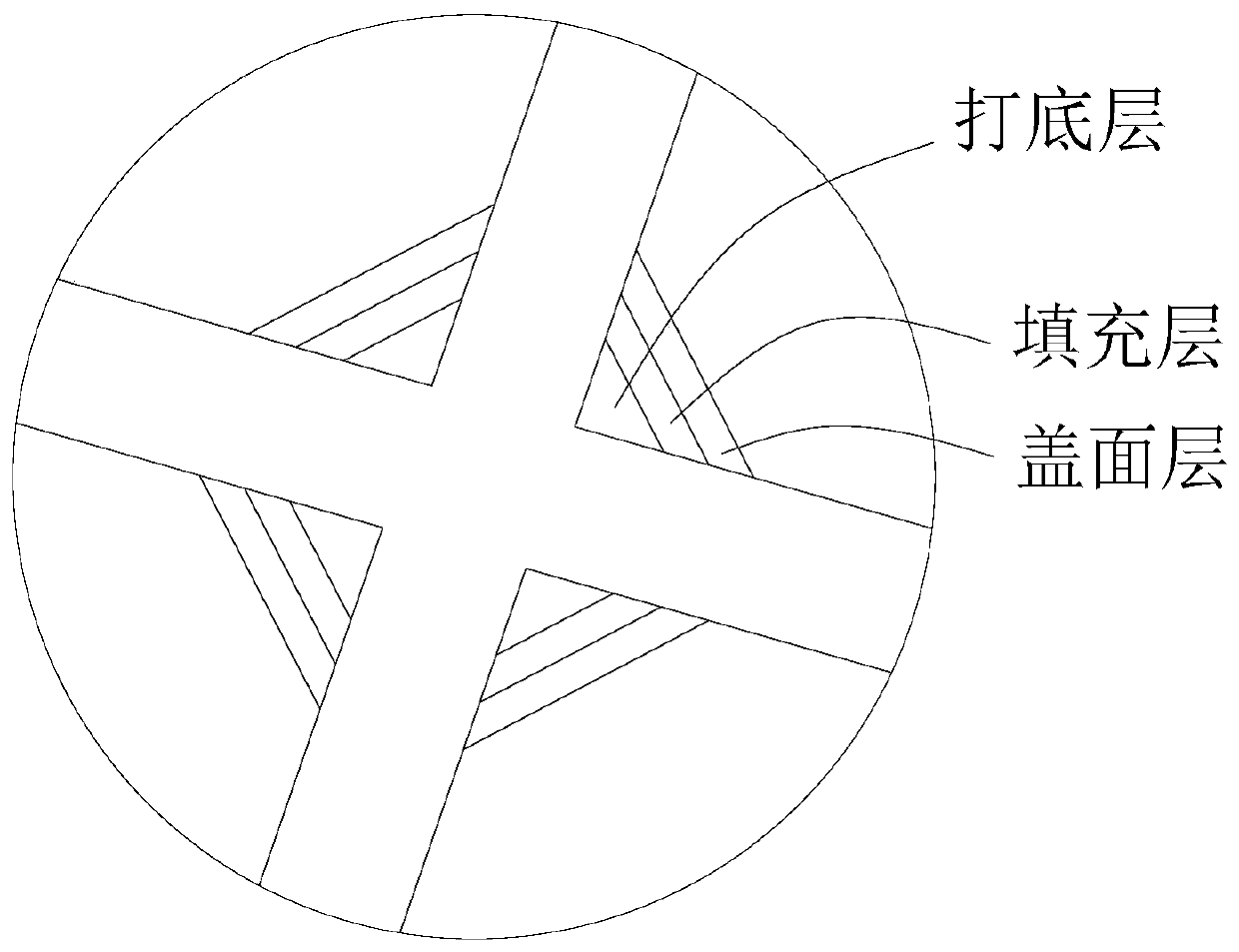

ActiveCN110014242AShorten the intervalAvoid stress concentrationWorkpiece edge portionsWelding apparatusStress concentrationSurface layer

The invention provides a power transmission tower foot welding process. The mode that three welding passes are implemented in a staggered manner for two welding seams at symmetrical positions is matched; furthermore, the welding directions of base layers, surface layers and packing layers are the same; welding equipment does not need to be reset, and therefore, the welding efficiency is high; thetwo welding seams at the symmetrical positions are adopted; and firstly, the base layers of the two welding seams are welded, then, the packing layers of the two welding seams are welded, and finally,the surface layers of the two welding seams are welded. In this way, the time interval between the two symmetrical welding seams can be shortened, and stress concentration is prevented; in addition,staggered type welding is conducted between the two welding seams; the time interval between every two welding layers is long, heat accumulation is prevented, and the welding quality is higher; and for four welding seams at the staggering positions of main rib plates, three welding passes are completed in a symmetrical and alternate manner, and stress concentration and heat accumulation can be prevented.

Owner:中电建武汉铁塔有限公司

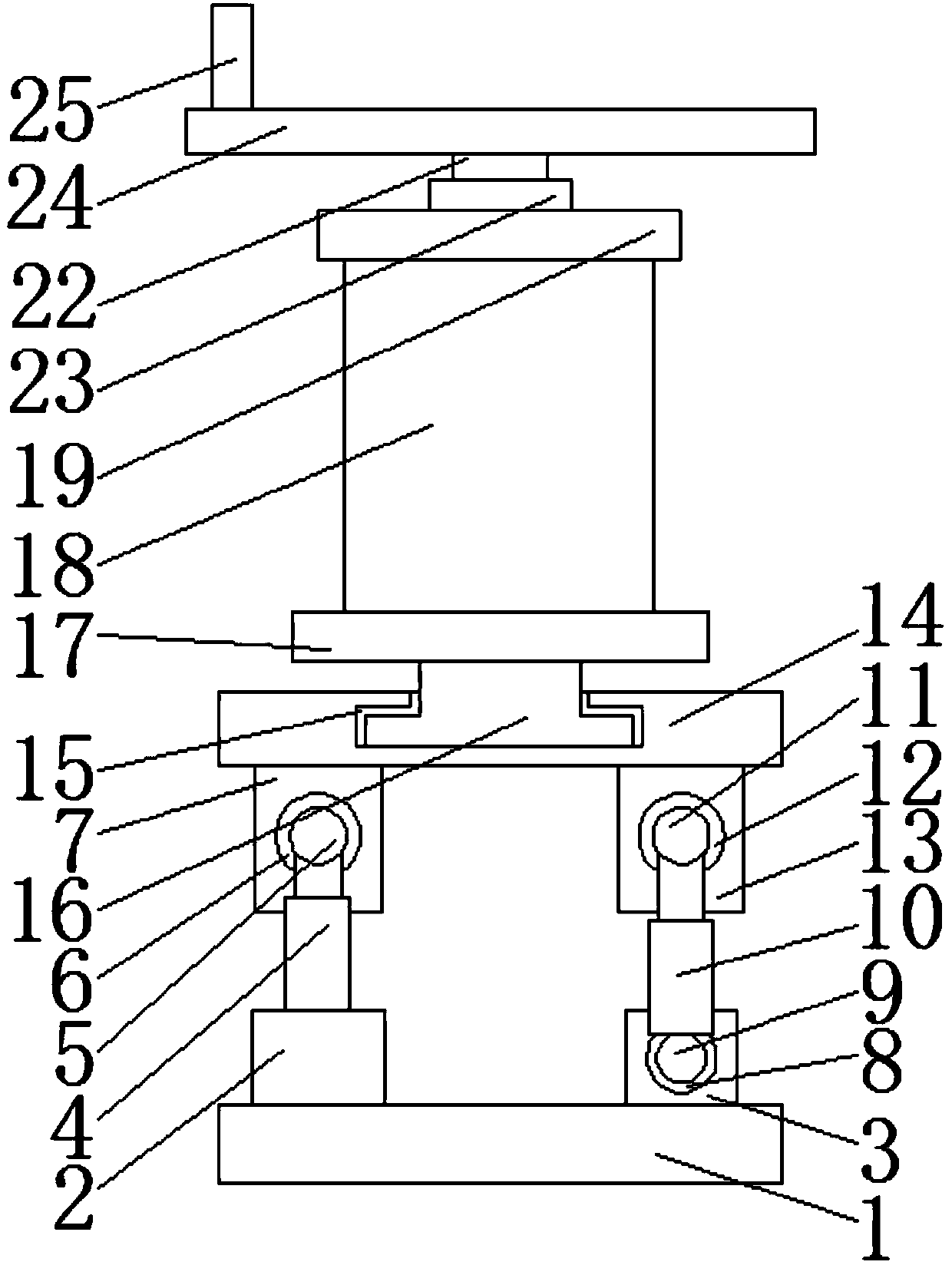

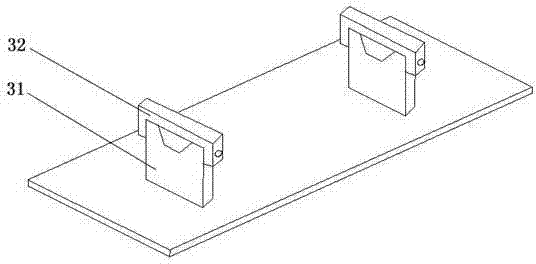

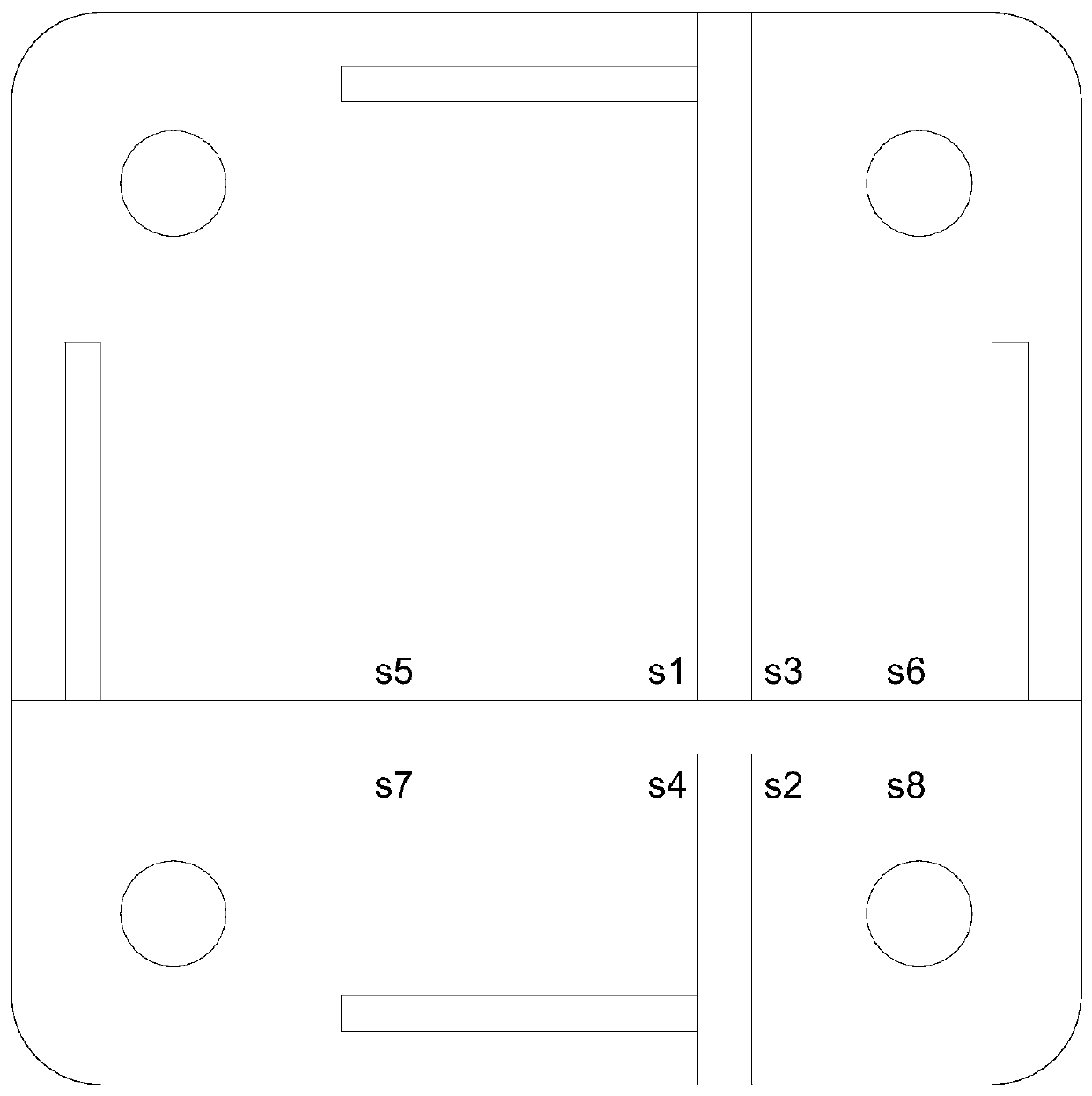

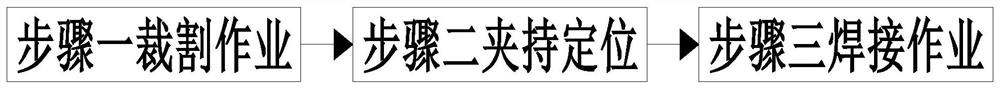

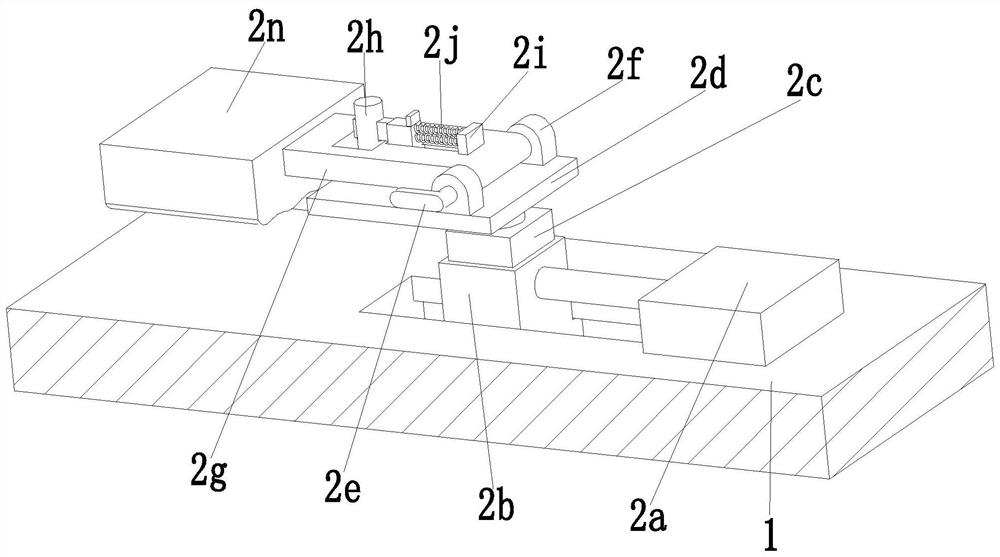

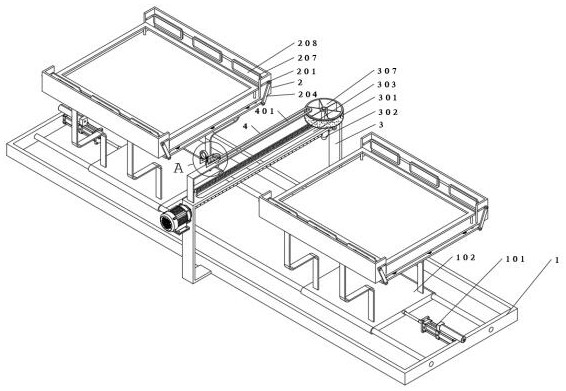

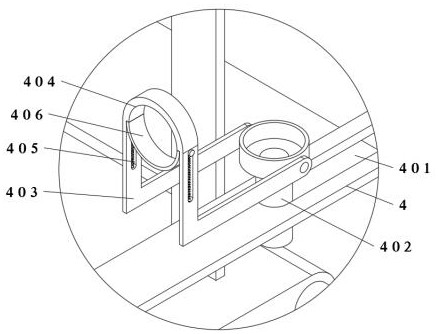

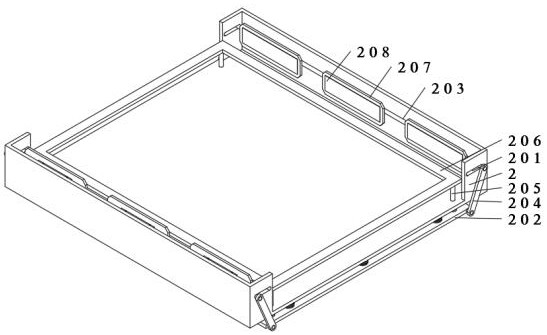

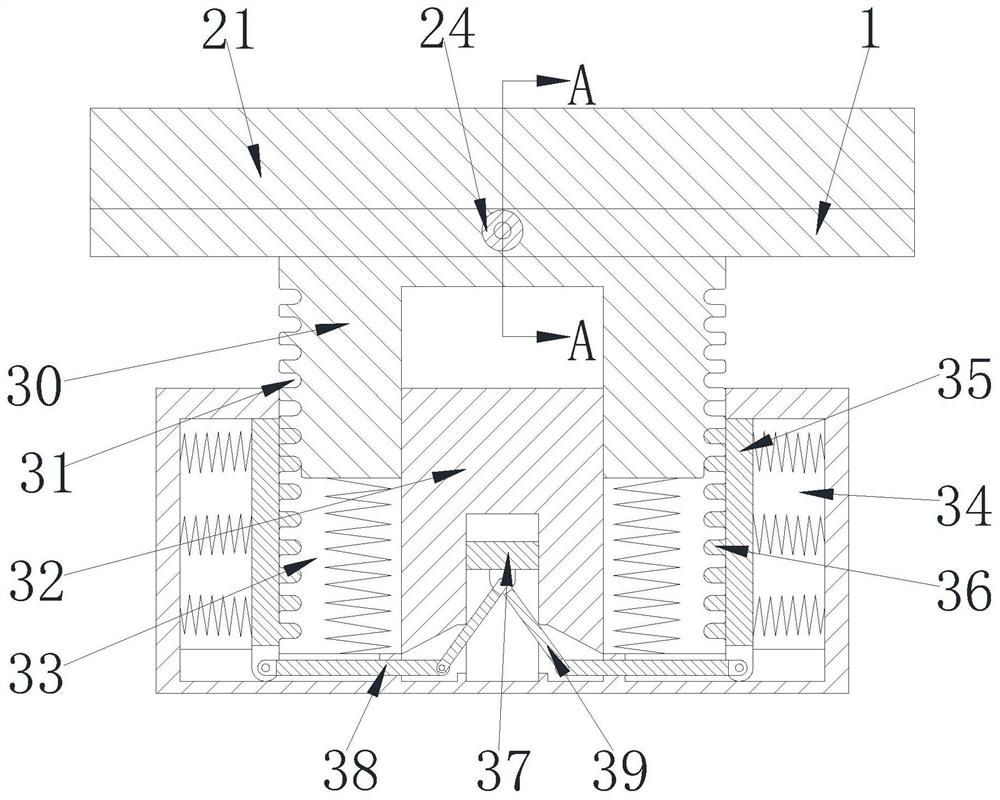

Welding forming process for keel frame of house light steel frame

ActiveCN111633391AImprove welding efficiency and effectGuaranteed stabilityWelding/cutting auxillary devicesAuxillary welding devicesWorkmanshipPositioning equipment

The invention relates to a welding forming process for a keel frame of a house light steel frame. The welding forming process mainly comprises the following steps of cutting operation, clamping positioning, welding operation and other various procedures. Used keel clamping positioning equipment comprises a bottom plate, a positioning device, a clamping device and a moving device. The welding forming process can solve the following problems existing in welding of existing keels that a, during traditional keel welding, the keels need to be manually spliced, the quality of the manually spliced keels is different, the keels are manually held by hands during welding, due to the fact that many subjective uncertain factors exist in manual operation, the phenomenon of keel dislocation often occurs, the welding quality is affected, even the building quality of a house is affected, the workload of workers is very heavy, and the keel welding efficiency is reduced; and b, existing keel welding positioning equipment is not accurate enough in keel positioning, the keel welding efficiency is affected, in addition, timely correction cannot be conducted when the keels are dispositioned, and the keel welding efficiency and effect are improved.

Owner:山东智迈德智能科技有限公司

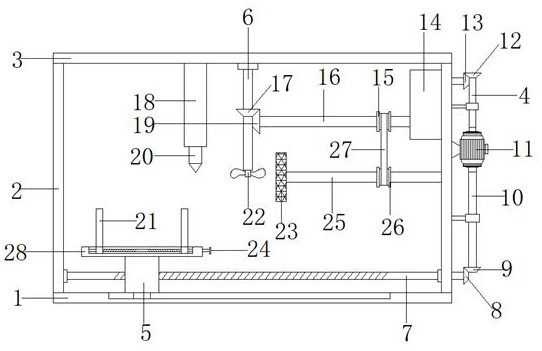

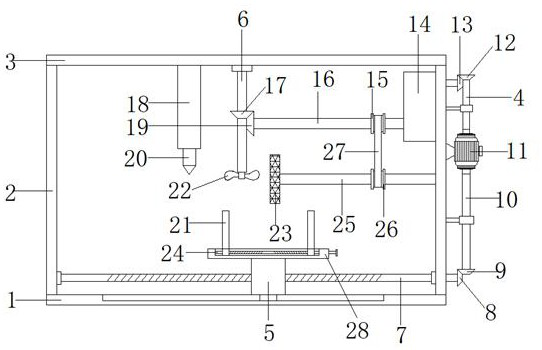

Automatic welding device for distribution box production

InactiveCN112247574ASolve manual operation, time-consuming and labor-intensiveTime-consuming and laborious to solveOther manufacturing equipments/toolsElectric machineryManual handling

The invention discloses an automatic welding device for distribution box production and relates to the technical field of automatic welding. Aiming at solving the problems that an existing distribution box needs to be manually operated in the welding process, time and labor are wasted, operation is complex, the labor cost is improved, the welding efficiency is reduced, the welding position cannotbe polished after welding is completed, and subsequent machining is inconvenient, the following scheme is put forwards. According to the scheme, the device comprises a base, supporting plates are fixedly connected to the tops of the two sides of the base, a cover plate is fixedly connected to the tops of the two supporting plates, and a double-shaft motor is fixedly connected to the right side ofthe supporting plate located on the right side. The automatic welding device for distribution box production is novel in design and easy to operate, through the arrangement of a polishing disc, a fanand the like, a movable block can drive a to-be-welded plate to move rightwards, meanwhile, a welding head is used for welding the plate, the fan cools the welding position, the polishing disc polishes the welding position, the labor cost is reduced, the welding efficiency is improved, and subsequent plate machining is facilitated.

Owner:湖南中晟电气设备有限公司

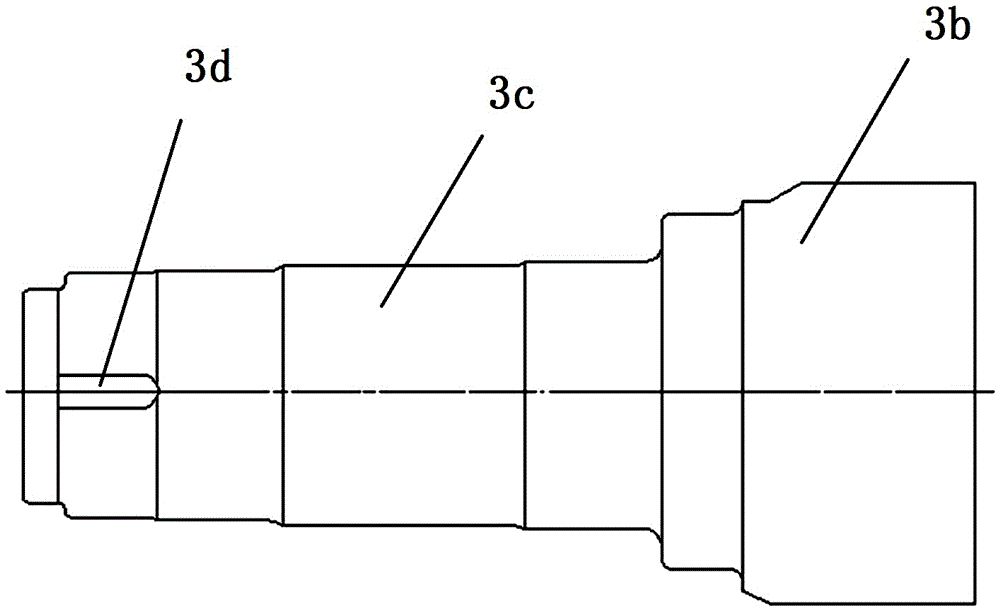

Welding method of rear drive axle housing assembly

InactiveCN105665916AReduce processSave materialVehicle componentsMetal working apparatusElectricityEngineering

The invention relates to a welding method of the rear drive axle housing assembly, which comprises the following steps: a. Processing the blank (3a) of the half-shaft sleeve (3), roughing and finishing the bearing neck of the stepped structure (3c), and then mill the keyway to process the keyway to form the finished part (3b) of the half shaft sleeve (3); b, the finished part (3b) and the axle housing body (1) are correspondingly matched on the friction welding machine; c . Weld the axle casing (3) and the axle housing body (1) by a special friction welding machine. Advantages of the present invention: the welding efficiency of this method is higher than that of the existing arc welding process, material is saved, labor intensity is significantly reduced, arc radiation is not generated during the welding process, and there is no smoke, so that the working environment has been significantly improved, and its welding quality is stable. The risk of weld fracture at the casing is reduced, the processing cost is low, electricity is saved, mechanization and automation are easy to realize, the operation is simple, and there is no spark, arc light and harmful gas in the welding work site.

Owner:HEFEI AAM AUTOMOBILE DRIVELINE & CHASSIS SYST

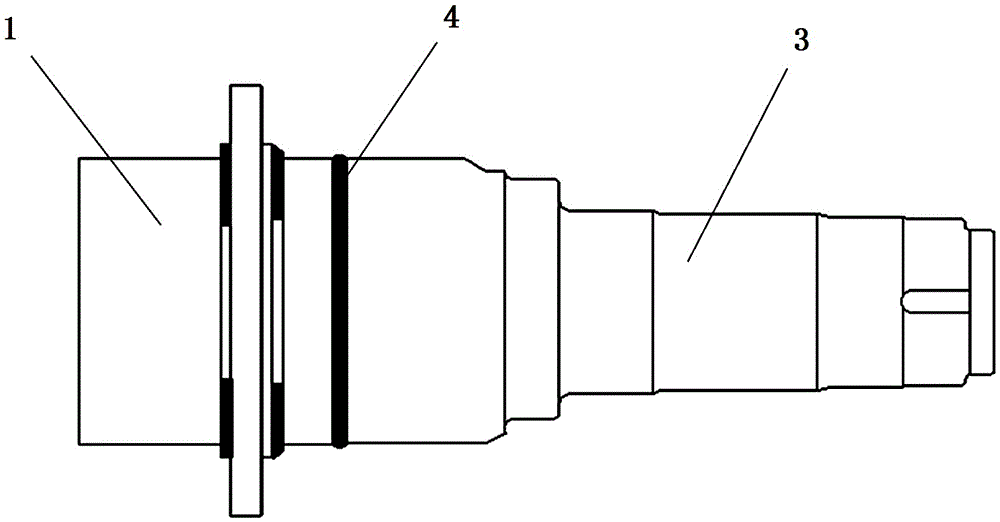

Electron beam welding method for aluminum alloy piston of automobile air-conditioning compressor

InactiveCN102554446BIncrease vacuumImprove vacuum efficiencyWelding/cutting auxillary devicesAuxillary welding devicesVacuum chamberPiston

The invention provides an electron beam welding method for an aluminium alloy piston of an automotive air condition compressor. The aluminium alloy piston is installed in air, and then enters a vacuum chamber at twice. The installed aluminium alloy piston enters a semi-vacuum chamber and then enters the vacuum chamber. The aluminium alloy piston is assembled by a special fixture in the vacuum chamber, so that the assembly precision can be ensured. As the assembly is performed in the vacuum chamber, the vacuumizing speed for the vacuum chamber is enabled to be very fast. The electron beam welding is also performed in the vacuum chamber, so that the number of air holes in welding is less, the depth of welding is great, the strength of welding is high, and the quality of welding is good. The welded aluminium alloy piston is demounted by entering the air at twice. In the invention, the special fixture is adopted to assembly two parts of the aluminium alloy piston in the vacuum chamber, so that the vacuumizing operation is easier, and the vacuumizing efficiency is greatly improved.

Owner:SHANGHAI LEIHONG LASER TECH

A bridge girder plate reinforcement welding equipment

ActiveCN113601078BAvoid the phenomenon of accumulationReduce welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderClassical mechanics

Owner:南通平冉智能科技有限公司

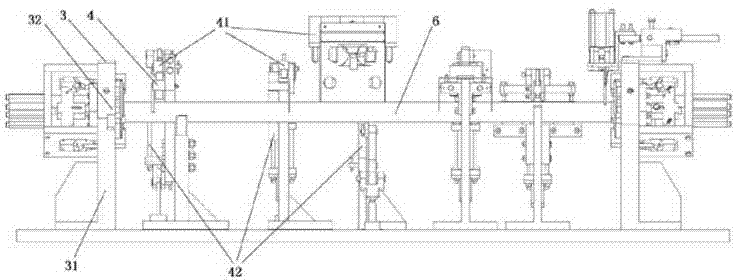

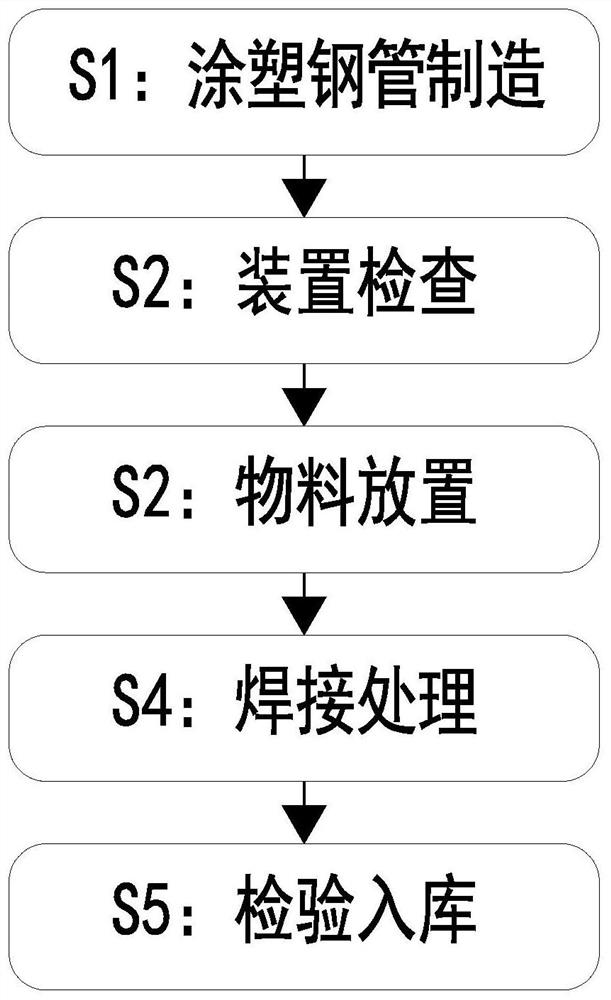

Manufacturing method of large-diameter anti-corrosion plastic-coated steel tube

PendingCN112894254AReduce welding effectReduce welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesMaterials scienceSteel tube

The invention relates to a manufacturing method of a large-diameter anti-corrosion plastic-coated steel tube. The manufacturing method of the large-diameter anti-corrosion plastic-coated steel tube adopts the following manufacturing device of the large-diameter anti-corrosion plastic-coated steel tube. The manufacturing device of the large-diameter anti-corrosion plastic-coated steel tube comprises a base, a bearing mechanism, sliding bottom plates, an adjusting mechanism, a welding mechanism and a driving mechanism, wherein the bearing mechanism is arranged in the middle of the upper end face of the base, the sliding bottom plates are arranged on the upper end face of the base and located on the left side and the right side of the bearing mechanism in a left-right sliding fit mode, and the adjusting mechanism, the welding mechanism and the driving mechanism are sequentially arranged on the upper end faces of the sliding bottom plates from back to front. The problems that in the process of welding a flange and a large-diameter anti-corrosion plastic-coated steel tube in a manual mode, the plastic-coated steel tube and the flange are prone to shaking, then the welding effect between the flange and the plastic-coated steel tube is lowered, and the efficiency of manually welding the flange and the plastic-coated steel tube is low and the like are solved.

Owner:徐萍

Narrow Gap Metal Active Gas Shielded Arc Welding Process

ActiveCN103801808BIncrease filling volumeLess consumablesArc welding apparatusWelding/soldering/cutting articlesReactive gasMaterial consumption

The invention discloses a narrow-gap melting polar reactive gas shielded arc welding technology. The technology comprises a pre-welding preparation step, a positive multilevel narrow-gap vertical welding step, a mechanical back gouging step, a back multilevel narrow-gap vertical welding step, a both-side narrow-gap alternated vertical welding step and a postwelding retarded cooling step. Aiming at the characteristics of large racks of pile legs, thick walls, large bevel filler level, low welding efficiency and large cold cracking tendency, the narrow-gap melting polar reactive gas shielded arc welding disclosed by the invention provides a new technology with high efficiency, good quality, energy saving and low material consumption. Compared with traditional welding, by the adoption of the technology disclosed by the invention, the production efficiency is increased by 3 to 5 times, welding filler level is reduced by 50%, impact toughness at a low temperature of 40 DEG C below zero achieves more than 69J, and welding quality is also effectively guaranteed.

Owner:SHANGHAI ZHENHUA HEAVY IND

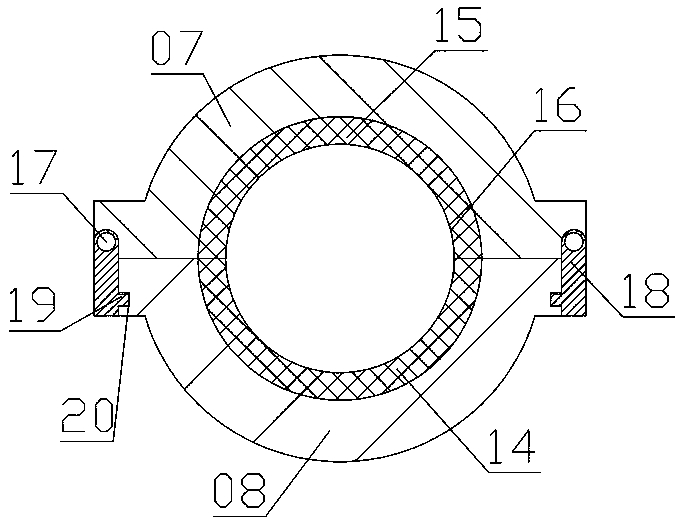

Automatic steel cylinder welding device

ActiveCN112476078AImprove welding efficiencyEasy to operateRevolution surface grinding machinesGrinding drivesElectric machineryGrinding

The invention relates to the technical field of prestressed steel cylinder concrete pipes, and particularly discloses an automatic steel cylinder welding device. The automatic steel cylinder welding device comprises a rack, driving mechanisms and a grinding cylinder. The driving mechanisms comprise motors and hydraulic cylinders and need to be used in pairs. The two paired driving mechanisms are located on the two sides of steel cylinders correspondingly and oppositely arranged. The grinding cylinder is fixed to the rack and comprises a first fixed ring and a second fixed ring. The first fixedring is coaxially placed in one of the steel cylinders, and the outer side wall of the first fixed ring is connected with a first grinding block. The second fixed ring coaxially sleeves the peripheryof a bearing ring of the other steel cylinder, the inner side wall of the second fixed ring is connected with a second grinding block, and the second grinding block abuts against the periphery of thebearing ring of the other steel cylinder. The automatic steel cylinder welding device aims to solve the problem of low welding efficiency caused by manual rotary welding of a welder.

Owner:贵州西南装备制造有限公司

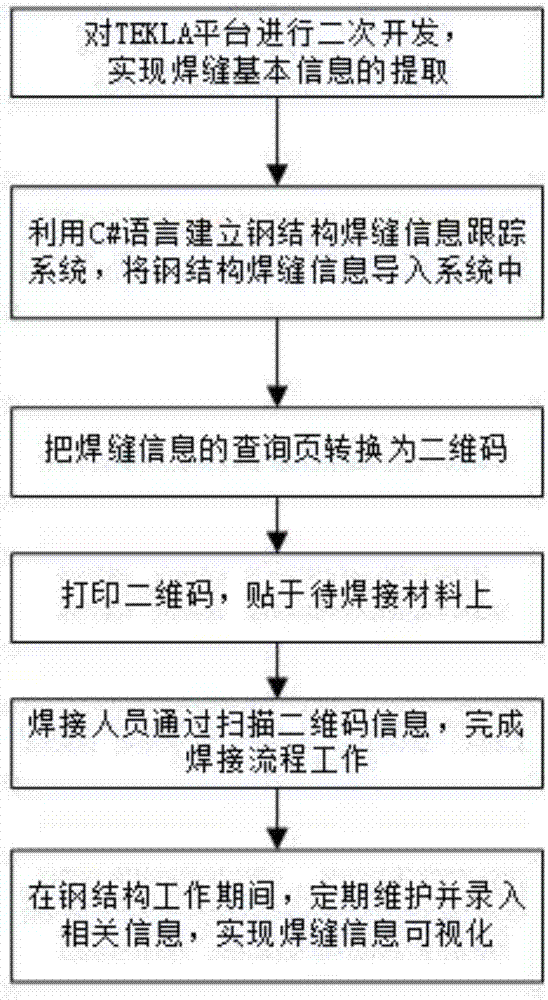

Full life cycle tracking method for welding seam information of oil platform steel structure

InactiveCN107067269AQuick storageCombined form of storage, resulting in fast transfer of welding informationCommerceSpecial data processing applicationsFull life cycleRelevant information

The invention discloses a full life cycle tracking method for welding seam information of an oil platform steel structure, which comprises the steps of performing modeling on the oil platform steel structure by adopting TEKLA software, performing secondary development on a TEKLA platform, and realizing extraction for basic welding seam information of an oil platform steel structure model; building an oil platform steel structure welding seam information tracking system by using a C# language, inputting the basic welding seam information extracted from the TEKLA into the welding seam information tracking system, and editing and storing the basic welding seam information according to requirements; generating a retrieval two-dimensional code for each piece of welding seam information; respectively printing the retrieval two-dimensional codes, and pasting each two-dimensional code at one side of the corresponding welding seam; completing the welding work according to the basic information of the welding seams; and inputting relevant information of the welding personnel, welding seam detection quality information, welding seam maintenance information into a welding seam information query webpage corresponding to the retrieval two-dimensional codes of the welding seams. The work efficiency of welding seam tracking is improved by adopting the method disclosed by the invention.

Owner:TIANJIN UNIV

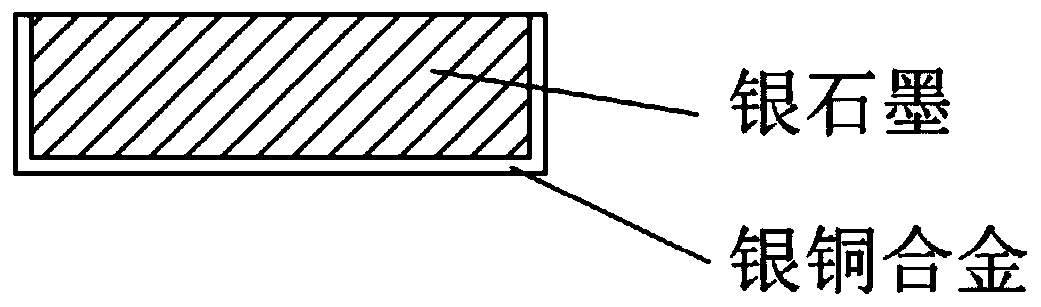

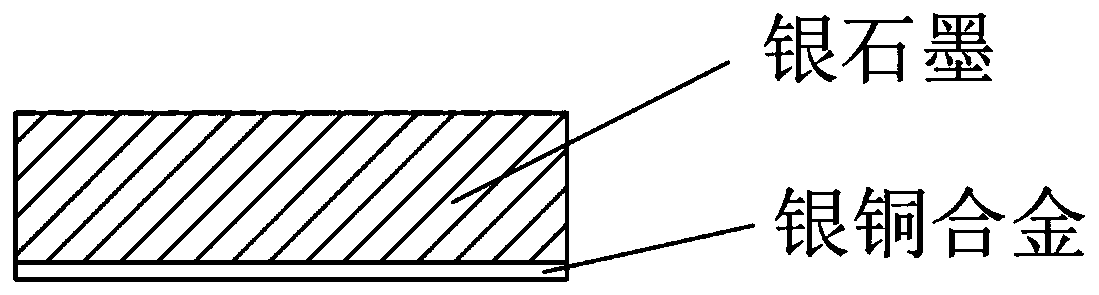

Parallel fiber reinforced silver graphite strip-shaped contact material and preparation method thereof

ActiveCN111451497ALow melting pointMeet the requirements of automatic weldingWelding/cutting media/materialsSoldering mediaFiberSilver copper

The invention discloses a parallel fiber reinforced silver graphite strip-shaped contact material and a preparation method thereof. The material is composed of a working layer and a welding layer, wherein the welding layer is made of silver-copper alloy. The preparation method comprises the steps that silver graphite powder and silver-copper alloy powder are pressed into a composite ingot blank with a silver-copper alloy layer wrapping a silver graphite layer, then sintering, re-pressing and backward extrusion are conducted to obtain a silver graphite / silver-copper alloy composite strip, and the composite strip is subjected to hot rolling, longitudinal shearing, rolling, surface treatment and other procedures to obtain a silver graphite strip-shaped contact finished product. The parallel fiber reinforced silver graphite strip-shaped contact material is mainly applied to the field of miniature circuit breakers adopting automatic welding. Compared with a traditional silver graphite strip-shaped contact material, the strip-shaped contact material prepared by the method meets the automatic welding requirement, the risks of welding blistering and poor bonding strength in the prior art are avoided, and the prepared silver graphite strip-shaped contact material is excellent in processability, high in material utilization rate and suitable for batch production.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

Welding device of radiating tube of radiator

InactiveCN110315275AAvoid misalignmentEasy to take outWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFlange

The invention provides a welding device of a radiating tube of a radiator. The welding device comprises a bottom plate, a back plate, a positioning plate, a welding gun frame, a reinforcing plate, a supporting plate, a first bearing, a second bearing and a buckling plate. The bottom of the back plate is connected with the bottom plate, the inner side of the back plate is connected with the weldinggun frame, the back plate is connected with the outer side of the first bearing, the inner side of the first bearing is connected with the positioning plate, the positioning plate is connected with aflange, the flange is provided with multiple mounting holes, the positioning plate is provided with multiple positioning rods, the positioning rods adapt to the mounting holes, the positioning rods are connected with the mounting holes, the flange is connected with the radiating tube, the radiating tube is connected with the supporting plate, the supporting plate is provided with a through hole,the through hole adapts to the radiating tube, the radiating tube penetrates through the through hole, the upper side of the radiating tube is connected with the inner side of an upper non-slip mat, the outer side of the upper non-slip mat is connected with the reinforcing plate, the lower side of the radiating tube is connected with the inner side of the lower non-slip mat, and the outer side ofthe lower non-slip mat is connected with the supporting plate.

Owner:天津鑫亨工贸有限责任公司

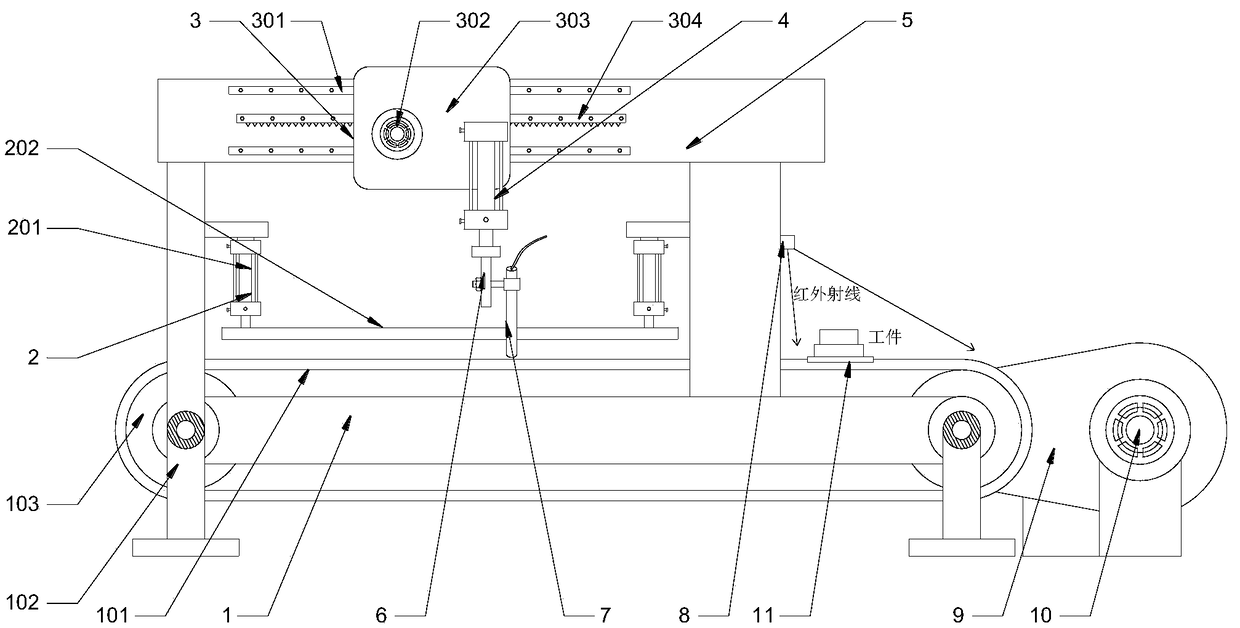

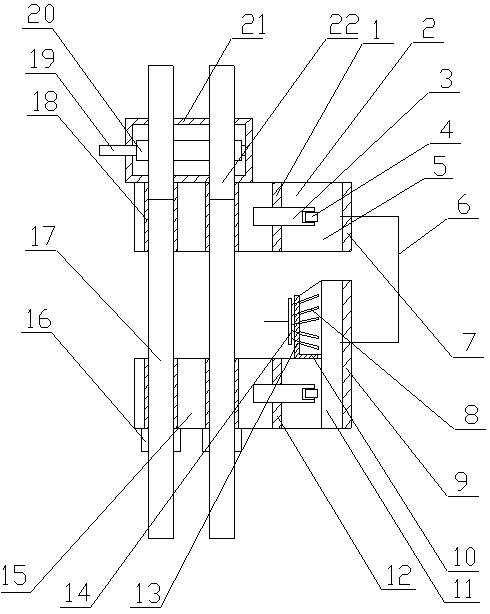

M-shaped sizing block automatic welding equipment

InactiveCN109365953AWide range of automatic weldingImprove ergonomicsElectrode supporting devicesWelding accessoriesMachiningSizing

The invention relates to the field of welding automatic machining equipment. M-shaped sizing block automatic welding equipment comprises a welding gun and further comprises a conveying device for conveying a workpiece and a pressing device for pressing the workpiece; a welding moving device is arranged above the conveying device and provided with a welding lifting pneumatic cylinder facing towardsthe conveying device; the head of a telescopic rod of the welding lifting pneumatic cylinder is connected with a welding gun installation plate; and a plurality of welding guns are installed on the welding gun installation plate. The M-shaped sizing block automatic welding equipment is suitable for linear welding and wide in automatic welding range, the working efficiency is improved by 1.4 timescompared with that of manual welding, professional welding personnel are not needed for operation, common personnel can operate the equipment after being trained, the working efficiency is improved by 0.9 time compared with two-welding-gun welding equipment, the working efficiency is greatly improved, and the cost is reduced.

Owner:富顺县电力金具有限公司

Welding method for building steel structure components

InactiveCN111805112AReduce welding efficiencyReduced ability to carry loadsWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsEngineering

The invention relates to a welding method for building steel structure components. Welding equipment for the building steel structure components is used for the welding method. The welding equipment for the building steel structure components comprises a workbench, a clamping device and an auxiliary unit. The clamping device is arranged on the upper surface of the workbench, and the auxiliary unitis arranged on the lower surface of the workbench. The problems that when any two sections of angle steel are welded into different angles, different clamping devices need to be replaced for clampingand fixing the angle steel, time is wasted as the clamping devices are frequently replaced, and the welding efficiency of the angle steel is reduced; and when any two sections of angle steel are welded, the lengths of the portions stretching out after the angle steel is clamped are difficult to control precisely through the clamping devices, so that the welding positions of the two sections of angle steel cannot be aligned, a gap is formed between the welding positions, and the capacity of bearing loads of the angle steel is reduced existing during current welding of any two sections of anglesteel can be solved.

Owner:王鹏

Metal pipe welding device for building construction

ActiveCN107695554AImprove resource utilizationReduce gapMetal working apparatusWelding apparatusArchitectural engineeringPipe welding

The invention discloses a metal pipe welding device for building construction, and the welding device is a device for carrying out complete and continuous welding on connection gaps through the rotation of pipes and for carrying out welding by cooperating with a situation that the pipes are pressed against and close to each other. The metal pipe welding device for the building construction is characterized in that a fixed box body is arranged on a main support plate, one end of a driving rod is arranged on the inner wall of one side of the fixed box body through a bearing, and the other end ofthe driving rod passes through the other side of the fixed box body through the bearing. Worm wheels are arranged on the driving rod and are located in the fixed box body, and two guide sleeves are respectively arranged on the main support plate and are parallel to each other. Two screws respectively penetrate through the fixed box body, and one ends of the two screws are respectively installed in the two guide sleeves on the main support plate. The screws are meshed with the worm wheels, a main vertical plate is arranged on the main support plate and is located on one side of the fixed box body. A through hole is formed in the main vertical plate, a baffle plate is arranged at one end of the main support plate, a second connecting cavity is arranged between the baffle plate and the mainvertical plate, and one end of a pressing rod passes through the through hole in the main vertical plate and is arranged between the main vertical plate and the baffle plate.

Owner:上海中巽科技股份有限公司

Welding assisting device

InactiveCN109227026AAvoid displacementPrevent rotationWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringExhaust pipe

The invention discloses a welding assisting device. The welding assisting device comprises a welding table, a welding base is fixedly arranged in the middle of the top of the welding table, a weldinghead is arranged at the top of the welding base, fixed plates are arranged at the two ends of the welding base, and are arranged in an axial symmetry manner with respect to the vertical center axis ofthe welding base, movable plates are arranged at the tops of the fixed plates, dovetail grooves are formed in the middles of the tops of the fixed plates, and dovetail sliding blocks are arranged inthe middles of the bottoms of the movable plates, are arranged in the dovetail grooves and are movably connected with the dovetail grooves. According to the welding assisting device, exhaust pipes arefixed through arc racks of left semi-rings and right semi-rings, then locking blocks on the left semi-rings and the right semi-rings are fixed through locking bolts, servo motors drive gears to rotate, and therefore arc toothed plates are driven to rotate on fixed ring sets; autorotation of the exhaust pipes can be achieved, and therefore the welding effect of the exhaust pipes is achieved.

Owner:安徽岳塑汽车工业股份有限公司

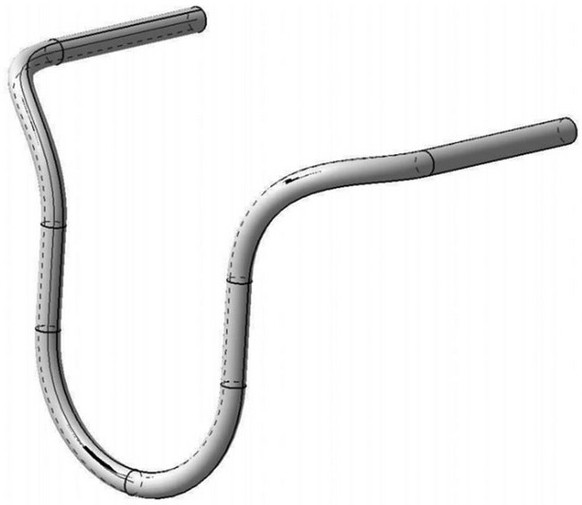

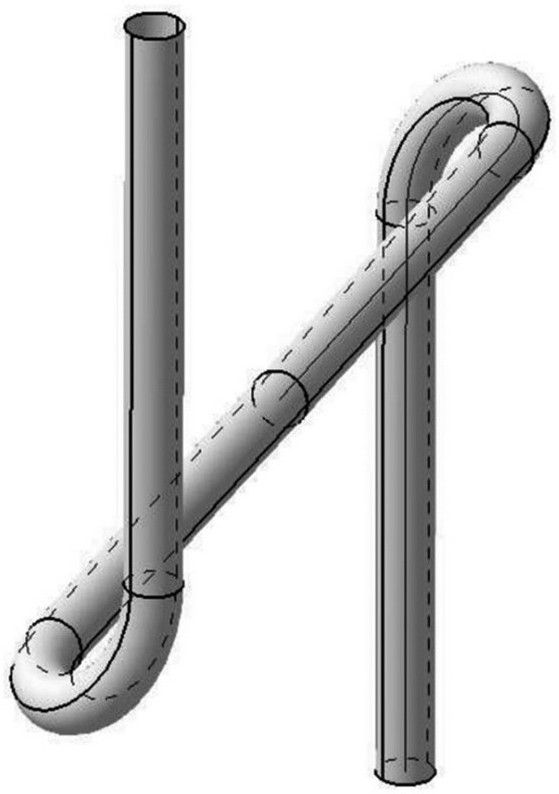

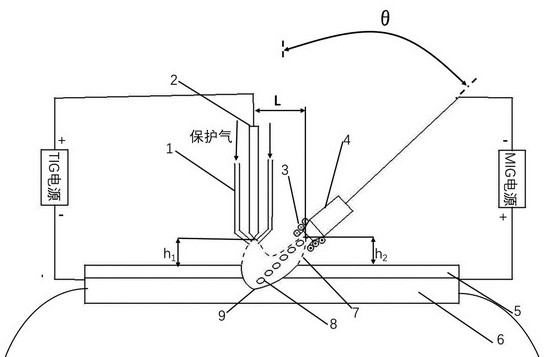

Large-size special-shaped stainless steel pipeline and efficient additive manufacturing device and method thereof

InactiveCN114515886AReduce welding efficiencyCathode spot stabilizationArc welding apparatusIncreasing energy efficiencyMetallurgyThin slab

The invention discloses a large-size special-shaped stainless steel pipeline and an efficient additive manufacturing device and method thereof, and innovatively provides a TIG + MIG double-gun electric arc additive manufacturing process, a medium carbon steel pipe base body with the surface wrapped with a layer of stainless steel thin plate is selected as a mold core, multiple sections of straight bent pipes with different lengths are prepared, grooves are prefabricated in the connecting positions of the straight pipes, and the large-size special-shaped stainless steel pipeline is manufactured. And laser deep penetration welding connection is carried out at the groove, so that the large-size special-shaped stainless steel pipeline with excellent performance is obtained.

Owner:北京煜鼎增材制造研究院股份有限公司

Elbow welding fixing fixture for engineering construction

InactiveCN108581331AImprove versatilityEasy to holdWelding/cutting auxillary devicesAuxillary welding devicesEngineeringTroffer

The invention discloses an elbow welding fixing fixture for engineering construction. The elbow welding fixing fixture comprises a bottom plate. An elbow and straight pipes are arranged on the bottomplate. The outer side face of the elbow is provided with a first arc-shaped limiting block, a second arc-shaped limiting block, a third arc-shaped limiting block and a fourth arc-shaped limiting blockfrom left to right in sequence. The bottoms of the first arc-shaped limiting block, the second arc-shaped limiting block, the third arc-shaped limiting block and the fourth arc-shaped limiting blockare all inserted into a first insertion groove. The first arc-shaped limiting block, the second arc-shaped limiting block, the third arc-shaped limiting block and the fourth arc-shaped limiting blockare all provided with grooves and protrusions. The two ends of the first arc-shaped limiting block, the two ends of the second arc-shaped limiting block, the two ends of the third arc-shaped limitingblock and the two ends of the fourth arc-shaped limiting block are all provided with handles. The elbow welding fixing fixture is provided with the first arc-shaped limiting block, the second arc-shaped limiting block and notches, the problems that a traditional elbow welding fixture cannot clamp elbows with different pipe diameters and welding is not convenient are solved.

Owner:芜湖衡西微量计量科技有限公司

Pressing mechanism used for minibus welding

InactiveCN105269223AImprove structural strengthGuaranteed flatnessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringBlock match

The invention discloses a pressing mechanism used for minibus welding. An angle base is arranged in the middle of the front of a platform, a template is installed on the angle base, and two cushion blocks are arranged in parallel on the top surface of the template and are in an L shape. A support is installed in the middle of the platform, an air cylinder is arranged on a vertical plate at the upper end of the support, a piston rod of the air cylinder is hinged to one end of a pressing arm, two pressing blocks are arranged on the bottom surface of the pressing arm, and a positioning block matched with the pressing blocks is fixed to the top surface of the vertical plate. A supporting block is arranged on the plate surface of the upper portion of the vertical plate, an electrode guiding block is installed on the top surface of the supporting block, a backing plate fixedly supports the electrode guiding block, and a connecting block is arranged over the backing plate. Firmness of clamping positioning is good, control buttons of the air cylinder are arranged on the top plate in a concentrated and clear mode, and an operation box is firmly connected with the platform to effectively prevent shaking when the buttons are operated.

Owner:CHONGQING DADONG AUTO PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com