Full life cycle tracking method for welding seam information of oil platform steel structure

A full life cycle, oil platform technology, applied in the field of full life cycle tracking of steel structure weld information on oil platforms based on QR codes, can solve problems such as poor transmission of welding information, lack of a tracking system, and low welding efficiency , to achieve the effect of convenient query, lower welding cost and low welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

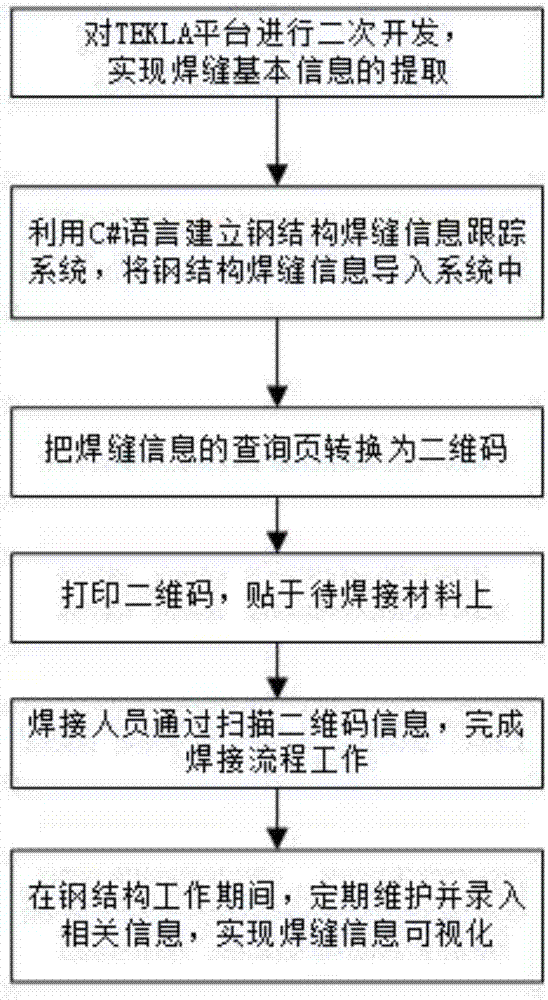

[0016] Such as figure 1 As shown, the oil platform steel structure weld information life cycle tracking method of the present invention includes the following steps:

[0017] Step 1. Use TEKLA software to model the steel structure of the oil platform, and carry out secondary development on the TEKLA platform to realize the extraction of the basic information of the weld of the steel structure model of the oil platform. The basic information of the weld includes the corresponding The drawing number, item number and weld property number of platform parts and welds, where the weld properties include weld height, length, weld leg, filling, edge trim, type, grinding and connection type;

[0018] Step 2. Use C# language to establish a steel structure weld information tracking system for oil platforms, and import the basic weld inform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com