M-shaped sizing block automatic welding equipment

An automatic welding and equipment technology, applied in welding equipment, arc welding equipment, welding accessories, etc., can solve the problems of low welding work efficiency and unstable welding quality, and achieve low welding efficiency, good welding effect, and wide automatic welding range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

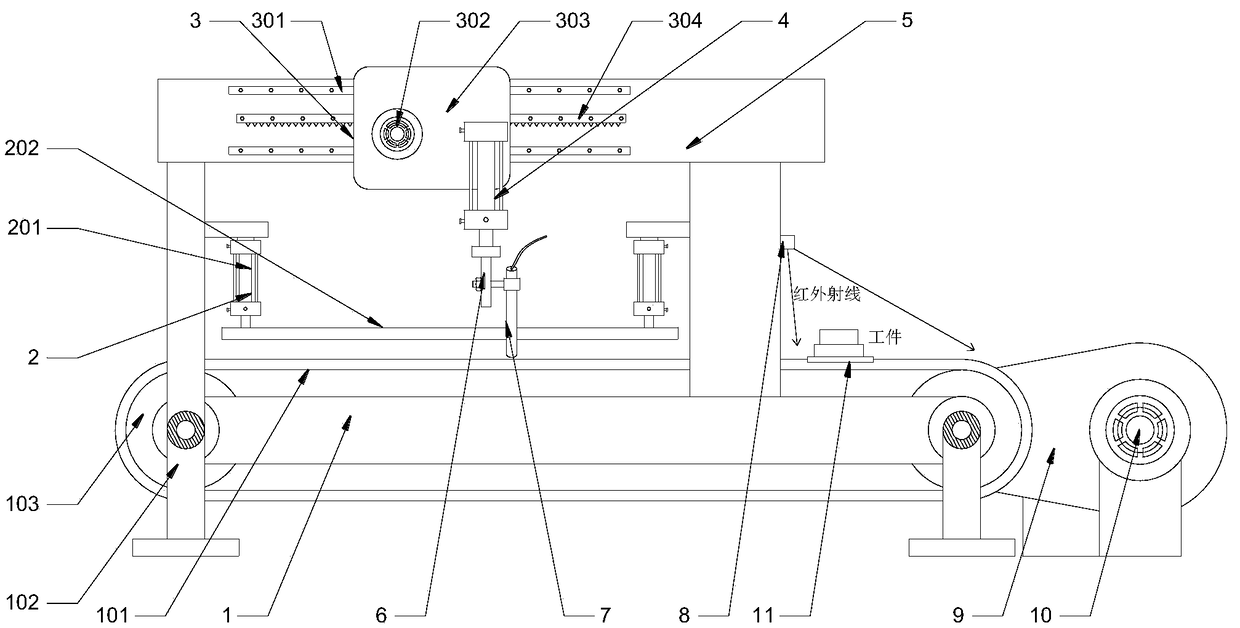

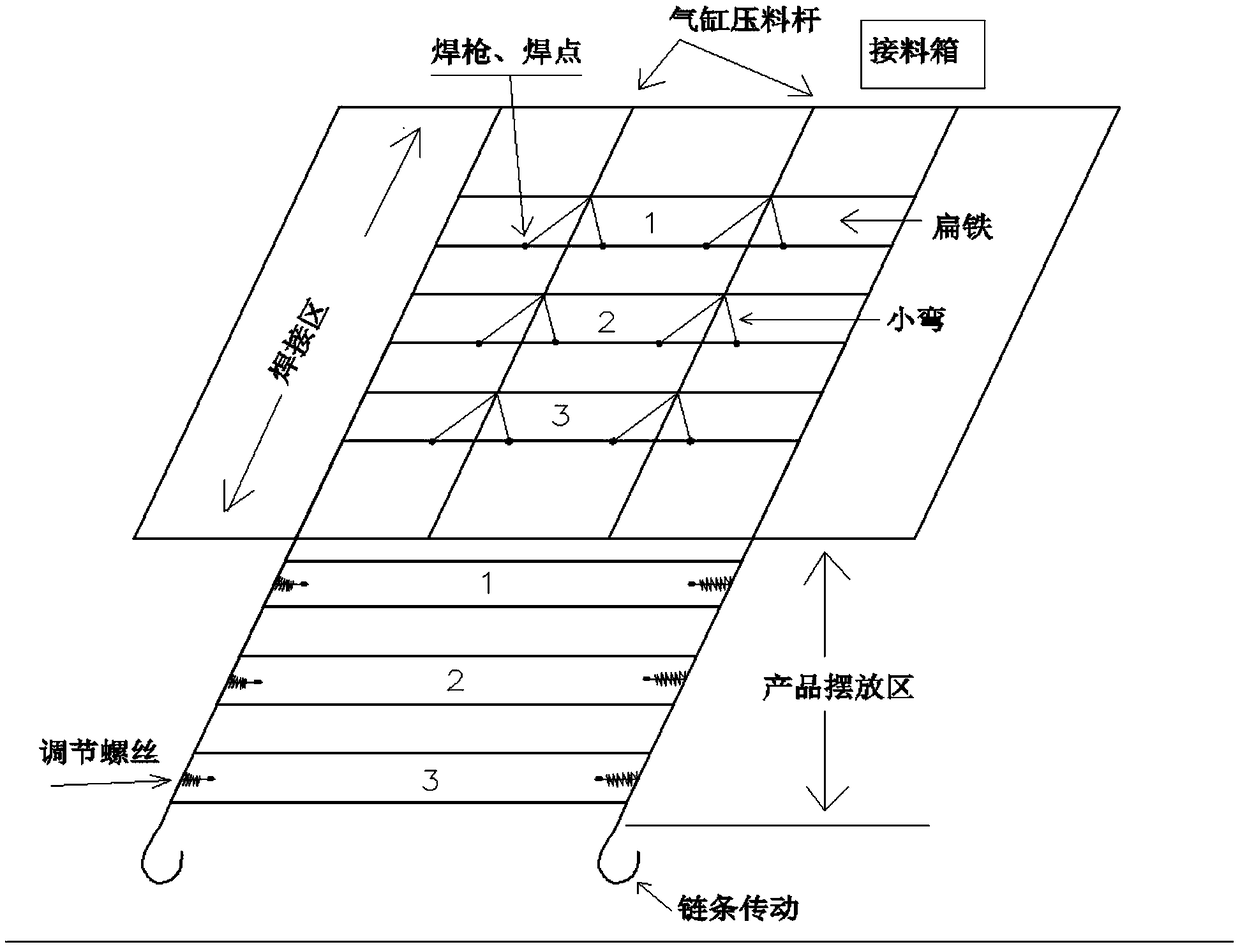

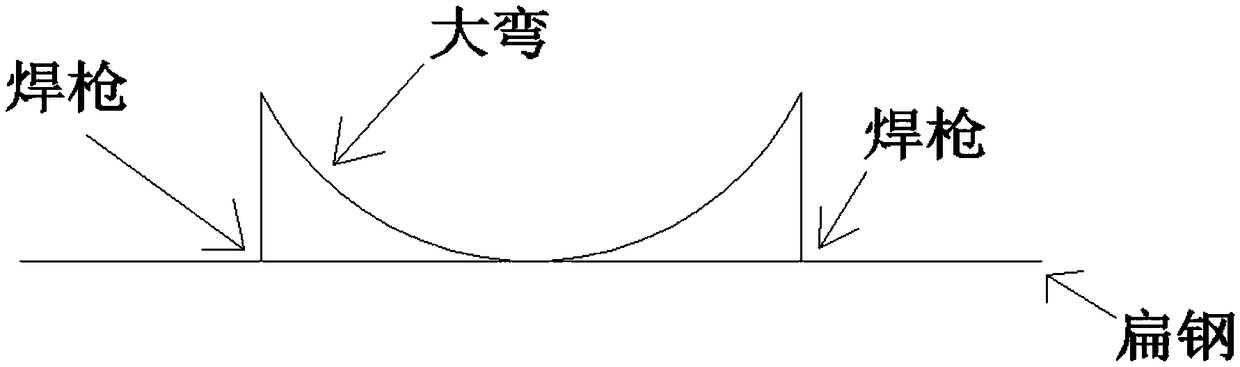

[0031] see Figure 1~4 , an M-shaped pad iron automatic welding equipment, including a welding torch 7, also includes a conveying device 1 for conveying workpieces and a pressing device 2 for pressing workpieces, a welding mobile device 3 is arranged above the conveying device 1, and the welding mobile device 3 is equipped with a welding lifting pneumatic cylinder 4 facing the transmission device 1, and the telescoping rod head of the welding lifting pneumatic cylinder 4 is connected with a welding torch mounting plate 6, and a plurality of welding torches 7 are installed on the welding torch mounting plate 6.

[0032] In the present invention, welding torch 7 can adopt conventional gooseneck welding torch 7, also can adopt pistol type welding torch 7, conveyer 1 adopts conventional chain conveyer, mesh belt conveyer, conveyer belt machine to get final product, welding mobile device 3 can Adopt the leading screw mechanism of high precision, also can adopt to use widely linear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com