Novel one-eighth sphere corner aluminum alloy end socket and manufacturing method

A manufacturing method and technology of aluminum alloy, applied in the direction of pipe/pipe joint/pipe fitting, gas/liquid distribution and storage, pressure vessel, etc., can solve the problems of easily damaged by impact, low welding efficiency, stress concentration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The content of the present invention will be described below in conjunction with specific embodiments.

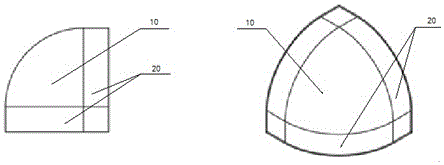

[0027] Such as figure 1 As shown, it is a new one-eighth spherical aluminum alloy head described in the present invention. The one-eighth spherical aluminum alloy head is used to replace the eight corners of the vehicle-mounted rectangular box. The eight corners of the vehicle-mounted rectangular box are replaced with eight spherical fillets 10, and straight-edge sections 20 are added to the three sides of the spherical fillets 10, so that the three sides of the spherical fillets 10 and The three sides of the vehicle-mounted rectangular box are assembled in the same plane;

[0028] The spherical fillets 10 are all one-eighth spherical fillets.

[0029] Specifically, the new one-eighth ball angle (5083-O) aluminum alloy head and its manufacturing method include the following steps:

[0030] Step 1. Mold making: Design the mold according to the specific structure an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com