A strip-head rolling method for cold continuous rolling limit thickness strip steel

A continuous cold rolling and extreme technology, applied in the direction of metal rolling, tail end control, etc., can solve problems such as regression abnormality, slow regression process speed, and low control accuracy, so as to reduce the number of broken strips, solve welding difficulties, and improve rolling The effect of control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

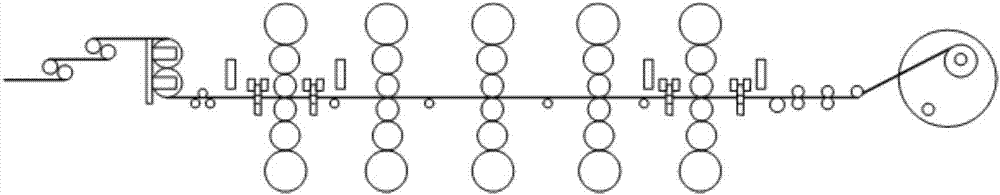

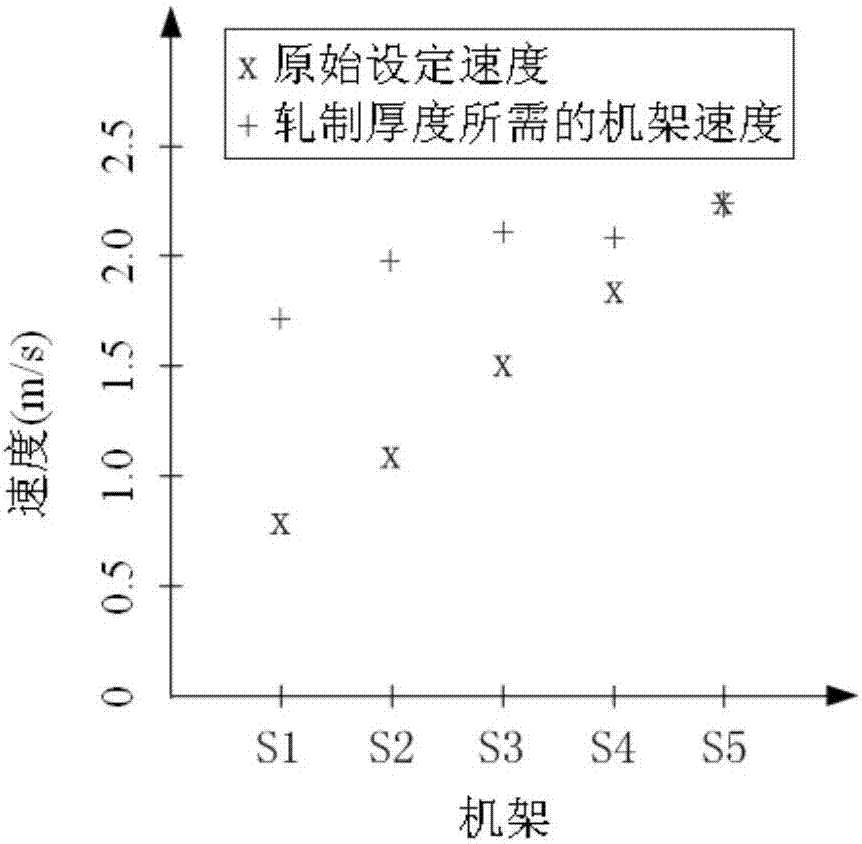

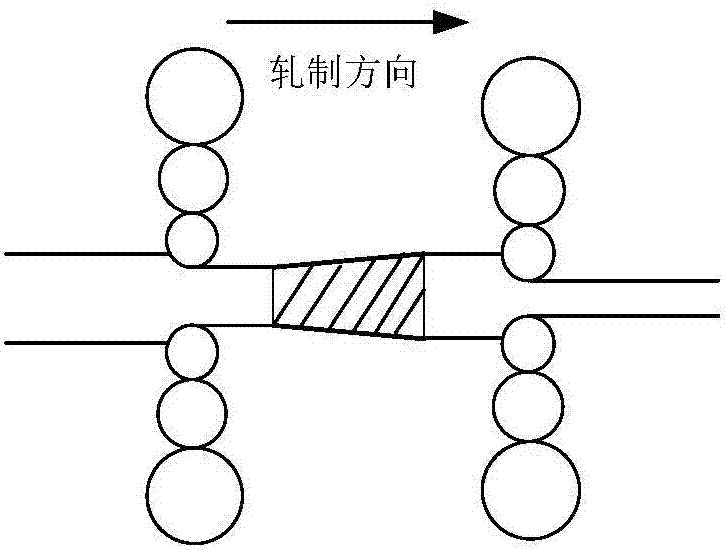

[0038] Such as figure 1 As shown, a strip-rolling method for cold-rolled limit-thickness strip steel is used as an example in a cold-rolling mill in a cold-rolling factory to produce thin-gauge cold-rolled strip products of 0.25 mm, and the strip-rolled thickness is 0.5mm, the strip width is 1250mm, and the tensile strength is 650Mpa. The specific rolling method is as follows:

[0039] (1) Start the automatic head rolling mode

[0040] When the rolling mill meets the following 3 conditions, the automatic strip rolling mode starts:

[0041] Condition 1: The thickness at the exit of the rolling mill is set to 0.25mm;

[0042] Condition 2: The strip weld is less than 12m away from the first frame;

[0043] Condition 3: Strip exit speed v=1m / s.

[0044] (2) Calculate the thickness ratio coefficient

[0045]

[0046] Substitute the value of:

[0047]

[0048] In formula (1), T G is the target thickness of strip rolling; T N Set the thickness for the outlet; A is the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com