A bridge girder plate reinforcement welding equipment

A technology for welding equipment and bridges, used in welding equipment, bridge reinforcement, auxiliary welding equipment, etc., can solve the lack of a mechanism for cleaning the butt surface of bridge plates, the inability to automatically limit and fix the bridge plates, and the lack of a mechanism for direct guidance of welding torches, etc. problems, to achieve the effect of saving trivial processes, enhancing stability, and avoiding excessive time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

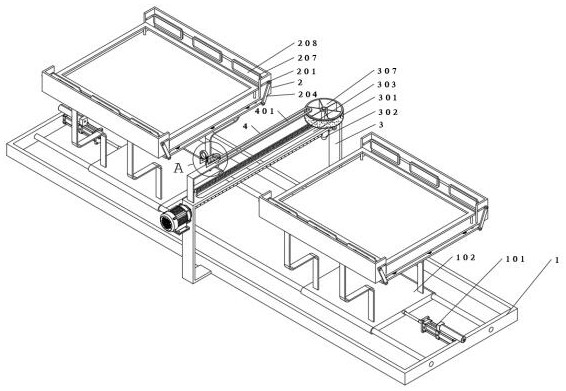

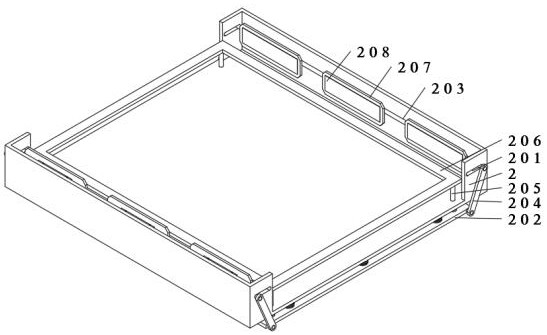

[0025] see Figure 1 to Figure 8 , an embodiment provided by the present invention: a bridge beam plate reinforcement welding equipment, comprising:

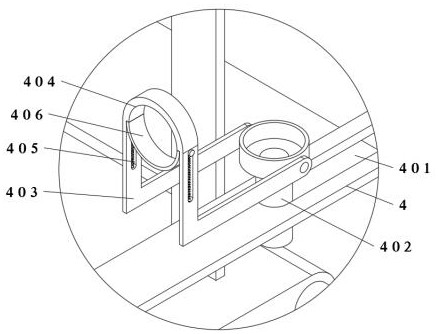

[0026] refer to figure 1 Frame body 1; frame body 1 includes: hydraulic cylinder 101, two hydraulic cylinders 101 are arranged on both sides of the interior of frame body 1; slide plate 102, two slide plates 102 are slidably installed inside frame body 1, and two slide plates The outer sides of 102 are respectively connected with the inner ends of two hydraulic cylinders 101, and the two slide plates 102 are pushed inwardly by the two hydraulic cylinders 101, so that they drive the two supporting plates 2 and the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com