Metal pipe welding device for building construction

A technology of metal pipes and welding devices, which is applied in welding equipment, metal processing, metal processing equipment, etc., can solve problems such as difficulty in matching, affecting weld integrity and welding quality, and large usage of welding rods, so as to reduce the usage , improve resource utilization, improve the effect of welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

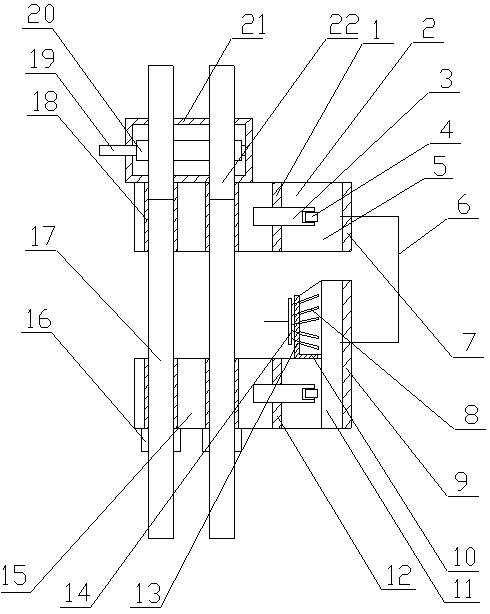

[0020] The welding device for building construction metal pipes of the present invention is realized in this way. When in use, when welding two metal pipes, first connect the drive rod (19) with the external motor and place it on the semicircular ring (10). Into a certain amount of welding slag, one end of the first metal pipe passes through the first connection cavity (11) and is placed between the arc plate (13) and the cover plate (9), and one end of the second metal pipe passes through the second connection cavity (5) Place between the arc plate (13) and the cover plate (9), and leave a certain gap between one end of the first metal pipe and one end of the second metal pipe, and push the two compression rods (3), The first metal tube and the second metal tube are respectively compressed and fixed, and a certain gap is left between one end of the first metal tube and the second metal tube and the plurality of cathode rods (8) respectively, and the first metal tube and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com