Multifunctional welding robot

A welding robot and multi-functional technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as piercing light, lack of self-moving function, and easy to produce glare, so as to avoid environmental pollution and facilitate Operate and ensure the effect of welding requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

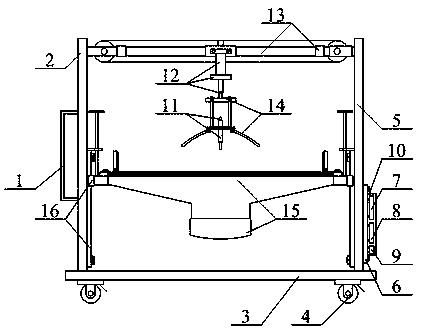

[0048] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, a multifunctional welding robot includes a U-shaped pusher 1, a main support base 2, a mobile base 3, a universal wheel with brake pads 4, an auxiliary support base 5, a circuit board 6, a host 7, a control panel 8, Master control switch 9, dustproof shield 10, welding torch 11, lifting cylinder 12, self-moving robot moving machine 13, liftable and adjustable light shield structure 14, push-pull type cleaning waste collection bucket structure 15 and liftable adjustment rod Structure 16, the bolts of the U-shaped push handle 1 are installed in the left middle position of the main support base 2; the longitudinal lower end bolts of the main support base 2 are installed in the upper left part of the mobile base 3; The wheels 4 are respectively bolted to the four corners of the bottom of the mobile base 3; the longitudinal lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com