Alternate circulation self-moving track type hydraulic support in tunnel roadway

An alternate cycle, hydraulic support technology, applied in the direction of mine roof support, mining equipment, earthwork drilling and mining, etc., can solve the problems of single transportation direction, hidden safety hazards, easy to run cars, etc., to achieve flexible movement, easy installation and disassembly, and improved The effect of endurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

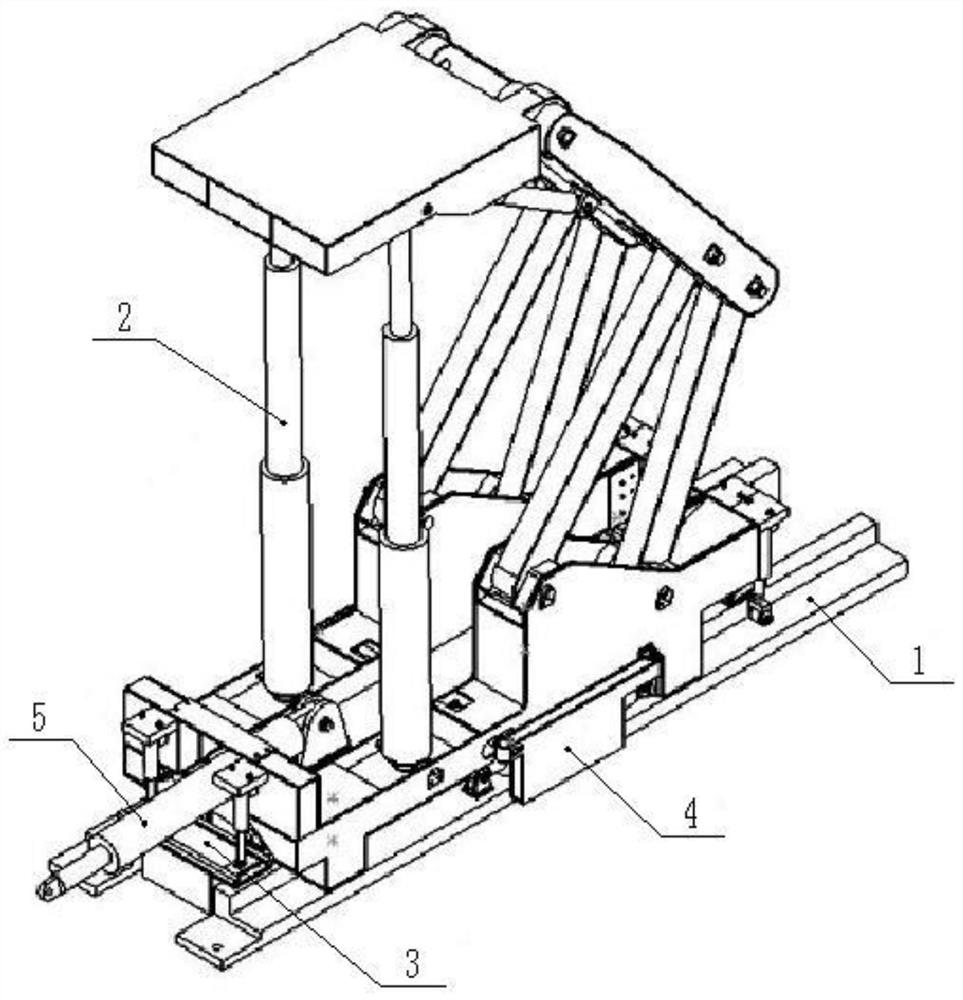

[0033] Such as figure 1 As shown, the present invention is an alternate cycle self-moving track-type hydraulic support in a tunnel roadway, including a stepping structure 1, a lifting support structure 2, a steering structure 3, an anti-rolling structure 4 and a traction jack 5;

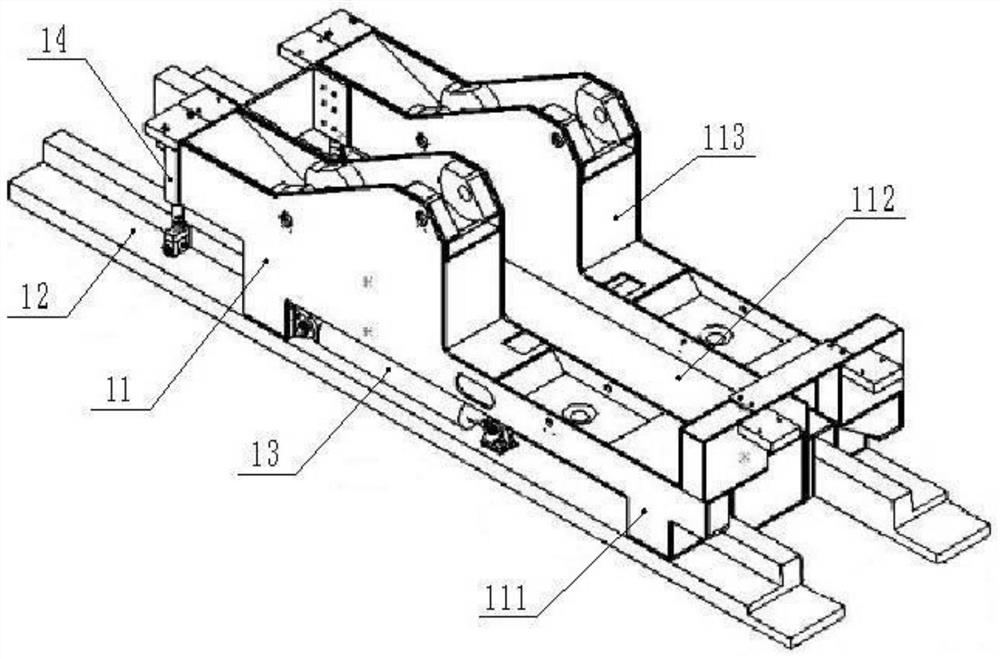

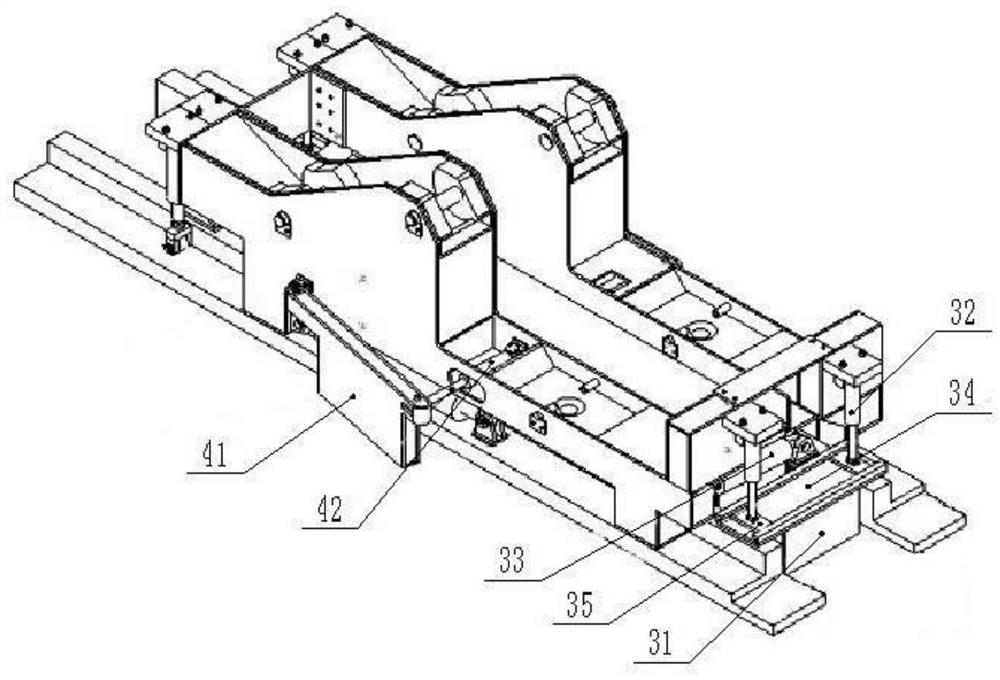

[0034] The stepping structure 1 comprises a support base 11, a track 12, a pushing jack 13 and a lifting jack 14, two tracks 12 are arranged in parallel, the support base 11 is placed on the two tracks 12 and the bottom of the support base 11 contacts the ground, and the two tracks 12 are arranged in parallel. Two moving jacks 13 are installed corresponding to two rails 12, and one end is hinged on the support base 11, and the other end is hinged on the track 12. Rollers 15 are installed downwards and at the ends, and the rollers 15 of the two lifting jacks 14 face the two rails 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com