Electrocoppering method for TC2 titanium alloy

A titanium alloy and copper electroplating technology, applied in the field of TC2 titanium alloy copper electroplating, can solve the problems of inactivity, peeling and cracking of the film layer, and achieve the effects of improving comprehensive performance, improving electrical conductivity and preventing contact corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 A kind of method of TC2 titanium alloy electroplating copper

[0026] (1) including the following steps:

[0027] 1) Use corundum sand with a particle size not greater than 60 mesh to perform sandblasting on TC2 titanium alloy, and the sandblasting pressure is 0.4MPa;

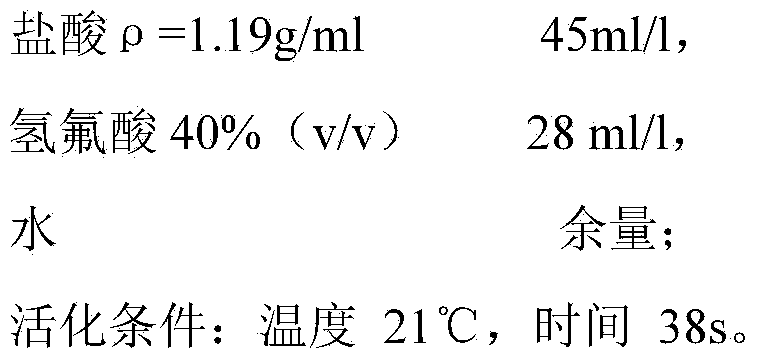

[0028] 2) Activate the TC2 titanium alloy after sandblasting in the following acidic solution and conditions, so that the surface of the TC2 titanium alloy is removed to a thickness of 4-5 μm, and the solution is prepared before each use.

[0029]

[0030] 3) Place the activated TC2 titanium alloy in a mixed solution of sulfuric acid and hydrochloric acid at a temperature of 18-25°C for 30min to 60min for hydrogenation treatment. The solution is prepared before each use. The mixed solution of sulfuric acid and hydrochloric acid is specifically:

[0031] Sulfuric acid ρ=1.84g / ml500g / L,

[0032] Hydrochloric acid ρ=1.19g / ml210g / L,

[0033] water balance.

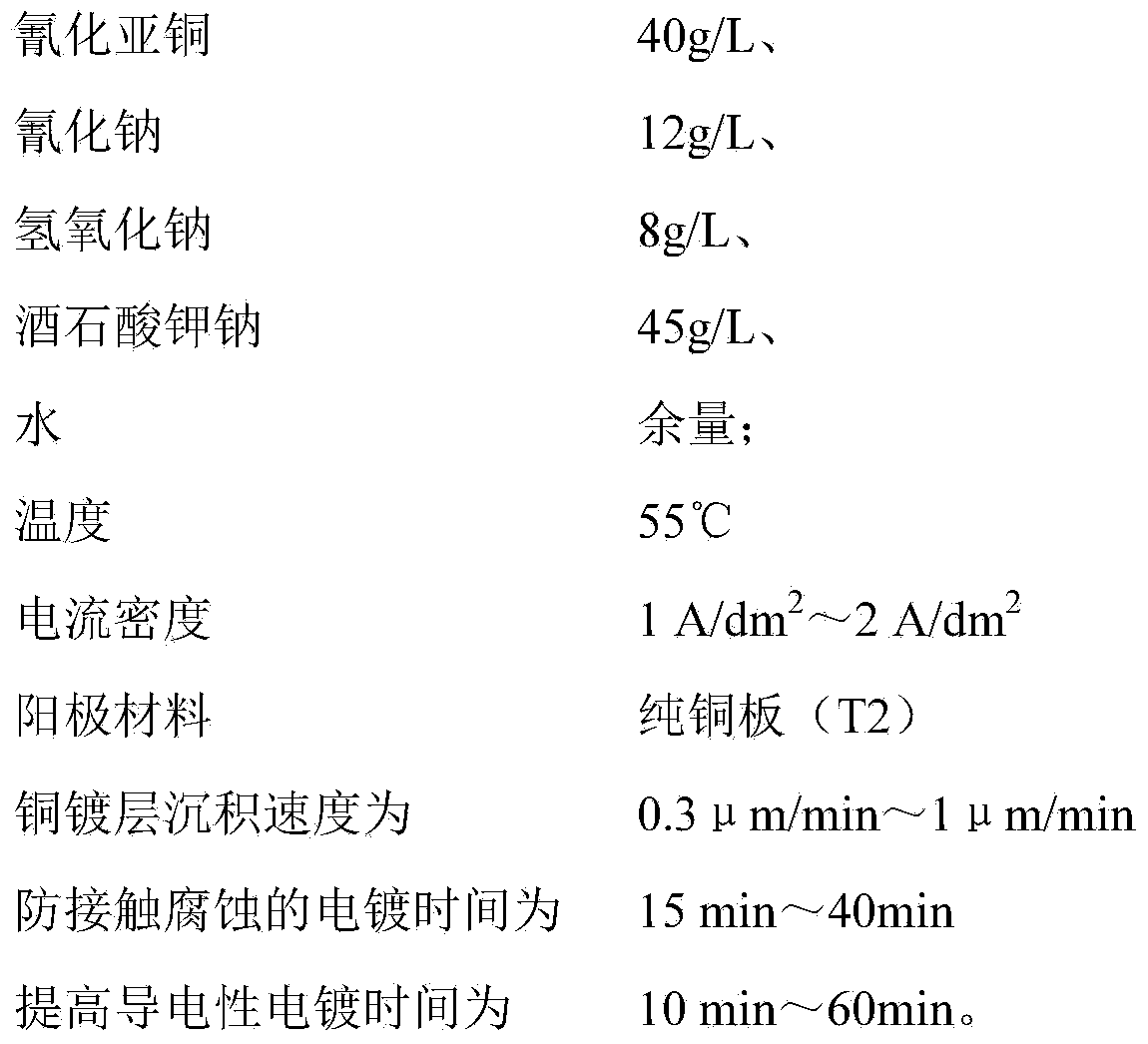

[0034] 4) Copper plating is pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com