Calcium barium zirconate titanate base piezoceramics and preparation method thereof

A technology of barium calcium zirconate titanate and electric ceramics, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problems of poor process performance of high-performance barium titanate ceramics, and achieve production Low cost, simple process flow, and enhanced piezoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

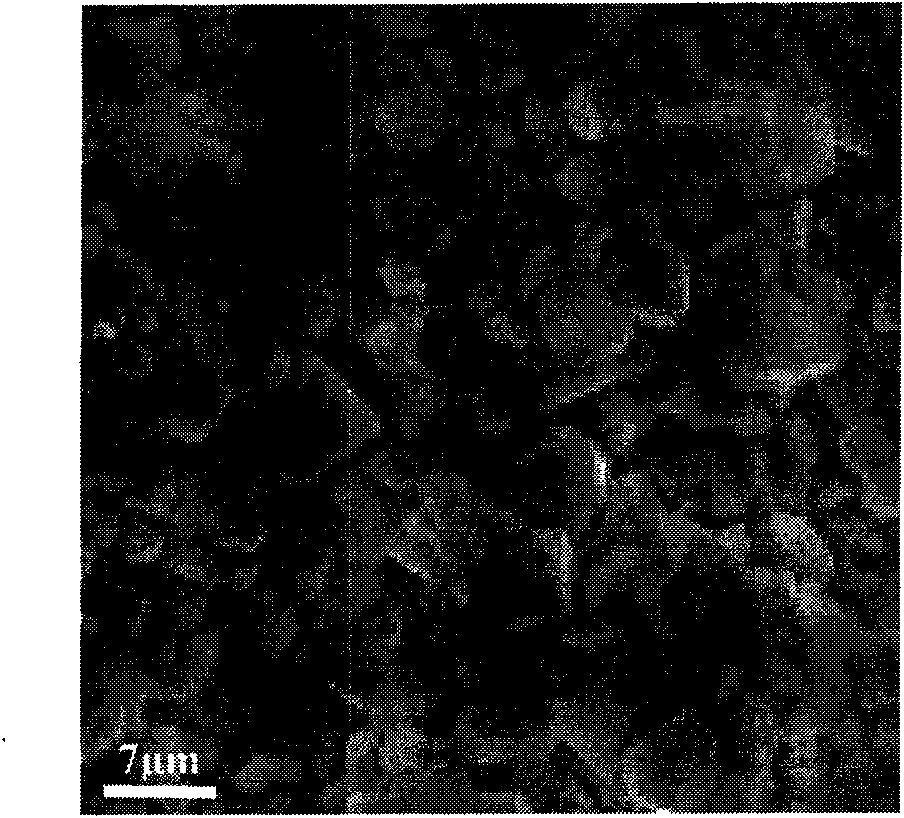

Image

Examples

Embodiment 1

[0022] With the barium carbonate whose mass percentage content is 99.9%, the calcium carbonate that the mass percentage content is 99.8%, the titanium dioxide that the mass percentage content is 98.0%, and the zirconium dioxide that the mass percentage content is 99.0%, the stoichiometric ratio is 0.76 BaTiO 3 -0.12CaTiO 3 -0.12BaZrO 3 Weigh ingredients. The prepared materials are put into a ball mill and mixed according to the ratio of zirconia balls:materials at 10:1, and no other medium is added during the mixing process. The time of ball milling is 6 hours, and the rotating speed is 400 rpm. The mixed material briquette is pre-fired at 1250°C for 2 hours, the calcined material is taken out and ground, and then passed through a 40-mesh sieve after ball milling for 6 hours. The ball milling speed is 400 rev / min; add the powder to its mass ratio of 32% pure water, mass ratio of 1.2% polyacrylic acid ammonia dispersant and mass ratio of 0.8% polyvinyl alcohol binder, and mi...

Embodiment 2

[0024] The barium carbonate whose mass percentage content is 99.9%, the calcium carbonate whose mass percentage content is 99.8%, the titanium dioxide whose mass percentage content is 98.0%, and the zirconium dioxide whose mass percentage content is 99.0% are used to analyze the pure grade, and the stoichiometric ratio is 0.75 BaTiO 3 -0.15CaTiO 3 -0.1BaZrO 3 Weigh ingredients. The prepared materials are put into a ball mill and mixed according to the ratio of zirconia balls:materials at 15:1, and no other medium is added during the mixing process. The time of ball milling is 6 hours, and the rotating speed is 350 rpm. The mixed material briquette is pre-fired at 1250° C. for 2 hours. The calcined material is taken out and ground, and then ball milled for 6 hours and passed through a 40-mesh sieve. The ball milling speed is 350 rev / min; add the powder to the pure water with a mass ratio of 30%, the polyacrylic acid ammonia dispersant with a mass ratio of 1.1%, and the polyv...

Embodiment 3

[0026] It is 99.9% barium carbonate, 99.8% calcium carbonate, 98.0% titanium dioxide and 99.0% zirconia of 99.0% by mass, and the stoichiometric ratio is 0.74 BaTiO 3 -0.18CaTiO 3 -0.08BaZrO 3Weigh ingredients. The prepared materials are put into a ball mill and mixed according to the ratio of zirconia balls:materials at 8:1, and no other medium is added during the mixing process. The time of ball milling is 6 hours, and the rotating speed is 450 rpm. The mixed material briquette is pre-fired at 1250°C for 2 hours, the calcined material is taken out and ground, and then passed through a 40-mesh sieve after ball milling for 6 hours. The ball milling speed is 450 rpm; add the powder to its mass ratio of 40% pure water, mass ratio of 1% polyacrylic acid ammonia dispersant and mass ratio of 1% polyvinyl alcohol binder, and mix it evenly by ball milling for 2 hours to form a material Slurry, the ball milling speed is 80 rev / min, and air spray granulation is adopted; the powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com