Silver paste for multilayer wiring of low-temperature co-fired low-dielectric-constant dielectric ceramic

A low dielectric constant, dielectric ceramic technology, applied in the field of materials, can solve problems such as unsuitable co-firing temperature, sintering mismatch, etc., and achieve the effect of eliminating silver diffusion phenomenon, clear pattern and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

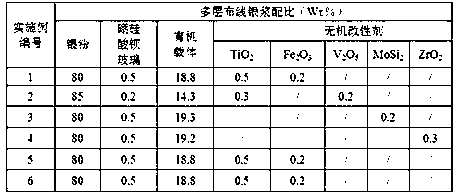

Examples

Embodiment 1

[0037] Sampling according to the following mass percentages: spherical silver powder 80wt%, aluminum borosilicate barium glass powder 0.5wt%, inorganic modifier TiO 2 0.5wt%, Fe 2 o 3 0.2wt%, organic vehicle 18.8wt%. The D50 of the spherical silver powder is 2.3 μm, and the tap density is 4.9 g / cm3. The preparation method is as described above. The prepared slurry has a viscosity of 260±50dPa ▪S, a slurry fineness≦8μm, and a solid content of 81.2%. It is used to make four-layer co-fired test samples, and the test results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com