Instant ceramic heating tube and processing technology thereof

A technology of ceramic heating tube and processing technology, applied in the direction of heating element shape, etc., can solve the problems of slow heating speed, large energy consumption, low safety performance, etc., and achieve the effect of fast heating speed, fast heat dissipation and easy composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

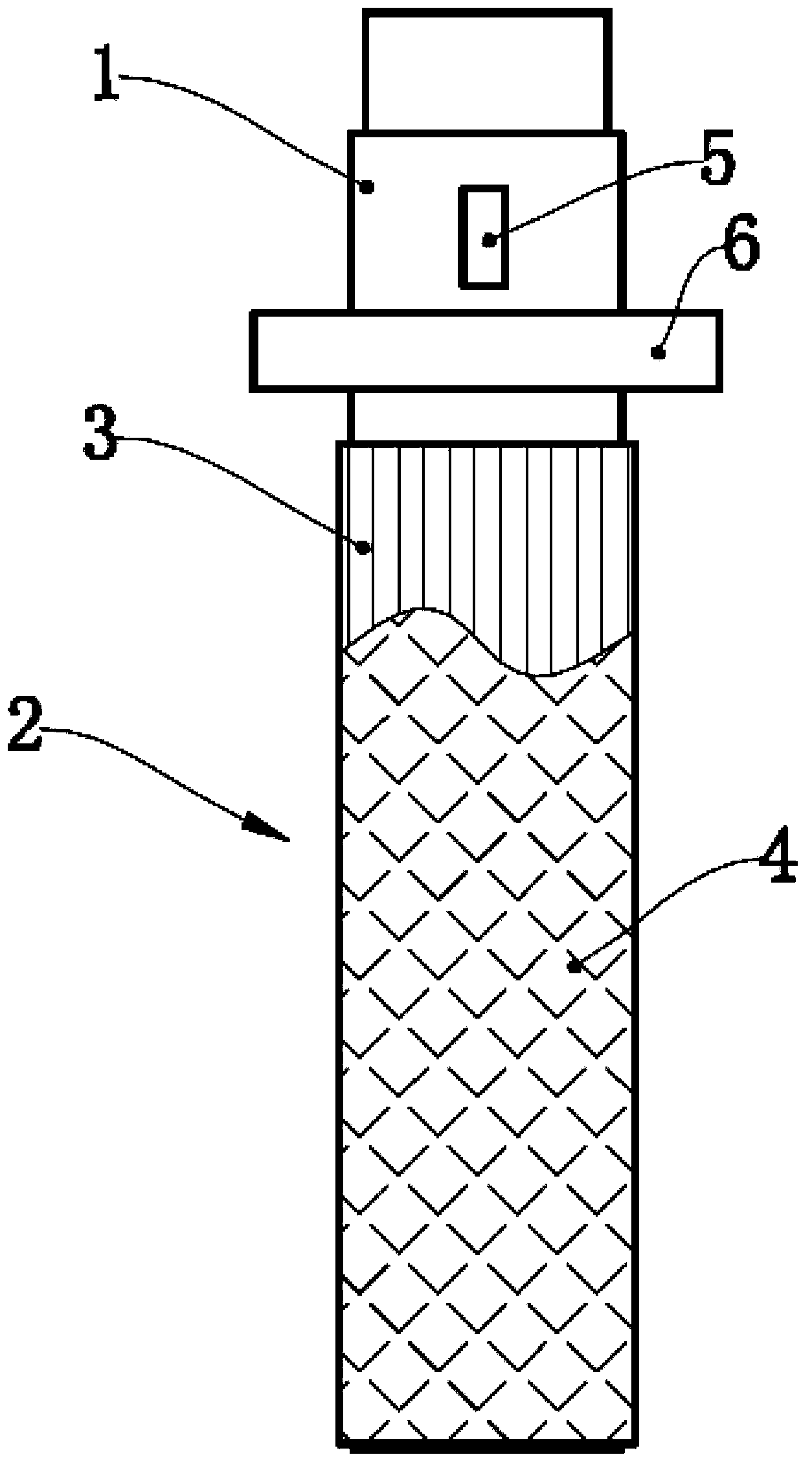

Image

Examples

Embodiment 1

[0046] A processing technology for an instant heating ceramic heating tube, comprising the following steps:

[0047] S1. Ceramic Rod Preparation

[0048] The ceramic rod includes the following raw materials:

[0049] α-alumina 93.5kg

[0050] Suzhou soil 1.55kg

[0051] Calcium Carbonate and SiO 2 Mixture 2.65kg

[0052] Yttrium oxide 0.3kg

[0053] Zirconia 2kg

[0054] The overall process of the process steps is: raw material processing—baking—ingredients—ball milling—wax adding and stirring—wax cake making—molding—blank inspection—wax removal and biscuit—semi-finished product inspection, wherein 11.3kg of wax is added after the raw materials are mixed and ball milled hot pressing at 60°C and bisque firing at 1350°C to form the ceramic rod;

[0055] S2. Preparation of resistive film

[0056]Alumina green ceramic sheets for resistive film include the following raw materials:

[0057] α-alumina 93kg

[0058] Suzhou soil 1kg

[0060] A...

Embodiment 2

[0067] A processing technology for an instant heating ceramic heating tube, comprising the following steps:

[0068] S1. Ceramic Rod Preparation

[0069] The ceramic rod includes the following raw materials:

[0070] α-alumina 93.5kg

[0071] Suzhou soil 1.55kg

[0072] Calcium Carbonate and SiO 2 Mixture 2.65kg

[0073] Yttrium oxide 0.3kg

[0074] Zirconia 2kg

[0075] The overall process of the process steps is: raw material processing—baking—ingredients—ball milling—wax adding and stirring—wax cake making—molding—blank inspection—wax removal and biscuit—semi-finished product inspection, wherein 11.3kg of wax is added after the raw materials are mixed and ball milled hot pressing at 60°C and bisque firing at 1350°C to form the ceramic rod;

[0076] S2. Preparation of resistive film

[0077] Alumina green ceramic sheets for resistive film include the following raw materials:

[0078] α-alumina 96kg

[0079] Suzhou soil 2kg

[0080] Calcium carbonate 3kg

[0081] ...

Embodiment 3

[0088] A processing technology for an instant heating ceramic heating tube, comprising the following steps:

[0089] S1. Ceramic Rod Preparation

[0090] The ceramic rod includes the following raw materials:

[0091] α-alumina 93.5kg

[0092] Suzhou soil 1.55kg

[0093] Calcium Carbonate and SiO 2 Mixture 2.65kg

[0094] Yttrium oxide 0.3kg

[0095] Zirconia 2kg

[0096] The overall process of the process steps is: raw material processing—baking—ingredients—ball milling—wax adding and stirring—wax cake making—molding—blank inspection—wax removal and biscuit—semi-finished product inspection, wherein 11.3kg of wax is added after the raw materials are mixed and ball milled hot pressing at 60°C and bisque firing at 1350°C to form the ceramic rod;

[0097] S2. Preparation of resistive film

[0098] Alumina green ceramic sheets for resistive film include the following raw materials:

[0099] α-alumina 95kg

[0100] Suzhou soil 1.5kg

[0101] Calcium carbonate 2kg

[0102...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com