Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Small deformation at high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

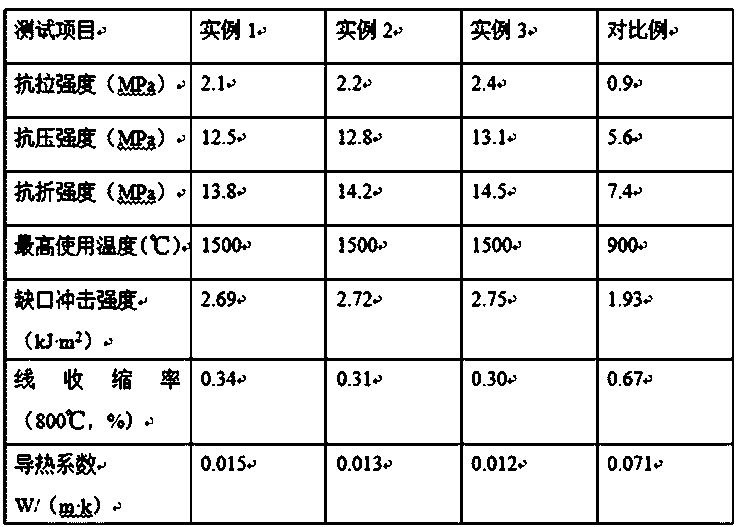

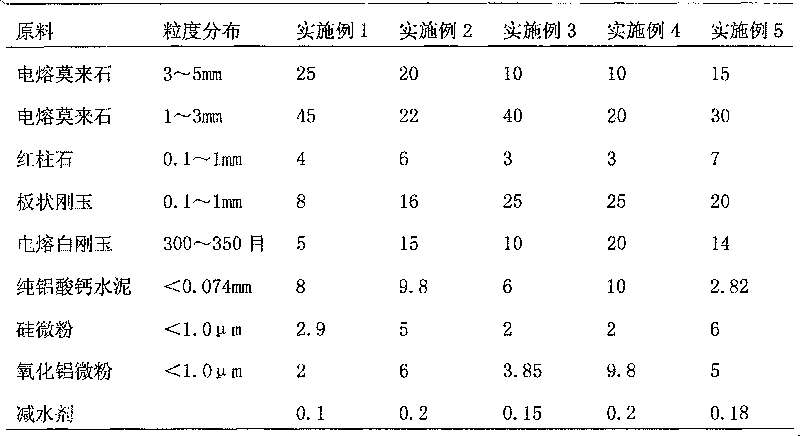

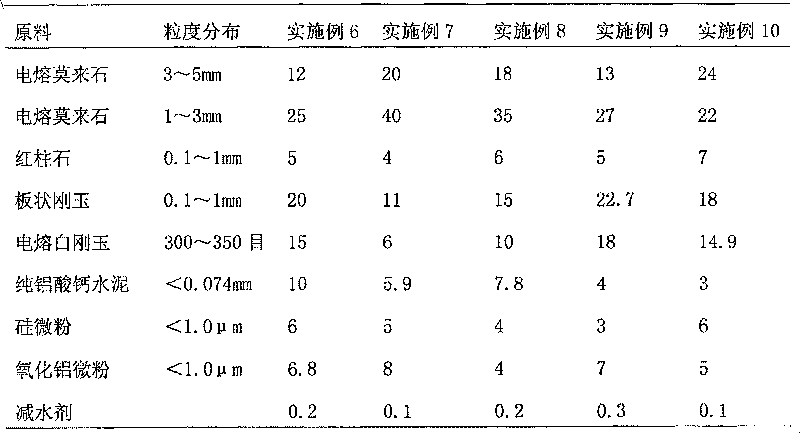

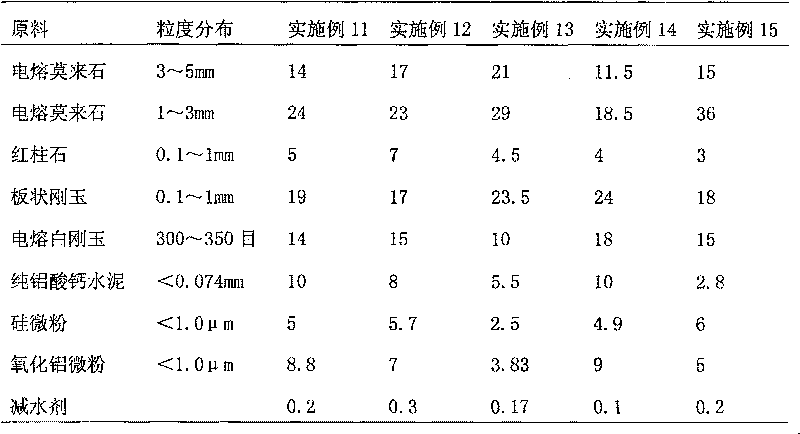

Pouring material for producing high-temperature ceramic abrasion-proof lining body

The invention relates to a castable for preparing a high-temperature ceramic wear-resistant lining, which contains 10-25% of fused mullite with a particle size of 3-5mm, and 20-45% of fused mullite with a particle size of 1-3mm. 3-7% of andalusite with a particle size of 0.1mm-1mm, 8-25% of platy corundum with a particle size of 0.1-1mm, 5-20% of fused white corundum with a particle size of 0.1-1mm, 5-20% of fused white corundum, and pure calcium aluminate with a particle size of <0.074mm 2-10% of cement, 2-6% of silicon micropowder, and 2-10% of alumina micropowder. The castable can be applied to the intersection of blast furnace hot air pipe and air supply branch pipe, etc. where thermal shock stability is high. The lining made of it has good thermal stability, high temperature air erosion resistance, good thermal shock resistance, It has the advantages of long life cycle, simple manufacturing method, short construction period, environmental protection and pollution-free, low cost, and easy industrial production.

Owner:HENAN HAOYUNXIANG REFRACTORY MATERIAL CO LTD

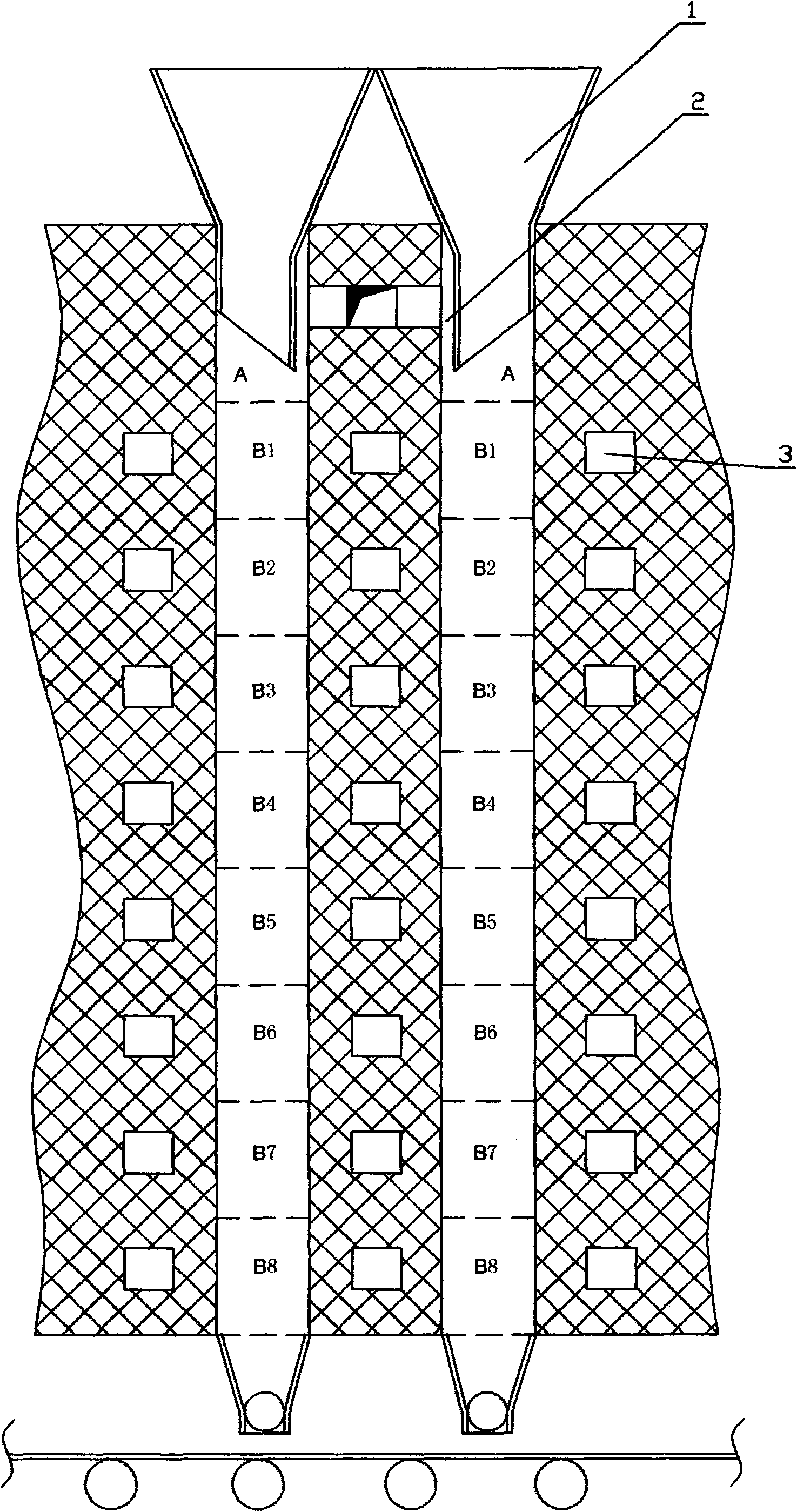

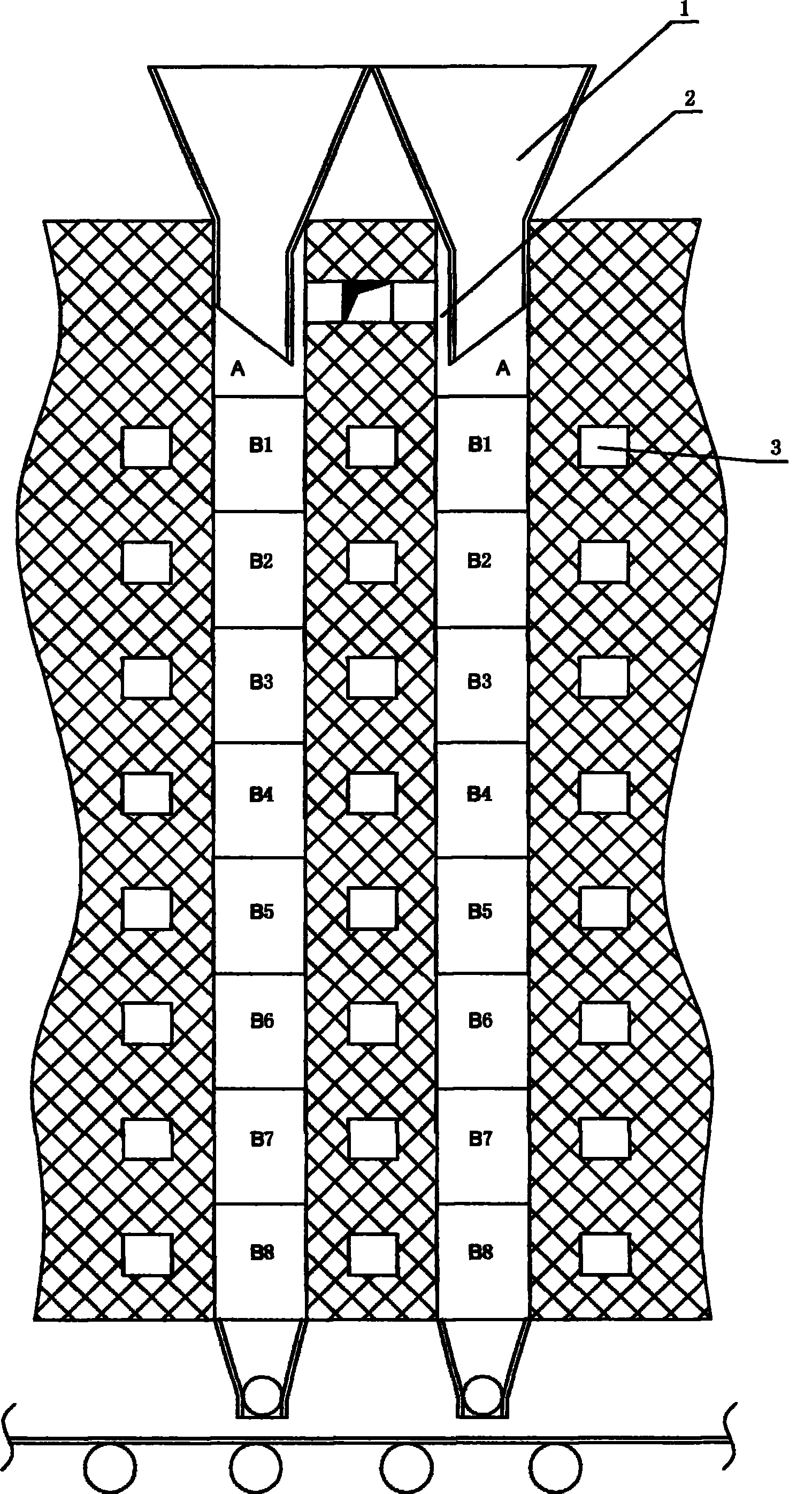

Process for calcining petroleum coke

The invention discloses a process for calcining petroleum coke. The calcination of the petroleum coke is carried out in a tank type calcining furnace, and the tank body of the tank type calcining furnace is provided with a preheating zone and 6-8 calcining zones sequentially from top to bottom, wherein the calcining temperature of the first calcining zone at the uppermost part is controlled in the maximum calcining temperature interval allowed by the petroleum coke; the calcining temperature of the second calcining zone in the downstream position of the first calcining zone is kept in the maximum calcining temperature interval and is not higher than the calcining temperature of the first calcining zone; starting from the third calcining zone, the calcining temperature of each calcining zone gradually reduces relative to the calcining temperature of the adjacent calcining zone in the upstream position; and in the undermost calcining zone, the calcining temperature is reduced to the discharging temperature. In the invention, when the petroleum coke is calcined, the high temperature zone is positioned at the top end of the calcining furnace, thereby relieving the high temperature deformation phenomenon of the furnace body, being more favorable for overflow of combustible gas in the petroleum coke, reducing the corrosion of the combustible gas on wall bricks, and being favorable for prolonging the service life of the tank type furnace.

Owner:WEIFANG LIANXING NEW MATERIAL TECH

Brake disc and preparation method thereof

The invention discloses a brake disc. The brake disc is used for a brake system of a motor vehicle, rail traffic and an aircraft. The brake disc comprises a brake disc body; the brake disc body is analuminium alloy brake disc body; a wear resistant layer is compounded on each of the two working surfaces of the aluminium alloy brake disc body; the wear resistant layers are ceramic-high temperatureresistant metal composite reinforcement material wear resistant layers; the ceramic-high temperature resistant metal composite reinforcement material wear resistant layers are metallurgical combinedwith the aluminium alloy brake disc body through an extruding casting process; the brake disc disclosed by the invention is light in weight, high in strength, good in wear resistance, good in radiating property and long in service life; the weight and the service life of the brake disc are close that those of a carbon-ceramic brake disc; the machining cost and the maintenance cost are low; the service life is over three hundred thousand kilometres; the using cost is close to ductile iron brake disc; the passage capacity of the motor vehicle, the rail traffic and the aircraft can be improved, and the brake distance can be shortened; the safety is improved; and the brake disc is suitable for large-batch production.

Owner:NINGBO HIGHRISE NEW MATERIAL CO LTD

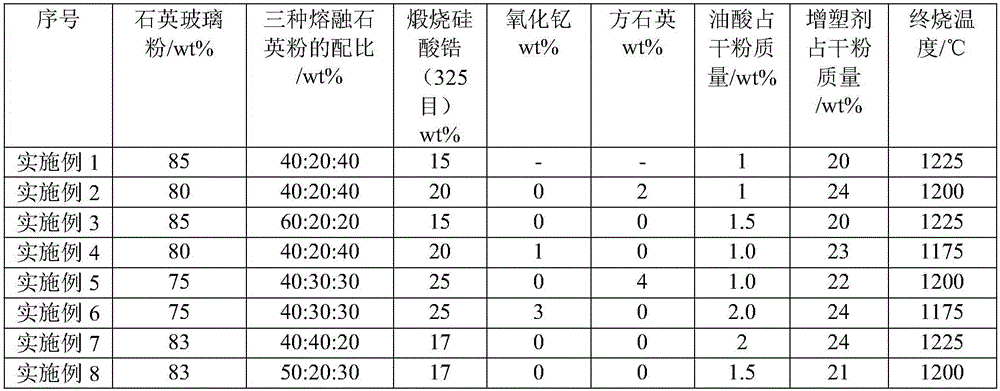

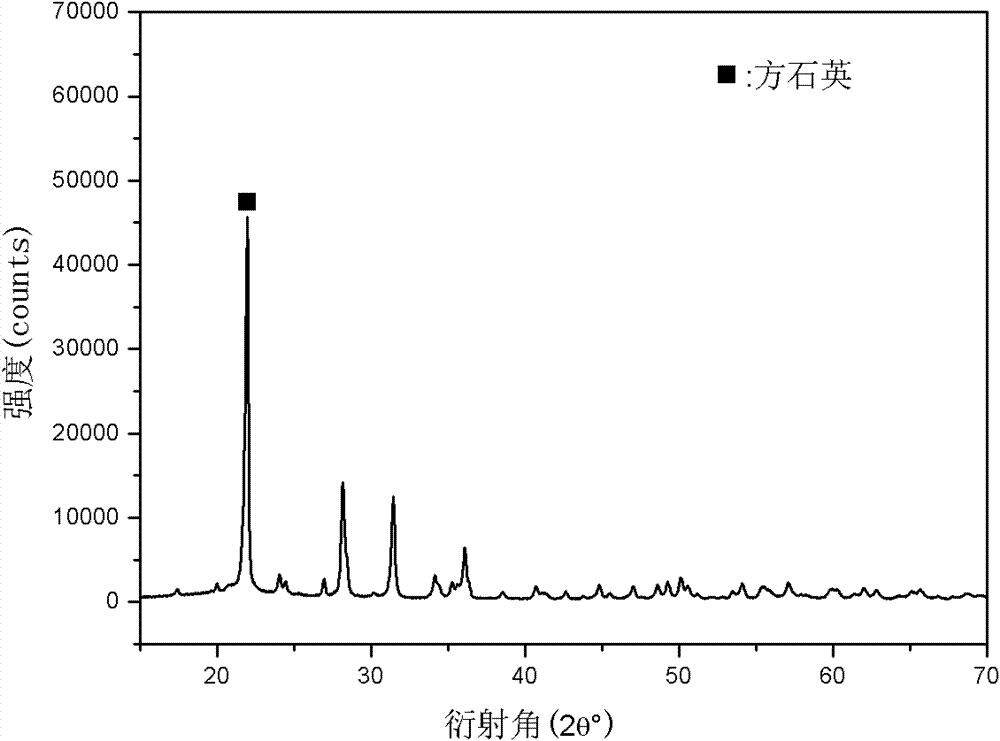

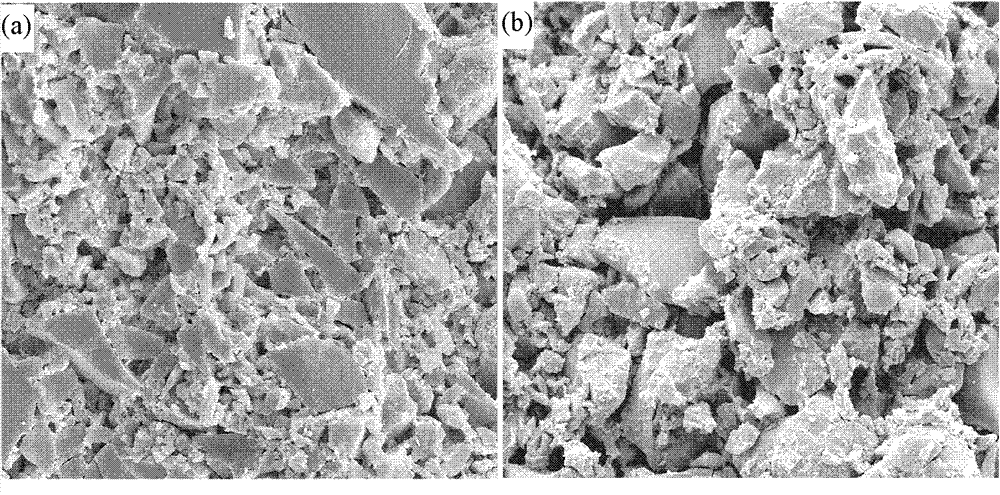

Silica-based ceramic mold core and preparation method thereof

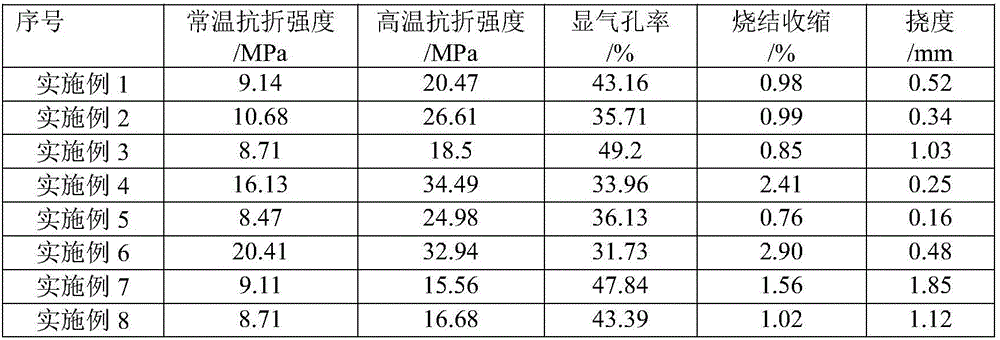

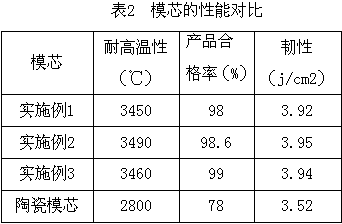

ActiveCN106747369ASmall deformation at high temperatureSmall sintering shrinkageUltimate tensile strengthSintering shrinkage

The invention provides a silica-based ceramic mold core and a preparation method thereof. The silica-based ceramic mold core and the preparation method are used for solving the problems of insufficient high-temperature intensity, great high-temperature deflection and the like of the silica-based ceramic mold core in the prior art. The invention provides the silica-based ceramic mold core with high high-temperature intensity, low high-temperature deformation and low sintering shrinkage, and the preparation method.

Owner:成都航大新材料有限公司

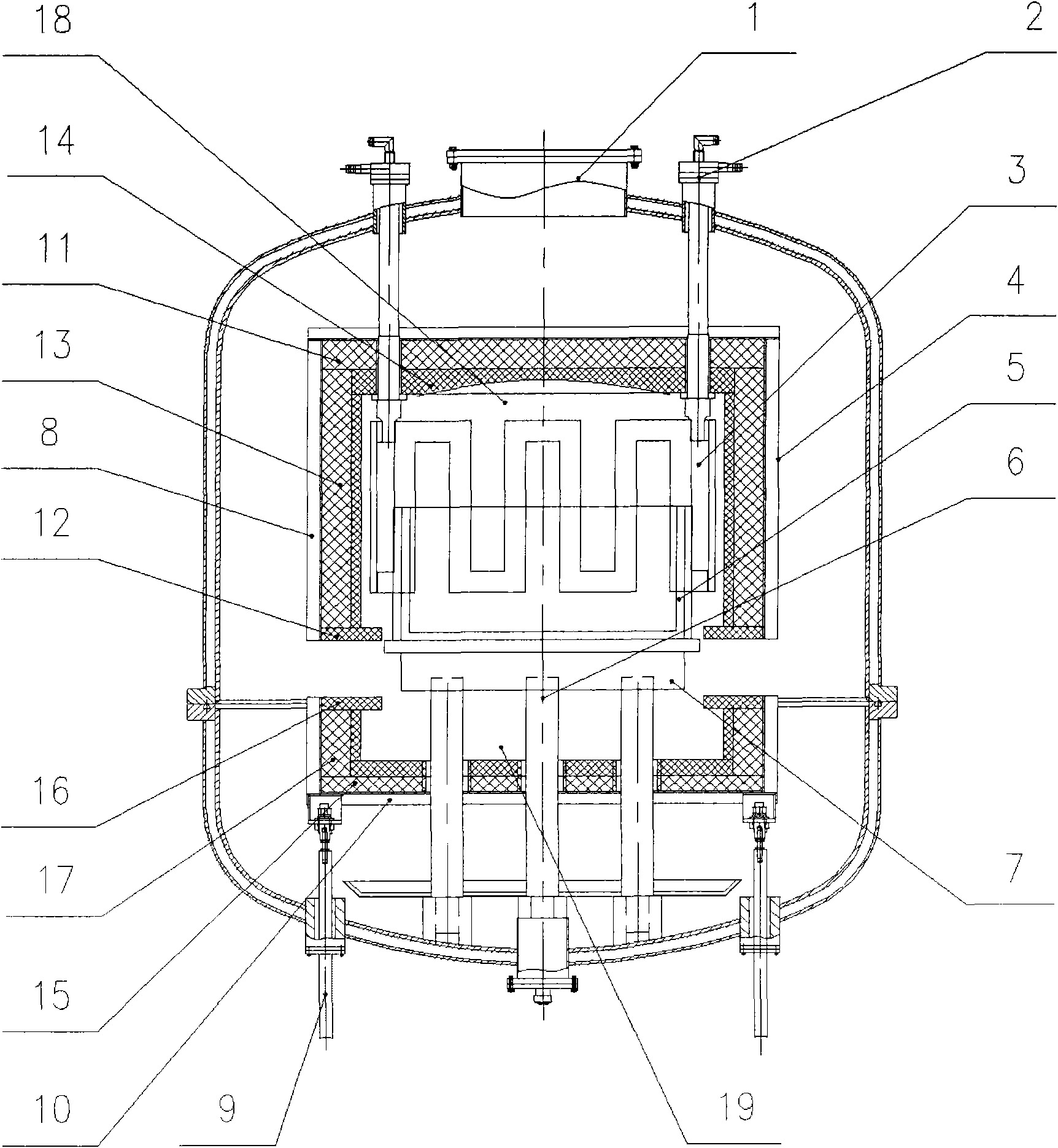

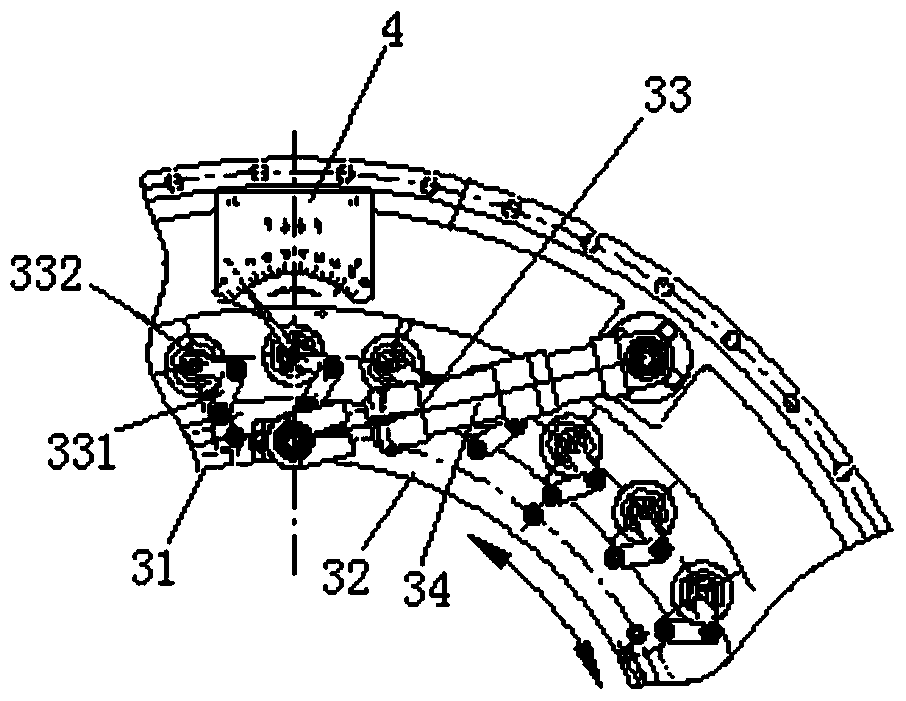

Crystalline silicon ingot furnace thermal field structure with two-stage thermal insulation cage

InactiveCN102002755ASmall deformation at high temperatureReduce Silicon LeakagePolycrystalline material growthSingle crystal growth detailsThermal insulationEngineering

The invention relates to a crystalline silicon ingot furnace thermal field structure with a two-stage thermal insulation cage. The thermal insulation cage has a two-stage structure, and consists of an upper thermal insulation cage fixed on the top of the furnace and a lower thermal insulation cage fixed on a lifting device at the bottom of the furnace; the upper thermal insulation cage is an inverted bucket, and consists of a top insulation board and an upper insulation cylinder of which the lower edge is provided with an L-shaped inner-turned upper insulation ring, wherein the top insulation board and the upper insulation cylinder are connected with each other into a whole and the inner surface of the top insulation board is provided with a concave arc reflector; the lower thermal insulation cage is an upright bucket, consists of a bottom insulation board and a lower insulation cylinder of which the upper edge is provided with an L-shaped inner-turned lower insulation ring, and is fixed on the lifting device controlled externally at the bottom of the furnace, wherein the bottom insulation board and the lower insulation cylinder are connected with each other into a whole; and the upper and lower insulating rings separate the inner cavity of the thermal insulation cage into an upper high-temperature area and a lower high-temperature area. The thermal field required by the production of the crystalline silicon is realized by adjusting the lift opening of the lower insulation cage through the lifting device; and the structure has the advantages that: the structure is simple and reasonable and obviously saves energy, the established thermal field has high stability and repeatability, the temperature is difficultly interfered by air disturbance and the structure has high practicability.

Owner:SHANGHAI CHEN HUA ELECTRIC FURNACE CORP

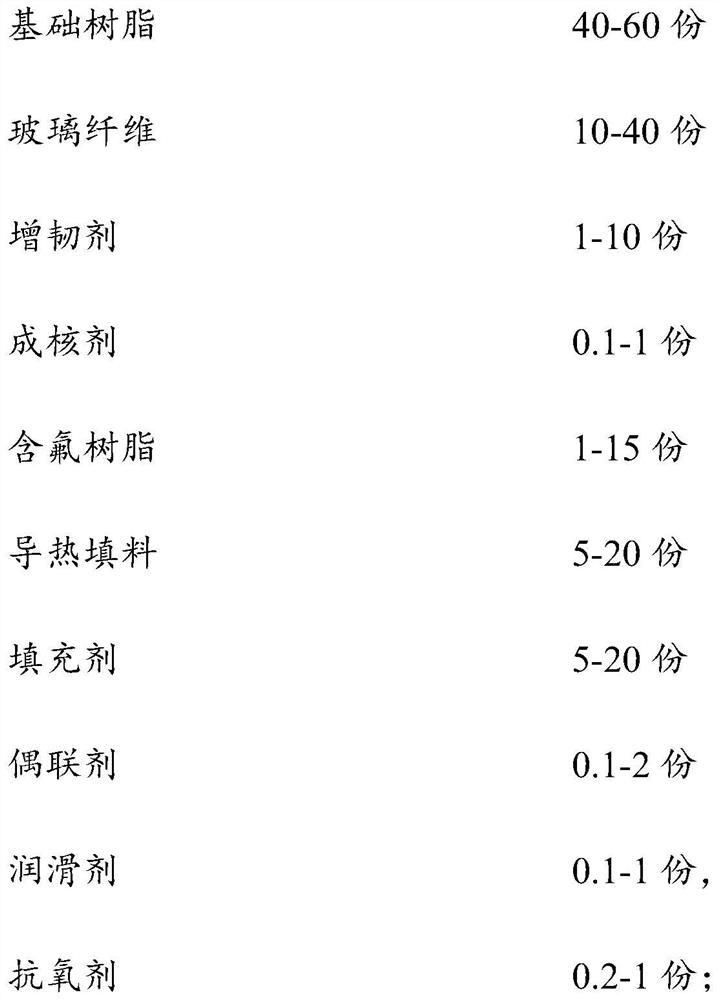

Modified engineering plastic for manufacturing 5G communication filter and preparation method thereof

The invention discloses modified engineering plastic for manufacturing a 5G communication filter and a preparation method of the modified engineering plastic. The modified engineering plastic comprises the following components in parts by weight: 40-60 parts of base resin, 10-40 parts of glass fibers, 1-10 parts of a toughening agent, 0.1-1 part of a nucleating agent, 1-15 parts of fluorine-containing resin, 5-20 parts of a heat-conducting filler, 5-20 parts of filler, 0.1-2 parts of a coupling agent, 0.1-1 part of a lubricant and 0.2-1 part of an antioxidant; the base resin is polyphenylene sulfide resin or LCP resin; and the glass fibers comprise low-dielectric glass fibers with the dielectric constant of 4-7. The modified engineering plastic for manufacturing the 5G communication filterhas the characteristics of linear thermal expansion coefficient similar to that of aluminum alloy, low and stable dielectric constant, excellent heat resistance, heat dissipation performance, dimensional stability and the like, and the purpose of replacing a metal cavity can be achieved through plastic electroplating.

Owner:中广核高新核材科技(苏州)有限公司

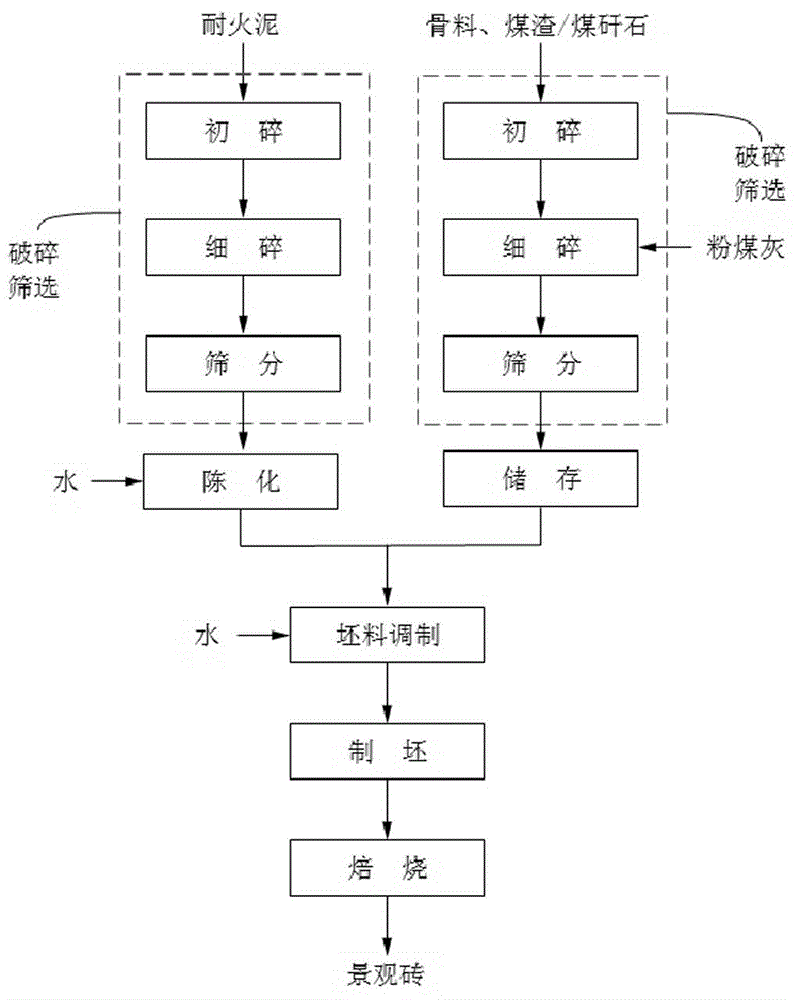

Yellow sintered landscape brick and production method thereof

InactiveCN104556962AImprove firing performanceReduce deformation of finished productFire clayHigh pressure

The invention discloses a yellow sintered landscape brick and a production method thereof. The yellow sintered landscape brick comprises 30 to 50 percent of fire clay and 50 to 70 percent of aggregate, wherein the sum of mass percent of all raw materials is not more than 100 percent. The production method comprises the steps of crushing, screening, blank mixing, blank preparation and roasting. According to the yellow landscape brick, aggregate is adopted as a main material, fire clay is adopted as an auxiliary material, and particularly hard fire clay and / or half-hard fire clay is adopted, so that the plasticity of the aggregate can be realized, and the blank is good in moldability; meanwhile, the raw materials are sintered at a high temperature of a specific range, the fire clay is thermally decomposed and toughened and covers and is bonded to the aggregate to present in faint yellow color and yellow color effects, so that the landscape brick has the characteristics of pure yellow color, relatively high pressure resistance and bending resistance and small deformation. The production method is pure in color, simple in process and stable in product quality.

Owner:楚雄诚鑫工贸有限公司

Method for preparing high-temperature-resisting anti-crack precoated sand through composite resin

InactiveCN106734854ALow gas productionHigh heat intensityFoundry mouldsFoundry coresOXALIC ACID DIHYDRATEFreeze-drying

The invention discloses a method for preparing high-temperature-resisting anti-crack precoated sand through composite resin, and belongs to the technical field of preparation of precoated sand. The method for preparing the high-temperature-resisting anti-crack precoated sand through the composite resin comprises the steps that quartz sand and waste ceramic are ground in a mixed mode, sieved and then mixed with pulp prepared from sticky rice and water, an obtained mixture is freeze-dried and sieved through wet ball-milling, and thus dry powder is obtained; afterwards, a formaldehyde solution reacts with phenol and oxalic acid, so that phenolic resin is obtained; the phenolic resin is dissolved in absolute ethyl alcohol, so that a phenolic resin-ethanol solution is obtained; and the dry powder, gypsum powder, simethicone and the like are poured into a sand mixer so as to be mixed, a urotropin solution and epoxy resin E-51 are added for a stirring reaction, the phenolic resin-ethanol solution and dibromotoluene glycidyl ether are added dropwise for a curing reaction, cooling is conducted till the room temperature is reached after curing, sand discharging is conducted, and thus the high-temperature-resisting anti-crack precoated sand is obtained. The precoated sand prepared through the method is good in curing effect and high in strength, has the excellent performance of low gas evolution and high temperature resistance, is good in material coordination and not prone to breakage when a casting is cast, and can meet production requirements of various complex precision castings.

Owner:丁玉琴

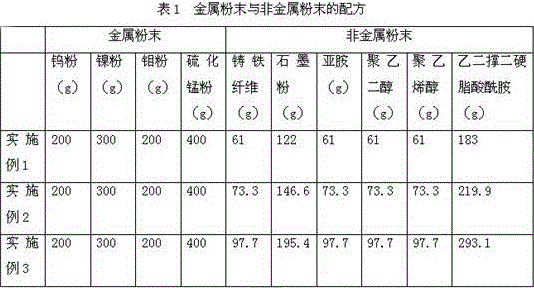

Preparation process of alloy mold core for high-temperature alloy monocrystal blade precision casting

ActiveCN106001553AImprove the success rate of demouldingImprove pass rateTurbinesOther manufacturing equipments/toolsNumerical controlFiber

The invention discloses a preparation process of an alloy mold core for high-temperature alloy monocrystal blade precision casting. Raw materials of the alloy mold core comprise metal powder and nonmetal powder; the metal powder is mainly prepared from cast iron fibers, tungsten powder, nickel powder, molybdenum powder and manganese sulfide powder in a mixed manner; and the nonmetal powder is mainly prepared from graphite powder, imine, polyethylene glycol, polyvinyl alcohol and ethylene bis stearamide in a mixed manner. The preparation process of the alloy mold core includes the following steps that the metal powder and the nonmetal powder are mixed in the proportion of 5:2; then the mixed powder is thrown into an acetone solution; an acetone solvent is removed in a heating manner; heating continues till 130 DEG C, and the mixture is fed into a mold to be pressed and formed; next, a machined mold blank is placed into a vacuum furnace to be subjected to degreasing, and sintering and forming are performed through hot pressing; and finally, the formed product is placed in a numerical control electrolytic machine tool to be subjected to precise electrolytic machining, and the alloy mold core is acquired. The alloy mold core acquired through the method is high in percent of pass of finished products, and the product is resistant to high temperature.

Owner:李庆

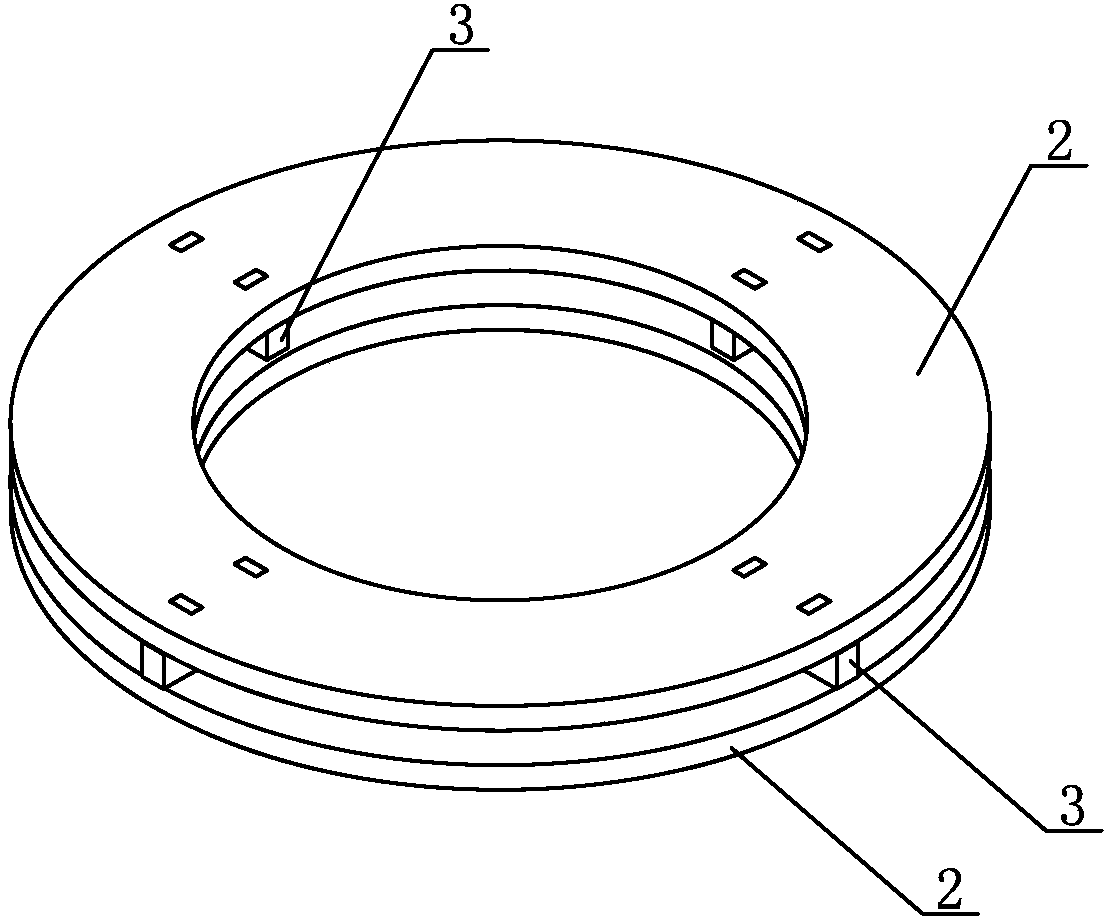

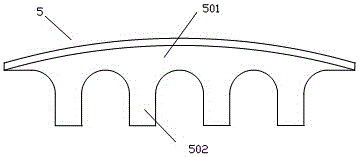

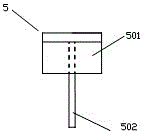

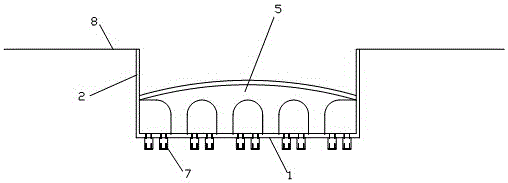

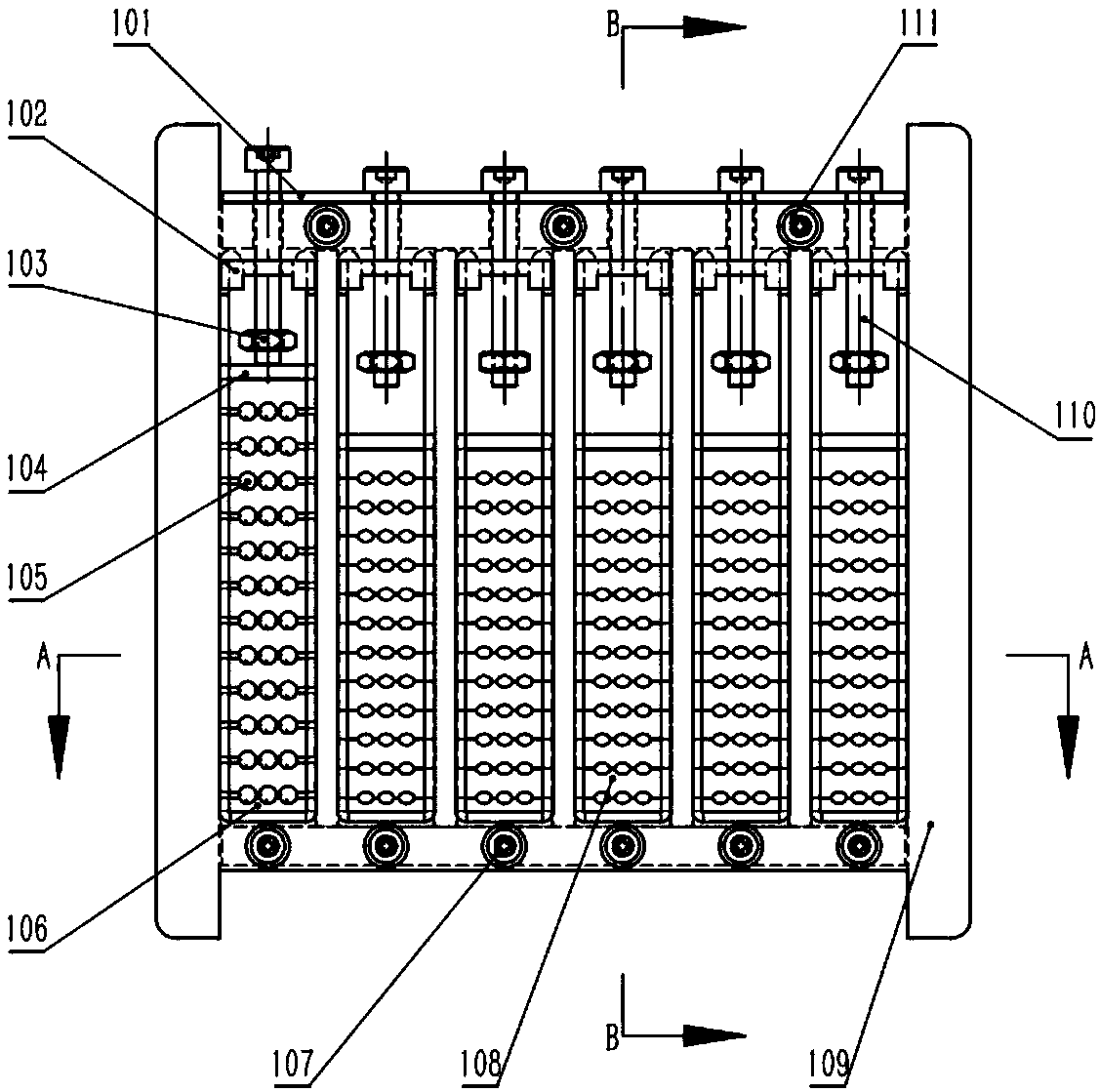

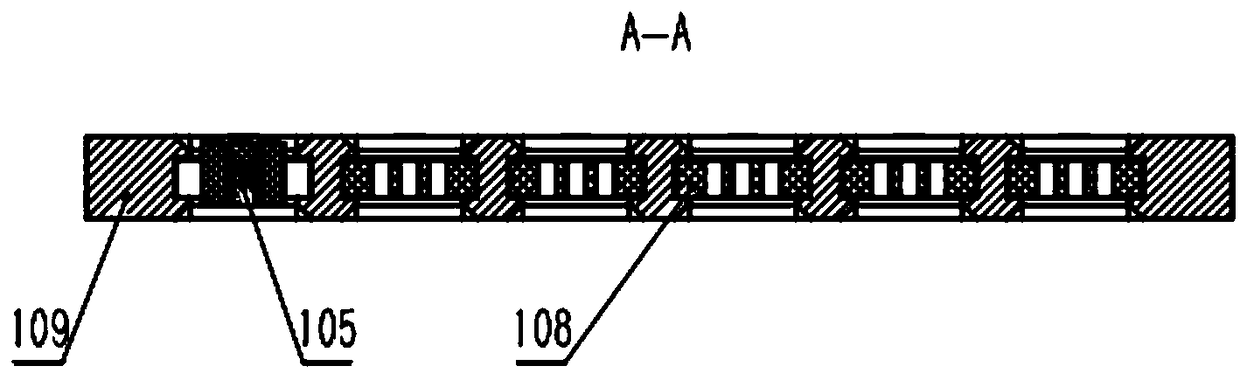

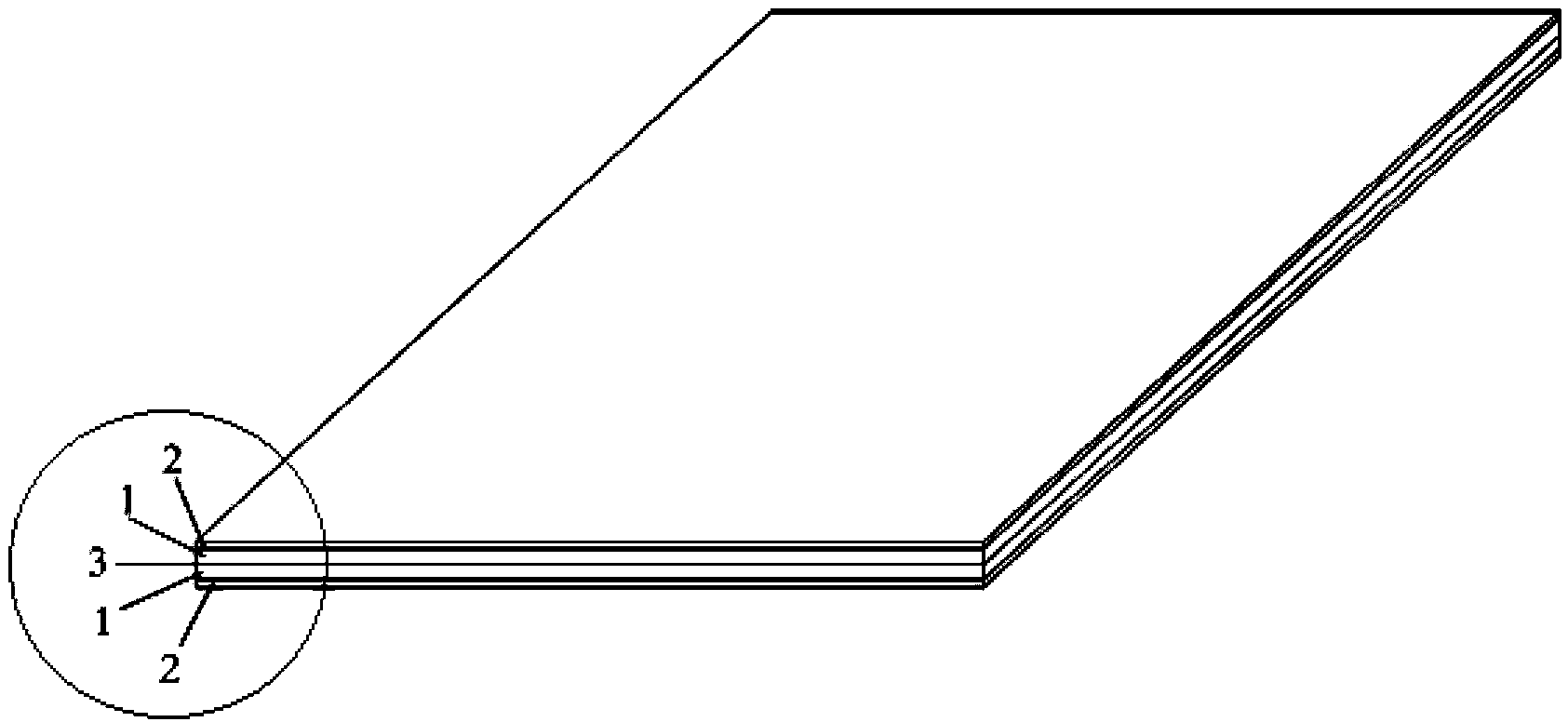

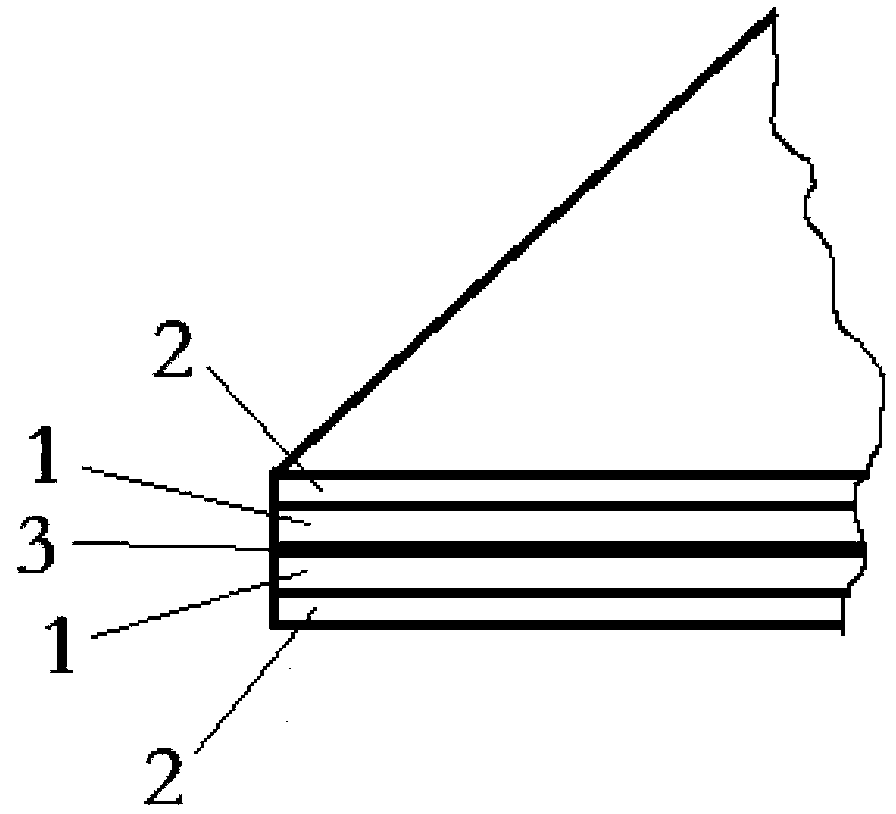

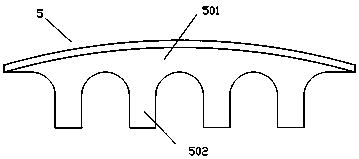

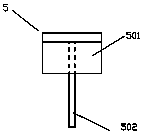

Reinforcing rib for long-service-life wire-drawing bushing for producing continuous basalt fibers and bushing

ActiveCN106116139AExtended service lifeSmall deformation at high temperatureGlass making apparatusEngineeringBasalt fiber

The invention discloses a reinforcing rib for a long-service-life wire-drawing bushing for producing continuous basalt fibers. The reinforcing rib is shaped like an arch and comprises rib columns and an arc-shaped rib face of which the top protrudes upwards, and the rib columns are welded to the lower surface of the rib face; an arch hole is formed between every two adjacent rib columns. The invention further discloses the long-service-life wire-drawing bushing for producing the continuous basalt fibers. The bushing comprises a substrate, a side wall plate, a plug plate, electrode plates, reinforcing ribs and discharge spouts. Each reinforcing rib is shaped like an arch and comprises rib columns and an arc-shaped rib face of which the top protrudes upwards, and the rib columns are welded to the lower surfaces of the rib faces; an arch hole is formed between every two adjacent rib columns. By means of the reinforcing rib, the service life of the wire-drawing bushing is prolonged.

Owner:SOUTHEAST UNIV

Preparation method of multilayer aluminium silicate thermal insulation board

InactiveCN110682628AHigh melting pointImprove toughnessLamination ancillary operationsLaminationFiberCompressive resistance

The invention discloses a preparation method of a multilayer aluminium silicate thermal insulation board and belongs to the technical field of preparation of thermal insulation materials. After high-temperature calcinations of bentonite added to the thermal insulation, micropores can be formed in the bentonite and inhibit oversintering among particles, expansible graphite can invade micropores, under the high-temperature effect, due to the large heat conductivity coefficient of the expansible graphite, the heat dissipation area of the outer surface of the thermal insulation board is increased,the inner layer of the thermal insulation board is cooled, composite aluminum silicate fiber on the surface of the thermal insulation board has high melting point and high toughness and has an enhanced protection effect on the thermal insulation board, the thermal insulation board prepared by the preparation method takes porous aluminum silicate fiber boards upper and lower layers, the middle isfilled with a composite enhancement emulsion and a high-temperature-resistant inorganic filler, a concentrate solution prepared from methyl silicone oil is polycarbosilane, the polycarbosilane and zirconium boride are used as enhanced binding components of the composite enhancement emulsion, the interface binding force of filler and the porous aluminum silicate fiber boards is improved, and the compressive strength of the thermal insulation board at high temperature is increased.

Owner:王郑

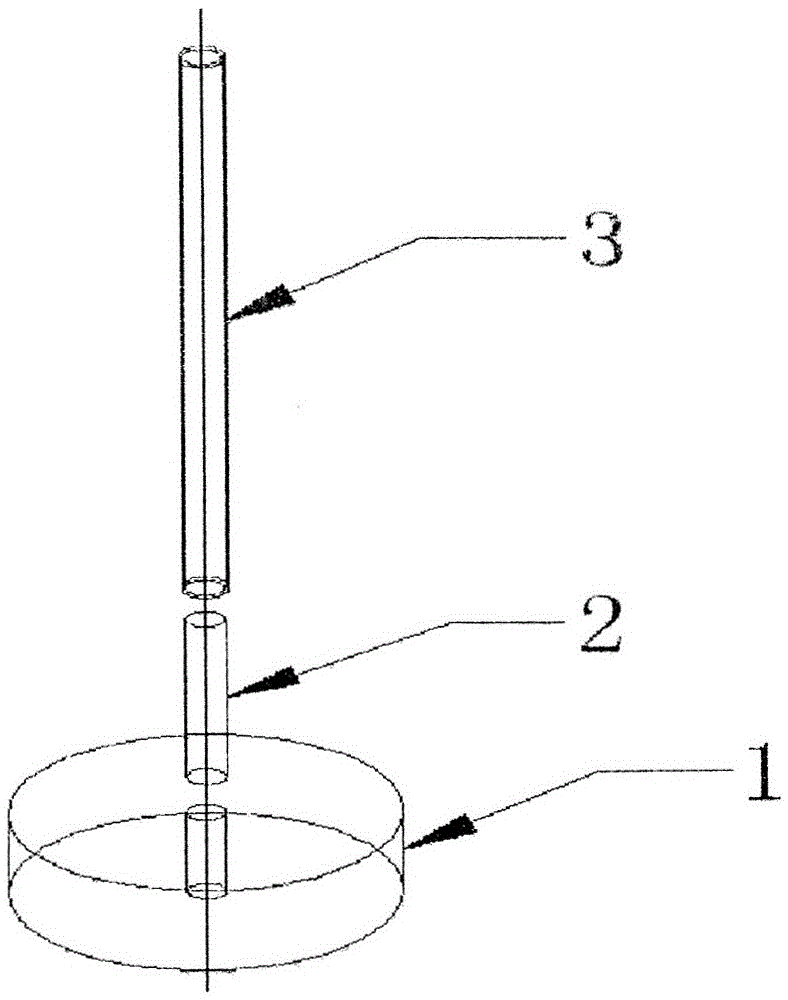

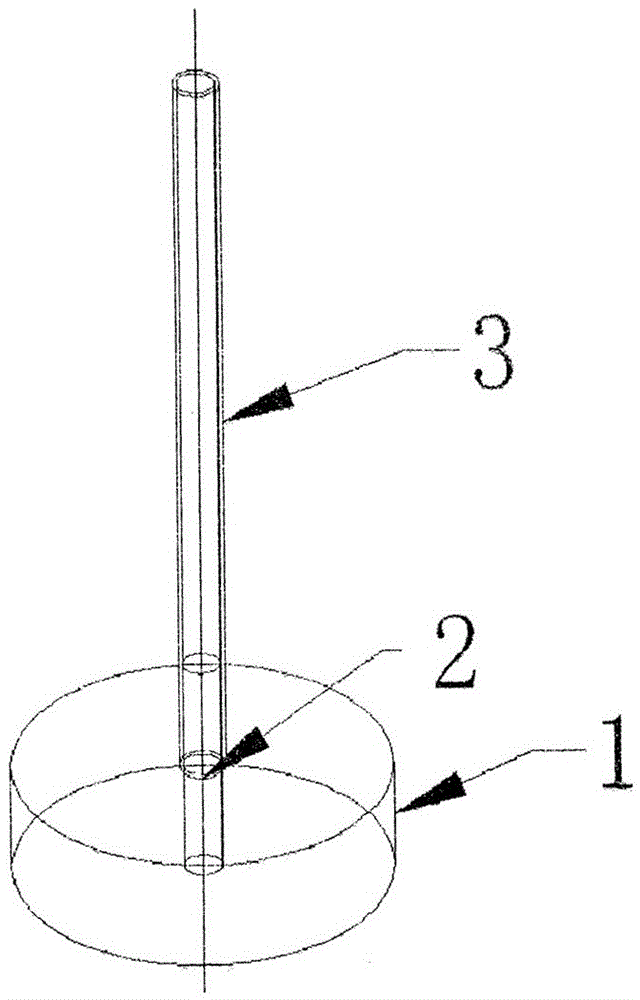

Combined heat treatment furnace temperature measuring rack and application method

InactiveCN105758207AEasy to assemble and disassembleMeet the use requirementsFurnace componentsFurnace temperatureEngineering

The invention provides a combined heat treatment furnace temperature measuring rack and an application method. The temperature measuring rack is formed by distributing a plurality of component units, wherein each component unit comprises a sleeve, a connecting rod and a base which are connected in sequence from the upper part to the lower part. When in use, the quantity of the component units is determined according to the size of an effective heating zone of a heat treatment furnace and the quantity of testing sensors; the connected component units are distributed according to size requirements, so as to ensure that the upper end point of each sleeve is positioned in the peak of the required effective heating zone; when the effective heating zone is tested, testing ends of the testing sensors are fixed to the end points or the midpoints of the sleeves, and a geometric space defined by the testing ends of all the sensors is just the measuring position of the required effective heating zone; after use, the component units are decomposed and stored for standby application. The combined heat treatment furnace temperature measuring rack is applicable to all heat treatment equipment with cuboid effective heating zones, and is convenient and fast to use.

Owner:SHENYANG AIRCRAFT CORP

Corrosion-resistant and heat-resistant quartz ceramic roller way production process

InactiveCN111377719AHigh strengthGood anti-corrosion and heat resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveSlurry

The invention provides a corrosion-resistant and heat-resistant quartz ceramic roller way production process. The production process comprises the following steps of 1) preparing slurry, 2) pressing,3) sintering, and 4) assembling. In the production process, a quartz ceramic roller is made of a specially-made quartz ceramic roller raw material; the prepared quartz ceramic roller is high in strength and good in corrosion resistance and heat resistance; the quartz ceramic roller is connected with a shaft sleeve by adopting a specially-made adhesive and the assembly is firm; the quartz ceramic roller way can be used as a horizontal conveying roller way in production lines of a horizontal toughening furnace, silicon steel heat treatment and the like, has the advantages of high density, high strength, small high-temperature deformation, smoothness, fineness, small radial runout and the like, and is widely applied to bearing and conveying glass in the horizontal toughening furnace.

Owner:徐州华焰特种陶瓷有限公司

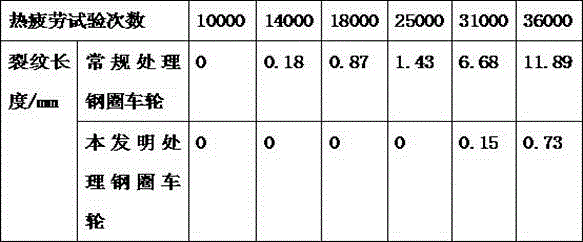

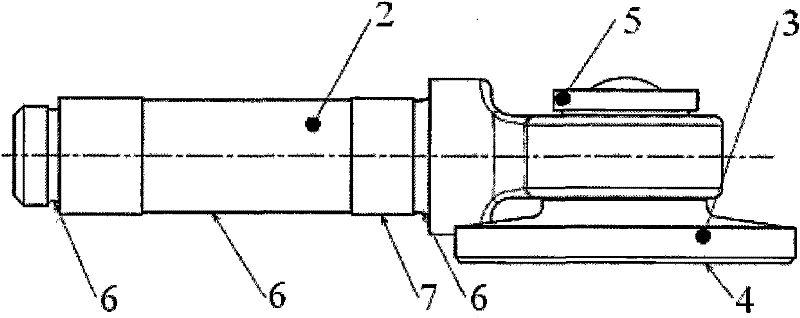

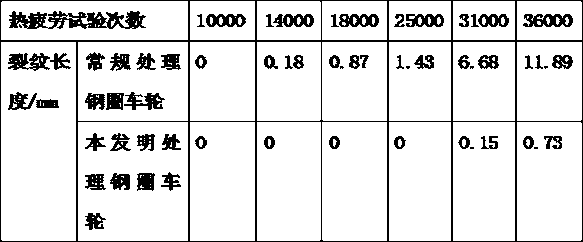

Steel ring car wheel surface treatment process

ActiveCN106222680AEfficient removalImprove surface mechanical propertiesFurnace typesMetallic material coating processesHigh resistanceShock resistance

The invention discloses a steel ring car wheel surface treatment process. The steel ring car wheel surface treatment process comprises the following steps of (1) cleaning, (2) surface preheating, (3) surface modification treatment, (4) cleaning and cold standing and (5) quenching treatment. The steel ring car wheel surface treated through the process has the high abrasion resistance, high hardness, high toughness and high shock resistance, subsequent quenching treatment is matched, the optimal quenching time and quenching temperature are optimized, and the tempering time and tempering temperature are adjusted, so that the impact toughness and hardness of a steel ring car wheel are improved; and inner hardness and outer hardness are balanced, the microhardness of the surface of a steel ring car wheel coating is quite high, the salt corrosion resistance and stress corrosion cracking resistance can be further improved. In addition, the fatigue resistance of the steel ring car wheel is greatly improved, the service life of the steel ring car wheel is prolonged, and the service life of the steel ring car wheel is prolonged by three to four times compared with untreated steel ring car wheels.

Owner:ANHUI JIANGHUAI WHEEL CO LTD

Preparation method for internal-expansion nanoporous thermal-insulation material

InactiveCN109208324AHigh melting pointIncrease the heat dissipation area of the outer surfaceInorganic material artificial filamentsFibre treatmentBorideThermal insulation

The invention specifically relates to a preparation method for an internal-expansion nanoporous thermal-insulation material, belonging to the technical field of preparation of thermal-insulation materials. The preparation method of the invention comprises the following steps: preparing mixed clay from diatomite and bentonite, and mixing the mixed clay and a nanometer silica aerogel to prepare nanometer silica aerogel slurry; heating mixed slurry and the nanometer silica aerogel slurry to obtain molten material liquid; subjecting zirconium boride powder, a concentrate and the like to high-speeddispersion so as to obtain a nanometer reinforced emulsion; pouring the nanometer reinforced emulsion at first and then performing filling with a high-temperature-resistant inorganic filler; and carrying out pressure filtration and drying so as to obtain the internal-expansion nanoporous thermal-insulation material. According to the invention, expanded graphite has cooling effect on the inner layer of the thermal-insulation material and also plays reinforcing and protective roles; and a zirconium dioxide-silicon dioxide film formed by a reaction further improves the compressive strength of the thermal-insulation material at a high temperature, and has broad application prospects.

Owner:方建波

Pouring material for producing high-temperature ceramic abrasion-proof lining body

The invention relates to pouring material for producing the ceramic wearable liner with high temperature, and comprises 10 to 25 percent of electric melting mullite with granularity of 3 to 5 mm, 20 to 45 percent of electric cast mullite with granularity of 1 to 3 mm, 3 to 7 percent of andalusite with granularity of 0.1 to 1 mm, 20 to 45 percent of clintheriform corundum with granularity is 0.1 to1 mm, 5 to 20 percent of electrofusion white alundum with 300 to 350 items, 2 to 10 percent of pure calcium aluminate concrete with granularity of less than 0.074 mm, 2 to 6 percent of silica micro mist and 2 to 10 percent of alumina micro mist. The pouring material can be used in the parts which have much higher requirements to the heat vibration stability such as the crossing part of the hot wind pipes and the wind sending pipes of a blast furnace. The produced liner has the advantages of good heat stability, durable capacity of scouring with high temperature airflow, good heat vibration resisting capacity and long life period, the preparation method is simple, and the construction period is short. The invention protects the environment and has no pollution, low cost and easy industrialized production.

Owner:HENAN HAOYUNXIANG REFRACTORY MATERIAL CO LTD

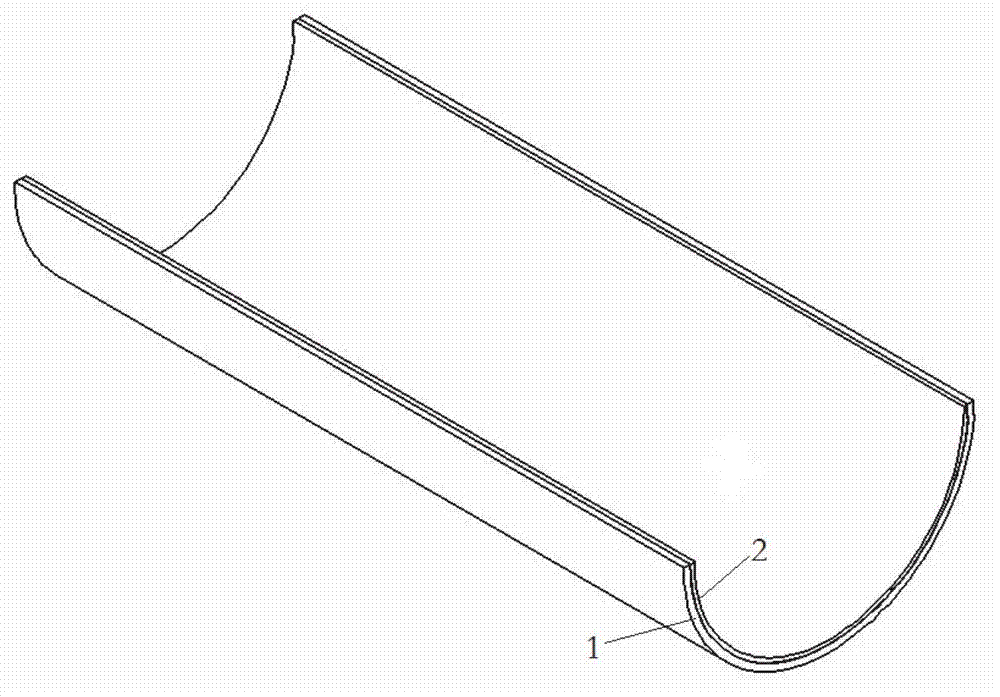

Shaft furnace cloth chute and manufacture method thereof

InactiveCN102864261ALarge contact surfaceTightly boundBell-and-hopper arrangementTemperature controlShaft furnace

The invention discloses a shaft furnace cloth chute and a manufacture method thereof. The shaft furnace cloth chute consists of a casing and a lining layer, wherein the lining layer is made of tempering abrasion-resistant steel, and the casing is made of structural low-alloy steel or an austenite heat-resisting steel plate. The manufacture method of the shaft furnace cloth chute sequentially comprises the steps of surface washing, blank assembly, welding, heating, rolling, temperature control, thermal treatment, processing and forming and the like. The shaft furnace cloth chute can achieve compounding of the casing of the cloth chute and an internal abrasion-resistant layer in a rolling-combined mode and is large in connecting and contacting face and tight in combination.

Owner:武钢集团有限公司

Long and thin column glass rod clamping device

ActiveCN109336404ARealize automatic card loadingEasy loading and unloadingGlass productionMechanical engineeringEngineering

The invention discloses a long and thin column glass rod clamping device which comprises a clamp, wherein the clamp is mounted on a clamping fixing jig; the clamping fixing jig is mounted on a fixingbase; the clamp comprises an integral bracket; a plurality groups of guide grooves are formed in the integral bracket; single-side clamping blocks and double-side clamping blocks are placed inside theguide grooves; the single-side clamping blocks and the double-side clamping blocks cooperate to clamp optical lenses; tetrafluorohydrazine pads on the single-side clamping blocks are connected with bottom ends of fixing screws; the fixing screws penetrate through the integral bracket; the integral bracket is connected with the clamping fixing jig; the clamping fixing jig comprises a fixing platefor fixing the integral bracket; a plurality groups of elastic pieces are arranged corresponding to the clamp on the fixing plate; the elastic pieces are used for constantly pressing the single-side clamping blocks and the double-side clamping blocks through compression springs; bulges on the back sides of the elastic pieces are clamped in long stripy holes of elastic plates; the elastic plates are hinged with rotating shifting forks; the rotating shifting forks are used for enabling the plurality groups of the elastic pieces to be lifted up simultaneously and be dissociated from top-layer single-side clamping blocks through cooperation of a pressing plate and the elastic plate. By adopting the device, automatic assembling and clamping can be achieved.

Owner:西安天穹智能机器科技有限公司

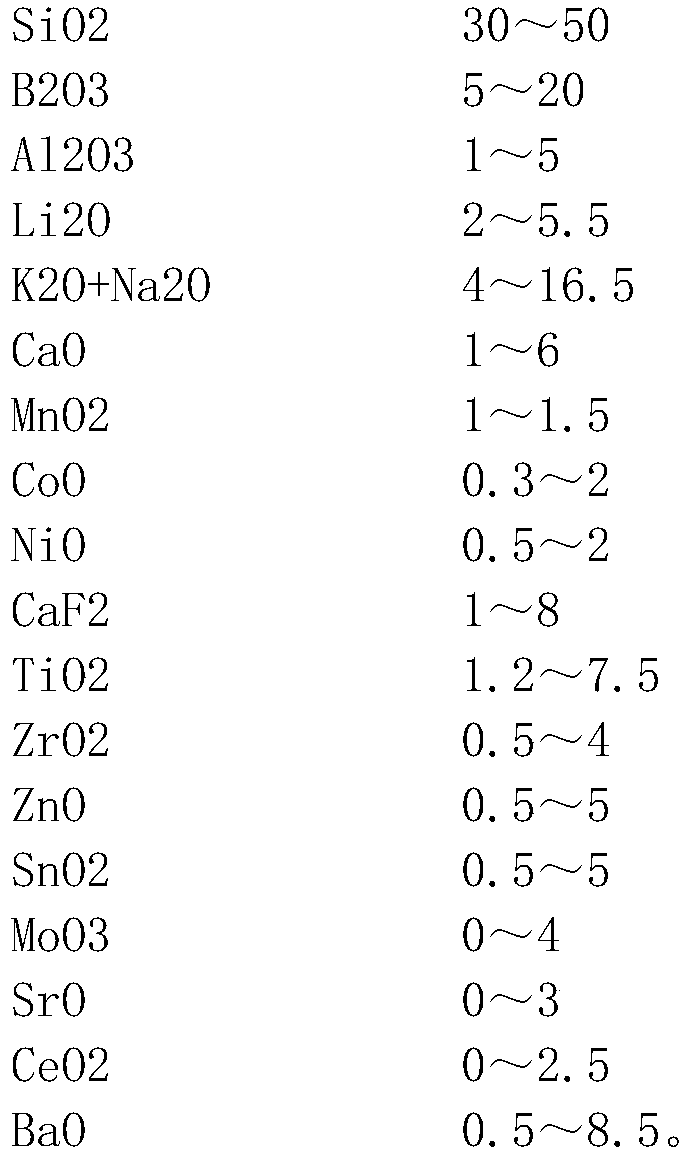

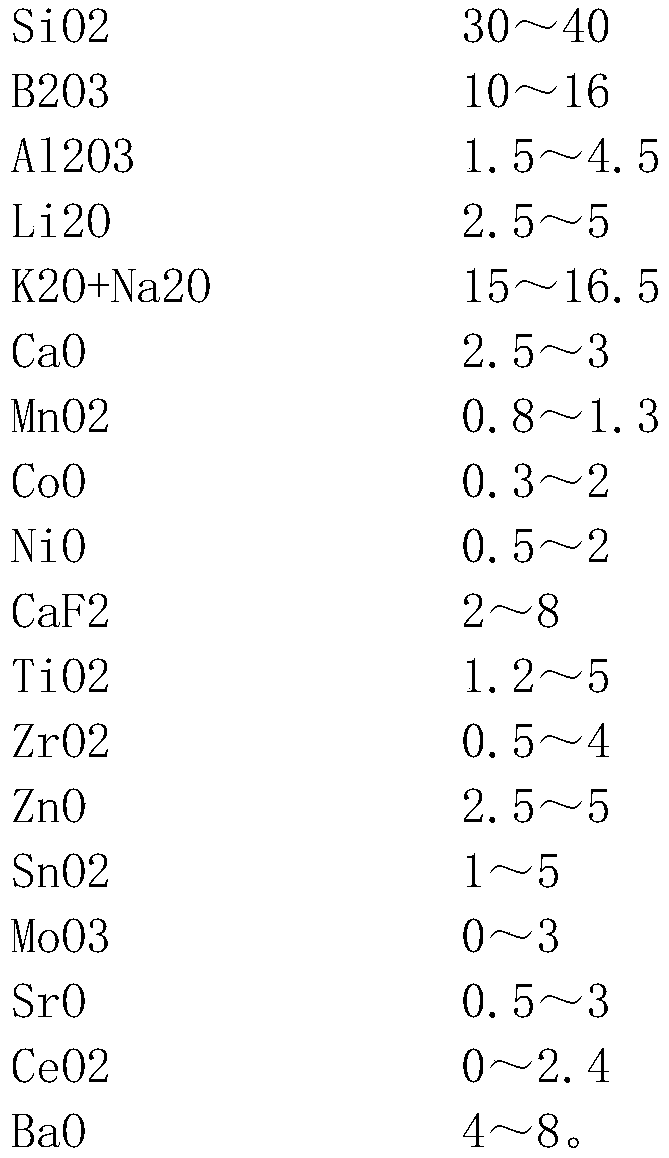

One-time enameling and low-temperature firing glass lining glaze for oil field pipeline corrosion prevention, as well as preparation method and applications

The invention belongs to the technical field of glass lining glaze, and specifically discloses a one-time enameling and low-temperature firing glass lining glaze for oil field pipeline corrosion prevention, and a preparation method and applications thereof. The glass lining glaze is prepared from the following components in percentage by weight: 30 to 50% of SiO2, 5 to 20% of B2O3, 1-5% of Al2O3,2-5.5% of Li2O, 4 to 16.5% of K2O and Na2O; 1-6% of CaO, 1-1.5% of MnO2, 0.3 to 2% of CoO, 0.5 to 2% of NiO, 1 to 8% of CaF2, 1.2 to 7.5% of TiO2, 0.5 to 4% of ZrO2, 0.5 to 5% of ZnO, 0.5 to 5% of SnO2, 0 to 4% of MoO3, 0 to 3% of SrO, 0 to 2.5% of CeO2 and 0.5 to 8.5% of BaO. The highest firing temperature of the glass lining glaze is lower than 800 DEG C, an anticorrosive coating layer can be manufactured through one-time enameling, the production efficiency of the pipeline anticorrosive coating layer can be greatly improved, and the glass lining glaze is suitable for corrosion prevention ofoil field pipelines.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

A surface fatigue-resistant treatment process for slewing bearings

ActiveCN106435467BSurface treatment process optimizationImprove surface wear resistanceSolid state diffusion coatingSurface fatigueEngineering

Owner:安徽省宁国顺昌机械有限公司

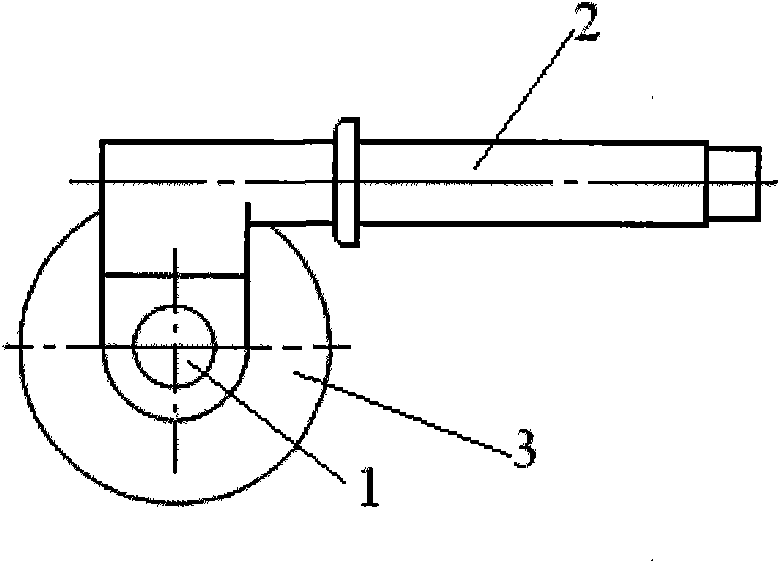

Petrol engine supercharger bypass valve

ActiveCN101649773BPrevent free spinsGuaranteed creep resistanceOperating means/releasing devices for valvesInternal combustion piston enginesFree rotationLow speed

The invention discloses a petrol engine supercharger bypass valve which comprises a bypass valve (3) and a rocking arm (2), wherein a valve connecting lug boss (9) is arranged on the bypass valve (3); the valve connecting lug boss (9) and the bypass valve (3) are in an integral structure; the end part of the rocking arm (2) is bent and pressed into a flat shape; a rocking arm connecting hole (10)is arranged on the flat shape structure; and the bypass valve (3) is connected with the rocking arm (2) by the match of the valve connecting lug boss (9) and the rocking arm connecting hole (10). Therocking arm and the bypass valve are formed by the precision casting of a novel stainless steel material melting die, and a spacer is formed by stamping novel stainless steel, therefore, the creep resistance at high temperature is ensured, the planeness of a volute attaching surface and the utilization of the supercharger on waste gas energy when an engine is at low speed are improved, the rotating freedom degree of the bypass valve is limited, the valve is prevented from generating free rotation by waste gas disturbance, the abrasion is reduced and the requirement for a high-performance petrol engine is met.

Owner:JAPHL POWERTRAIN SYST

A kind of steel rim wheel surface treatment process

ActiveCN106222680BEfficient removalImprove surface mechanical propertiesFurnace typesMetallic material coating processesHigh resistanceShock resistance

The invention discloses a steel ring car wheel surface treatment process. The steel ring car wheel surface treatment process comprises the following steps of (1) cleaning, (2) surface preheating, (3) surface modification treatment, (4) cleaning and cold standing and (5) quenching treatment. The steel ring car wheel surface treated through the process has the high abrasion resistance, high hardness, high toughness and high shock resistance, subsequent quenching treatment is matched, the optimal quenching time and quenching temperature are optimized, and the tempering time and tempering temperature are adjusted, so that the impact toughness and hardness of a steel ring car wheel are improved; and inner hardness and outer hardness are balanced, the microhardness of the surface of a steel ring car wheel coating is quite high, the salt corrosion resistance and stress corrosion cracking resistance can be further improved. In addition, the fatigue resistance of the steel ring car wheel is greatly improved, the service life of the steel ring car wheel is prolonged, and the service life of the steel ring car wheel is prolonged by three to four times compared with untreated steel ring car wheels.

Owner:ANHUI JIANGHUAI WHEEL CO LTD

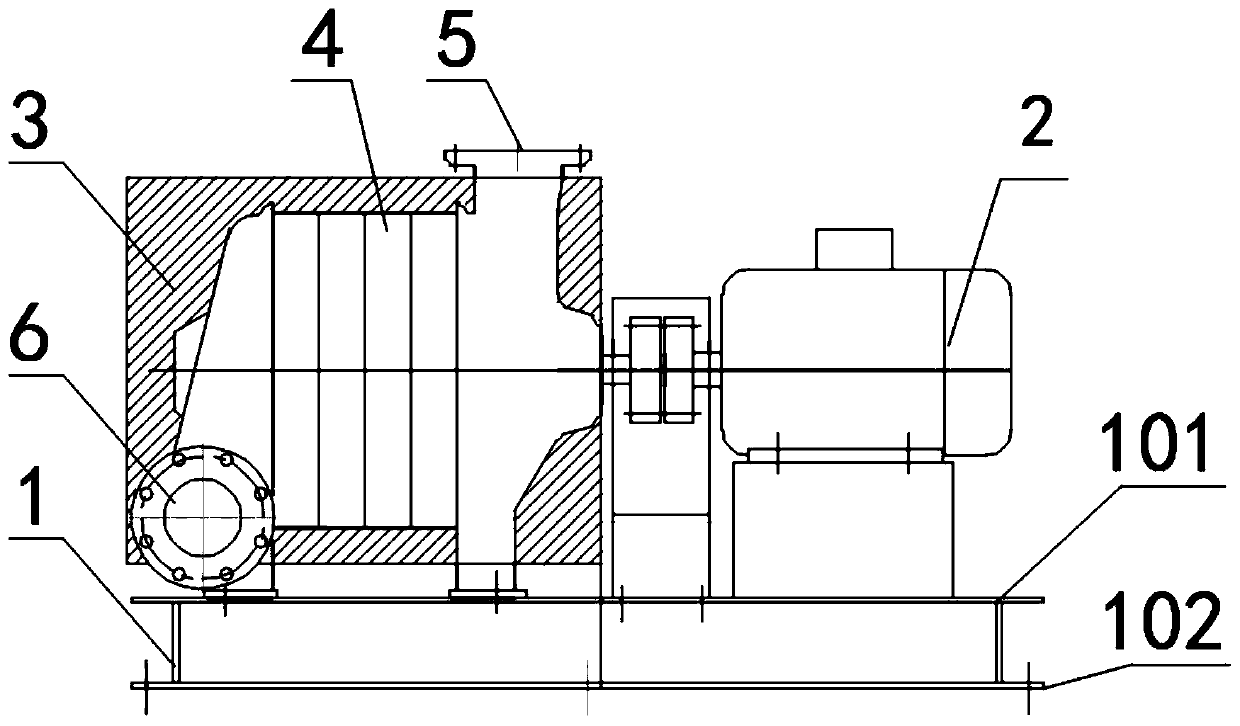

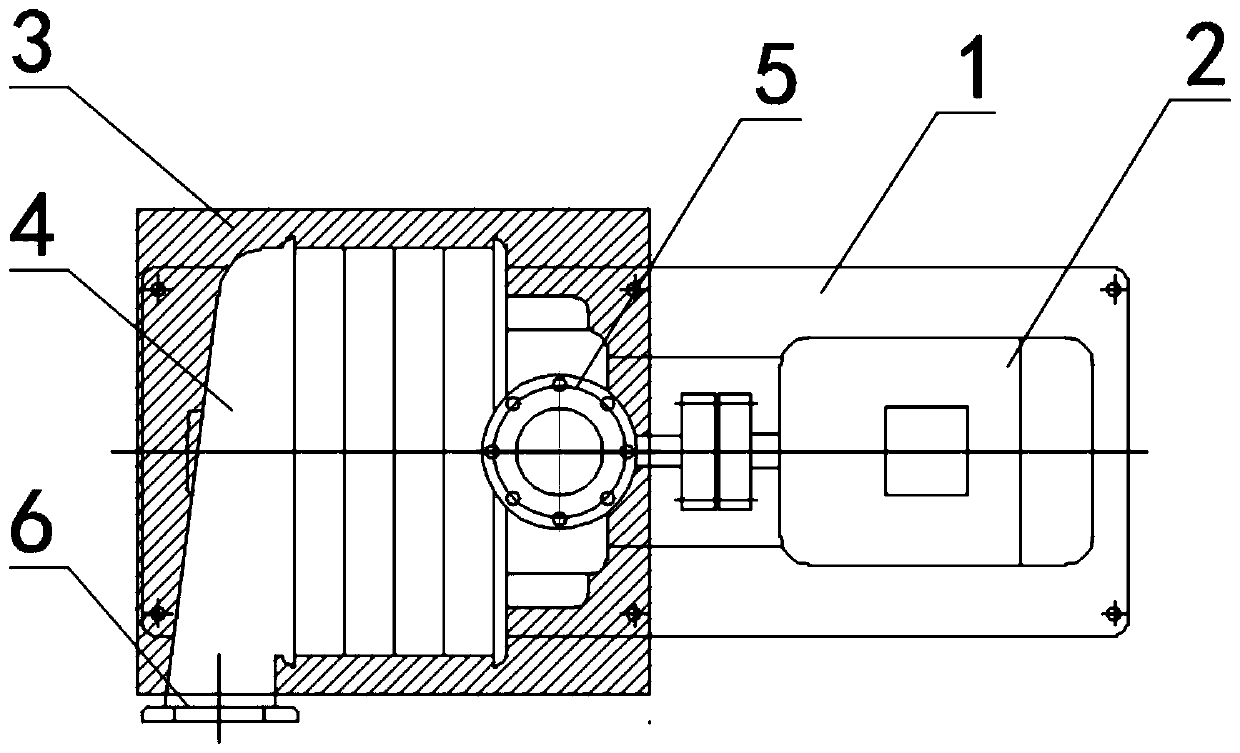

Efficient circulation automatic heating type multi-stage centrifugal blower

PendingCN109695585ASmall deformation at high temperatureImprove high temperature strengthPump componentsAir heatersImpellerAir volume

The invention discloses an efficient circulation automatic heating type multi-stage centrifugal blower. The efficient circulation automatic heating type multi-stage centrifugal blower comprises a base, a motor and a multi-stage centrifugal blower body, wherein the motor and the multi-stage centrifugal blower body are installed on the base, the multi-stage centrifugal blower body comprises a shell,an impeller and a main shaft, the main shaft is connected with the output end of the motor, a circulating air inlet and a circulating heating air outlet are formed in the two ends of the shell correspondingly, the impeller is driven by the main shaft to rotate so as to enable gas to be compressed and heated stage by stage from the circulating air inlet and be conveyed to the circulating heating air outlet, and a heat preservation layer is arranged on the outer wall of the shell. According to the multi-stage centrifugal blower, heat generated in the multi-stage compression process of the gas is effectively utilized, the heat energy is maximally used for drying and heating, then effective circulating and heating are achieved, the heat energy is maximally applied to places or objects required by drying and heating by utilizing the air volume circulating driving force, the highest temperature can be increased to several hundred degrees, the circulating air volume and the heating effect are guaranteed, and a good market application prospect is achieved.

Owner:JIANGSU LAISEN ENVIRONMENTAL PROTECTION EQUIP CO LTD

Shaft furnace cloth chute and manufacture method thereof

InactiveCN102864261BLarge contact surfaceTightly boundBell-and-hopper arrangementTemperature controlShaft furnace

Owner:武钢集团有限公司

Preparation process of alloy mold core for high-temperature alloy single crystal blade precision casting

ActiveCN106001553BImprove the success rate of demouldingImprove pass rateTurbinesOther manufacturing equipments/toolsFiberNumerical control

Owner:李庆

Ribs and bushings for the production of continuous basalt fiber high-life wire drawing bushings

ActiveCN106116139BExtended service lifeSmall deformation at high temperatureGlass making apparatusBasalt fiberBasalt

The invention discloses a reinforcing rib for a long-service-life wire-drawing bushing for producing continuous basalt fibers. The reinforcing rib is shaped like an arch and comprises rib columns and an arc-shaped rib face of which the top protrudes upwards, and the rib columns are welded to the lower surface of the rib face; an arch hole is formed between every two adjacent rib columns. The invention further discloses the long-service-life wire-drawing bushing for producing the continuous basalt fibers. The bushing comprises a substrate, a side wall plate, a plug plate, electrode plates, reinforcing ribs and discharge spouts. Each reinforcing rib is shaped like an arch and comprises rib columns and an arc-shaped rib face of which the top protrudes upwards, and the rib columns are welded to the lower surfaces of the rib faces; an arch hole is formed between every two adjacent rib columns. By means of the reinforcing rib, the service life of the wire-drawing bushing is prolonged.

Owner:SOUTHEAST UNIV

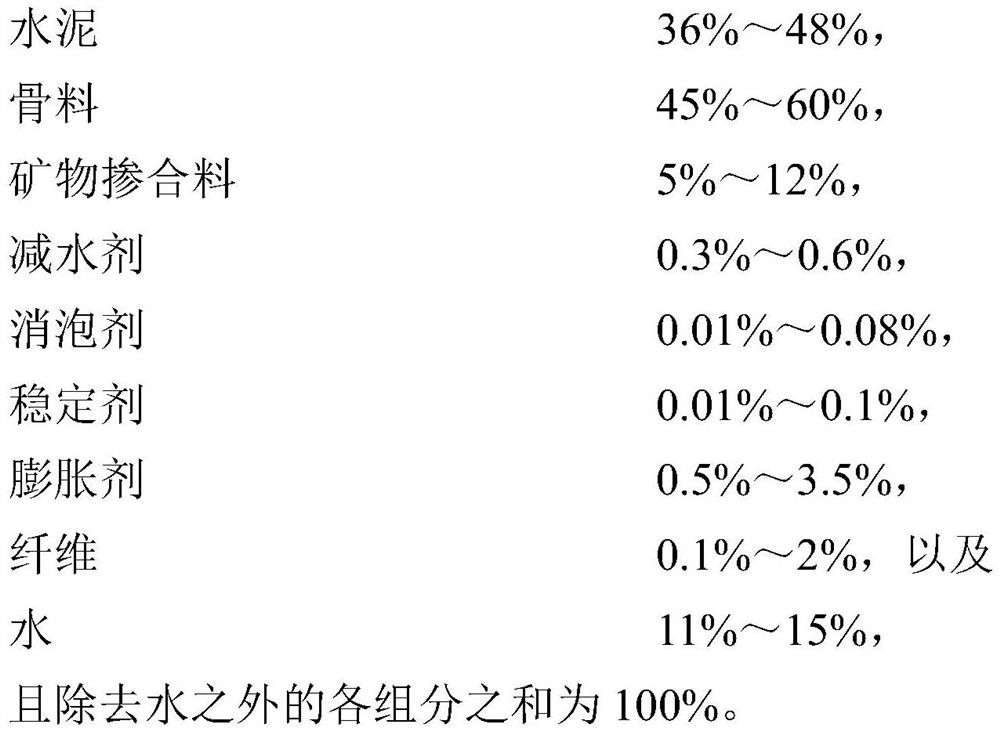

Heat-resistant cement-based grouting material and preparation method thereof

Owner:BEIJING NEW VISION BUILDING CONSTR TECH +2

High temperature resistant medium density battery

ActiveCN103700893BLighten the loadImprove uniformityCell electrodesFinal product manufactureWater useBarium titanate

The invention provides a high-temperature-resistant medium-density battery, in which strontium titanate is added to the lead paste of the positive plate, and the pure water used in the preparation of the lead paste is negative ion water. The battery plate is placed parallel to the bottom surface of the case, that is, placed parallel to the ground, and the battery case is made of high-temperature-resistant PPO material. The battery of the invention is suitable for use in a high-temperature environment above 45° C., and its high-temperature float charge and high-temperature cycle performances are significantly improved.

Owner:SHUANGDENG GRP +1

A throttle device and its test platform

ActiveCN105201855BIncrease exhaust pressureReduce leakagePump testingPositive-displacement liquid enginesEngineeringTest platform

The invention discloses a throttle device and a test platform having the same. The throttle device includes: a valve body (1), which is arranged in a pipe, and the inside is hollow, and the gas in the pipe can pass through the hollow inside of the valve body (1); a valve core (2), which is at least partially arranged Inside the valve body (1), the valve core (2) is provided with a gas channel (21) on the part inside the valve body (1); the transmission assembly (3), which is connected with the valve core (2 ) partly connected outside the valve body (1); wherein, the transmission assembly (3) is used to transmit rotational force for the valve core (2), so that the valve core (2) is relatively (1) Rotate, thereby changing the position of the gas channel (21) relative to the valve body (1). The throttle device in the invention has the advantages of high exhaust pressure, small leakage, small high-temperature deformation and no stagnation, good adjustment characteristics and high reliability.

Owner:AECC SHENYANG ENGINE RES INST

Silicon-base ceramic core added with cristobalite

InactiveCN102179477BImprove high temperature deformation resistanceReduce high temperature deflectionFoundry mouldsFoundry coresTurbine bladeAlloy

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com