Combined heat treatment furnace temperature measuring rack and application method

A heat treatment furnace and combined technology, applied in the field of heat treatment furnace temperature measuring rack, can solve the problems of processing, time-consuming, waste, etc., and achieve the effects of reducing high-temperature deformation, saving storage space, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

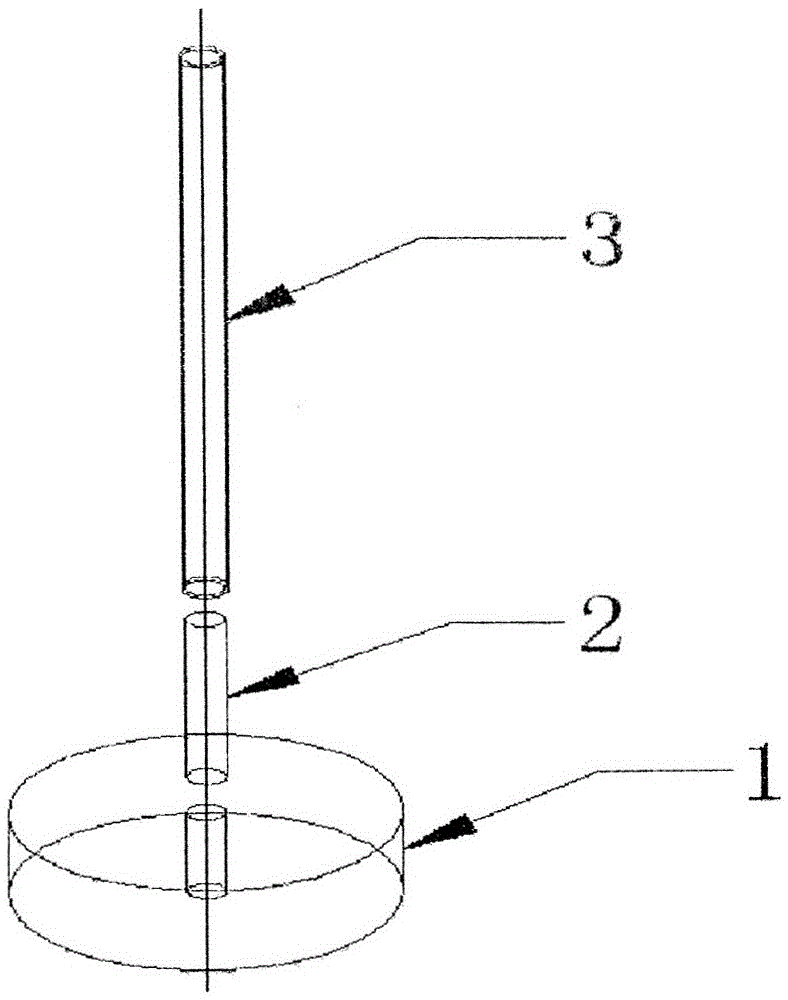

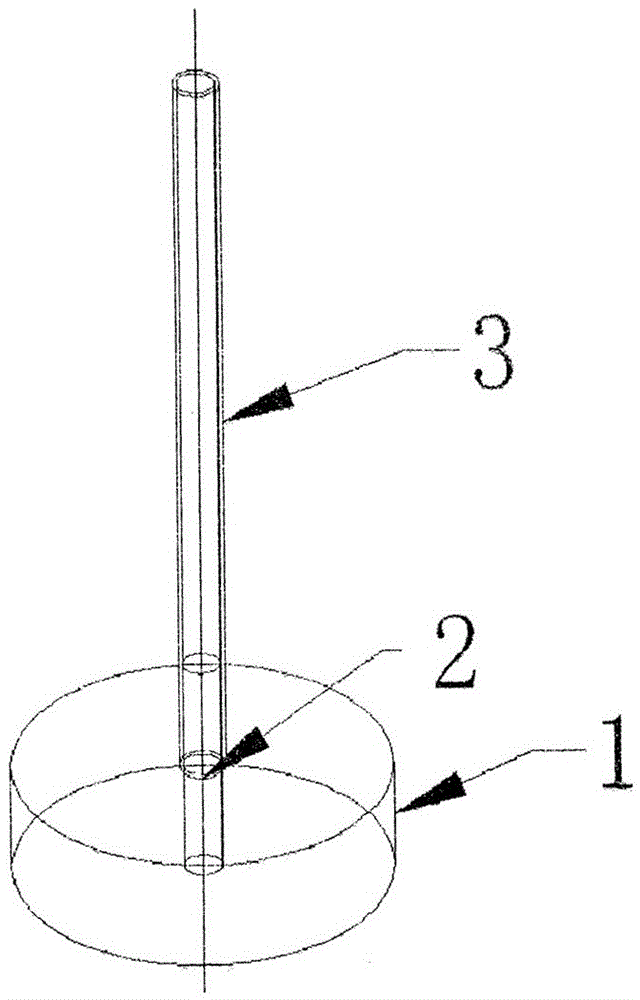

[0030] A combined heat treatment furnace temperature measuring frame, which is composed of five component units, wherein each component unit is composed of a sleeve 3, a connecting rod 2, and a base 1 connected in sequence from top to bottom, as shown in figure 1 and figure 2 shown.

[0031] In order to ensure stability, the base 1 is made of cylindrical heat-resistant steel, and the diameter of the cylinder is 3 to 4 times the height.

[0032] An insertion hole is provided at the center of the base 1 for inserting the connecting rod 2 . The diameter of the insertion hole is about 1mm larger than the diameter of the connecting rod 2, so as to ensure that the connecting rod 2 is conveniently inserted into the base 1, and the connecting rod 2 will not shake.

[0033] The connecting rod 2 is made of heat-resistant steel rod, and the casing 3 is made of heat-resistant steel pipe. The outer diameter of the connecting rod 2 is about 1mm smaller than the inner diameter of the casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com