Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Improve sputtering effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ion source apparatus and cleaning optimized method thereof

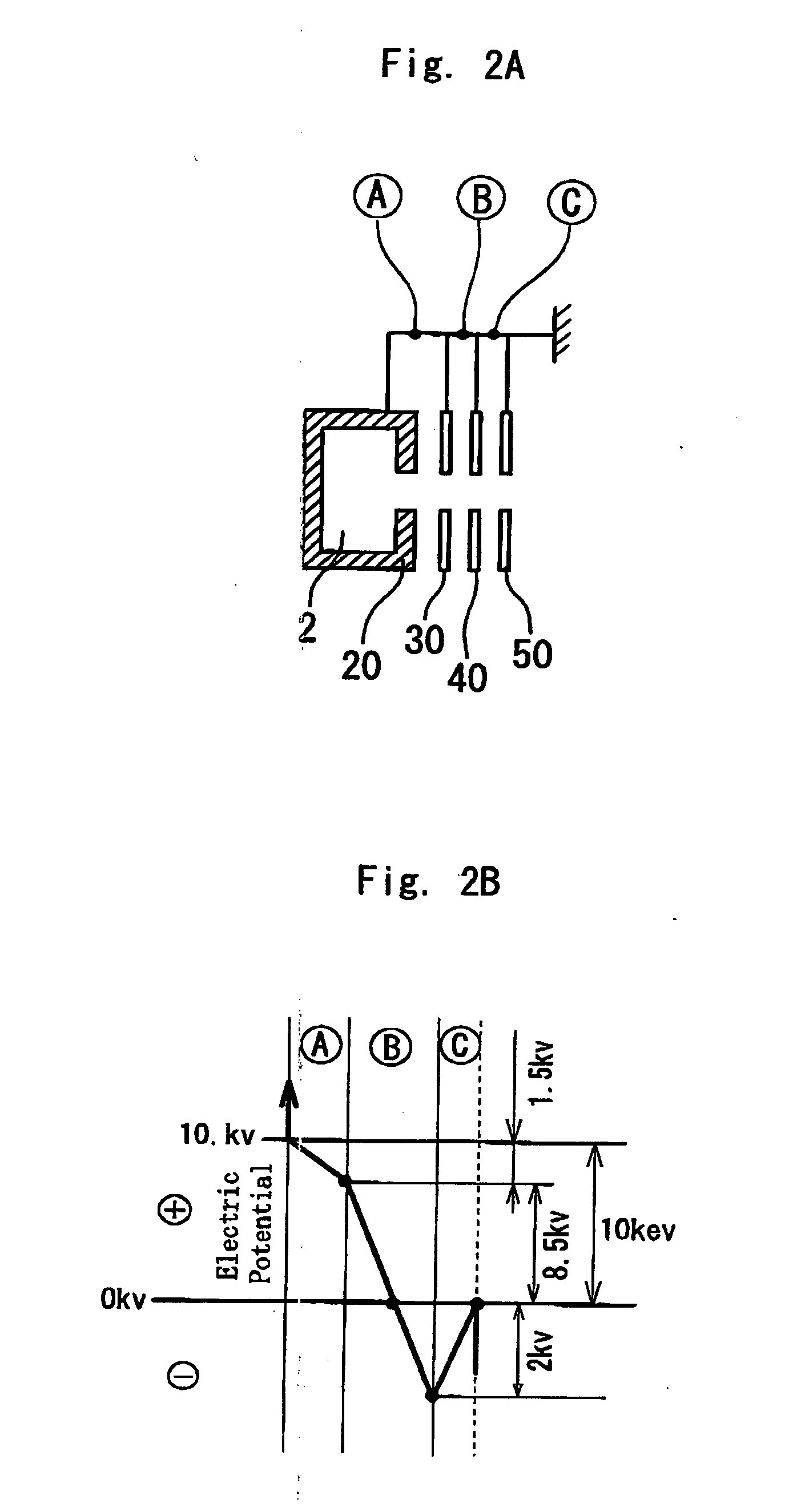

InactiveUS20050016838A1Optimized diameterIncreased durabilityCellsVacuum evaporation coatingNoble gasInsulation layer

An ion source apparatus includes a rare gas supply source supplying rare gas instead of ion source gas to a plasma chamber, means to determine time and timing for cleaning electrodes in consideration of a collecting amount of insulation layers accreting to the electrodes of an extraction electrode system. Based on the above, the ion source apparatus removes the insulation layers by sputtering with ion beam of the rare gas while adjusting extraction or accelerate voltage and supply amount of the rare gas as a setting parameter. Moreover, by adjusting the setting parameter which changes a diameter of ion beam based on the rare gas when the ion beam collides onto each electrode surface of the extraction electrode system, the beam diameter is focused within an effective range in which intension of the sputtering of the insulation layers is maximized thus evenly removing the insulation layers.

Owner:SEN CORP AN SHI & AXCELIS

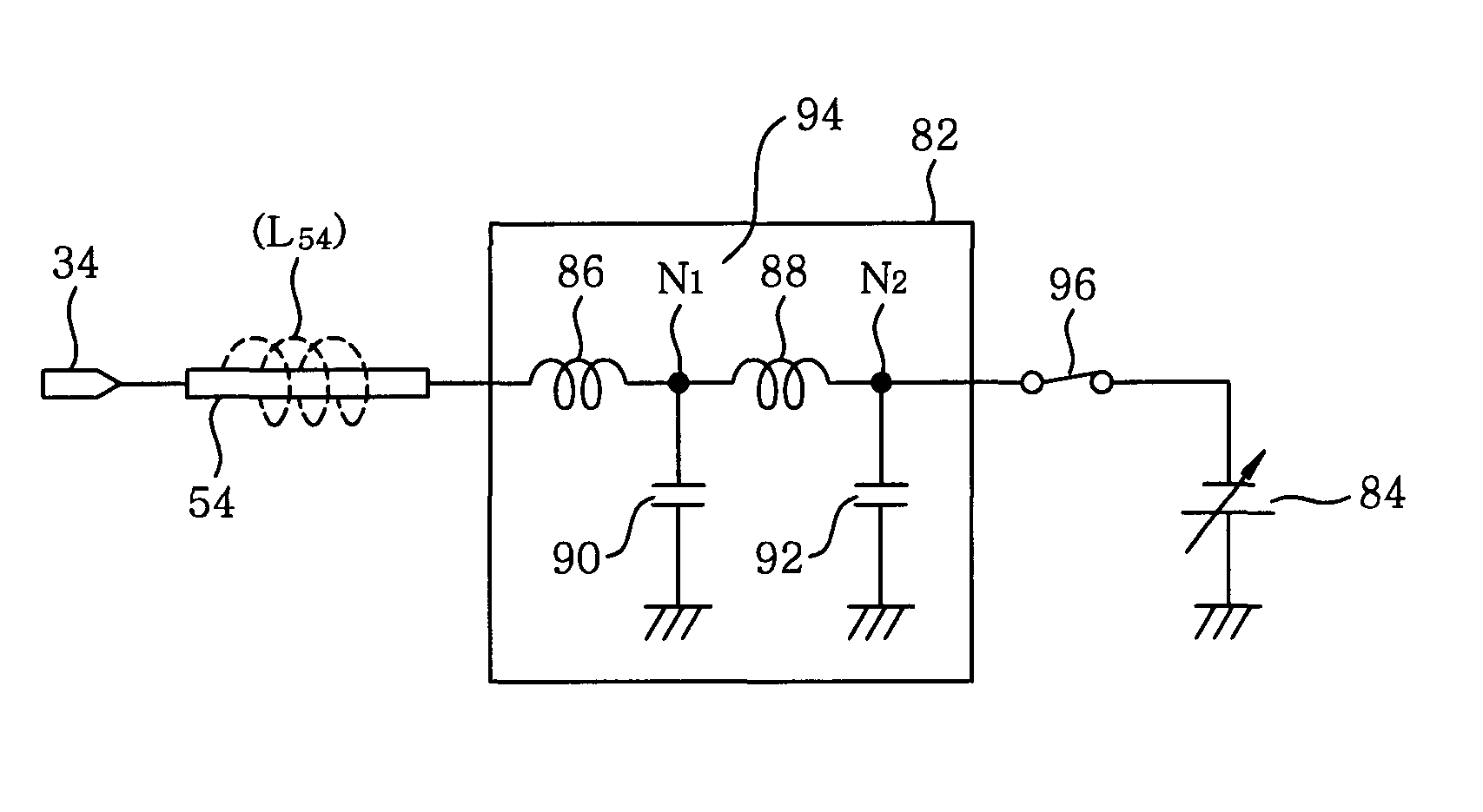

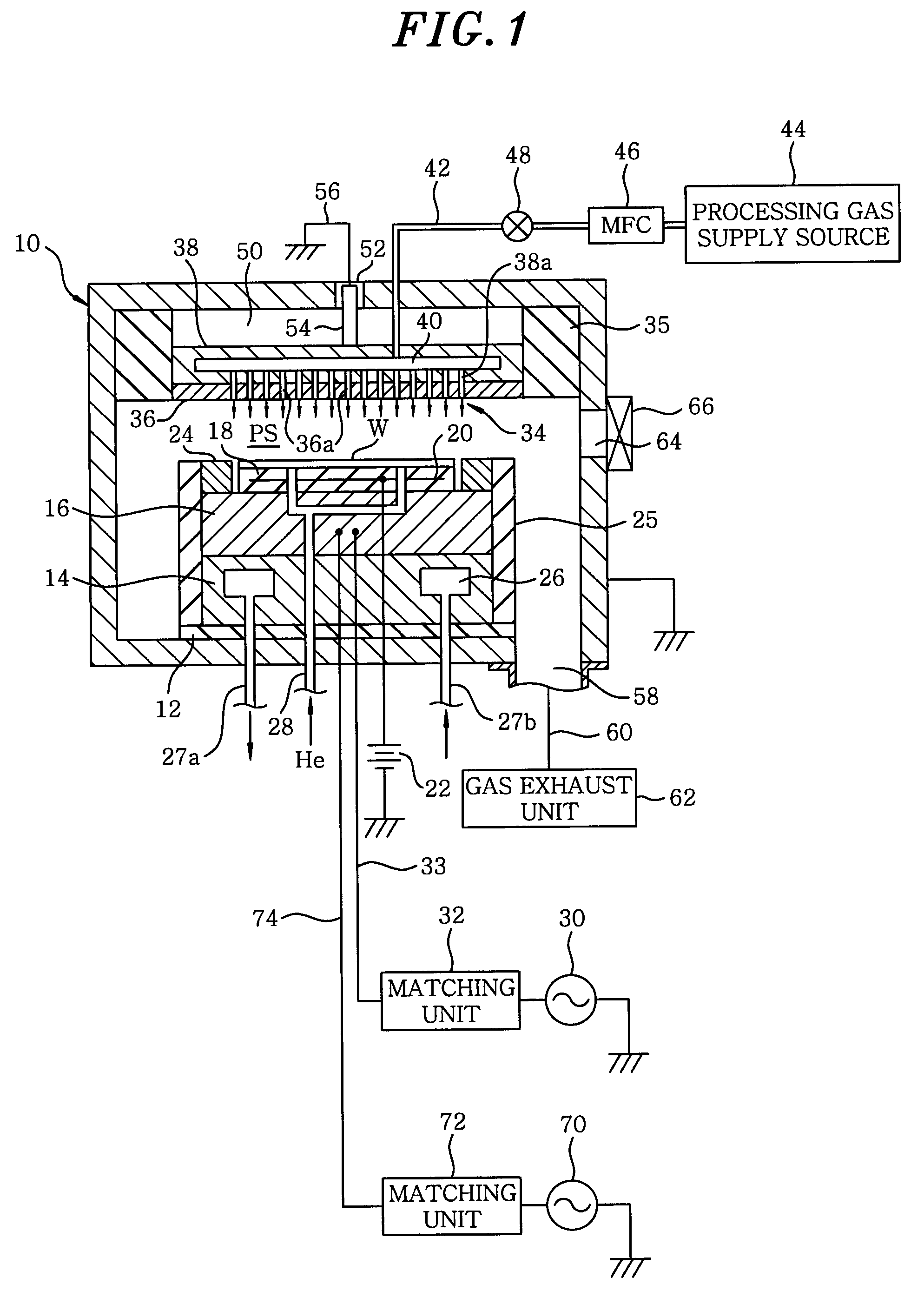

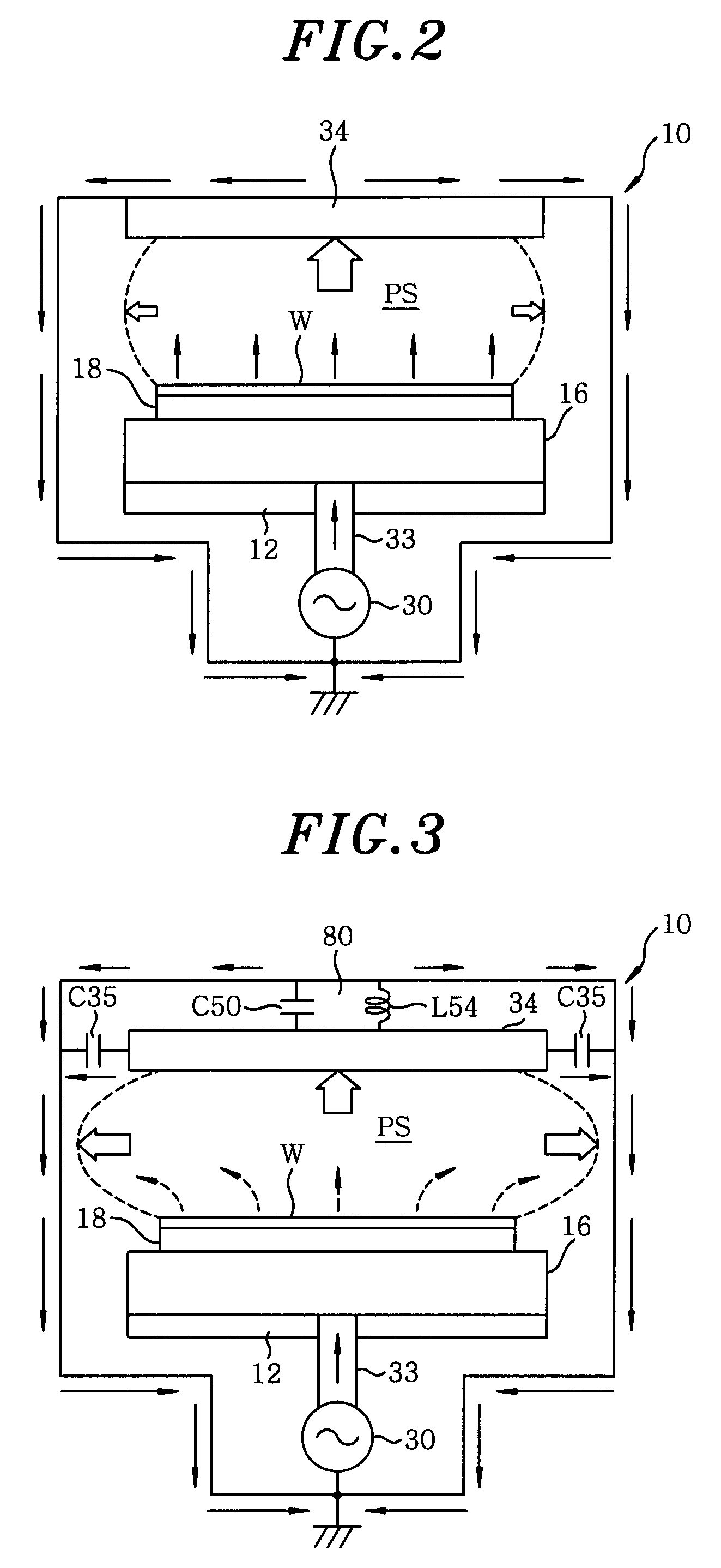

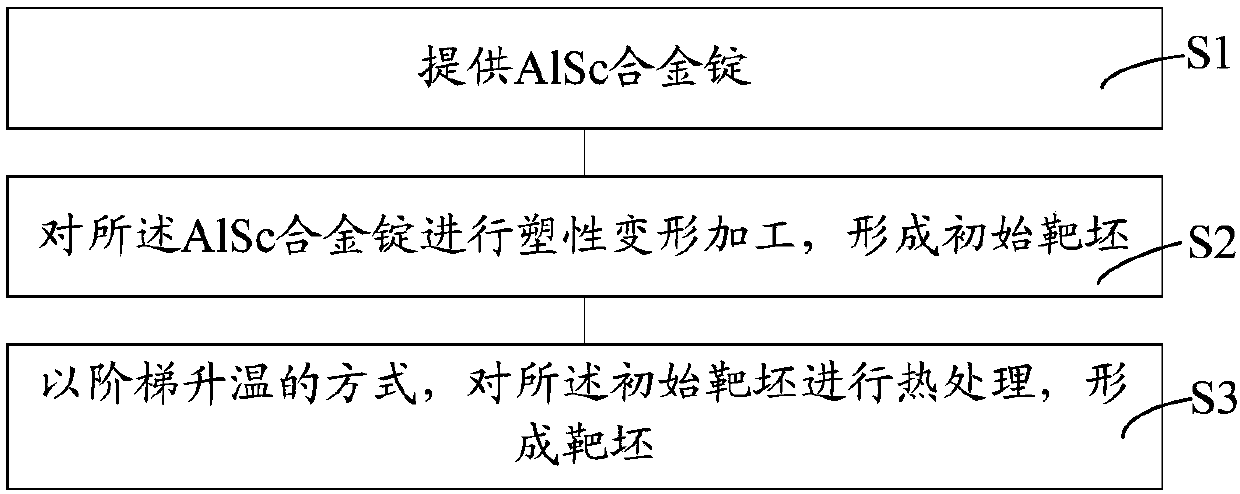

Plasma processing apparatus and plasma processing method

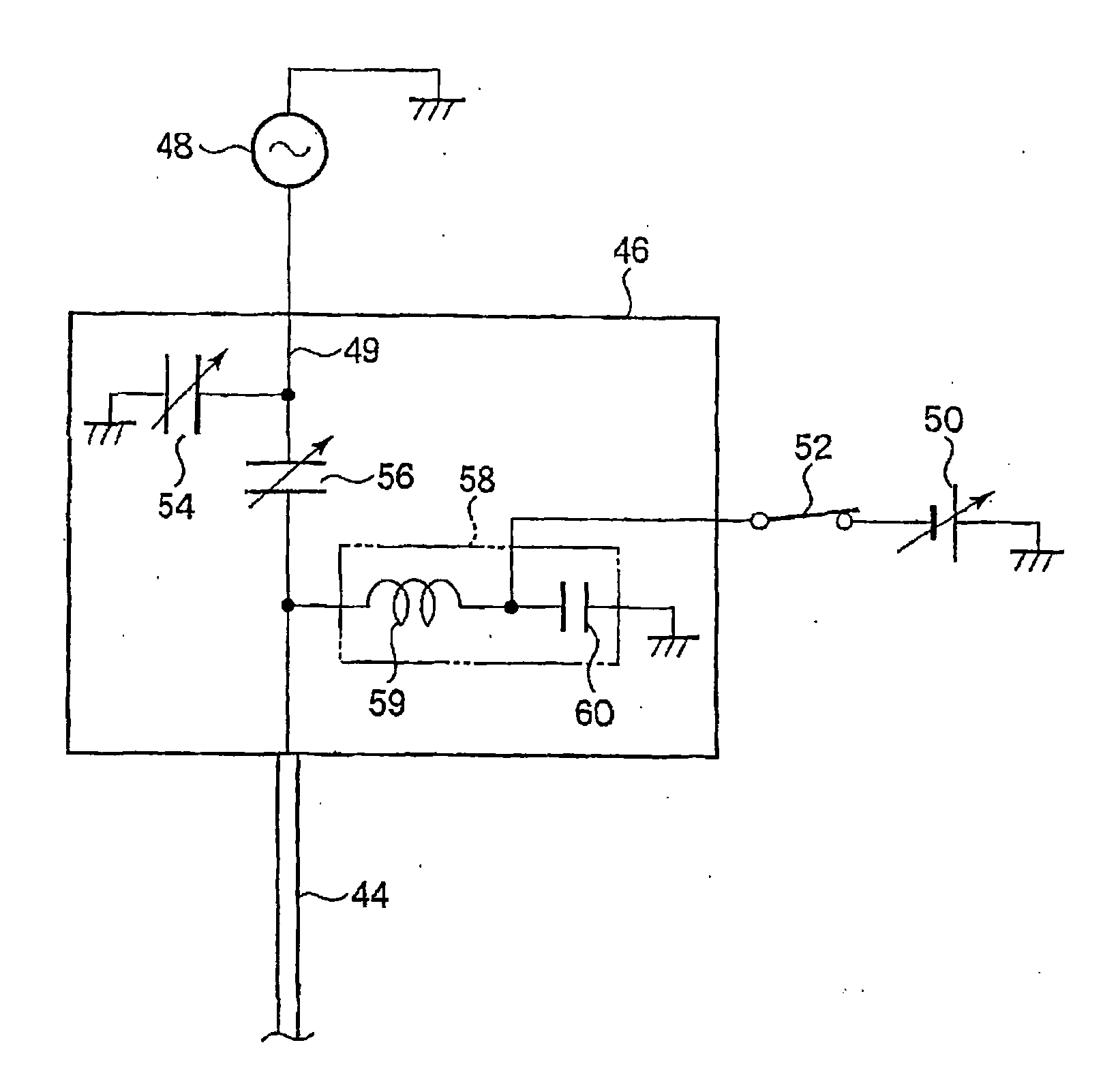

ActiveUS20070235426A1Improve uniformityEffectively sputteredElectric discharge tubesSemiconductor/solid-state device manufacturingElectricityInductor

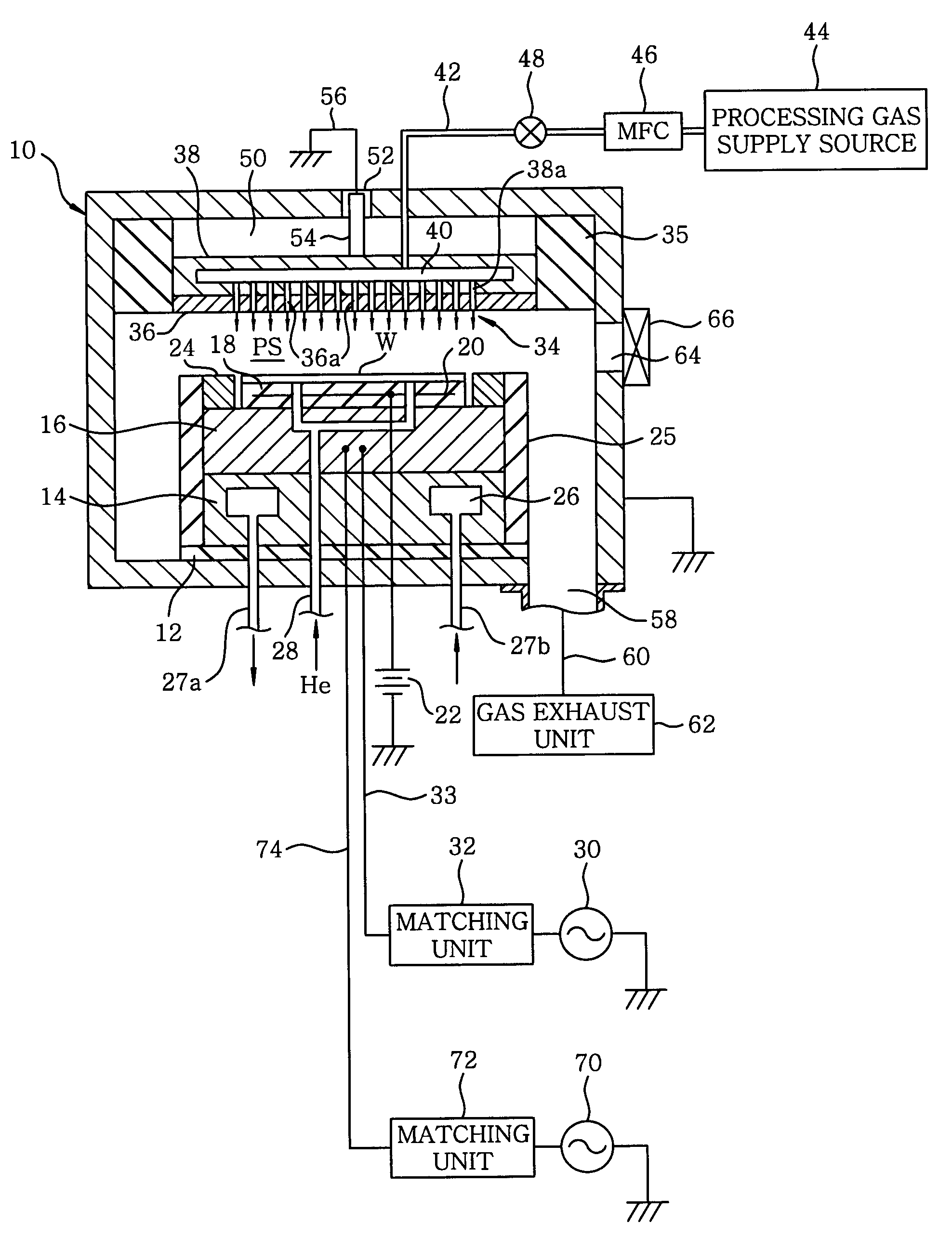

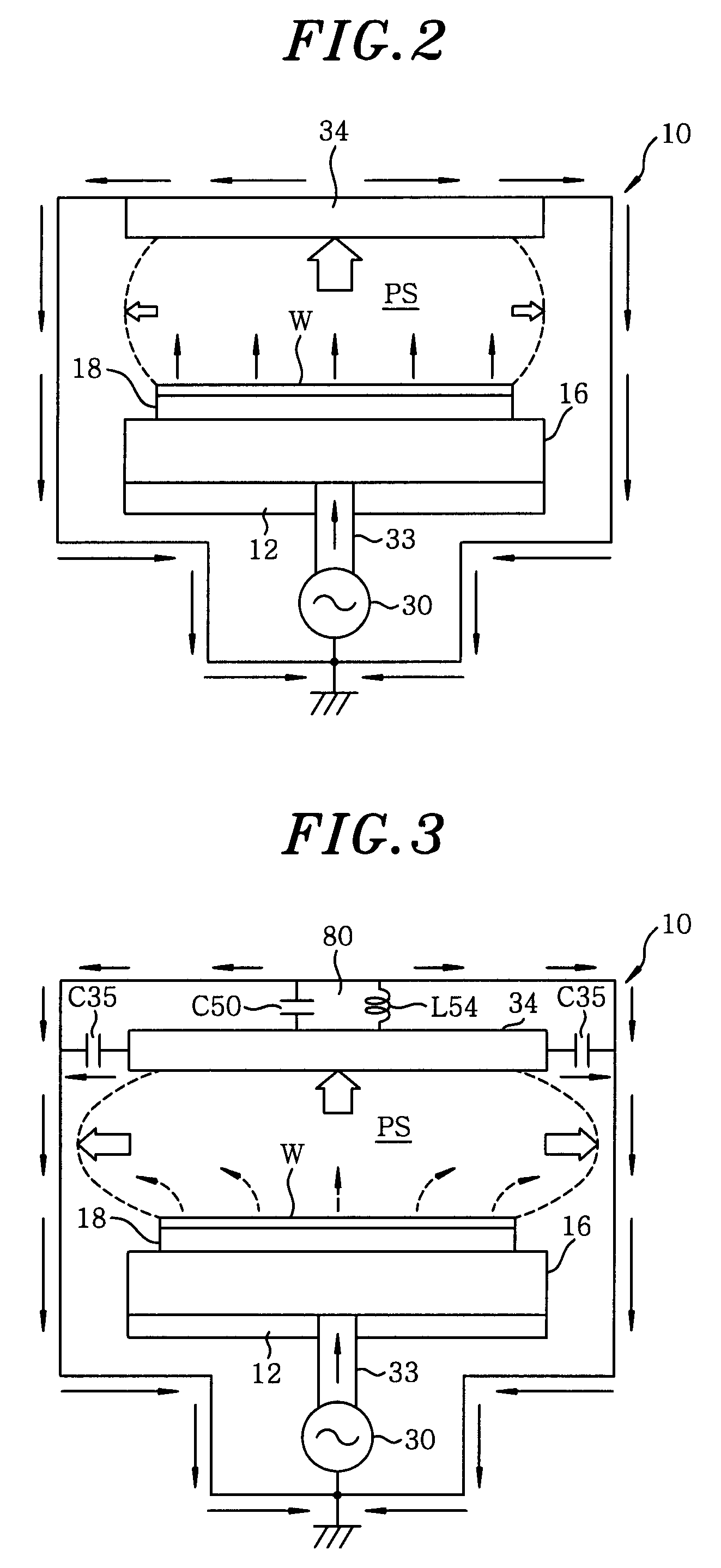

In a plasma processing apparatus, a first electrode is attached to a grounded evacuable processing chamber via an insulating material or a space and a second electrode disposed in parallel with the first electrode spaced apart therefrom in the processing chamber, the second electrode supporting a target substrate to face the first electrode. A first radio frequency power supply unit applies a first radio frequency power of a first frequency to the second electrode, and a second radio frequency power supply unit applies a second radio frequency power of a second frequency lower than the first frequency to the second electrode. Further, a processing gas supply unit supplies a processing gas to a processing space formed by the first and the second electrode and a sidewall of the processing chamber. Moreover, an inductor electrically is connected between the first electrode and a ground potential.

Owner:TOKYO ELECTRON LTD

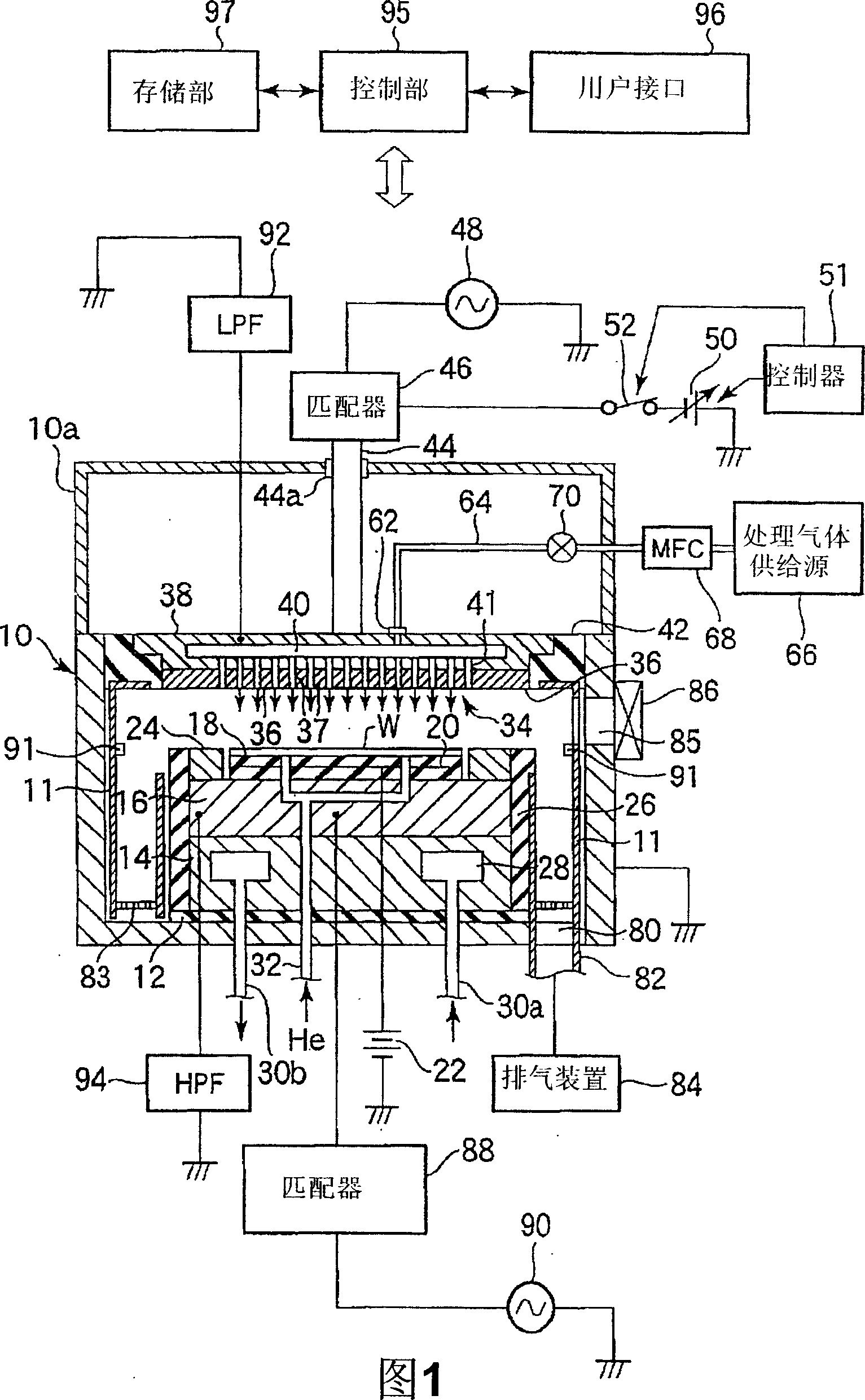

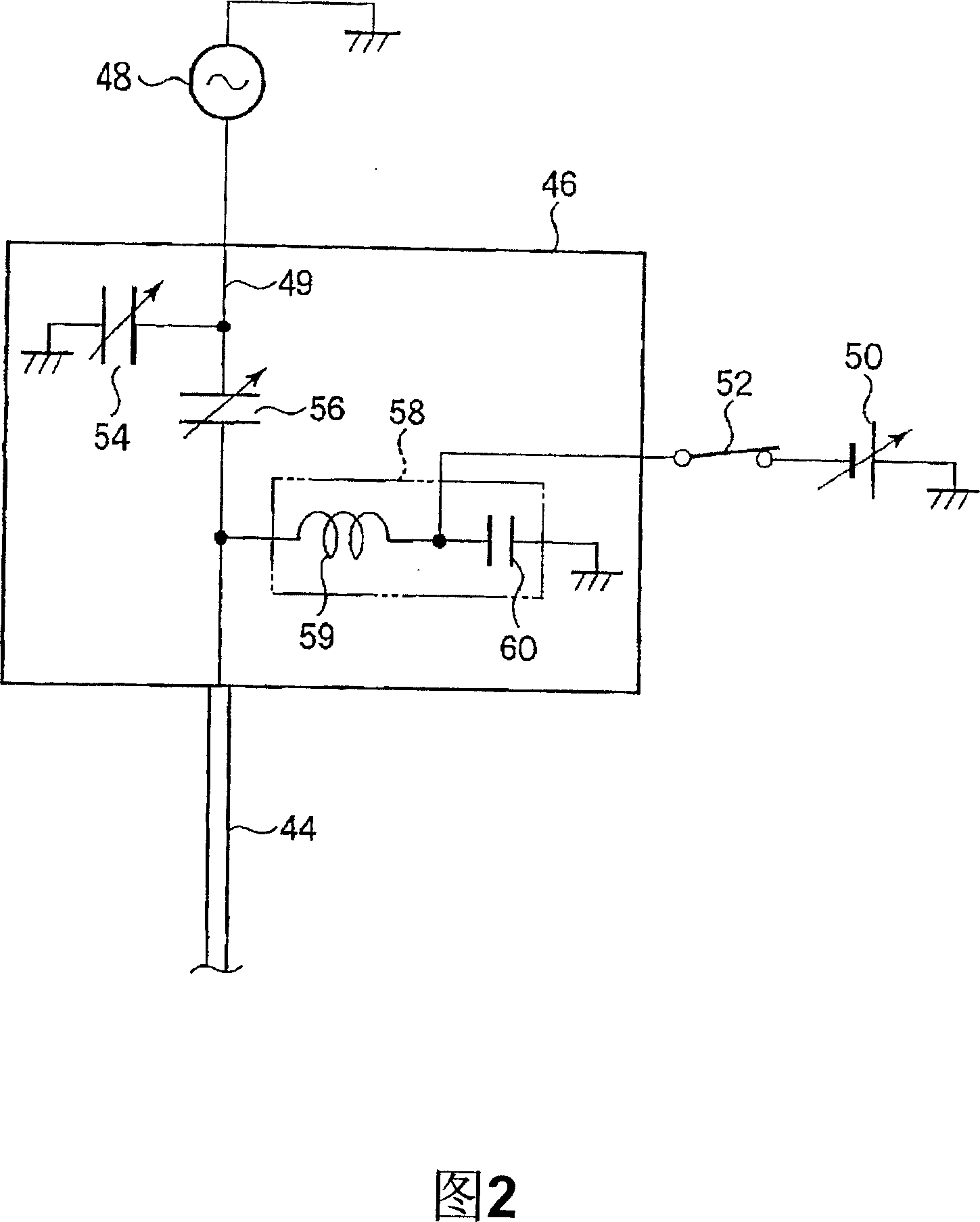

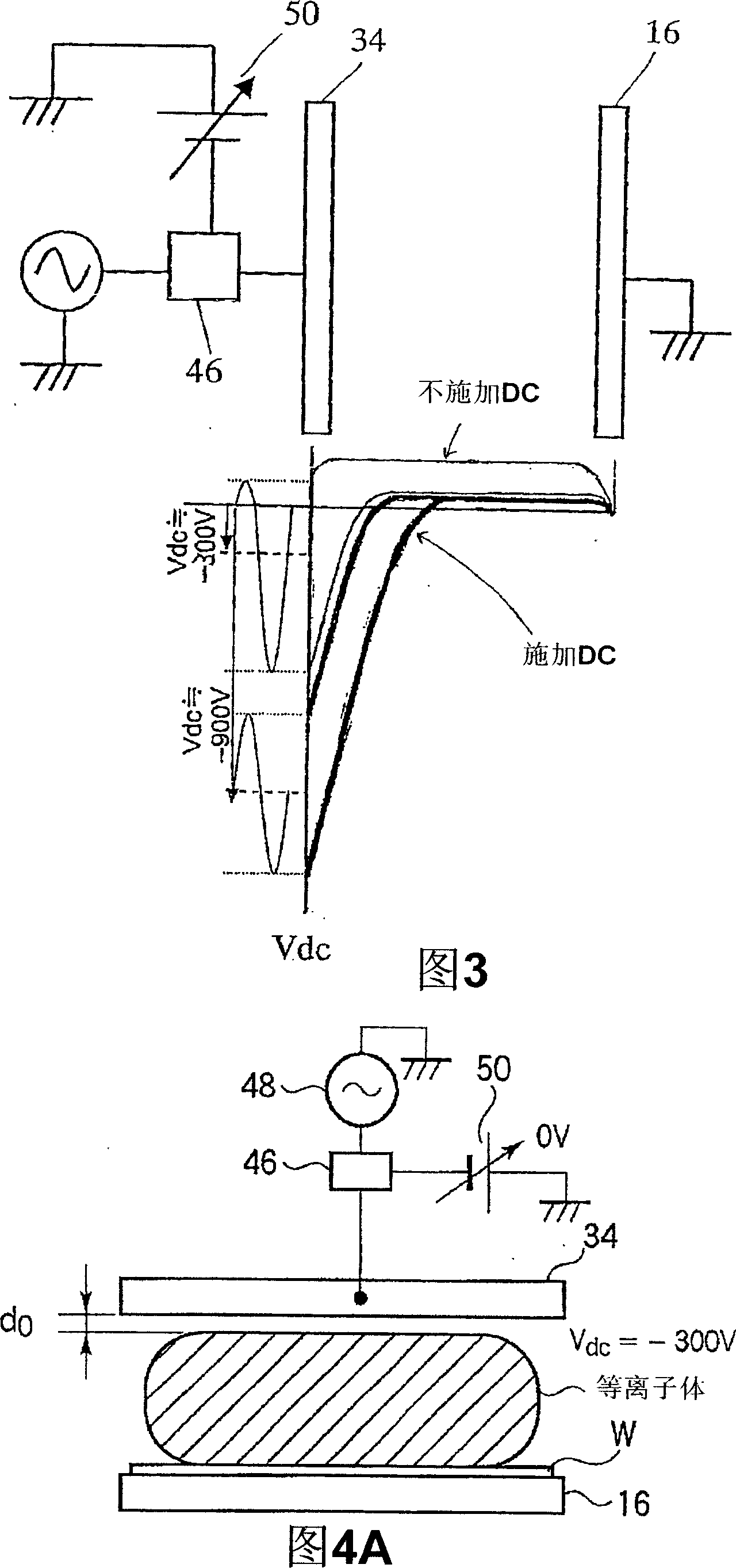

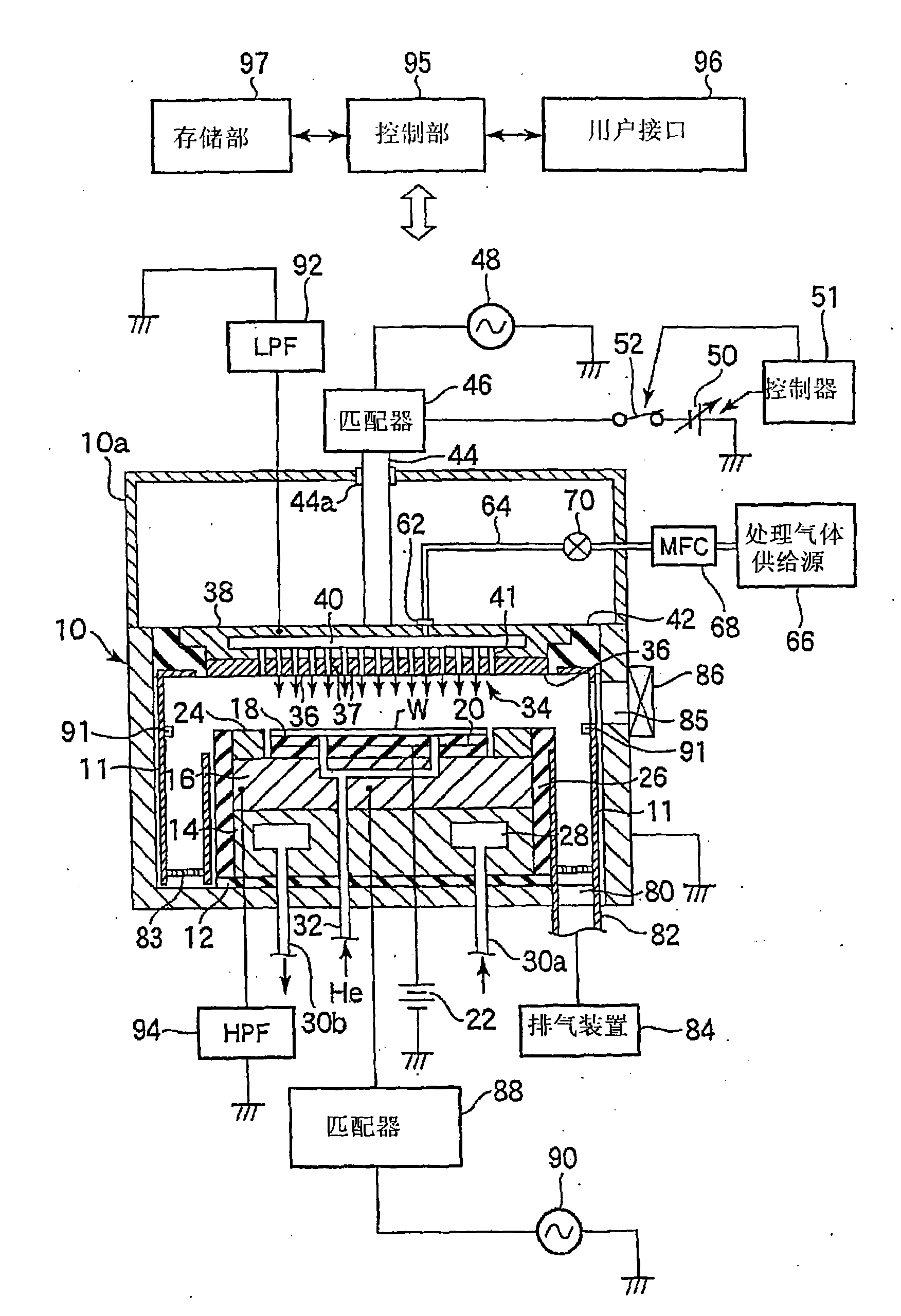

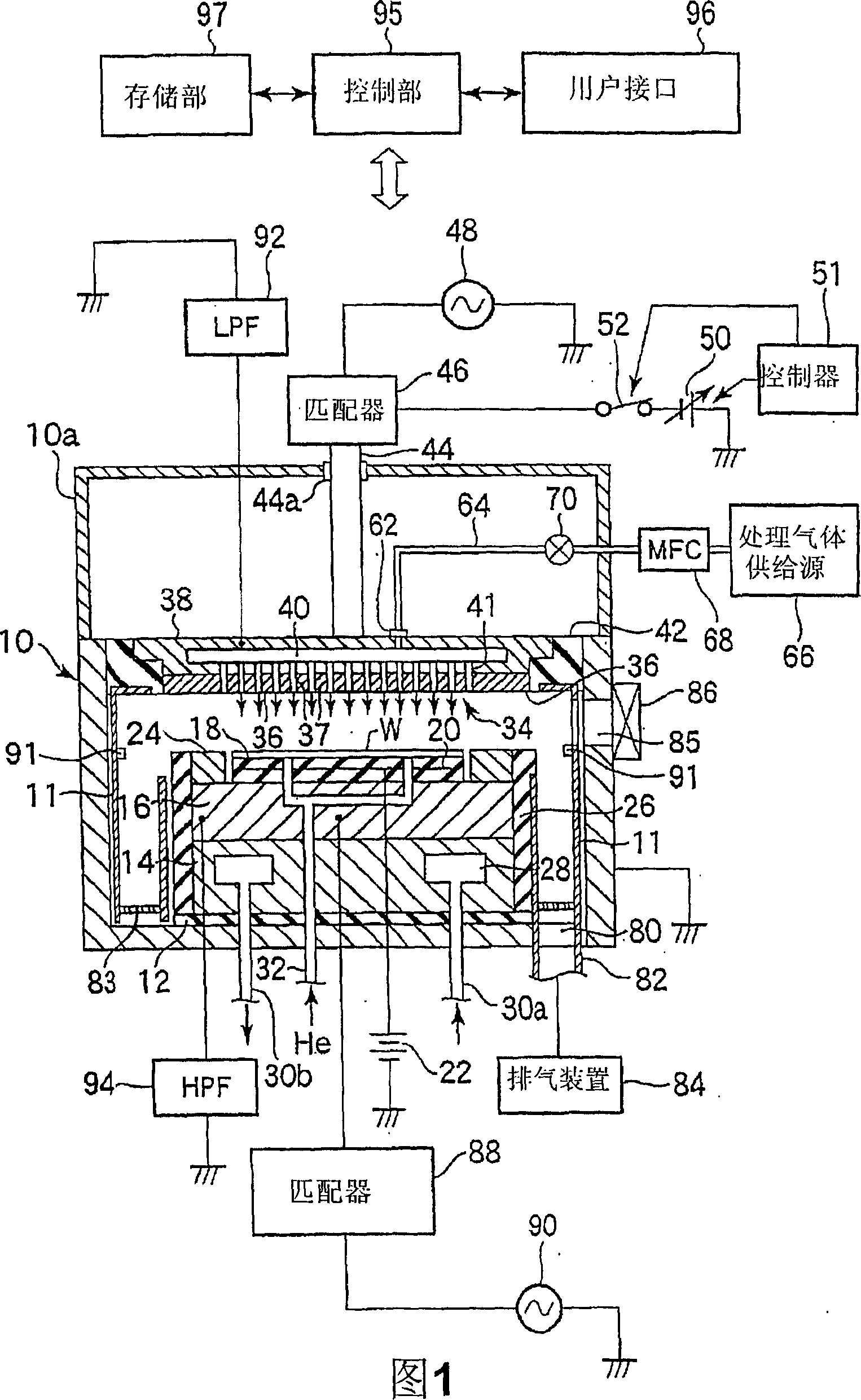

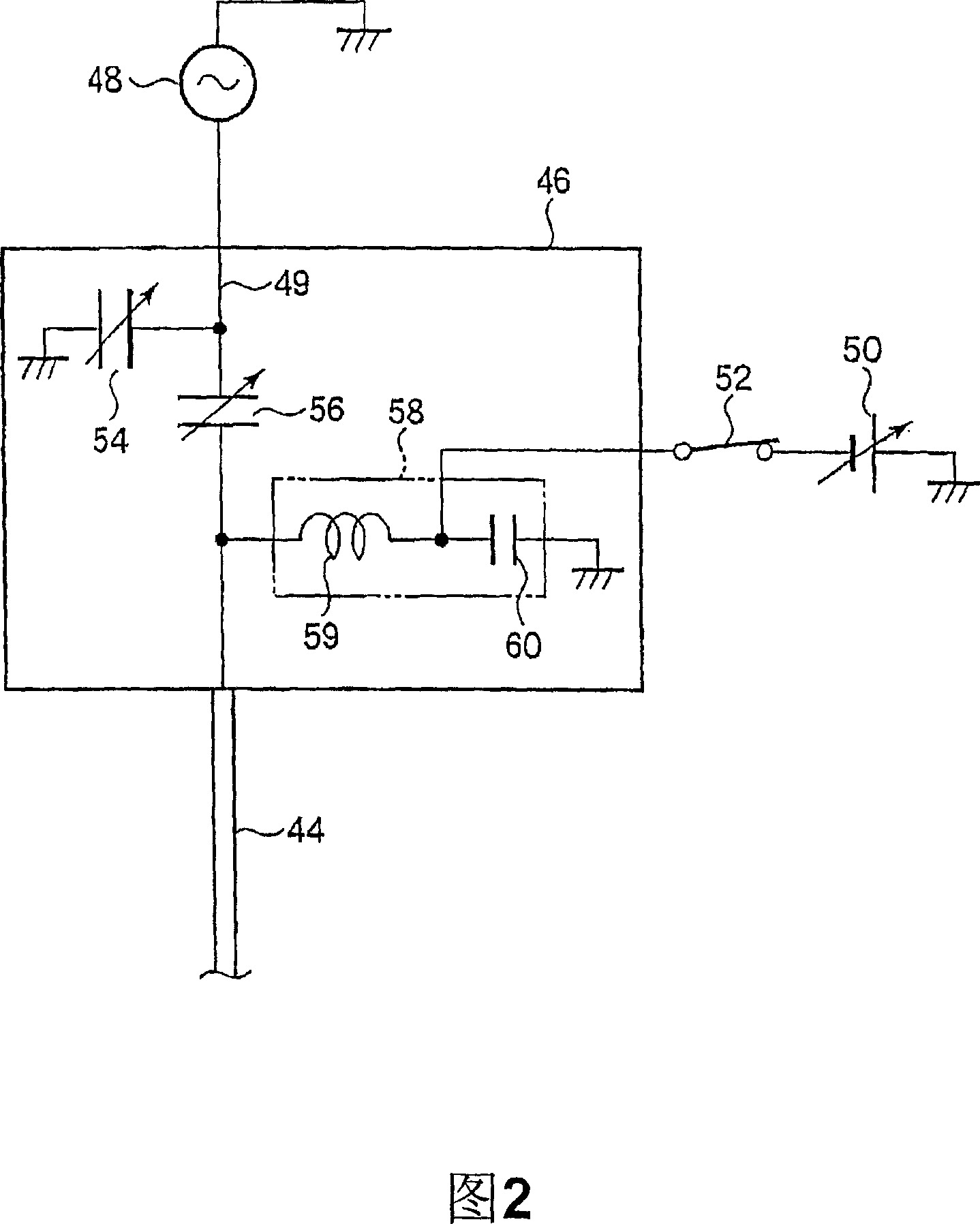

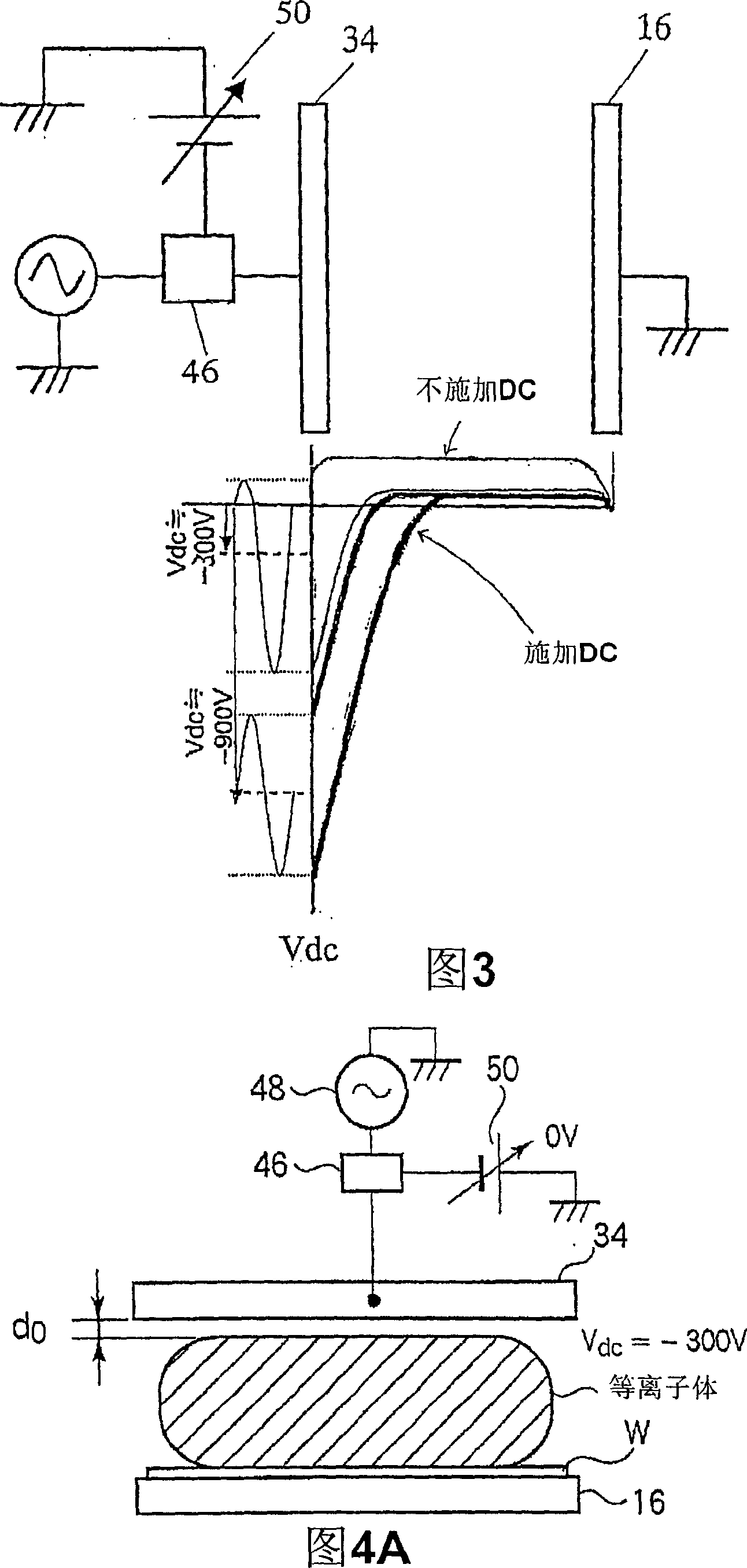

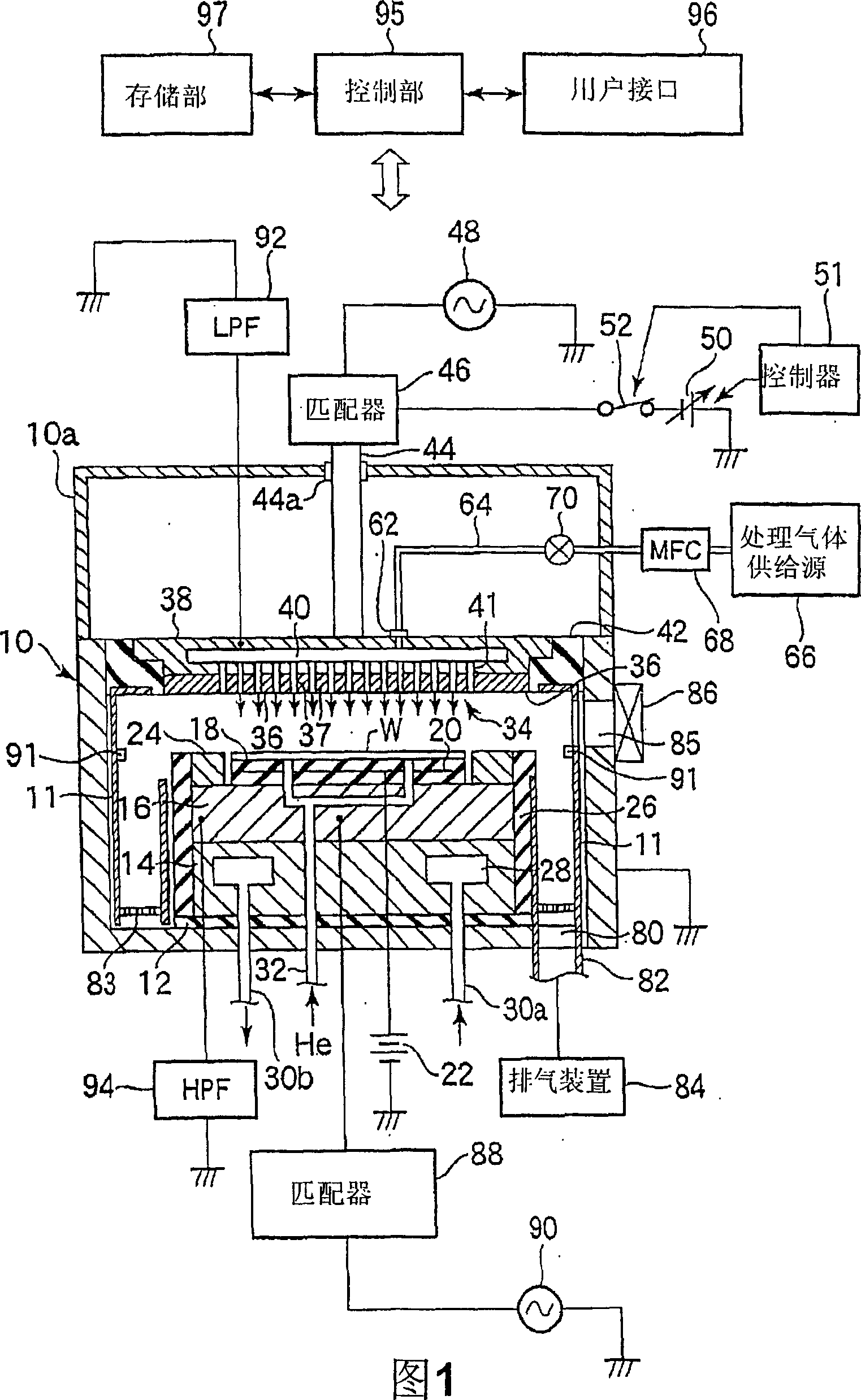

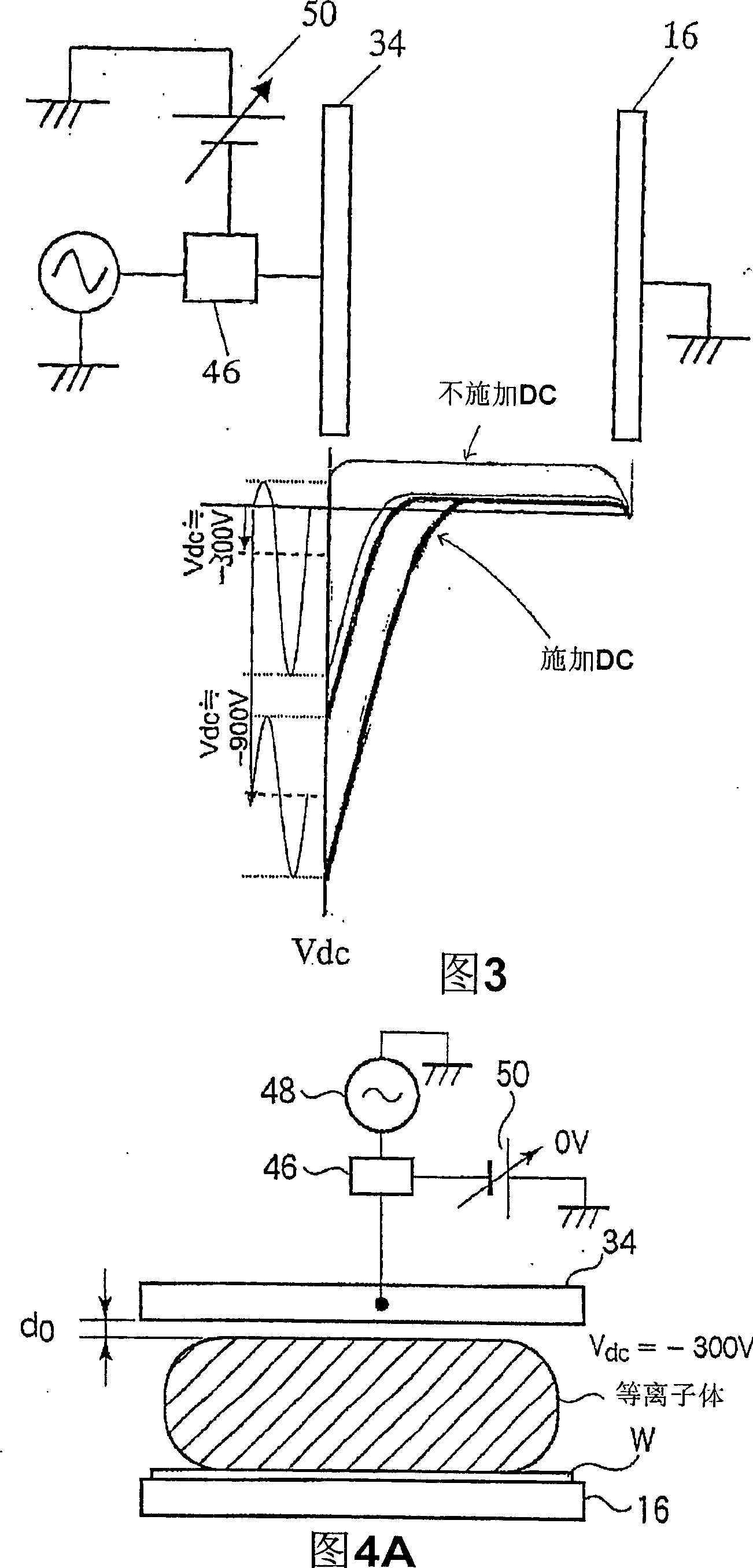

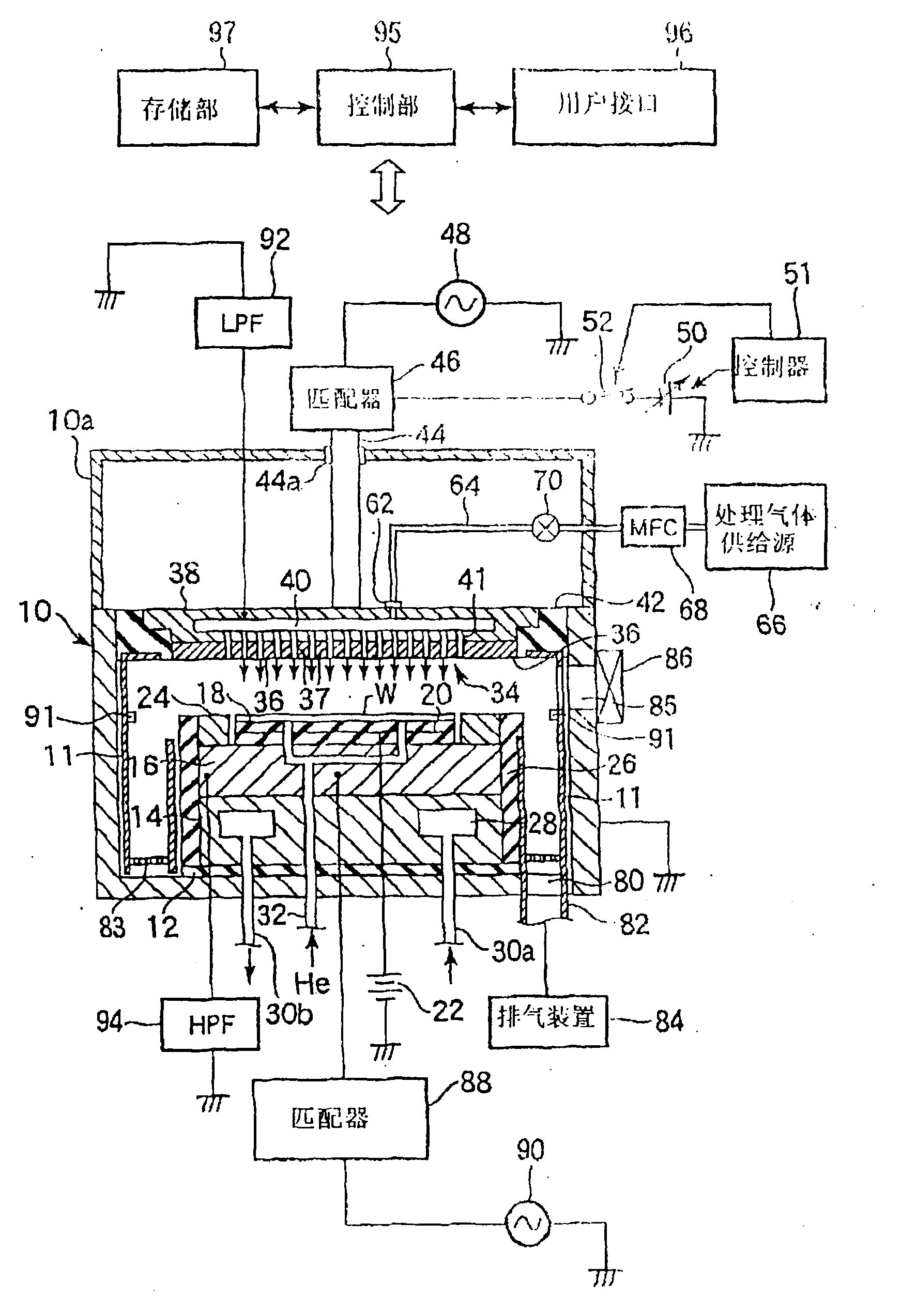

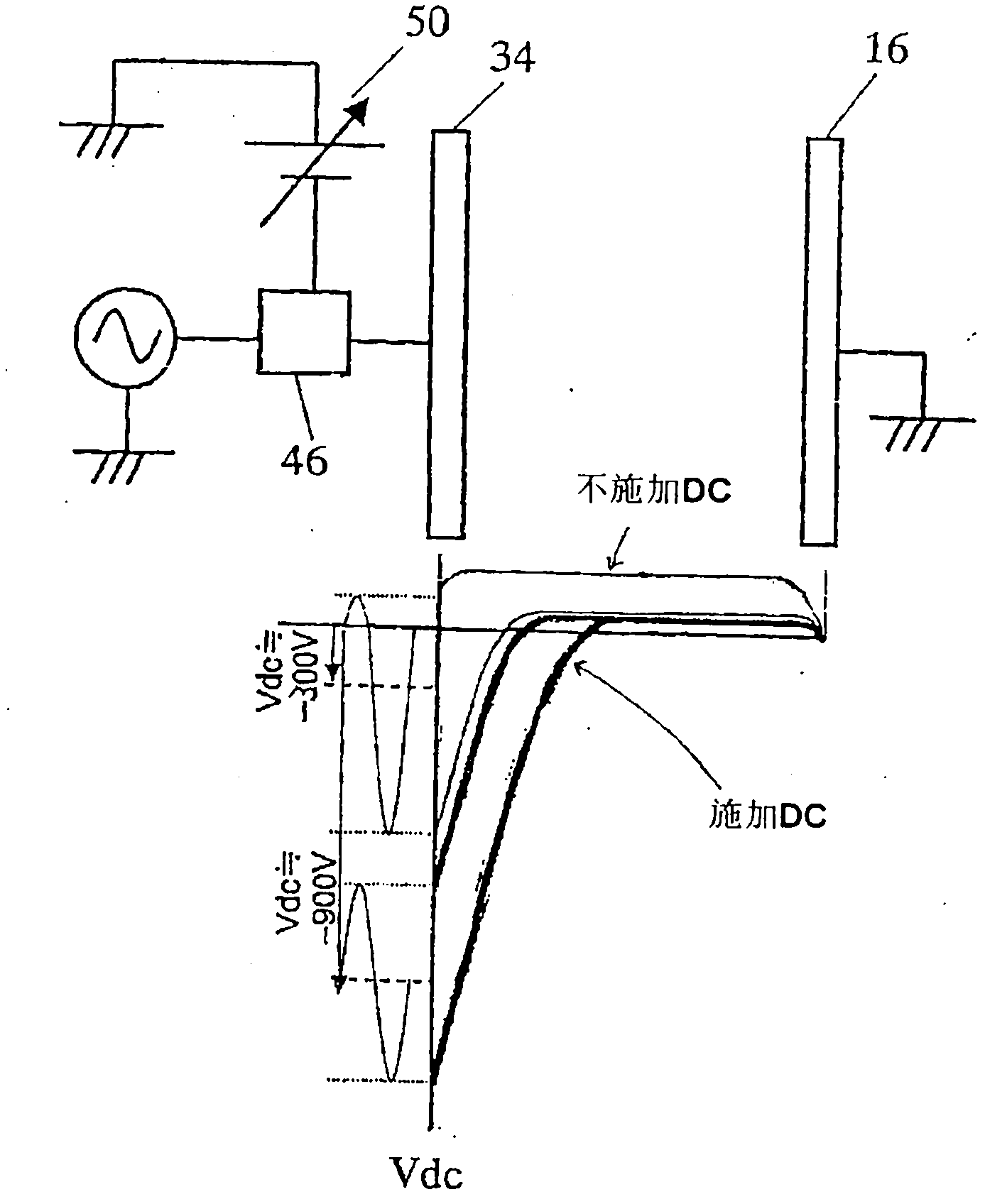

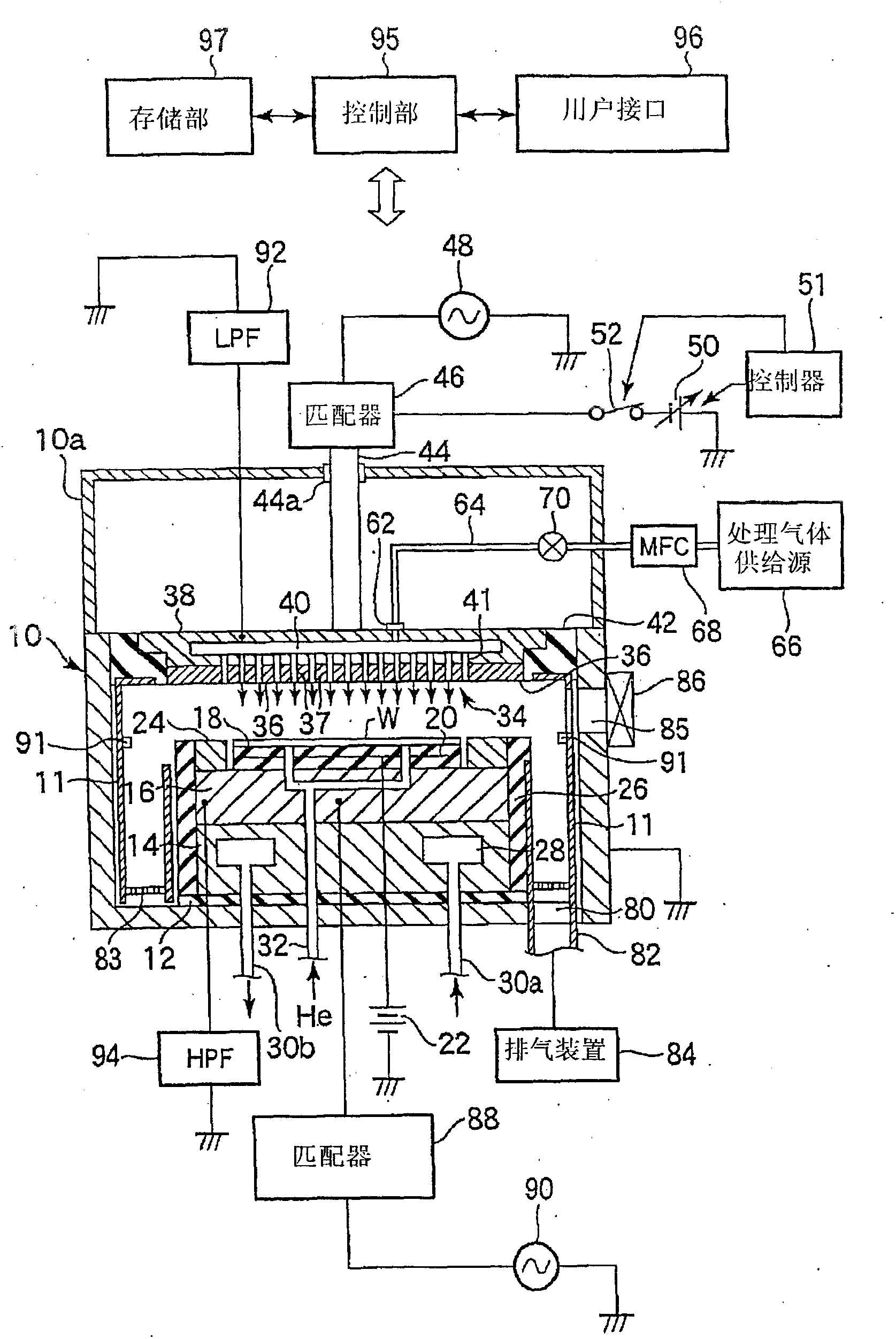

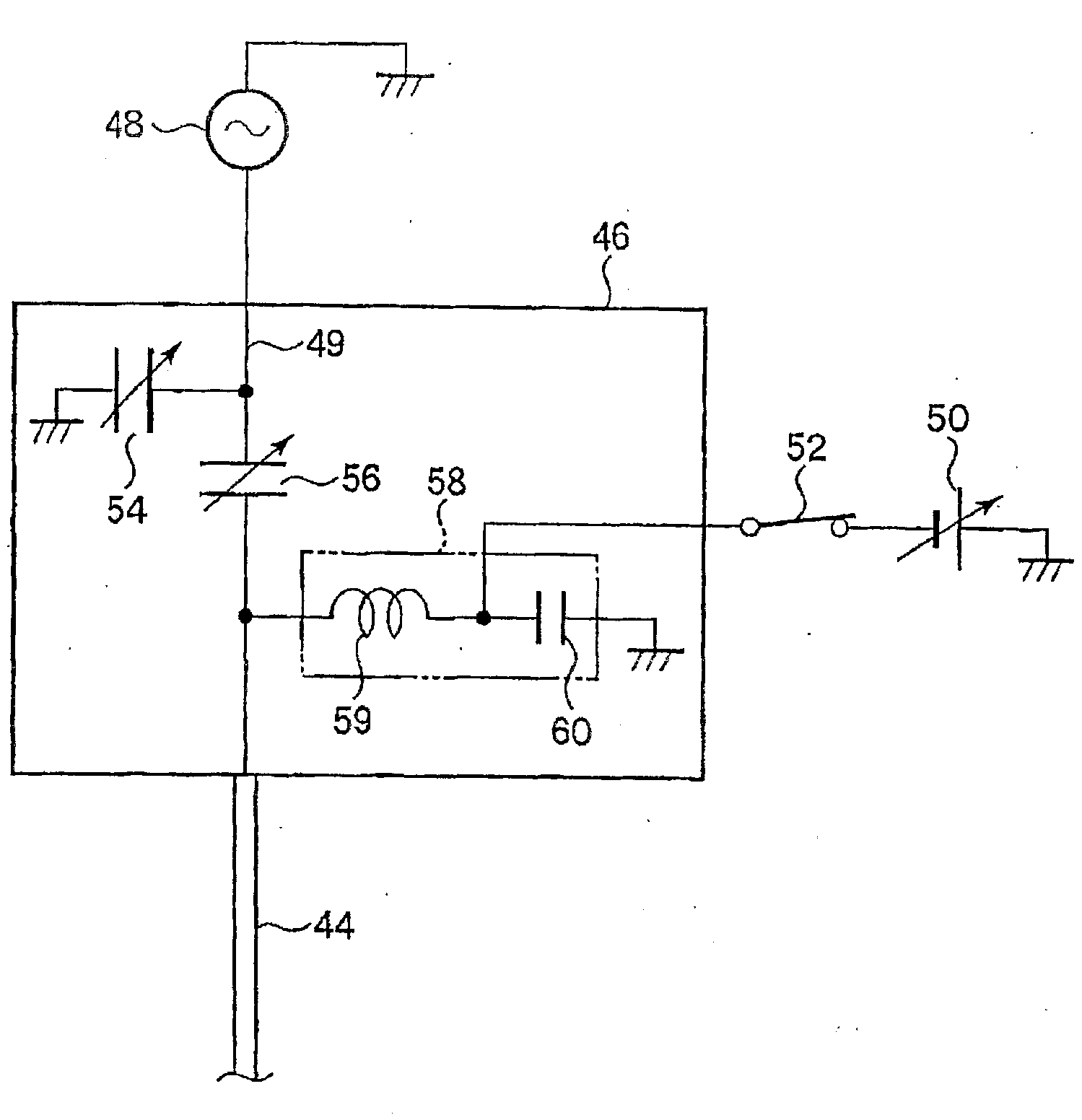

Plasma processing apparatus and method

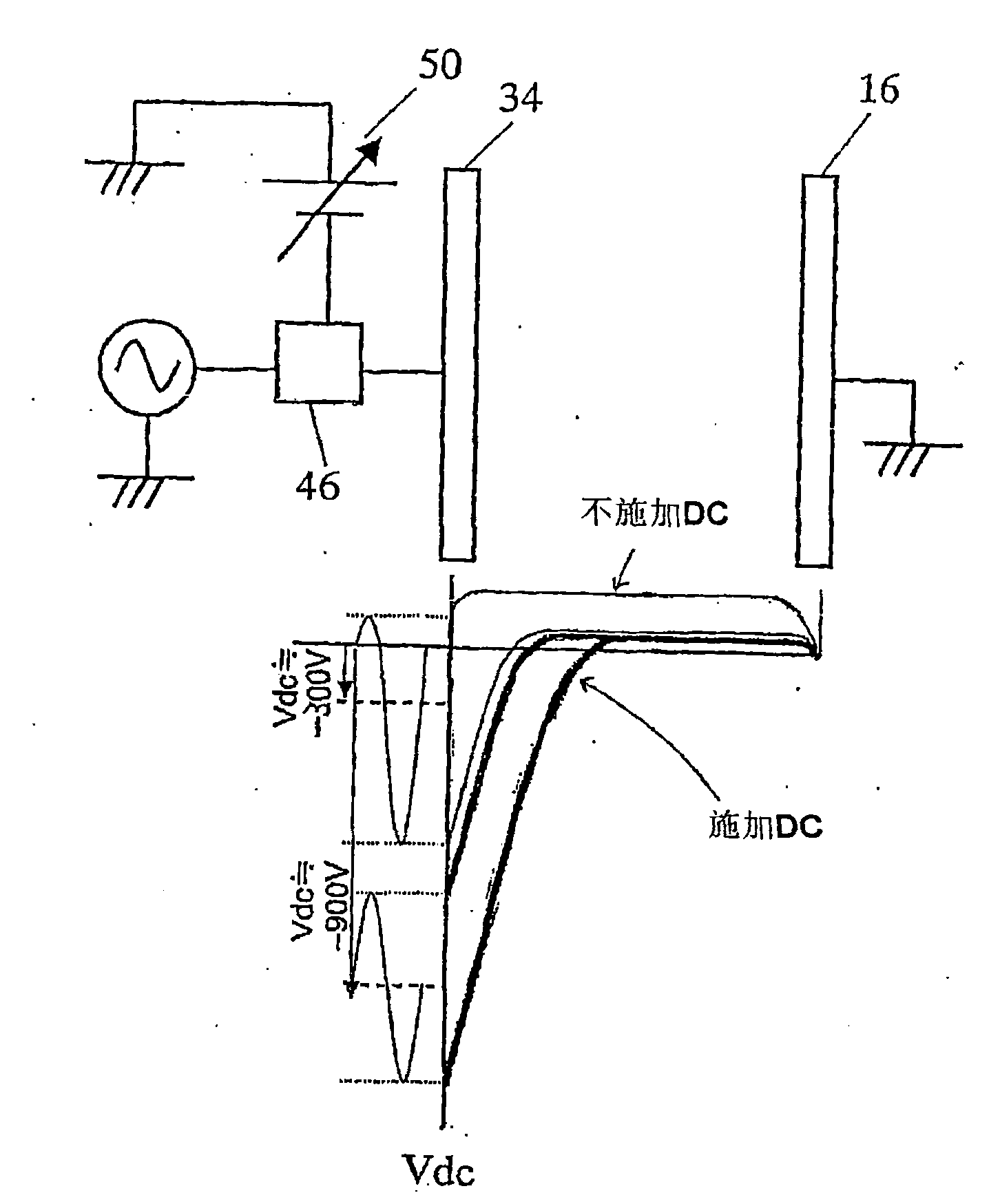

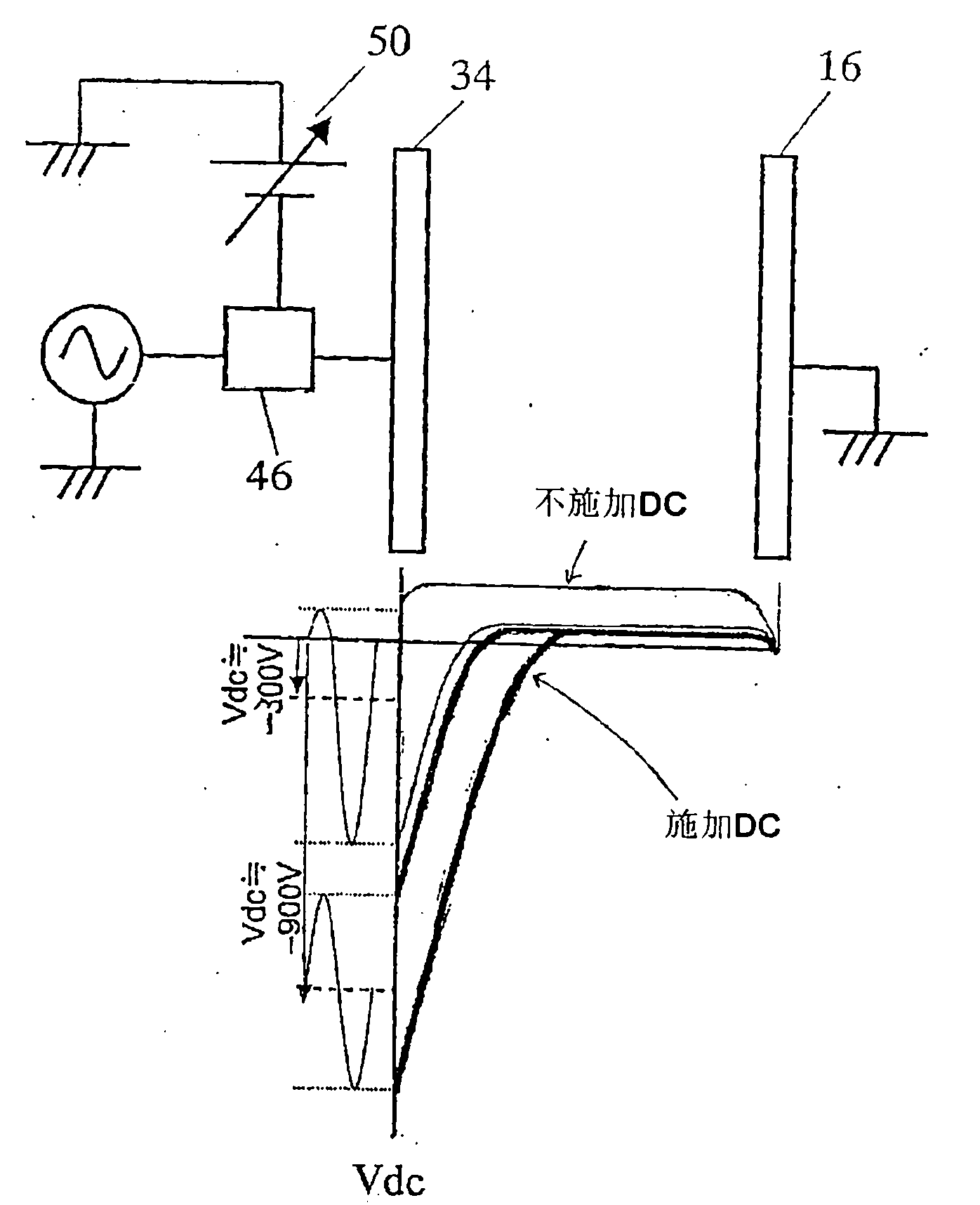

ActiveCN1973363AEliminate attachmentEtching high speedSemiconductor/solid-state device manufacturingMiniaturizationDc voltage

There is provided a plasma etching device for generating plasma as a processing gas between an upper electrode (34) and a lower electrode (16) and subjecting a wafer (W) to plasma etching. The upper electrode (34) includes a variable DC power source (50) for applying DC voltage so that the absolute value of the self bias voltage Vdc on the surface of the upper electrode (34) becomes large enough to obtain an appropriate sputter effect to the surface and the thickness of the plasma sheath on the upper electrode (34) becomes thick enough to form a desired miniaturization plasma.

Owner:TOKYO ELECTRON LTD

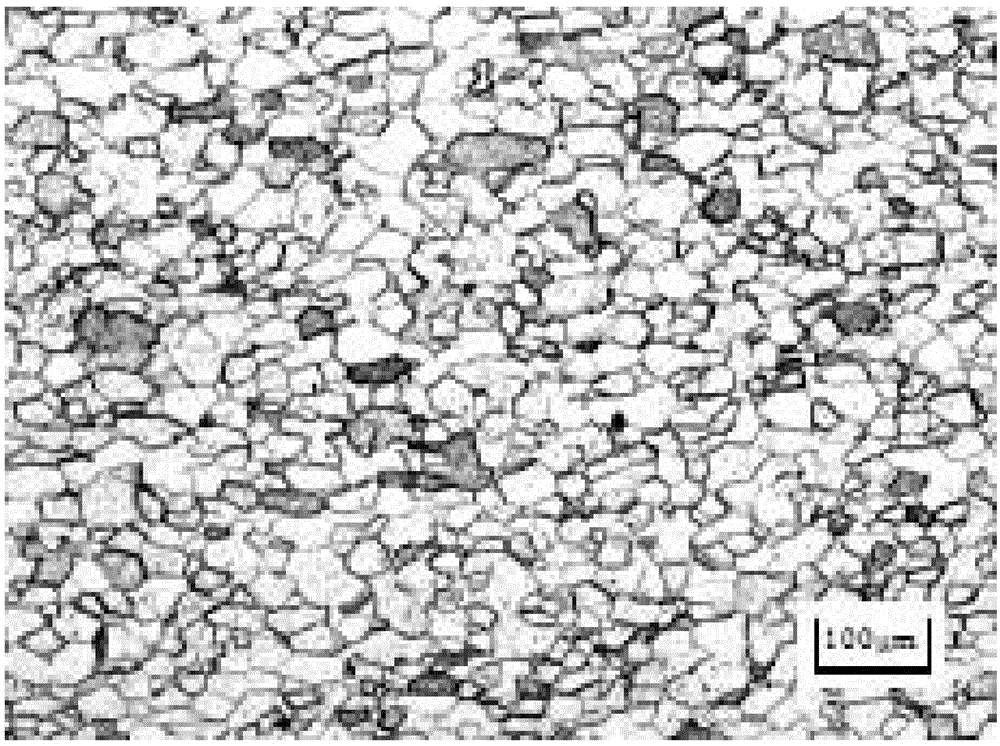

Tantalum target and manufacturing method thereof

ActiveCN104451567AFully brokenUniform deformationVacuum evaporation coatingSputtering coatingIngotThermal treatment

The invention provides a tantalum target and a manufacturing method thereof; the manufacturing method comprises the steps: firstly, performing a first forging to a tantalum ingot and obtaining a primary forged blank; performing a second forging and a first thermal treatment to the primary forged blank obtained in the previous step and obtaining a secondary forged blank; performing a third forging and a second thermal treatment to the secondary forged blank obtained in the previous step and obtaining a tertiary forged blank; performing a fourth forging and a third thermal treatment to the tertiary forged blank obtained in the previous step and obtaining a quartus forged blank; and finally, rolling and performing a fourth thermal treatment to the quartus forged blank obtained in the previous step and obtaining the tantalum target; the first forging is a rotary forging; the temperature of the first forging is 800-1400 degrees centigrade. The prepared tantalum target is uniform in texture distribution, small in grain size and capable of satisfying usage requirements in high-level semiconductor film-coating industries.

Owner:NINGXIA ORIENT TANTALUM IND

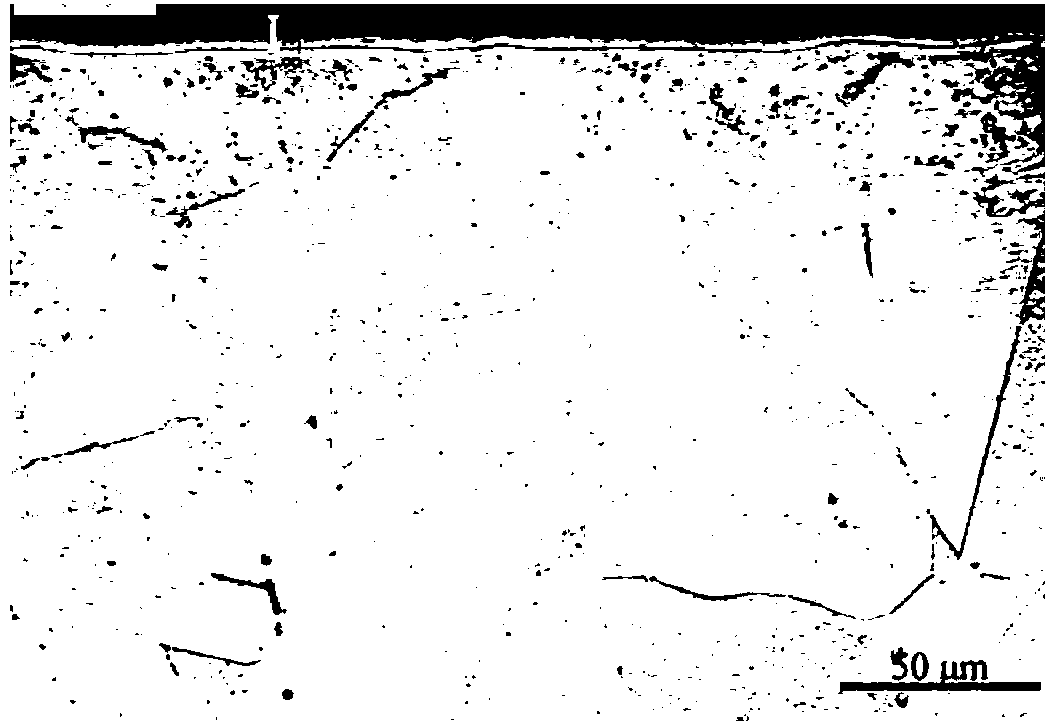

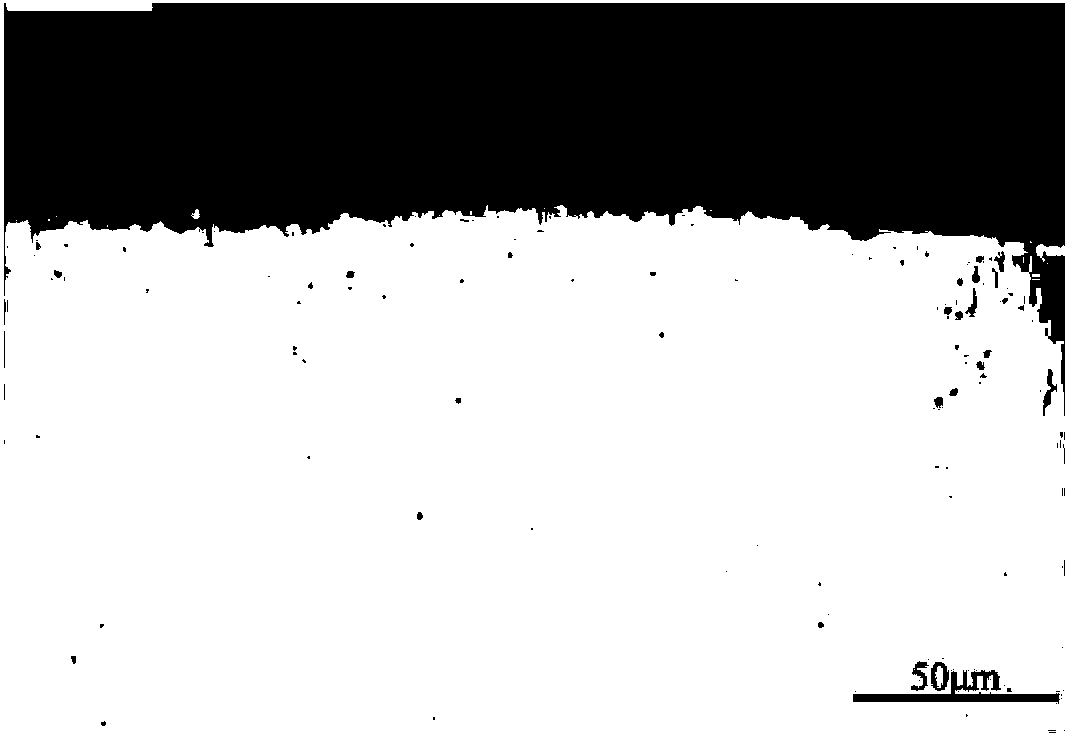

Low-temperature rapid ion nitriding method of austenitic stainless steel

InactiveCN103233197AImprove diffusion abilityHigh energySolid state diffusion coatingVacuum pumpAustenite

The invention relates to a surface treatment method and particularly relates to a low-temperature rapid ion nitriding method of austenitic stainless steel. According to the method disclosed by the invention, a thicker ion nitriding layer can be obtained by changing gas pressure in an ion nitriding furnace and performing heat preservation for a period of time at the ion nitriding temperature of 350-370 DEG C. The preparation method comprises the following steps of: firstly removing oil stains on the austenitic stainless steel, performing pre-grinding treatment on a test sample, and then performing ultrasonic cleaning and drying in an organic solvent; then placing the well prepared test sample into a vacuum chamber of an ion nitriding device, performing vacuum-pumping operation to the required vacuum degree, and then introducing hydrogen to perform ion bombard cleaning; and finally adjusting ion nitriding pressure and heat preservation time during the low-temperature ion nitriding process to obtain the thicker nitriding layer so as to solve the problems of thin ion nitriding layer and poor wear resistance under low-temperature conditions. By using the method disclosed by the invention to perform ion nitriding and respectively perform heat preservation for 4h, 6h and 8h, the maximum thickness of the nitriding layer can respectively achieve 22.2 mu m, 29.6 mu m and 51.7 mu m.

Owner:CHANGZHOU UNIV

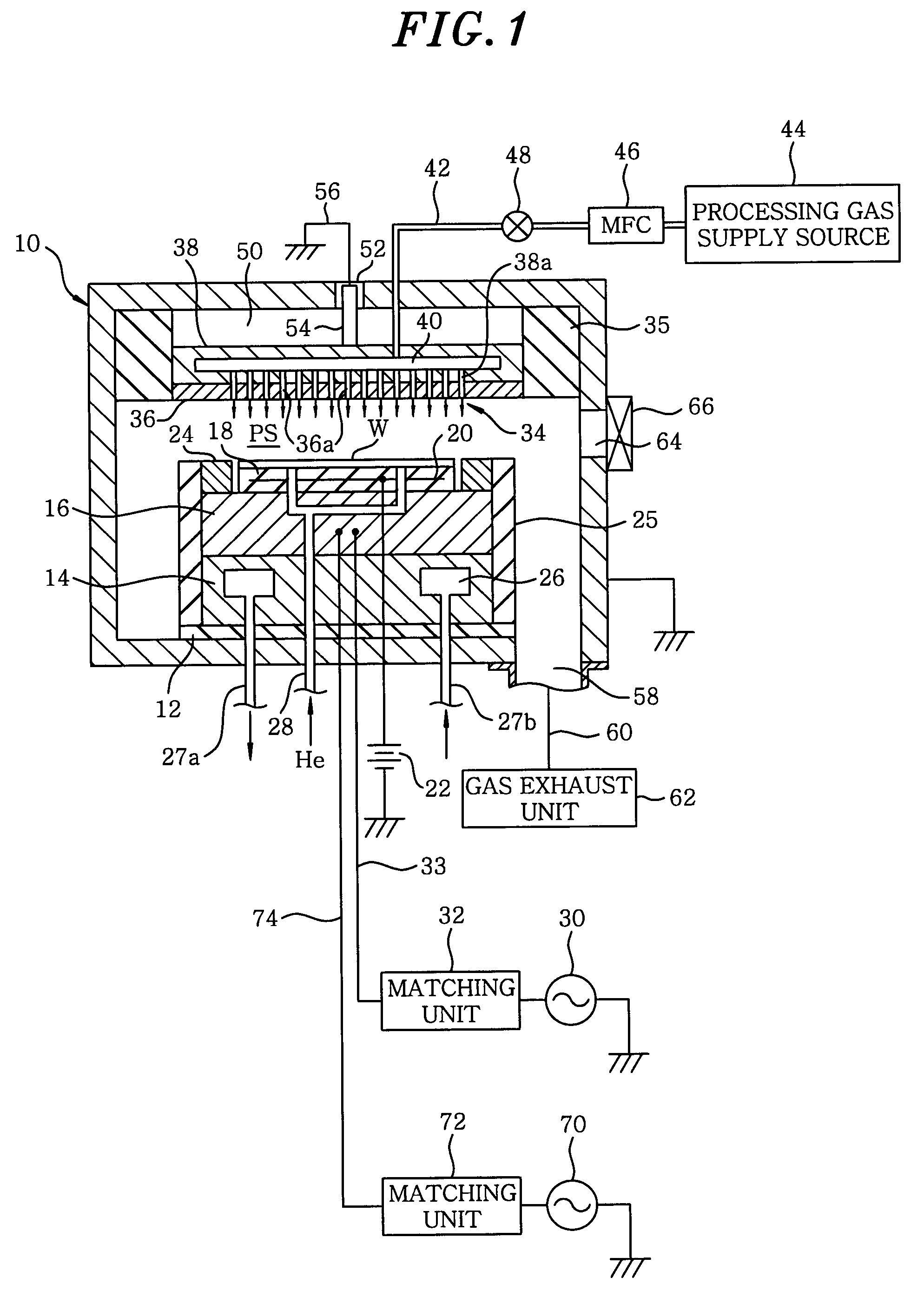

Plasma processing apparatus and method

ActiveCN102157372AEliminate attachmentEtching high speedElectric discharge tubesSemiconductor/solid-state device manufacturingMiniaturizationDc voltage

There is provided a plasma etching device for generating plasma as a processing gas between an upper electrode (34) and a lower electrode (16) and subjecting a wafer (W) to plasma etching. The upper electrode (34) includes a variable DC power source (50) for applying DC voltage so that the absolute value of the self bias voltage Vdc on the surface of the upper electrode (34) becomes large enough to obtain an appropriate sputter effect to the surface and the thickness of the plasma sheath on the upper electrode (34) becomes thick enough to form a desired miniaturization plasma.

Owner:TOKYO ELECTRON LTD

Weather-resistant silver mirror and preparation method thereof

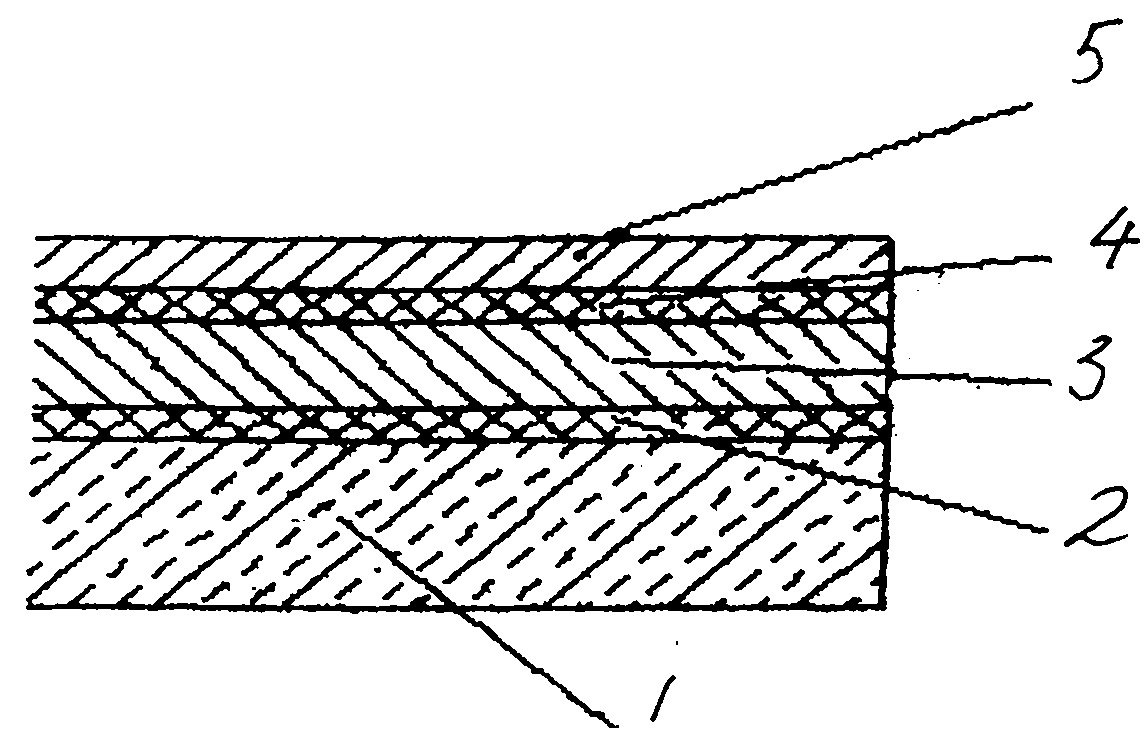

ActiveCN101776778AImprove reliabilityExtended service lifeMirrorsIntermediate frequencyReflective layer

The invention discloses a weather-resistant silver mirror which is particularly suitable for trough solar thermal power generation and a preparation method thereof. The silver mirror orderly consists of a transparent substrate, a first Al2O3 adhesive layer, an Ag reflective layer, a second Al2O3 adhesive protective layer and a SiOx protective layer. The preparation method thereof comprises the step of orderly and respectively plating the first Al2O3 adhesive layer, the Ag reflective layer, the second Al2O3 adhesive protective layer and the SiOx protective layer by adopting a multi-target intermediate frequency response vertical magnetic control sputter to prepare the weather-resistant silver mirror of the invention. The finished product of the weather-resistant silver mirror of the invention has the characteristics of high reflectivity, reliable work, long service life and the like. The preparation method of the invention has the characteristics of advance, reasonability, low cost, low energy consumption, good quality of the finished product and the like.

Owner:常州龙腾光热科技股份有限公司

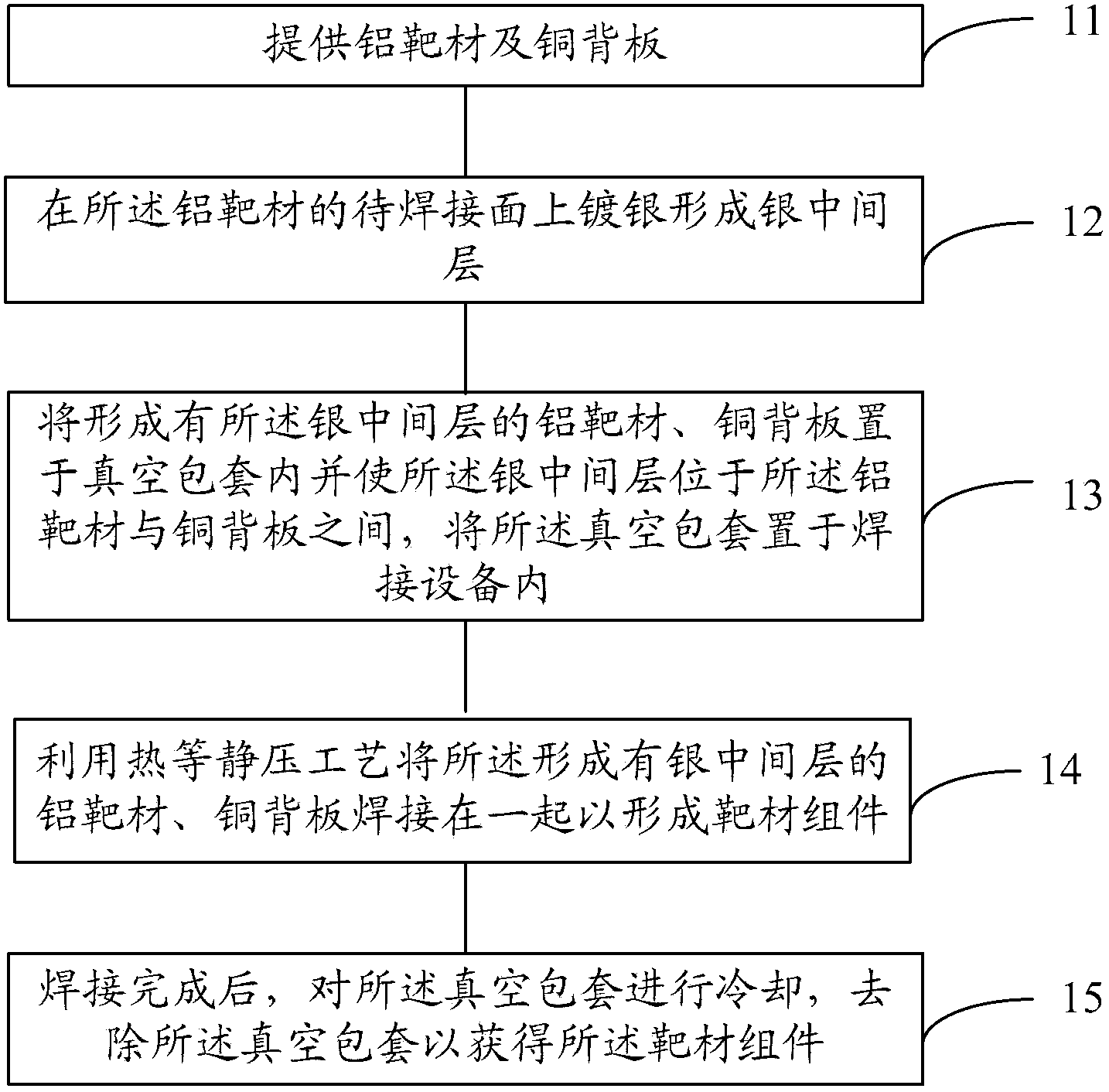

Method for target material component welding

InactiveCN103521910ANo falling offNot prone to recrystallizationVacuum evaporation coatingSputtering coatingSputteringWeld strength

The invention provides a method for target material component welding. The method comprises the following steps that an aluminum target material and a copper back board are provided; silver is plated on a face to be welded of the aluminum target material to form a silver middle layer; the aluminum target material with the silver middle layer and the copper back board are placed in a vacuum bag, the silver middle layer is located between the aluminum target material and the copper back board, and the vacuum bag is arranged in a welding device; the hot isostatic pressure technology is used for welding the aluminum target material with the silver middle layer and the copper back board together to form a target material component; after welding is completed, the vacuum bag is cooled and removed, so that the target material component is obtained. The method is high in welding efficiency, the formed target material component is good in welding binding rate, high in welding strength and small in deformation, the internal organization structure of the aluminum target material in the target material component meets the sputtering requirement, and therefore requirements for long-time stable production and using of target materials can be met.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

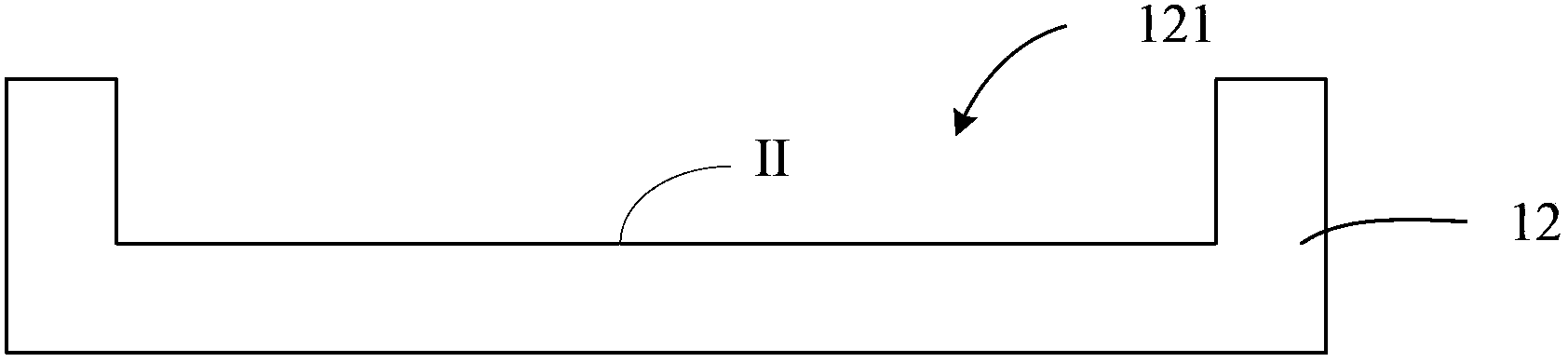

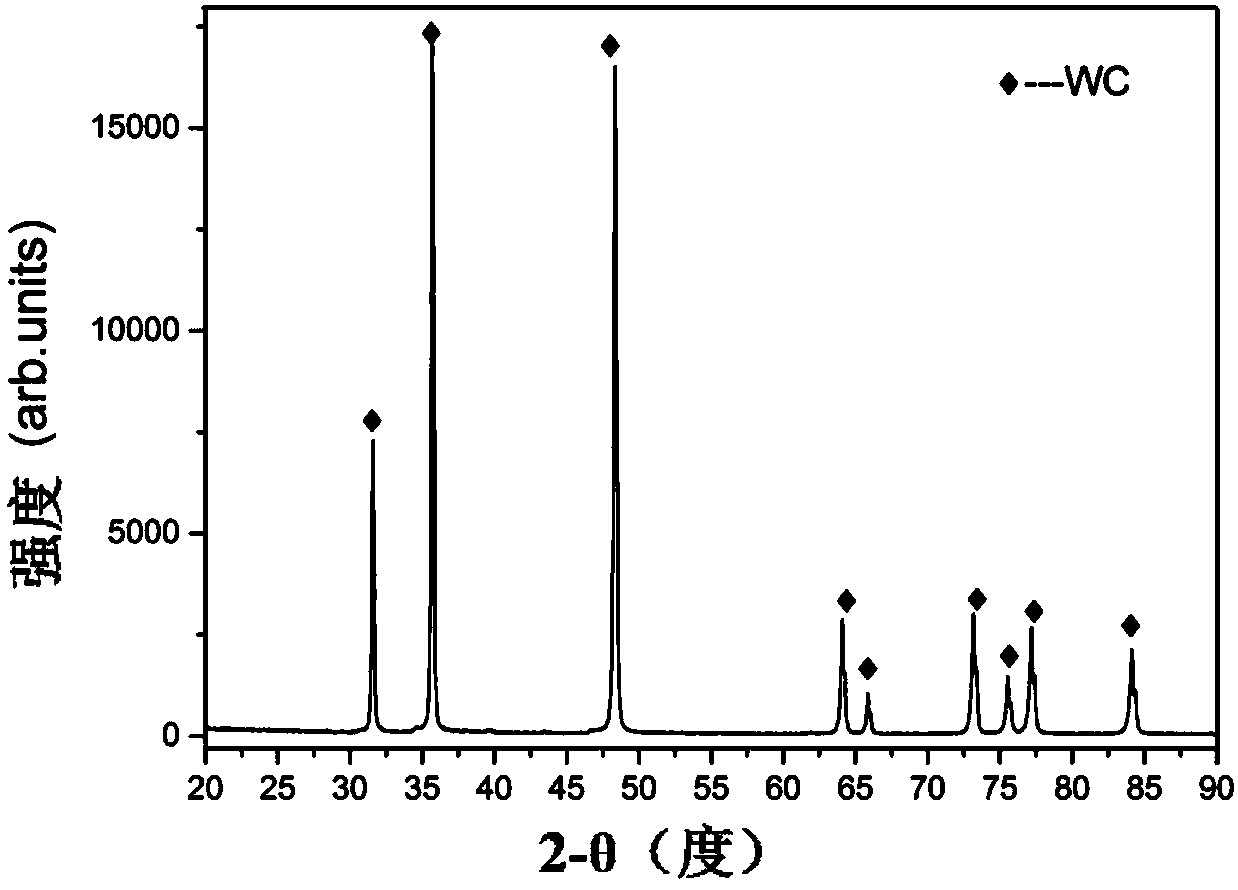

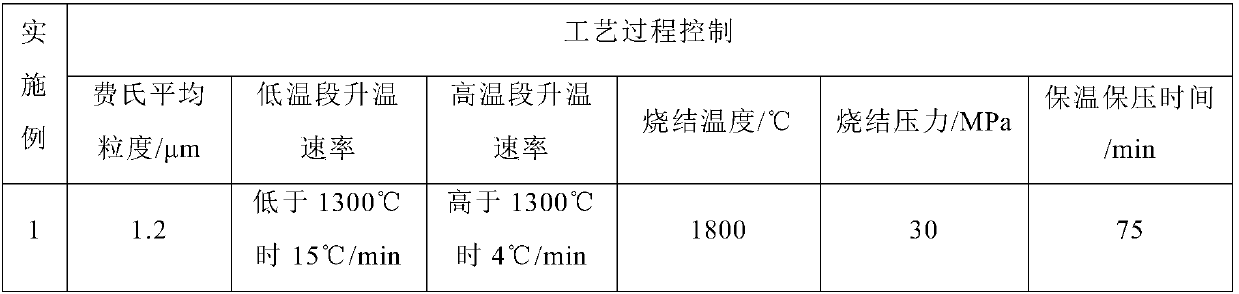

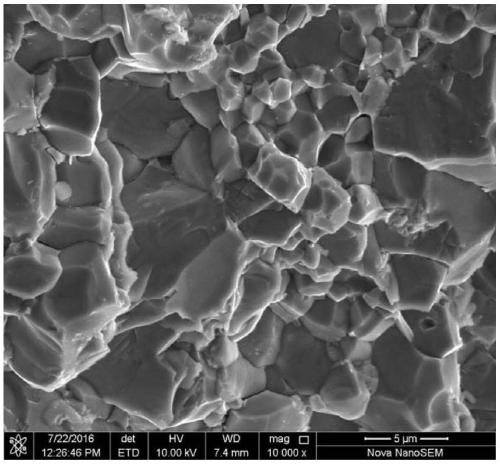

Preparation method for non-bonding-phase pure-carbonation tungsten target material

ActiveCN107620049AReduce surface defectsSimple preparation processVacuum evaporation coatingSputtering coatingDiamond-like carbonSuperficial mass

The invention provides a preparation method for a non-bonding-phase pure-carbonation tungsten target material. The method comprises the steps that pure-carbonation tungsten raw material powder is screened firstly to obtain pure-carbonation tungsten powder with the even particle size; then a mould is evenly filled with the pure-carbonation tungsten powder, hot-pressing sintering treatment is conducted under the vacuum condition, cooling is conducted, and then mould release is conducted to obtain a sintered blank; and finally, the sintered blank is machined to obtain the non-bonding-phase pure-carbonation tungsten target material meeting the size and surface-quality requirements. According to the preparation method for the non-bonding-phase pure-carbonation tungsten target material, the technique is simple, the forming effect is good, and industrialized large-scale production is facilitated; the target material does not contain any bonding phase component, grains are even, the average grain size is 5 [mu]m or below, the compactness can reach 99% or more, and the purity is 99.9% or more; and according to the target material, the arc starting discharging phenomenon in the sputtering process is reduced, the surface defects of a prepared film layer are few, a coating is more compact, the target material can be used for preparing an adulteration phase of diamond-like carbon (DLC) coating and a transitional layer, and coating mechanical performance and tribological performance are improved.

Owner:北京安泰六九新材料科技有限公司 +1

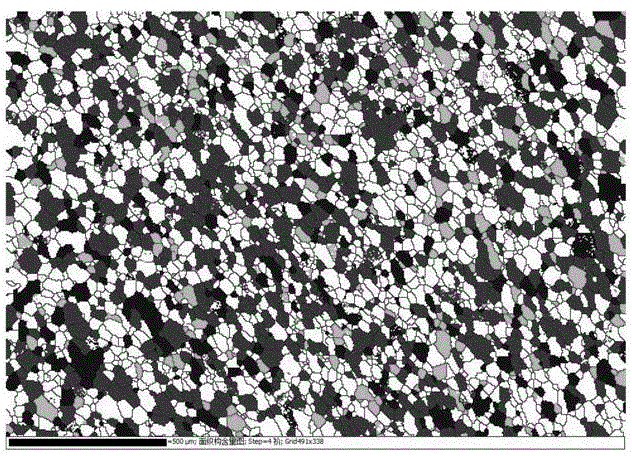

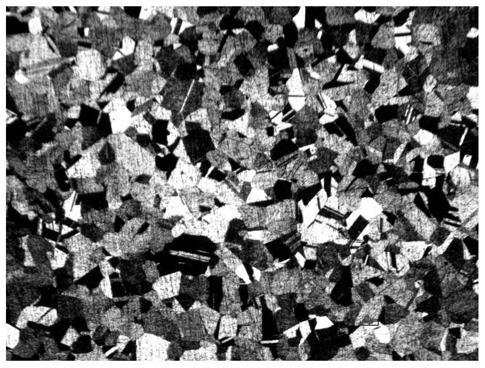

(CoFe)ZrNb/Ta/Hf Based Target Material and Method for Producing the Same

ActiveUS20080138235A1High sputtering efficiencyImprove sputtering effectCellsVacuum evaporation coatingSputteringAlloy

A (CoFe)ZrNb / Ta / Hf based target material is provided which is capable of achieving a high sputtering efficiency and a high sputtering effect by increasing the leakage magnetic flux in the magnetron sputtering, and a method for producing the target material. This target material is made of an Fe—Co based alloy comprising not less than 80 atomic % in total of Fe and Co having an Fe:Co atomic ratio of 80:20 to 0:100, and less than 20 atomic % of one or more selected from the group consisting of Zr, Hf, Nb and Ta. The Fe—Co based alloy comprises a Co—Fe phase being a ferromagnetic phase, and the one or more selected from the group consisting of Zr, Hf, Nb and Ta are solid-solved into the Co—Fe phase in a total amount of 0.5 to 2 atomic %.

Owner:SANYO SPECIAL STEEL COMPANY

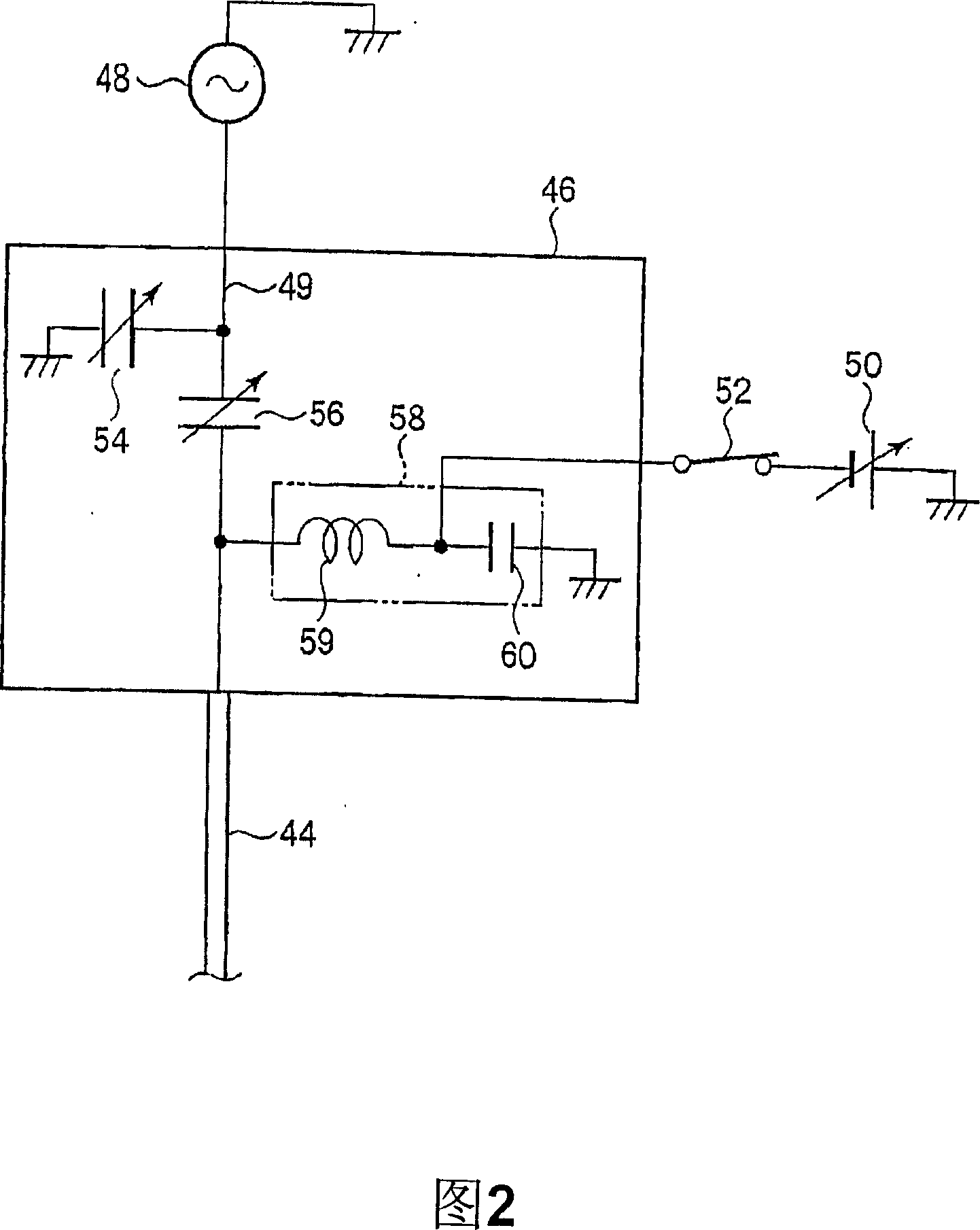

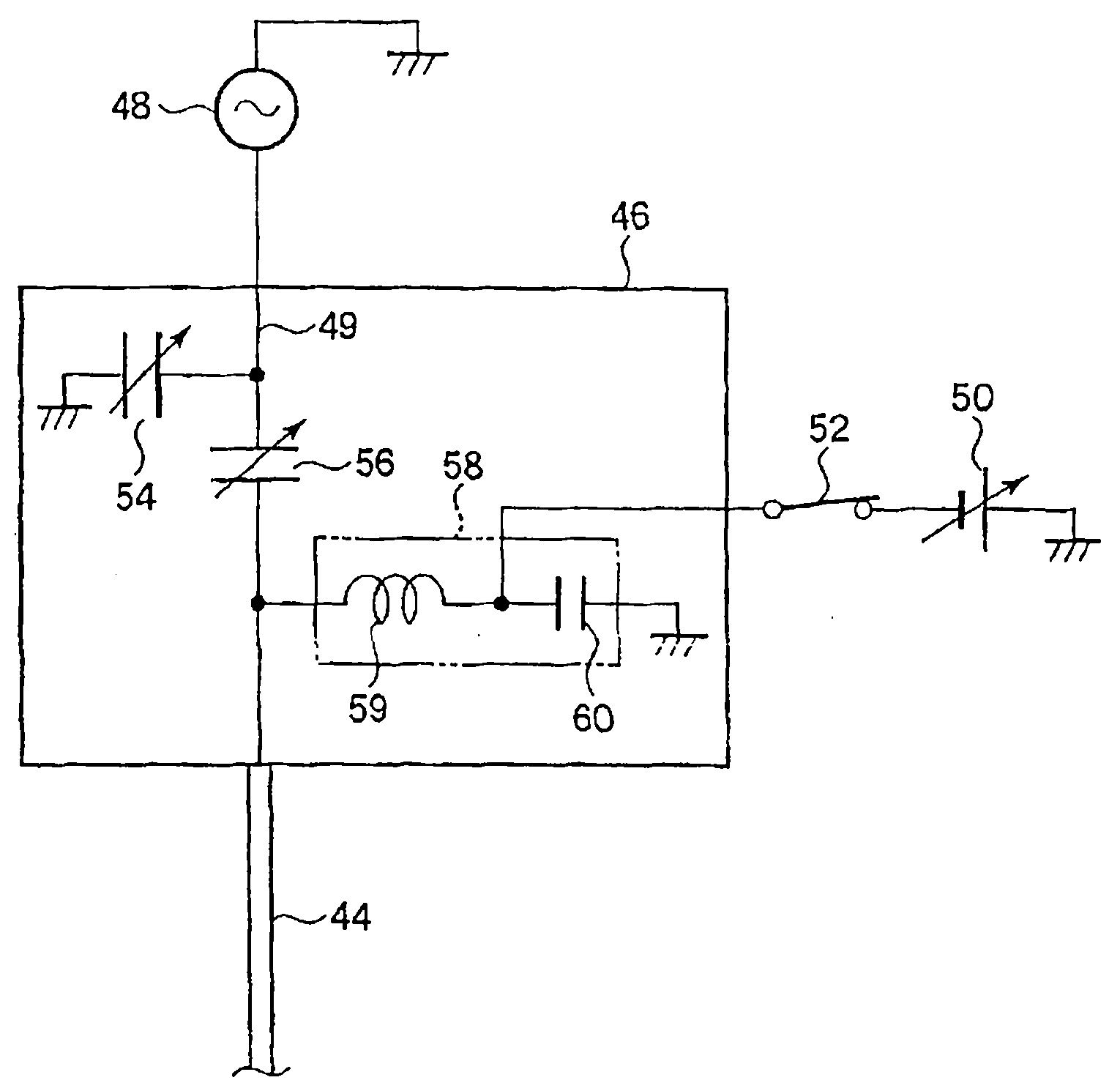

Plasma processing apparatus and method

ActiveCN1984523AEliminate attachmentEtching high speedSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHigh frequency powerEngineering

The invention provides a plasma processing system characterised in that comprises a processing container for receiving a substrate to be processed and performing vacuum exhausting air; a first electrode and a second electrode supporting the substrate to be processed arranged in the processing container oppositely; a first high-frequency power supply unit for applying a first high-frequency power of relatively high frequency to the second electrode; a second high-frequency power supply unit for applying a second high-frequency power of relatively low frequency to the second electrode; a DC power supply for applying a DC voltage to the first electrode; a gas supply unit for supplying gas which is to be processed to the processing container; and a controlling device for controlling one of the applied voltage, the applied current and the applied power from the DC power supply to the first electrode.

Owner:TOKYO ELECTRON LTD

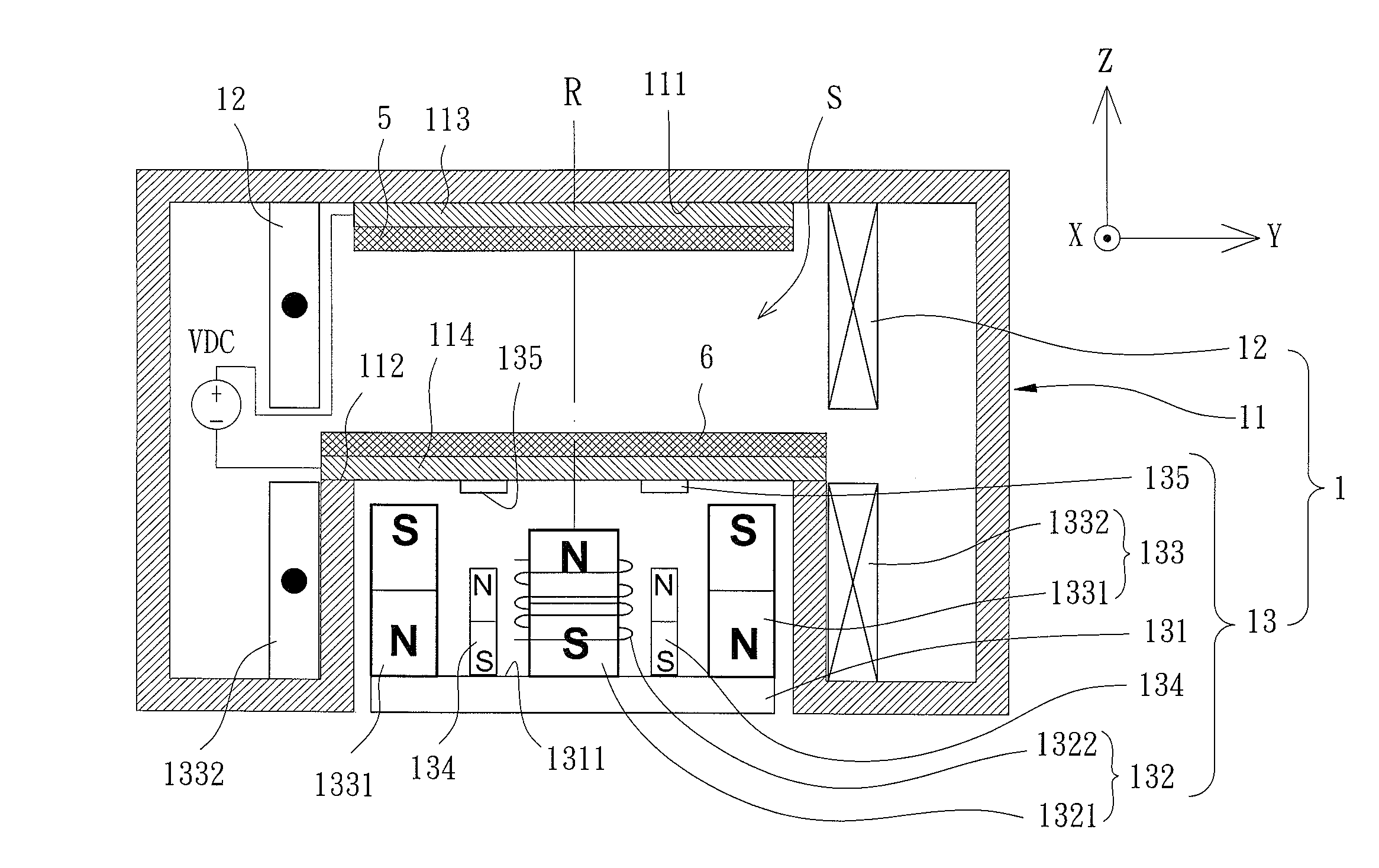

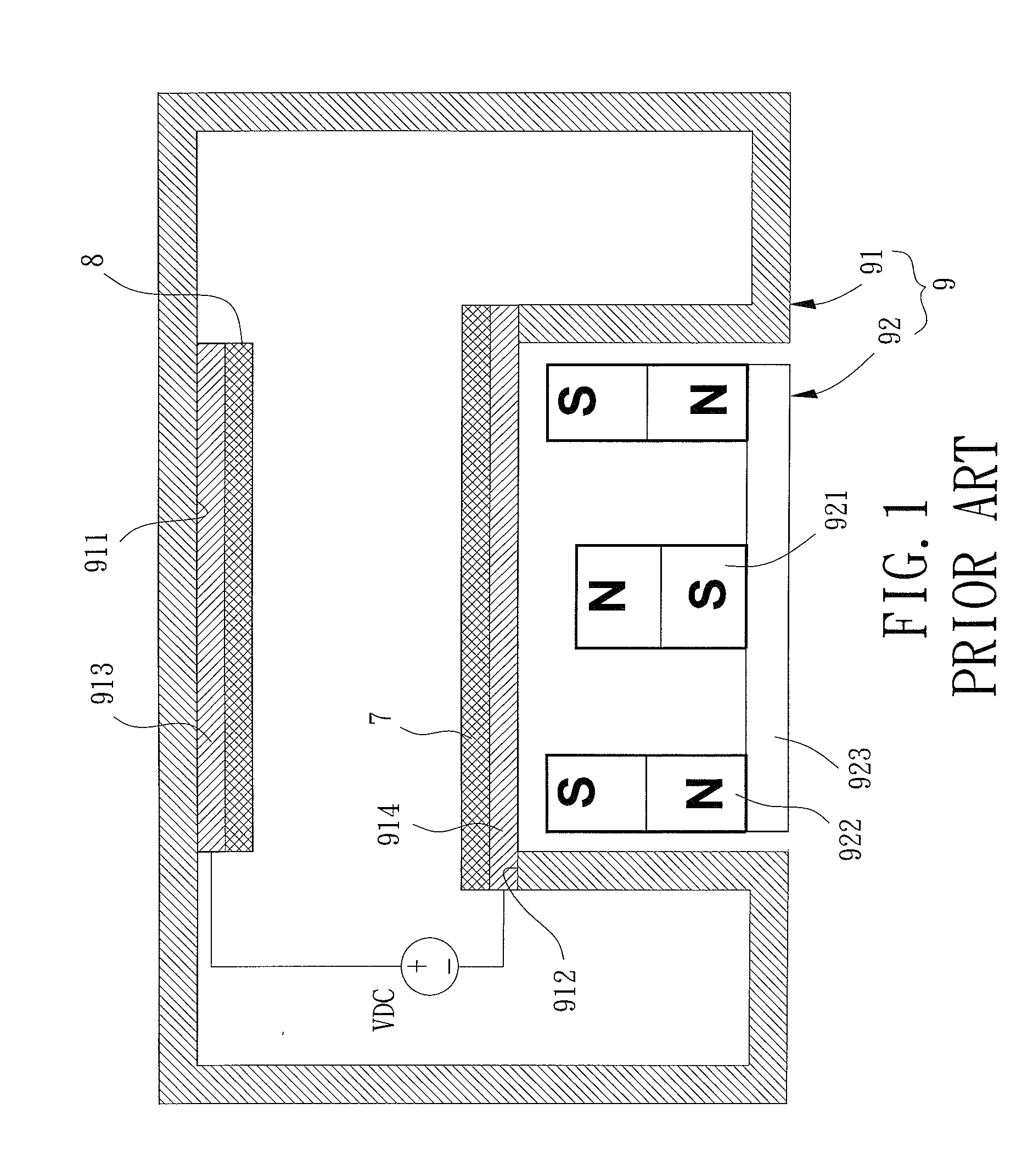

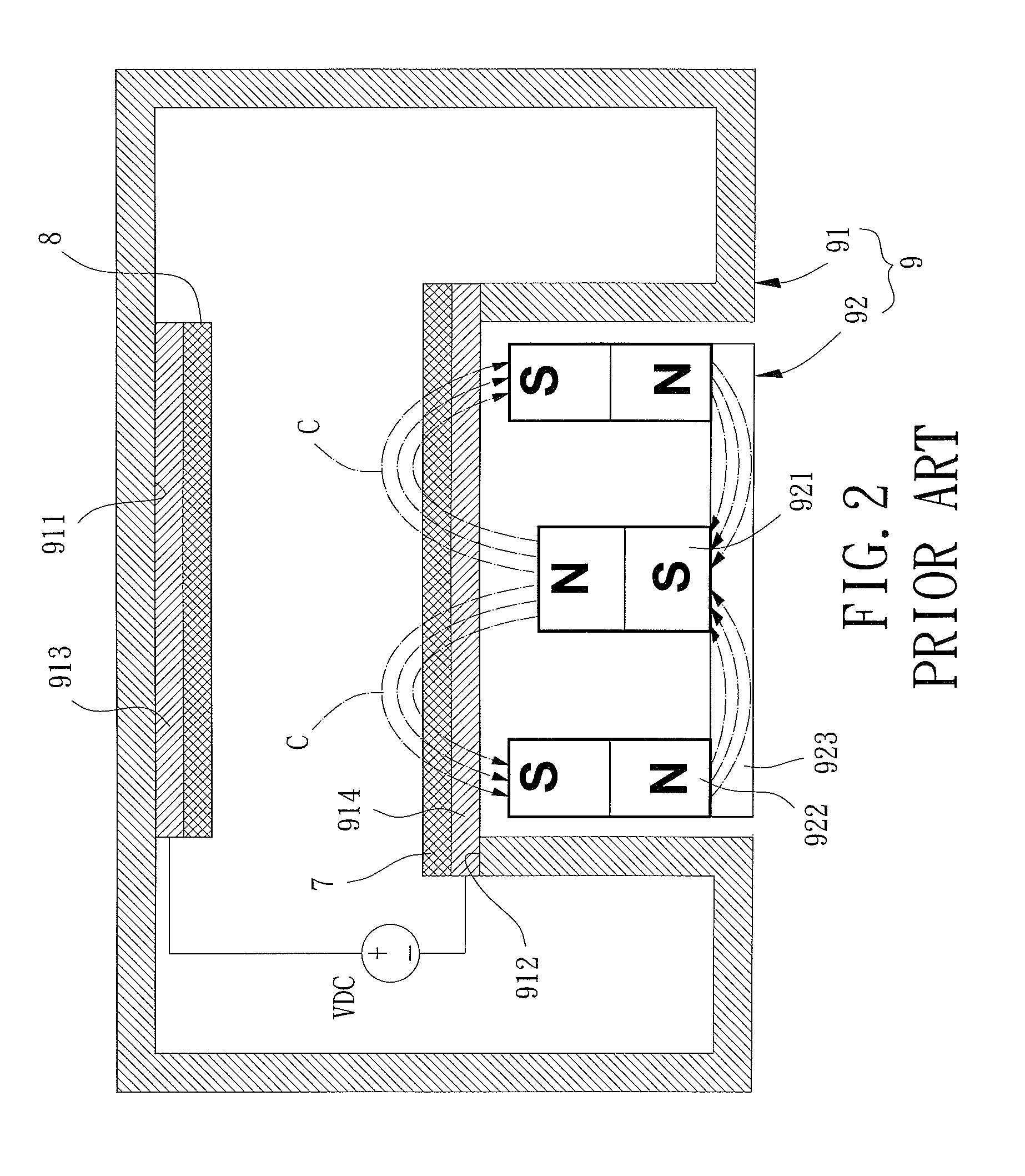

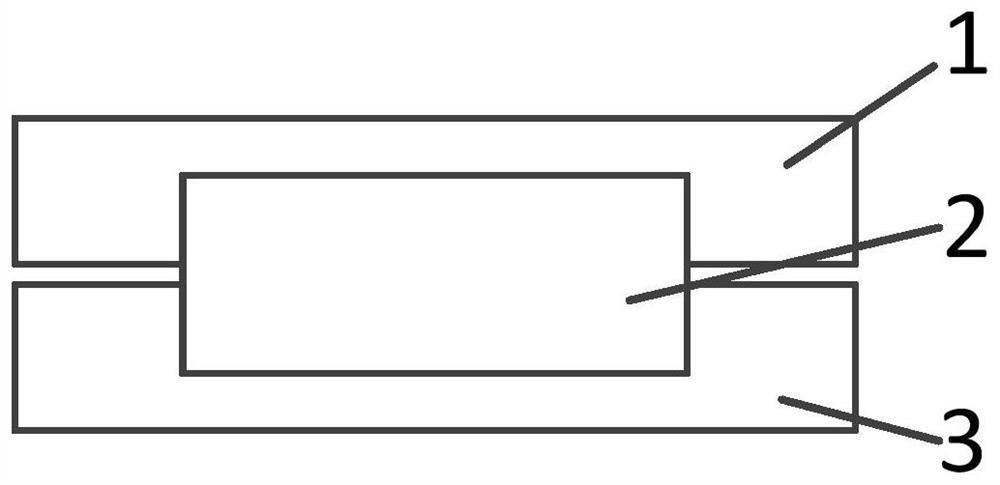

Magnetron Plasma Sputtering Apparatus

InactiveUS20110233058A1Improve sputtering effectCellsElectric discharge tubesSputteringMagnetization

A magnetron plasma sputtering apparatus includes a sputtering chamber having a loading portion and an engaging portion opposite to the loading portion. A substrate is mounted to the loading portion. A target is mounted to the engaging portion. A sputtering space is defined between the loading portion and the engaging portion. A reference line extends through the loading portion, the sputtering space, and the engaging portion in sequence. A guiding coil surrounds the sputtering space with the reference line located in the center. A magnetron device is located at a side of the sputtering chamber adjacent to the engaging portion. The magnetron device has a magnetization side facing the engaging portion.

Owner:NAT SUN YAT SEN UNIV

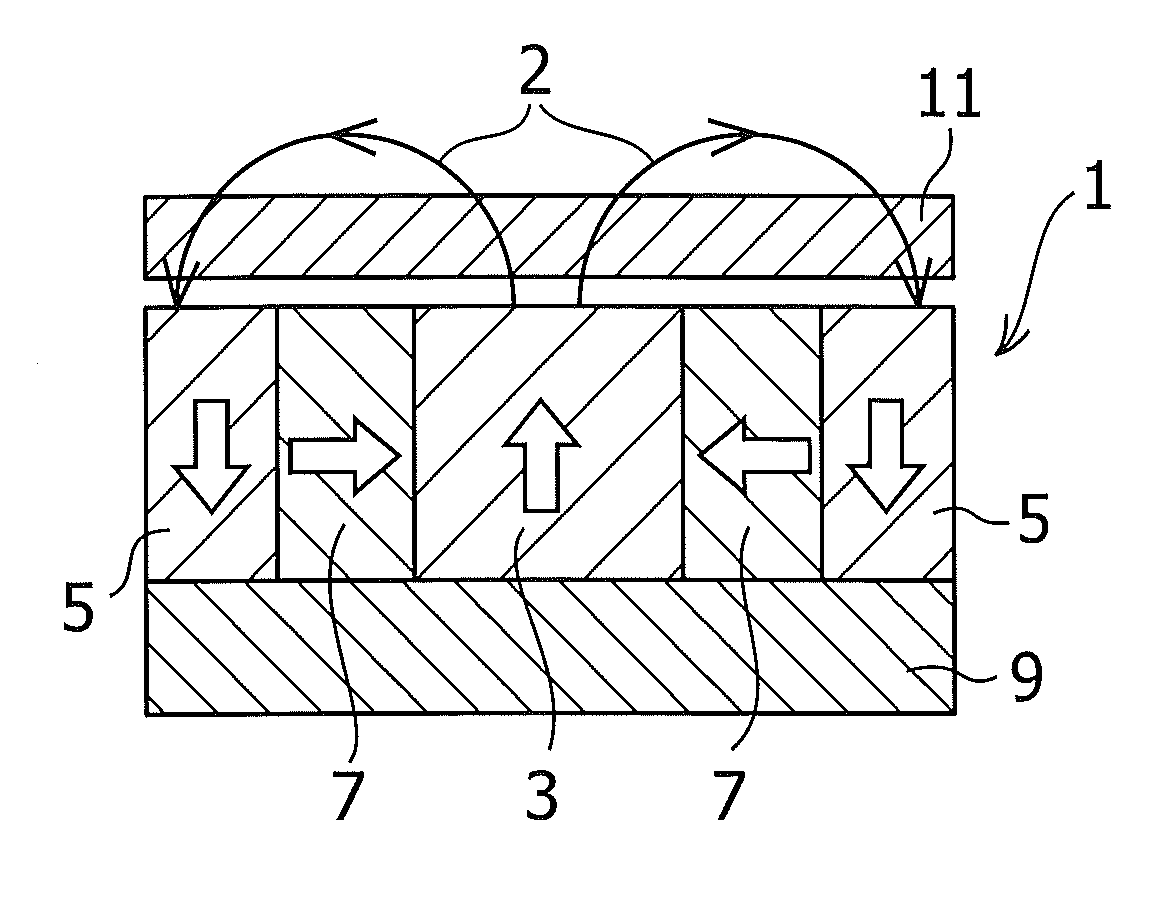

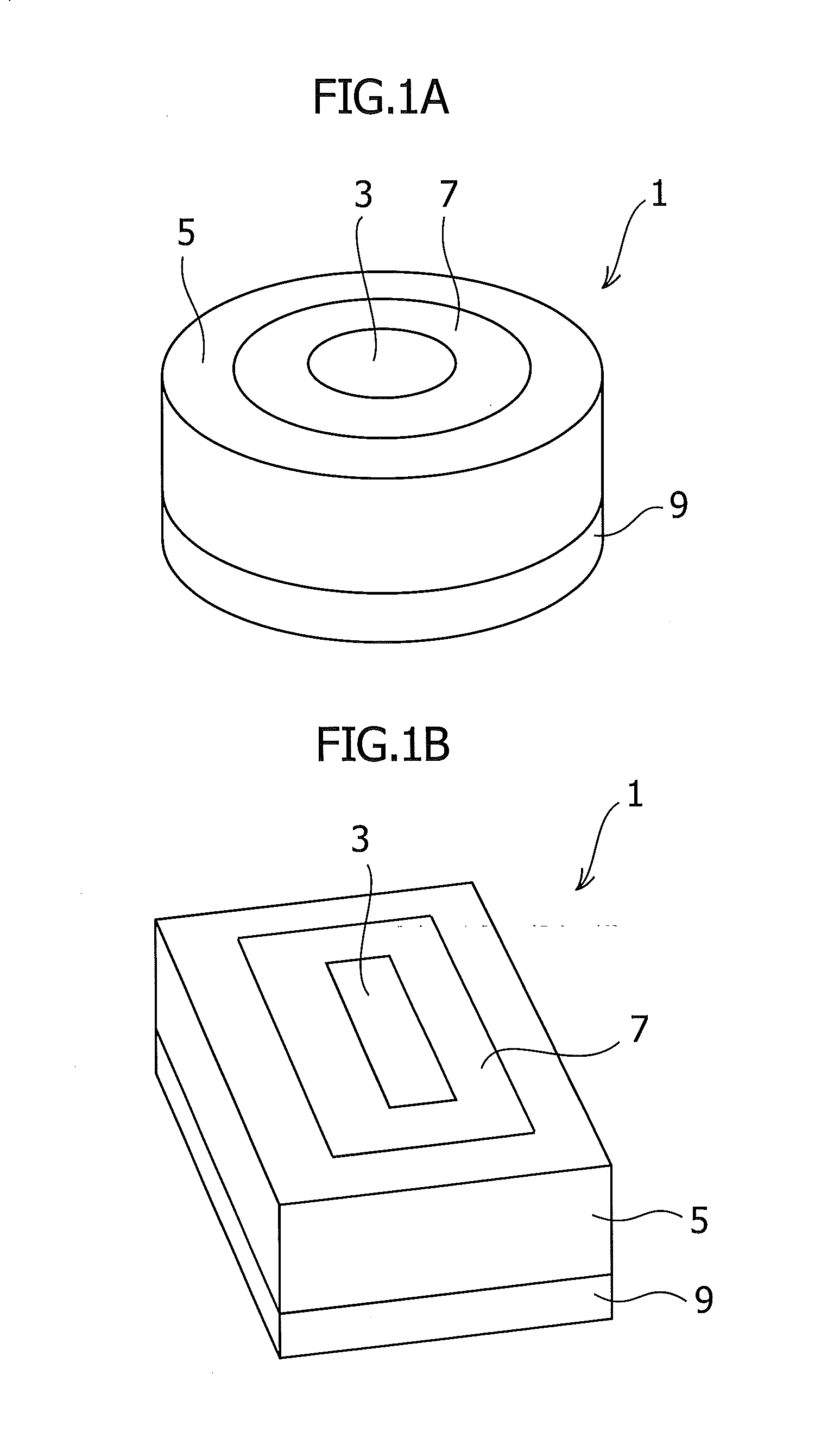

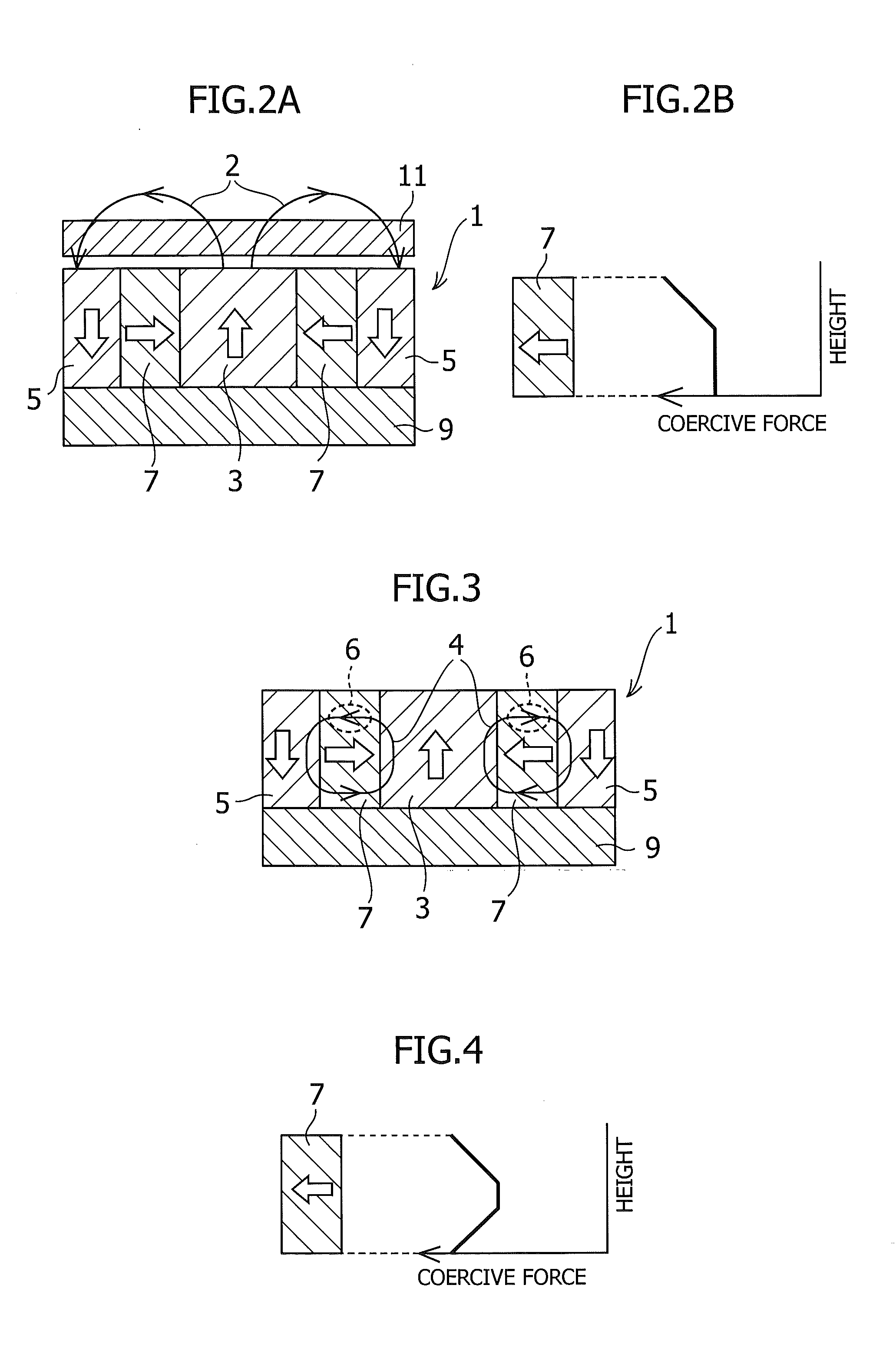

Magnetic circuit for sputtering apparatus

InactiveUS20120111724A1Increase the magnetic field strengthImprove resistance to demagnetizationCellsElectric discharge tubesHigh magnetic field strengthTarget surface

The present invention provides a magnetic circuit for a magnetron sputtering apparatus, which produces arc-shaped magnetic field lines of high magnetic field strength over a target surface, and has an improved demagnetization resistance. The magnetic circuit includes: an inner magnet; an outer magnet having a magnetization direction opposite to that of the inner magnet, and surrounding the inner magnet; a horizontally magnetized magnet disposed between the inner and outer magnets, and magnetized in a direction perpendicular to those of the inner and outer magnets, and in a direction from the inner magnet to the outer magnet, or from the outer magnet to the inner magnet; and a yoke configured so that a magnetic flux passes through the yoke between the inner and outer magnets, in which a magnetic coercive force of the horizontally magnetized magnet is greater in a region closer to the target side than in a center of the magnet interior.

Owner:SHIN ETSU CHEM IND CO LTD

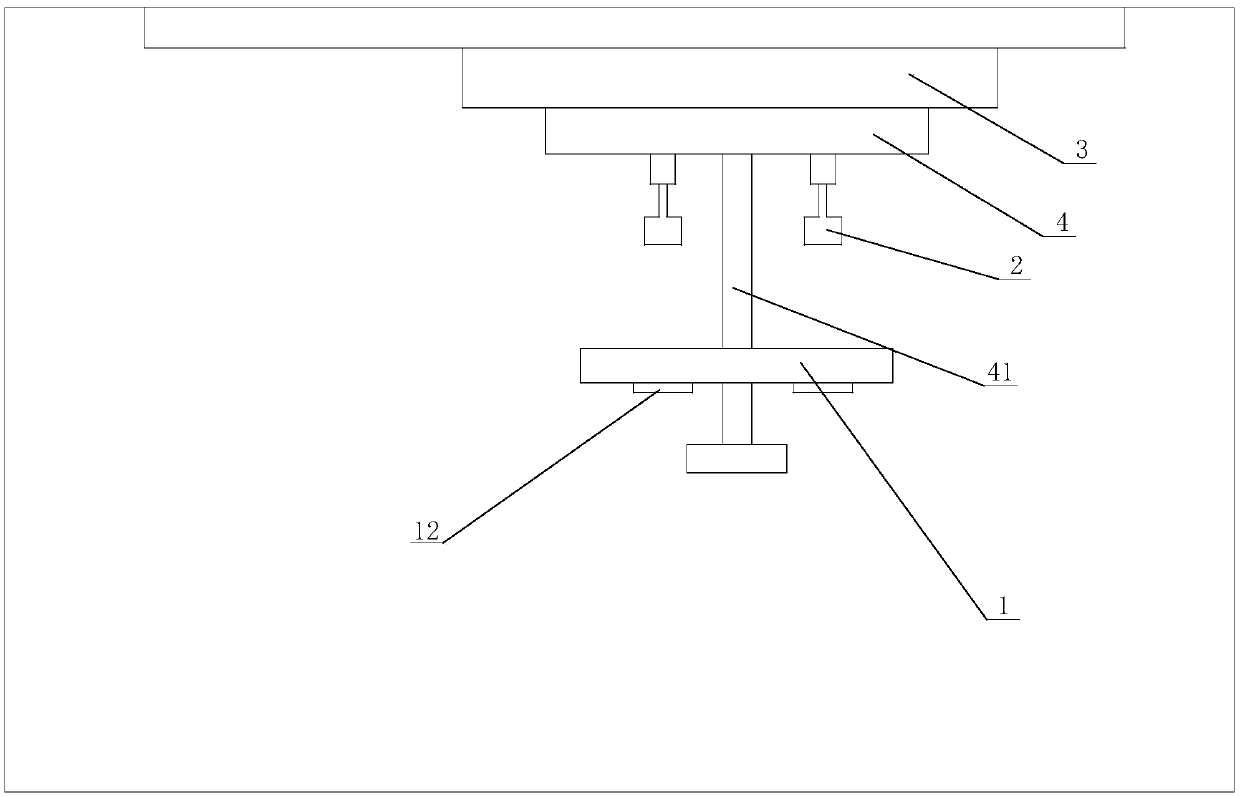

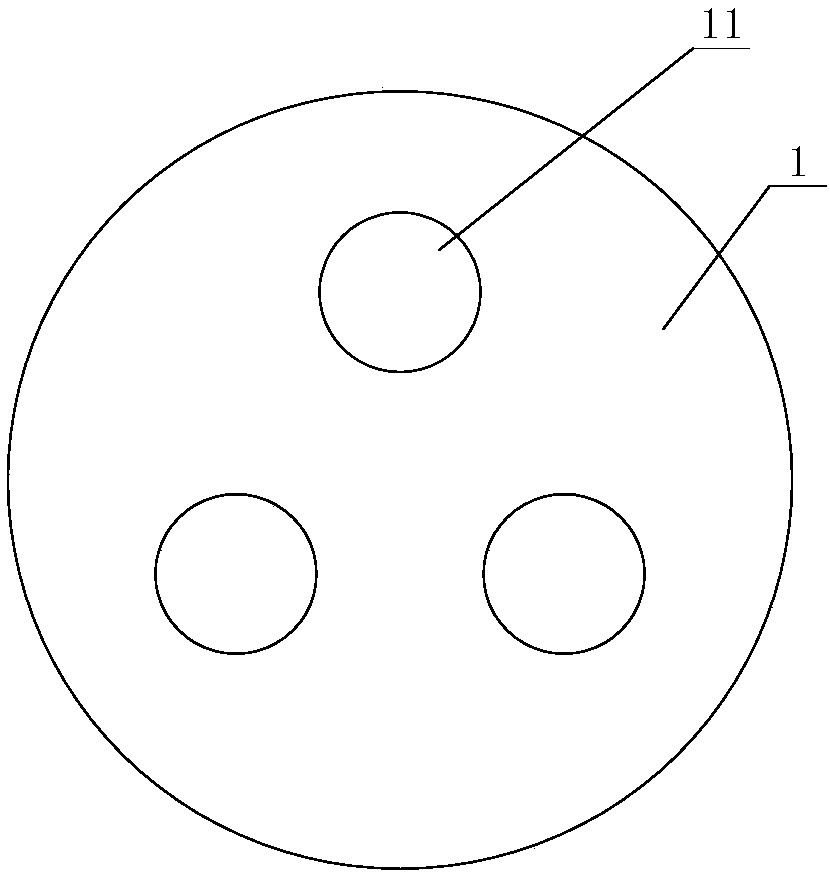

Sputtering turntable and sputtering device used by same

InactiveCN101892457AEvenly distributedImprove sputtering effectVacuum evaporation coatingSputtering coatingSputteringEngineering

The invention relates to a sputtering turntable which comprises a matrix, a driving device and at least one transmission device, wherein the matrix is connected to the driving device, and the transmission device is rotatablely connected to the matrix and is meshed with the driving device; and the matrix comprises an upper surface and a lower surface, the upper surface is provided with at least one groove for containing a base plate to be sputtered, and the depth of the groove ensures that the upper surface of the base plate to be sputtered, which is contained in the groove, can be flush with the upper surface of the matrix. By arranging the groove on the matrix and consequently enabling the upper surface of the base plate to be sputtered in the groove to be flush with the upper surface ofthe matrix, the sputtering turntable avoids uneven sputtering caused by height difference between the surface of the base plate and the surface of the base plate to be sputtered in the sputtering process.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

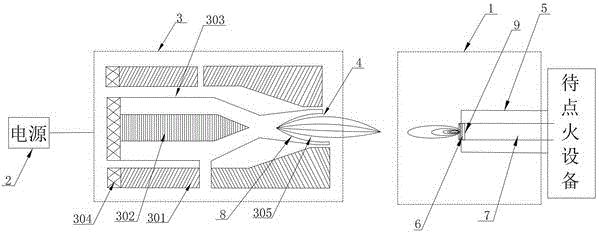

Non-impact self-adaptive trigger ignition device utilizing laminar flow plasma system

ActiveCN106304593AAchieve one ignitionAvoid arc breakingElectric spark ignitersPlasma techniquePlasma jetPlasma generator

The invention discloses a non-impact self-adaptive trigger ignition device utilizing a laminar flow plasma system, and belongs to the technical field of ignition equipment. The non-impact self-adaptive trigger ignition device comprises the laminar flow plasma system and an ignition nozzle. The laminar flow plasma system comprises a power supply, a laminar flow plasma generator and a jet nozzle, wherein the power supply is connected with the laminar flow plasma generator, and the jet nozzle and the laminar flow plasma generator are connected detachably. The ignition nozzle is arranged on equipment to be ignited, and comprises a shell, an ignition electrode and a guide tube, wherein the ignition electrode is arranged at the front end of the guide tube, the guide tube extends into the equipment to be ignited, and the shell is arranged outside the ignition electrode and the guide tube. The central axis of the jet nozzle coincides with the central axis of the ignition nozzle. The central axes of an electric arc channel, the jet nozzle and the ignition nozzle coincide, plasma is emitted along the central axis, an electric arc guidance effect is achieved through the design, the ignition steps are simplified, the ignition difficulty is reduced, ignition is achieved at a time with working gas, and meanwhile stability of laminar flow electric arc hot plasma jet is ensured.

Owner:四川金虹等离子技术有限公司

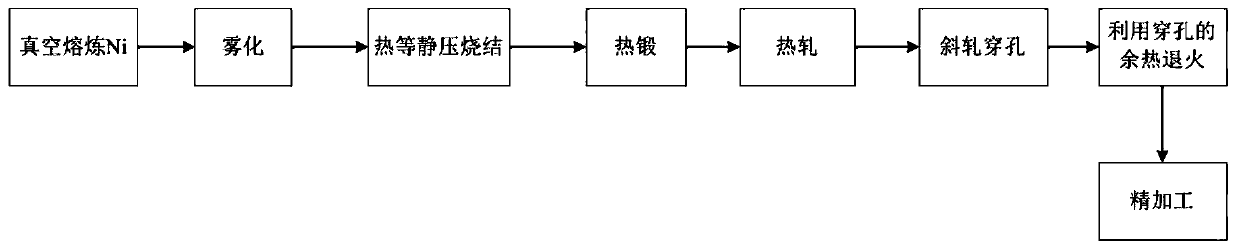

Nickel-rhenium alloy rotary tubular target containing trace rare earth elements and preparation method thereof

ActiveCN110484886AOptimize the preparation processImprove product qualityVacuum evaporation coatingSputtering coatingRare-earth elementHot isostatic pressing

The present invention discloses a nickel-rhenium alloy rotary tubular target containing trace rare earth elements and a preparation method thereof. The target comprises the following components in percentages by mass: Re 2-5%, Zr 0.02-0.1%, B 0.05-0.1%, Mg 0.01-0.05% and balance of Ni and inevitable impurities. The preparation method includes the processes such as vacuum melting, atomization ingotting, sintering, hot isostatic pressing, hot forging, hot rolling, cross roll piercing, annealing and machining. The invention is the rotary tubular target; the utilization rate of the material is improves; furthermore the target microstructure is fine and uniform; and the quality is higher. The invention is the integral target with low gas content and high purity; the target can return to a furnace as the returned material even after use; and the cost is saved.

Owner:南京达迈科技实业股份有限公司 +1

Plasma processing apparatus and plasma processing method

ActiveUS8138445B2Improve uniformityEffectively sputteredElectric discharge tubesSemiconductor/solid-state device manufacturingElectricityInductor

In a plasma processing apparatus, a first electrode is attached to a grounded evacuable processing chamber via an insulating material or a space and a second electrode disposed in parallel with the first electrode spaced apart therefrom in the processing chamber, the second electrode supporting a target substrate to face the first electrode. A first radio frequency power supply unit applies a first radio frequency power of a first frequency to the second electrode, and a second radio frequency power supply unit applies a second radio frequency power of a second frequency lower than the first frequency to the second electrode. Further, a processing gas supply unit supplies a processing gas to a processing space formed by the first and the second electrode and a sidewall of the processing chamber. Moreover, an inductor electrically is connected between the first electrode and a ground potential.

Owner:TOKYO ELECTRON LTD

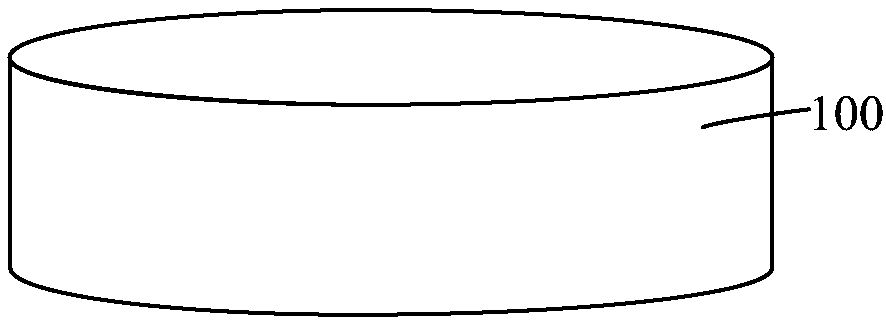

Manufacturing method of target blank and target assembly

ActiveCN107761062AEvenly heatedImprove heating uniformityVacuum evaporation coatingSputtering coatingCrystal orientationIngot

The invention provides a manufacturing method of a target blank and a target assembly. The manufacturing method of the target blank comprises the following steps: providing an AlSc alloy ingot; performing plastic deformation processing on the AlSc alloy ingot to form an initial target blank; and performing thermal treatment on the initial target blank by way of stepped temperature rise to form thetarget blank. By way of stepped temperature rise, thermal treatment is performed on the initial target blank. As the good heating uniformity of the initial target blank is hardly guaranteed in the temperature rise process, thermal treatment is performed in multiple stages; insulation is performed after temperature rise every time, so that the initial target blank in part of region reaching the predetermined temperature is insulated, and the initial target blank in part of region not reaching the predetermined temperature is heated continuously till the predetermined temperature is reached. Therefore, after thermal treatment of every stage, the initial target blank can be uniformly heated, that is, the heating uniformity of the initial target blank can be improved, so that the crystal orientation <200> content of the target blank after thermal treatment is increased, and the target blank is uniform in crystal orientation and small in grain size.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Plasma processing apparatus and method

ActiveCN1983518AEliminate attachmentEtching high speedElectric discharge tubesSemiconductor/solid-state device manufacturingHigh frequency powerEngineering

The invention provides a plasma processing system characterised in that comprises a processing container for receiving a substrate to be processed and performing vacuum exhausting air; a first electrode and a second electrode supporting the substrate to be processed arranged in the processing container oppositely; a first high-frequency power supply unit for applying a first high-frequency power of relatively high frequency to the second electrode; a second high-frequency power supply unit for applying a second high-frequency power of relatively low frequency to the second electrode; a DC power supply for applying a DC voltage to the first electrode; a gas supply unit for supplying gas which is to be processed to the processing container.

Owner:TOKYO ELECTRON LTD

Plasma processing device and method

ActiveCN102256431AEliminate attachmentEtching high speedElectric discharge tubesSemiconductor/solid-state device manufacturingGas supplyElectric power

Owner:TOKYO ELECTRON LTD

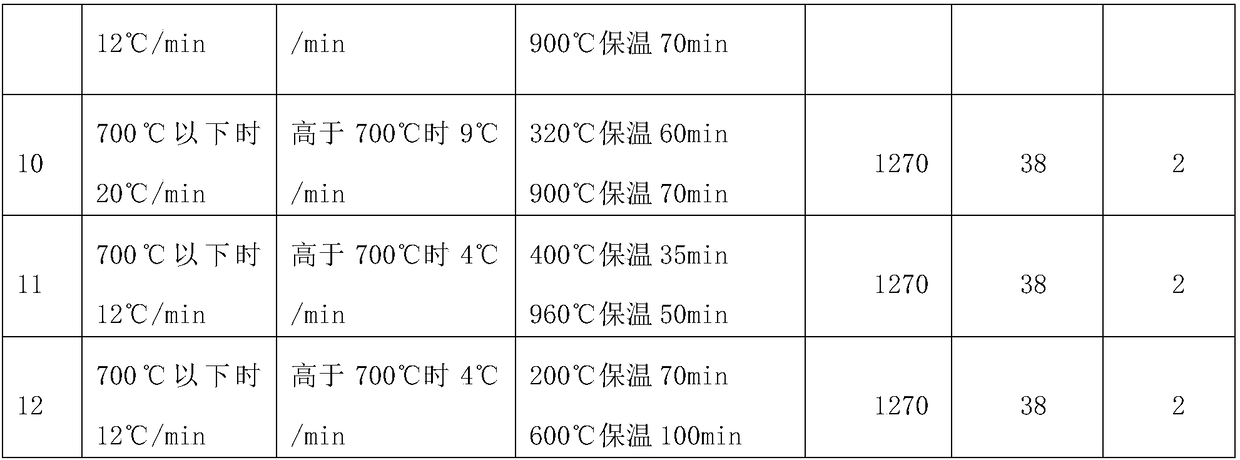

Preparation method of MoS2 ceramic target

ActiveCN108059459ASimple processGood formabilityVacuum evaporation coatingSputtering coatingCost effectivenessSource material

The invention relates to a preparation method of a MoS2 ceramic target. The preparation method comprises the following steps: drying and sieving a MoS2 raw material powder to obtain a MoS2 powder having a uniform particle size distribution and no agglomeration; uniformly introducing the MoS2 powder into a mold, carrying out hot-press sintering under vacuum conditions, and then carrying out coolingand demolding to obtain a sintered blank; and machining the sintered blank to obtain the target meeting size and surface quality requirements. The preparation method has the advantages of simple technological process, good forming effect, good cost effectiveness, facilitation of industrialized large-scale production, and broad application prospect; the prepared target has a high purity being notless than 99.5%, and has small and uniform crystal grains, the average grain size is not more than 5 [mu]m, the density is not less than 95%, and the target is a single MoS2 phase structure; and the target has stable performances and a good sputtering effect, and can improve the tribological property of a coating as a source material for preparing a solid lubricating coating.

Owner:北京安泰六九新材料科技有限公司 +1

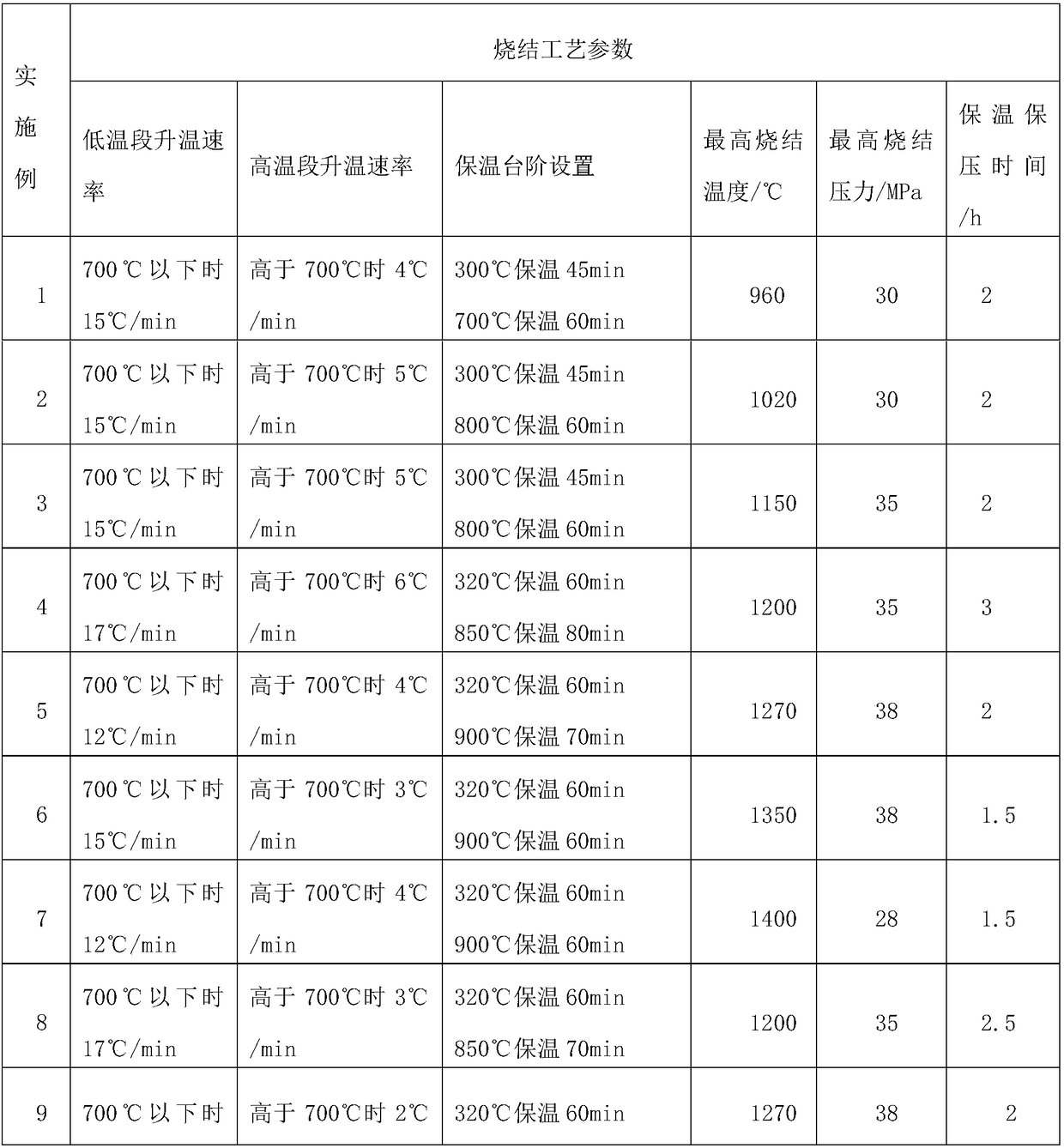

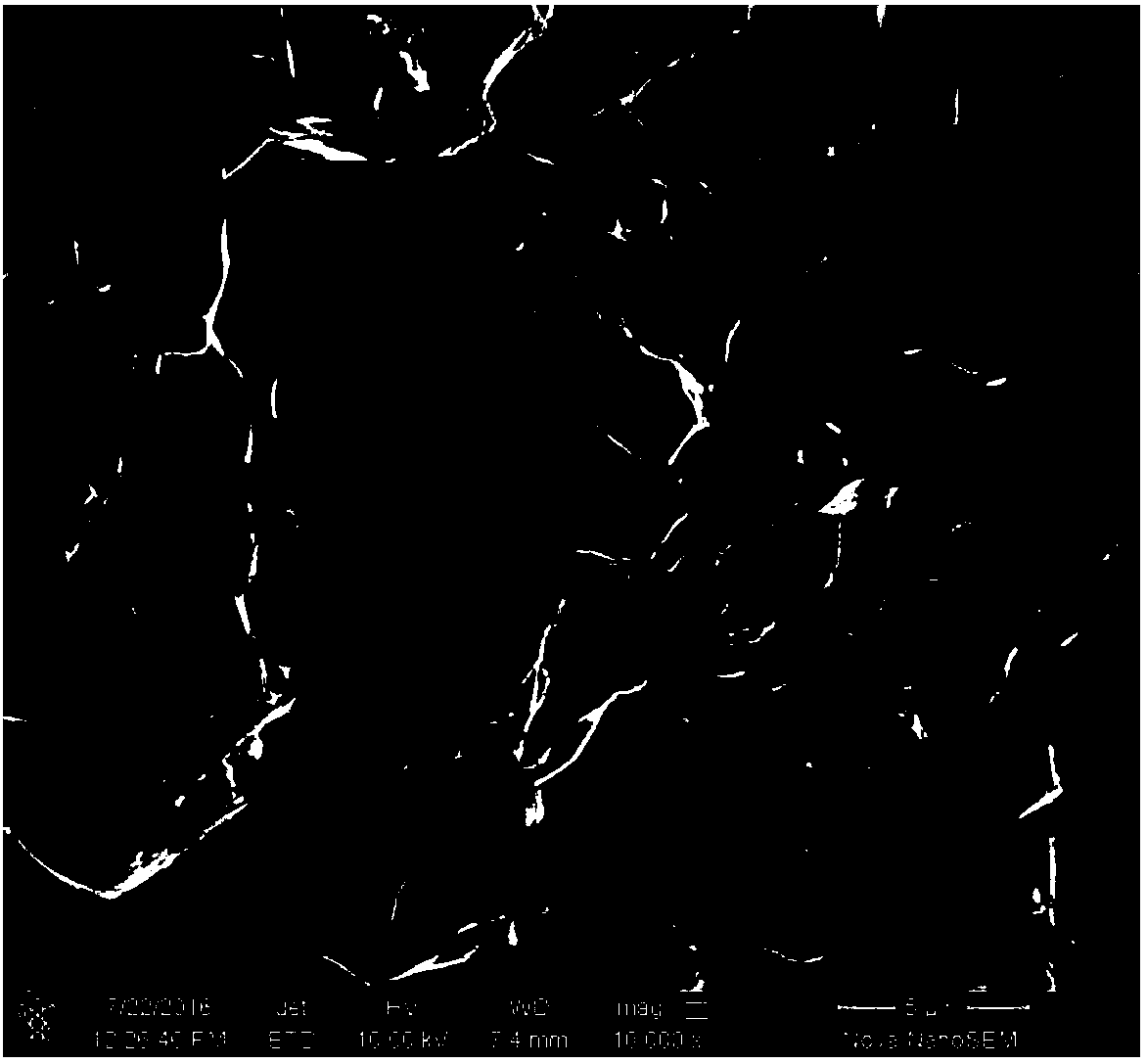

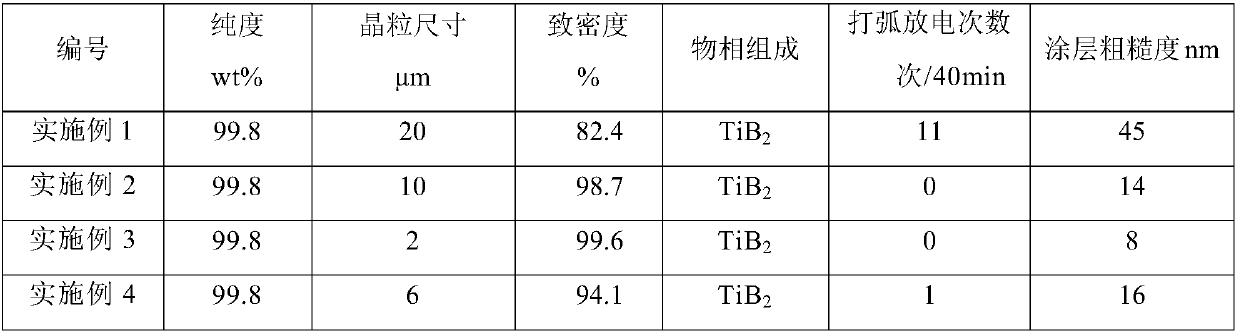

Preparation method for high-density TiB2 ceramic target material

The invention relates to a preparation method for a high-density TiB2 ceramic target material, wherein the preparation method includes the following steps: step one, drying and sieving a TiB2 raw material powder, to obtain a TiB2 powder having uniform particle size distribution and no caking; and step two, evenly filling a mould with the TiB2 powder, carrying out hot pressing sintering in a vacuumcondition, then cooling, and demoulding, to obtain the high-density TiB2 ceramic target material. According to the method, no any sintering aid is added, the powder is compressed by using the hot pressing process subsequently, the technological process is simplified, the production cycle is shortened, and the mass production can be achieved; the prepared TiB2 target material has the purity of more than or equal to 99.8%, the optimal average grain size reaching less than or equal to 2 [mu]m and the density reaching up to 99.6%; and the target material has a structure of single TiB2 phase, no alloy phase or harmful grain boundary is formed, the arc-starting electro-discharge phenomenon in a sputtering process is improved, and a prepared film layer has the advantages of high density, fewer surface defects and better sputtering effect.

Owner:北京安泰六九新材料科技有限公司 +1

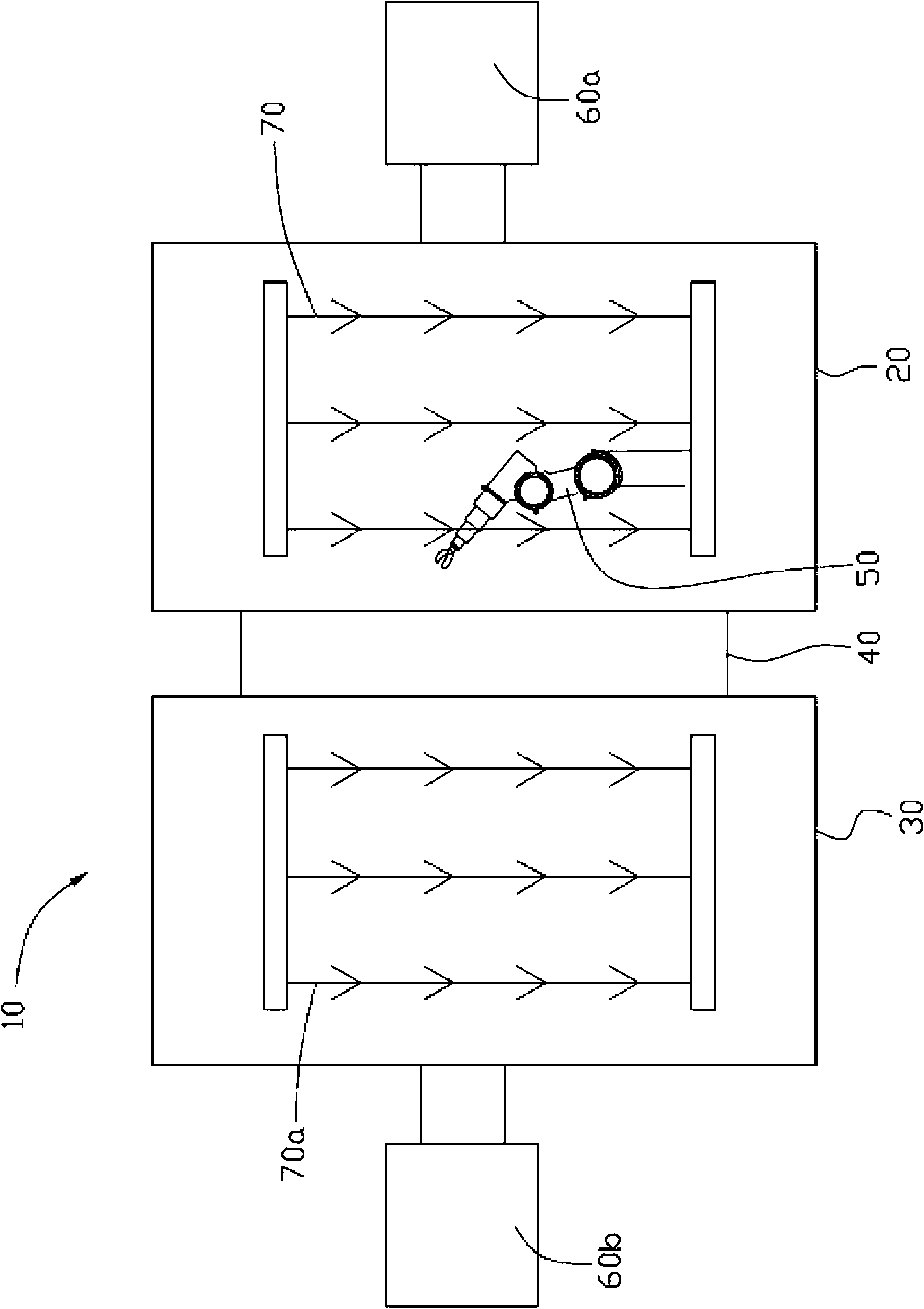

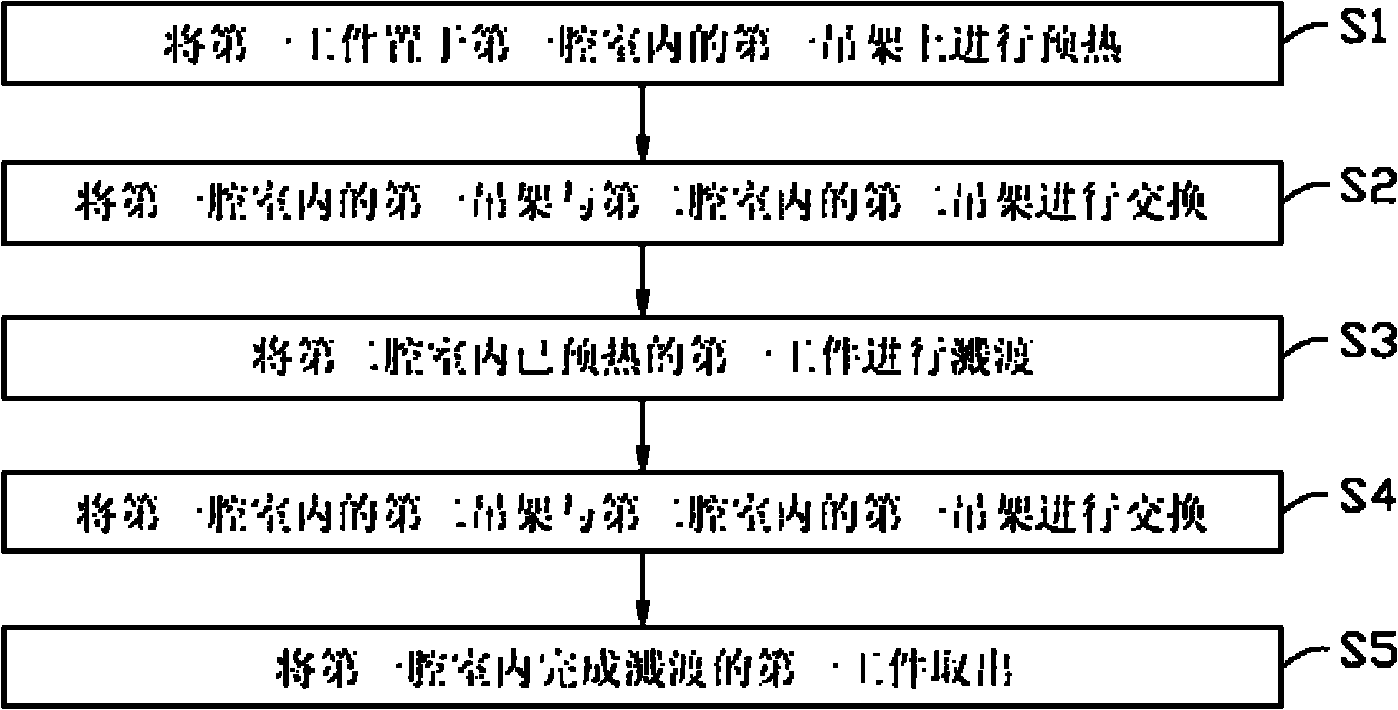

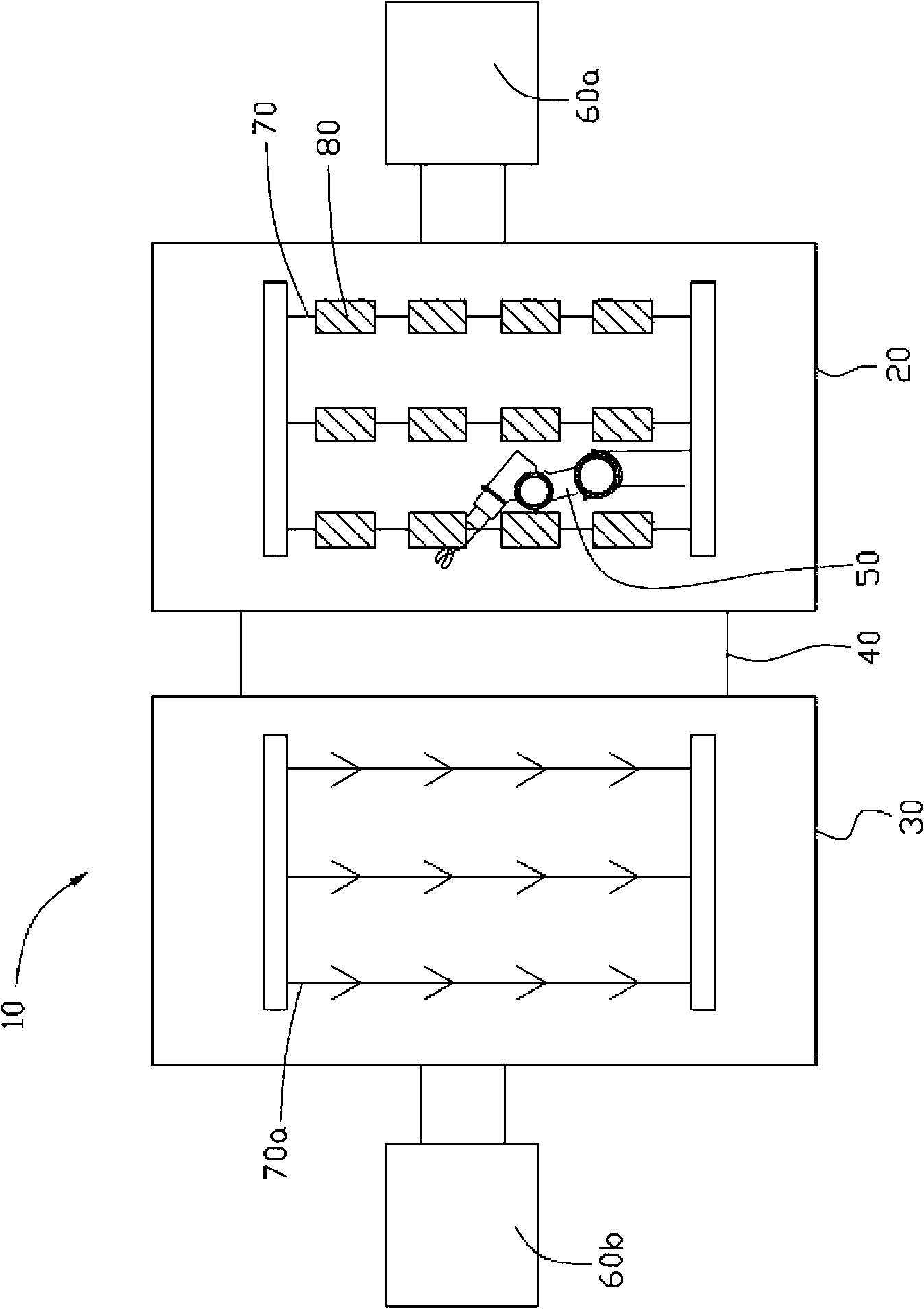

Workpiece vacuum sputtering method and device

InactiveCN101988186AShorten the timeHigh yieldVacuum evaporation coatingSputtering coatingSputteringEngineering

The invention relates to a workpiece vacuum sputtering method which is applied to a vacuum sputtering device provided with two communicated chambers. The vacuum sputtering device comprises a first chamber, a second chamber, a first lifting frame arranged in the first chamber, and a second lifting frame arranged on the second chamber. The method comprises the following steps: placing a first workpiece on the first lifting frame in the first chamber, and preheating the first workpiece; exchanging the first lifting frame in the first chamber with the second lifting frame in the second chamber; sputtering the preheated first workpiece in the second chamber; exchanging the second lifting frame in the first chamber with the first lifting frame in the second chamber; and taking out the sputteredfirst workpiece from the first chamber. The first chamber is used for preheating the workpiece, the second chamber is used for sputtering, and when the workpiece is subject to sputtering in the second chamber, the workpiece also can be taken, placed and preheated simultaneously in the first chamber, thus the yield is improved, and target materials in the second chamber is difficult to oxidize.

Owner:SHENZHEN XINJINGYUAN TECH

Preparation method of high-tap-density niobium oxide and high-tap-density niobium oxide prepared by same

ActiveCN104310478AImprove the reunion effectLarge granularityNiobium compoundsPhysical chemistryAmmonia gas

The invention discloses a preparation method of high-tap-density niobium oxide. The preparation method comprises the following steps: neutralization and sedimentation; washing and defluorination; drying; calcining; and sieving, wherein in the neutralization and sedimentation step, a high-purity niobium liquid is neutralized by ammonia gas for 2-4 hours till the pH is equal to 9-10; high-purity niobium hydroxide obtained by washing and defluorination is squeezed for 4-10 hours; high-purity niobium oxide which is calcined and cooled is sieved by a 30-mesh sieve. According to the high-tap-density niobium oxide prepared by the method disclosed by the invention, the tap density is greater than 1.5g / cm<3> and the diameter D50 is equal to 10-12 mu m. According to the high-tap density niobium oxide prepared by the method disclosed by the invention, the shrinking percentage and porosity in the target calcining and forming process are effectively reduced, thereby facilitating target moulding. The sputtering performance of the target is improved.

Owner:JIUJIANG TANBRE

Preparation method of weather-resistant silver mirror

The invention discloses a method for preparing a weather-resistant silver mirror which is suitable for trough solar thermal power generation. The silver mirror orderly consists of a transparent low-iron super white float glass substrate, a first Al2O3 adhesive layer, an Ag reflective layer, a second Al2O3 adhesive protective layer, a SiOx protective layer and at least two waterproof protective macromolecule paint layers. The preparation method thereof comprises the step of: adopting a multi-target intermediate frequency response vertical magnetic control sputtering coater, respectively and orderly plating the first Al2O3 adhesive layer, the Ag reflective layer, the second Al2O3 adhesive protective layer, the SiOx protective layer and the at least two waterproof protective macromolecule paint layers and preparing the weather-resistant silver mirror of the invention. The inventive preparation method has the characteristics of advanced and reasonable preparation method, low preparation cost, low energy consumption, high reflectivity of the prepared weather-resistant silver mirror, reliable work, long service life and the like.

Owner:常州龙腾光热科技股份有限公司

(CoFe)Zr/Nb/Ta/Hf based target material

ActiveUS8066825B2Improve efficiencyImprove sputtering effectCellsVacuum evaporation coatingSputteringAlloy

A (CoFe)Zr / Nb / Ta / Hf based target material is provided which is capable of achieving a high sputtering efficiency and a high sputtering effect by increasing the leakage magnetic flux in the magnetron sputtering, and a method for producing the target material. This target material is made of an Fe—Co based alloy comprising not less than 80 atomic % in total of Fe and Co having an Fe:Co atomic ratio of 80:20 to 0:100, and less than 20 atomic % of one or more selected from the group consisting of Zr, Hf, Nb and Ta. The Fe—Co based alloy comprises a Co—Fe phase being a ferromagnetic phase, and the one or more selected from the group consisting of Zr, Hf, Nb and Ta are incorporated in solid solution form into the Co—Fe phase in a total amount of 0.5 to 2 atomic %.

Owner:SANYO SPECIAL STEEL COMPANY

Plasma processing device and method

ActiveCN102256432AEliminate attachmentEtching high speedElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringGas supply

Owner:TOKYO ELECTRON LTD

Welding method of WTi target material assembly

PendingCN111843162ANo crack formationImprove sputtering effectWelding/soldering/cutting articlesNon-electric welding apparatusInternal stressWelding

The invention relates to a welding method of a WTi target material assembly. The welding method comprises the following steps that a WTi target material, an aluminum back plate and a cover plate are assembled and then placed into a sheath to be subjected to degassing treatment and welding in sequence; a groove is formed in the welding surface of the WTi target material; the welding surface of thealuminum back plate is subjected to alkali treatment; and assembling is conducted in a manner that the aluminum back plate and the cover plate are symmetrically assembled by taking the WTi target material as the center. According to the welding method, the groove is formed in the welding surface of the target material, the welding surface of the back plate is subjected to alkali treatment, and a specific assembling mode is adopted, so that effective welding of the WTi target material and the aluminum back plate is realized, the internal stress is obviously reduced, no crack is generated, the sputtering effect is enhanced, and the service life is long.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

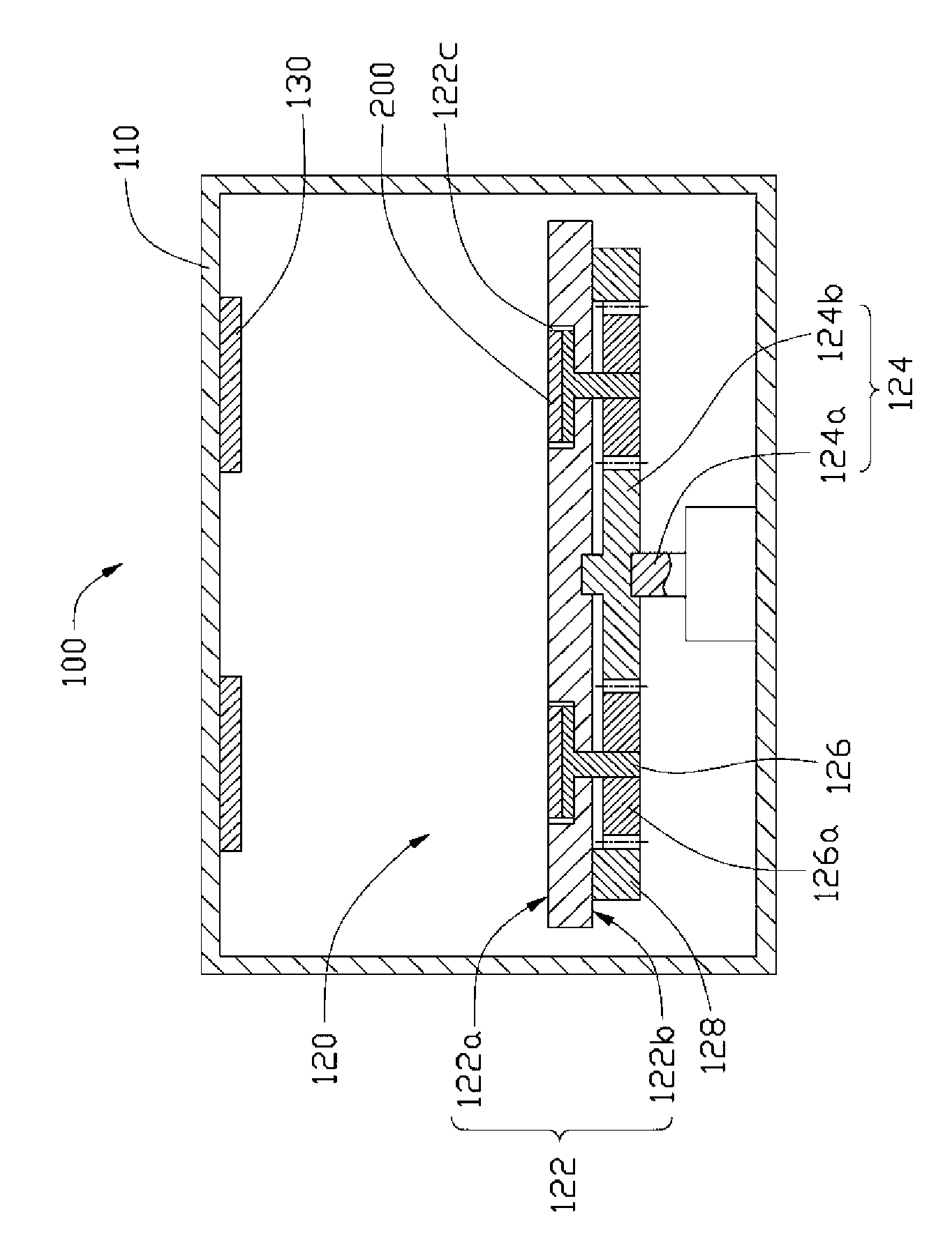

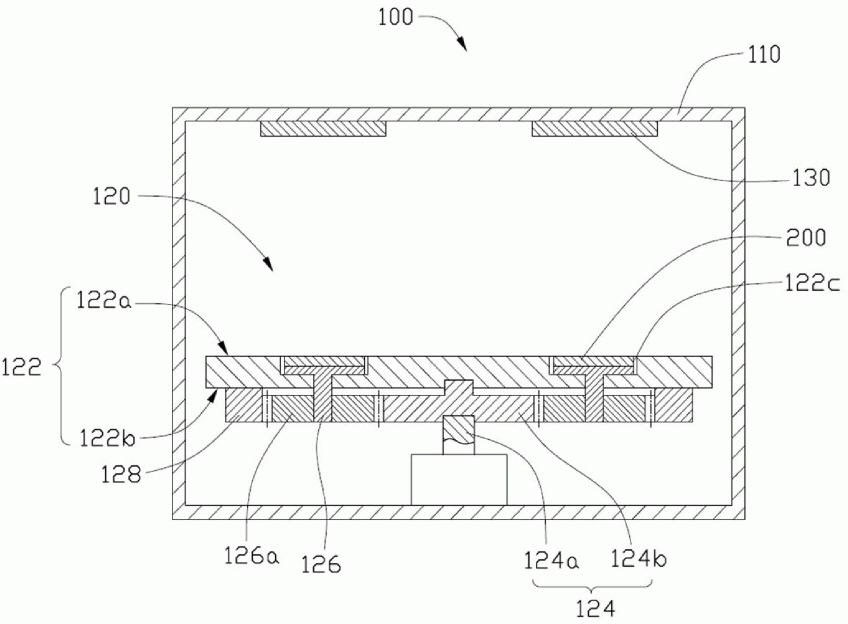

Sputtering device for large-area glass magnetron sputtering coating production line

InactiveCN109913832ASuitable for sputtering processImprove sputtering effectVacuum evaporation coatingSputtering coatingProduction lineSputtering

The invention discloses a sputtering device for a large-area glass magnetron sputtering coating production line. The sputtering device comprises a carrier, fixing frames, an installation frame and a plurality of conveyor belts, wherein each cavity of the production line is provided with one conveyor belt, the fixing frames are fixedly installed on the conveyor belts, the four fixing frames are arranged in pairs, every two fixing frames are spaced, the carrier is fixed on the installation frame, and the installation frame is clamped between the two pairs of fixing frames. The sputtering devicefor the large-area glass magnetron sputtering coating production line can stably convey large-area glass substrates, and is suitable for large-area glass substrates of various sizes.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

A high density tib 2 Preparation method of ceramic target

The invention relates to a preparation method for a high-density TiB2 ceramic target material, wherein the preparation method includes the following steps: step one, drying and sieving a TiB2 raw material powder, to obtain a TiB2 powder having uniform particle size distribution and no caking; and step two, evenly filling a mould with the TiB2 powder, carrying out hot pressing sintering in a vacuumcondition, then cooling, and demoulding, to obtain the high-density TiB2 ceramic target material. According to the method, no any sintering aid is added, the powder is compressed by using the hot pressing process subsequently, the technological process is simplified, the production cycle is shortened, and the mass production can be achieved; the prepared TiB2 target material has the purity of more than or equal to 99.8%, the optimal average grain size reaching less than or equal to 2 [mu]m and the density reaching up to 99.6%; and the target material has a structure of single TiB2 phase, no alloy phase or harmful grain boundary is formed, the arc-starting electro-discharge phenomenon in a sputtering process is improved, and a prepared film layer has the advantages of high density, fewer surface defects and better sputtering effect.

Owner:北京安泰六九新材料科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com