A high density tib 2 Preparation method of ceramic target

A ceramic target material and dense technology, applied in the field of materials, can solve the problems of high cost, poor mechanical properties, complex process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

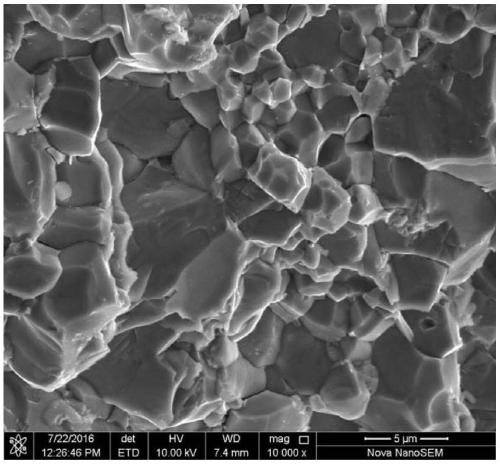

Image

Examples

Embodiment 1

[0039] The preparation method provided by the invention is used to prepare high-density TiB with a size of 135mm×135mm×10mm 2 Ceramic target, the specific steps are as follows:

[0040] (1) Using the above-mentioned purity TiB 2 Alloy powder, the particle size range is 2-40μm; firstly dry it in a vacuum drying oven at a drying temperature of 120°C and a holding time of 120min, then pass the above powder through a 200-mesh vibrating sieve to remove agglomerates and agglomerated phases, and take the sieve TiB with loose, uniform particle size distribution and average particle size D50=20.96μm was obtained from the following 2 powder;

[0041] (2) TiB obtained in step (1) 2 The powder is evenly filled in the graphite mold, and the initial pressure is 12MPa at the furnace temperature, and the vacuum is evacuated to 8Pa; then the temperature is raised to 700°C at a heating rate of 20°C / min and kept for 60min; Simultaneously pressurize linearly to 25MPa, heat and hold pressure f...

Embodiment 2

[0044] The preparation method provided by the invention is used to prepare high-density TiB with a size of 135mm×135mm×10mm 2 Ceramic target, the specific steps are as follows:

[0045] (1) Using the above-mentioned purity TiB 2 Alloy powder, the particle size range is 1-25μm; firstly dry it in a vacuum drying oven at a temperature of 120°C and a holding time of 120 minutes, then pass the above powder through a 200-mesh vibrating sieve to remove agglomerates and agglomerated phases to obtain the average particle size D50 = 8.92μm TiB 2 Alloy powder.

[0046] (2) TiB obtained in step (1) 2 The powder is evenly filled in the graphite mold, the initial pressure is 15MPa at the furnace temperature, and the vacuum is evacuated to 8Pa; then hot-pressed and sintered, and then cooled and demolded to obtain TiB with the above size 2 billet. The hot pressing sintering system in this example is as follows: firstly, the temperature is raised from the initial furnace temperature (usua...

Embodiment 3

[0049] The preparation method provided by the invention is used to prepare high-density TiB with a size of 135mm×135mm×10mm 2 Ceramic target, the specific steps are as follows:

[0050] (1) Using the above-mentioned purity TiB 2 Alloy powder, the particle size range is 1-16μm; firstly, it is dried in a vacuum drying oven at a drying temperature of 120°C and a holding time of 120 minutes, and then the above powder is passed through a 200-mesh vibrating sieve to remove agglomerates and agglomerated phases to obtain the average particle size D50 = 2.32μm TiB 2 Alloy powder.

[0051] (2) TiB obtained in step (1) 2 The powder is evenly filled in the graphite mold, the initial pressure is 14MPa at the furnace temperature, the vacuum is evacuated to 8Pa, and then hot-pressed and sintered, and then cooled and demolded to obtain the above-mentioned high-density TiB 2 Ceramic target. The hot pressing sintering system in this example is as follows: first, the initial furnace tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com